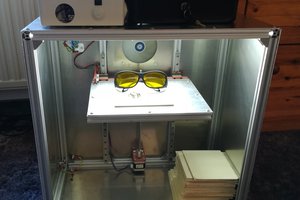

Laser cutter specs out of the box:

- 50W laser (generic)

- 400 x 600mm cutting Area

- Air Assist (aquarium pump which seems to work well)

- Water cooled (aquarium water pump, also working well)

- Water flow sensor (to shutdown laser if water is not flowing)

- moving Z platform with DC motor (manual up and down control)

- Honeycomb bed

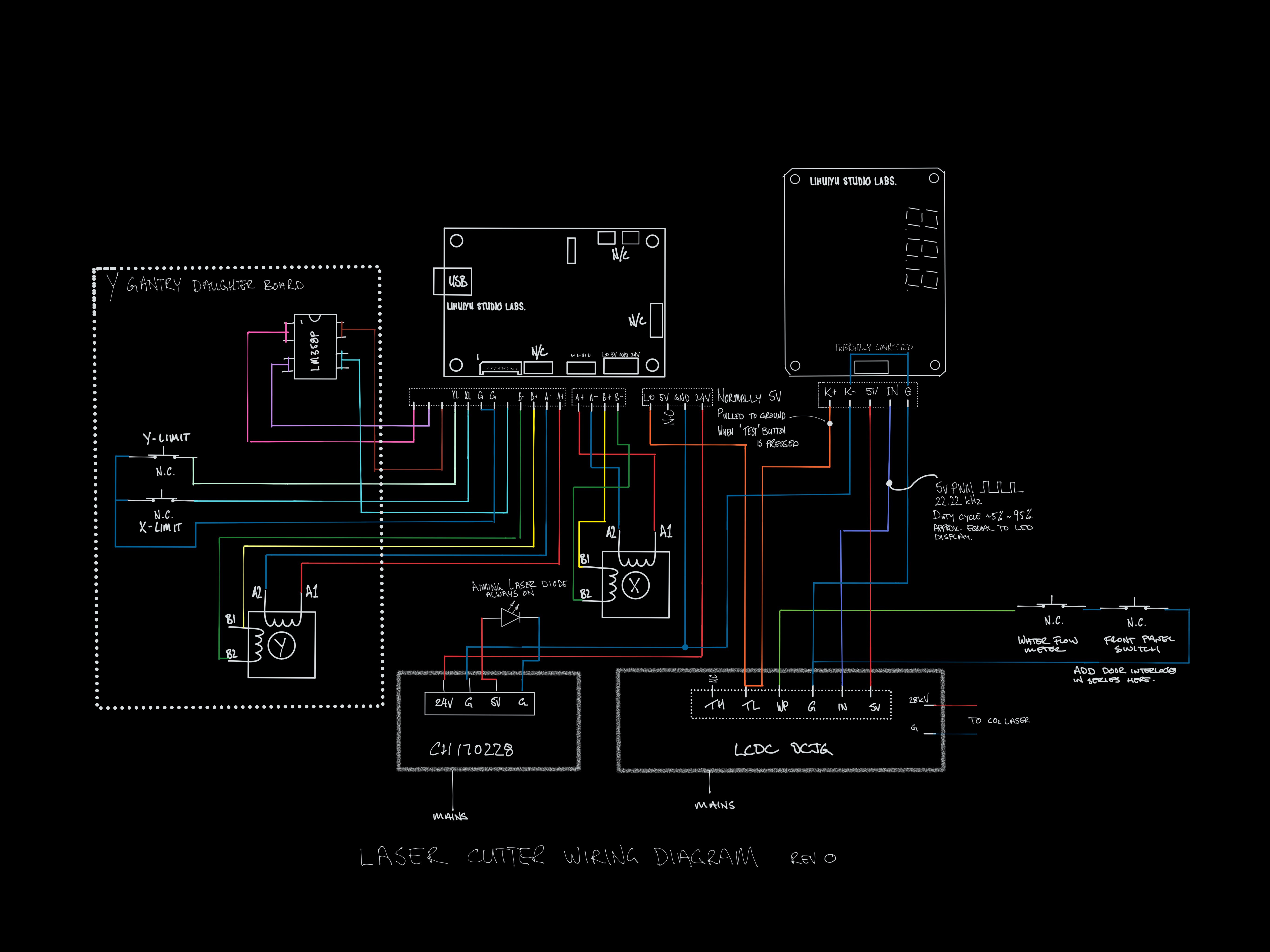

- Lihuiyu studio lab M2Nano controller

- Lihuiyu studio lab 6C6879-LEDPAD-A laser power controller

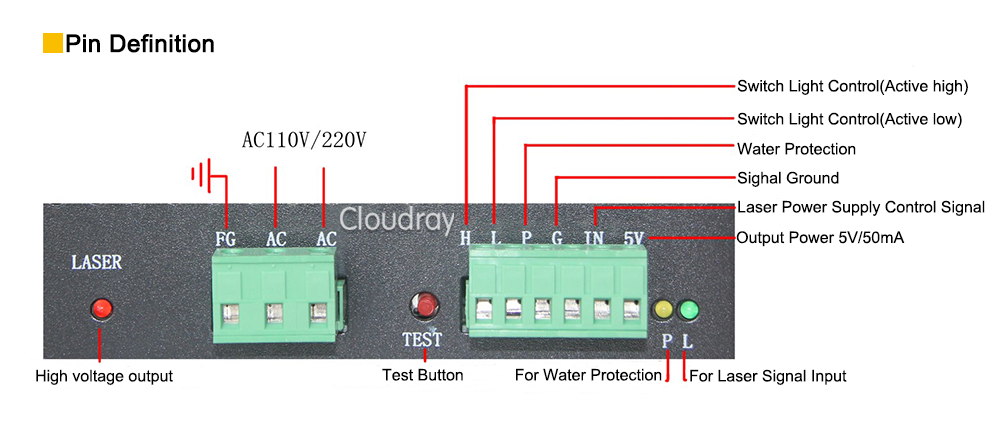

- LCDC DCJG-50W Laser power supply unit

- CH170228 power supply. 240vAC in --> 5v & 24v DC out

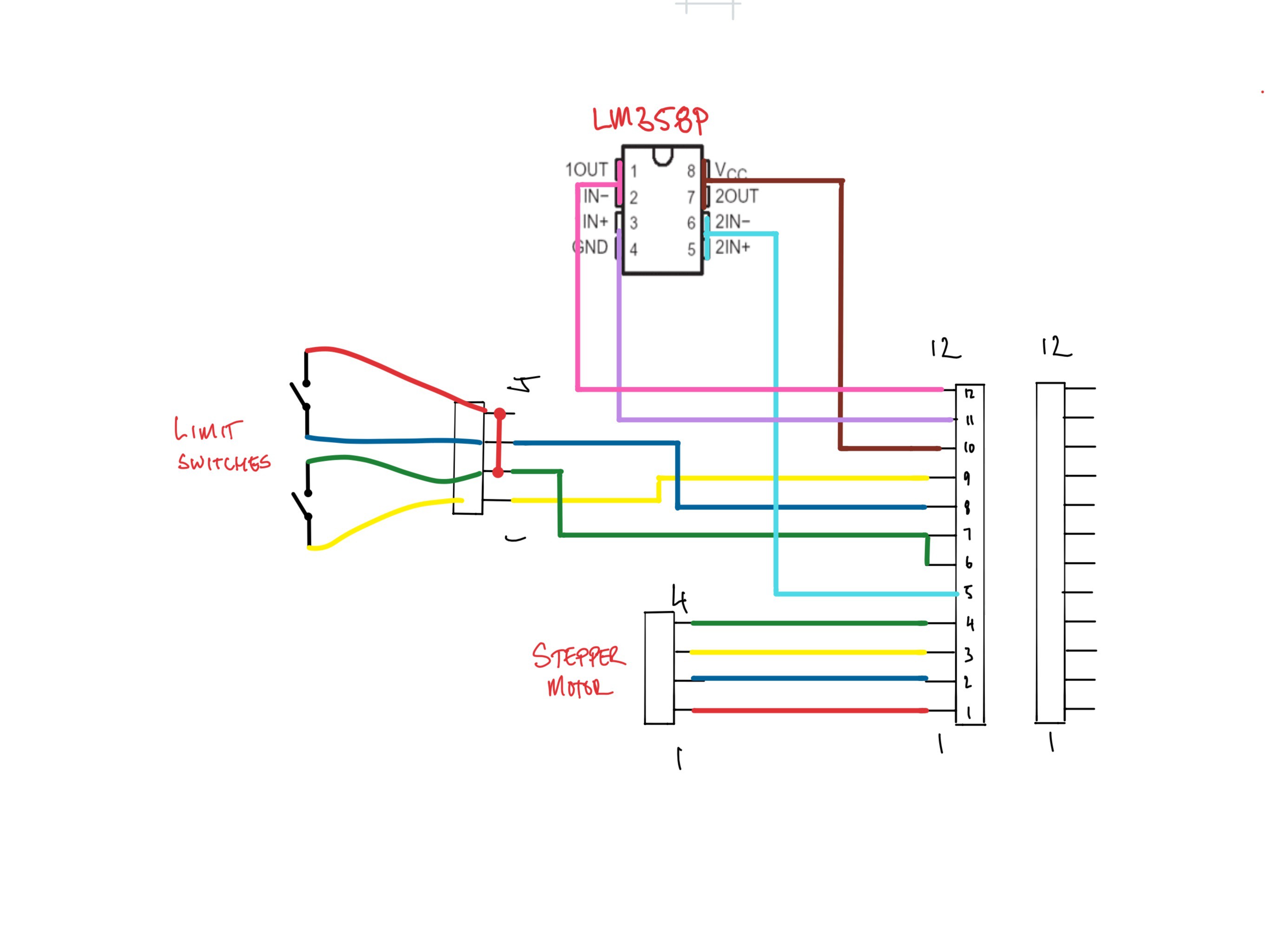

- limit switch board with LM358p op-amp. (debounce?)

And now for the wish list

- User friendly software tool chain

- full g-code control of the laser power. (this is currently set manually at the start of each operation)

- untethered operation - ok to connect to upload the job but not leave a pc there for the duration.

- Limit the maximum current supplied to the laser to prevent burnout

- Safety

- add door interlocks to stop the laser firing when a door is open

- led on the front panel to be lit whenever the laser is firing

- Cooling system

- keep the water flow interlock on the cooling system

- monitor and display water temperature

- shut down the laser if the water temperature goes above a certain limit

- provide audible / visual alarm for over temperature

- Manually control the laser to focus, mirror alignment etc using "Test" button (software control would be ok.)

- Gcode control of the Z axis (low priority)

- Hardware jog controls (Next Project)

AltMarcxs

AltMarcxs

JP Gleyzes

JP Gleyzes

Dominik Meffert

Dominik Meffert

Great wishlist... especially the interlocks. Looking forward to watching as this comes together!