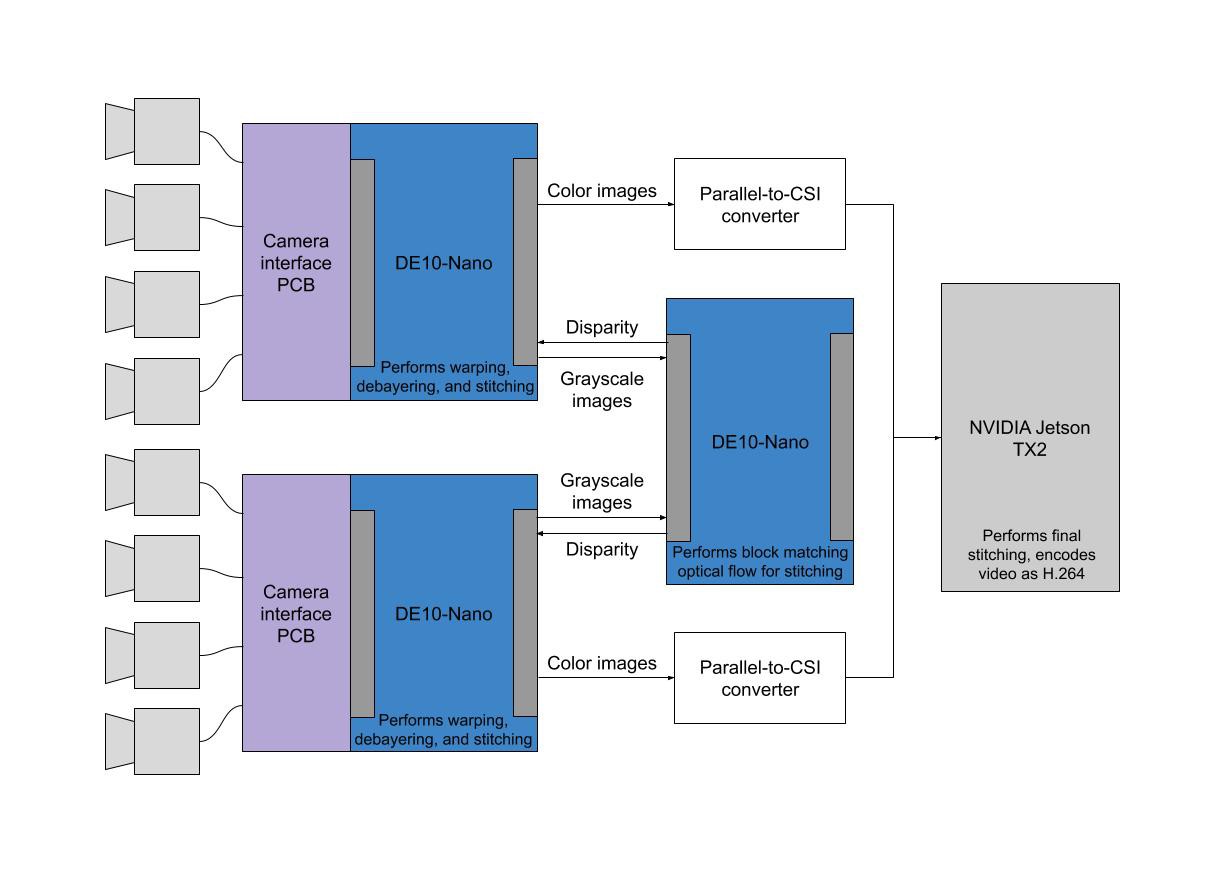

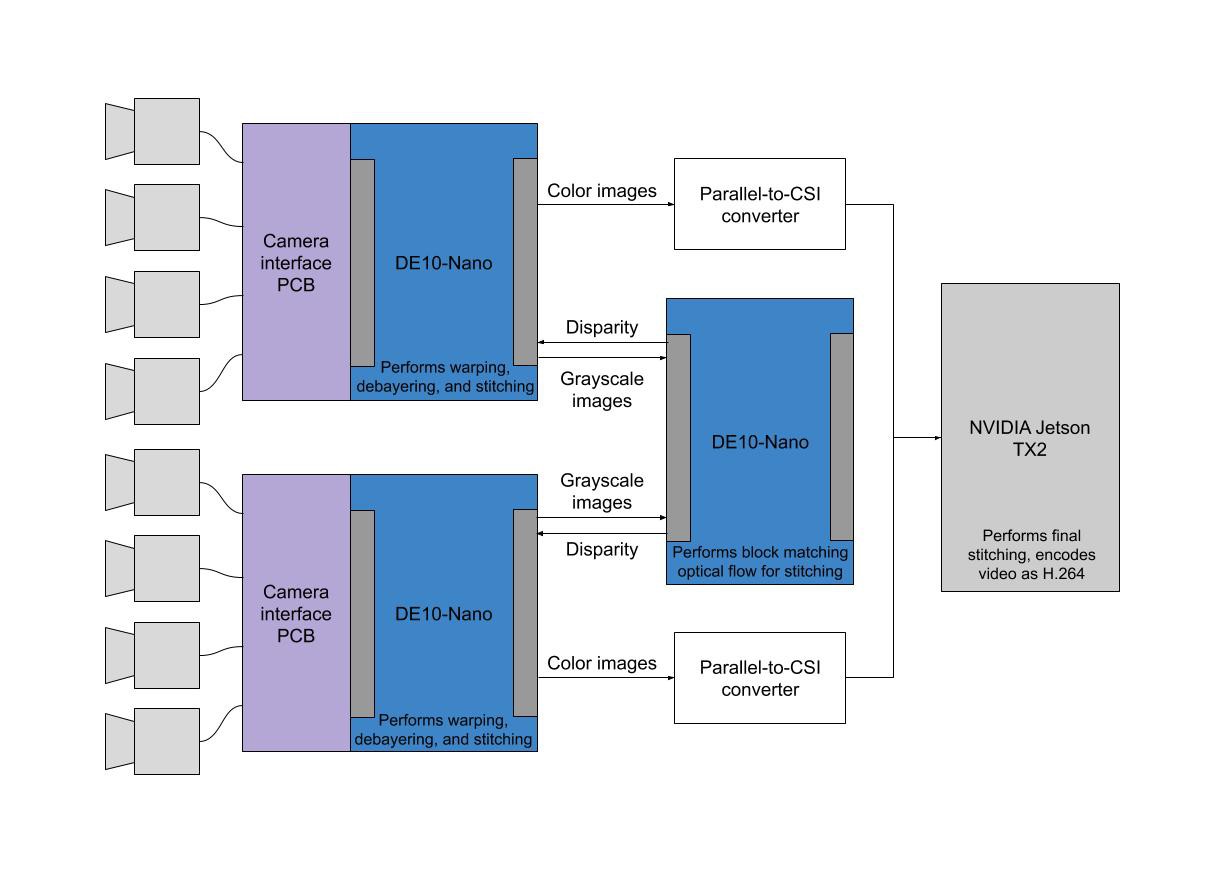

Shown below is the high-level data flow and hardware connection diagram for the camera.

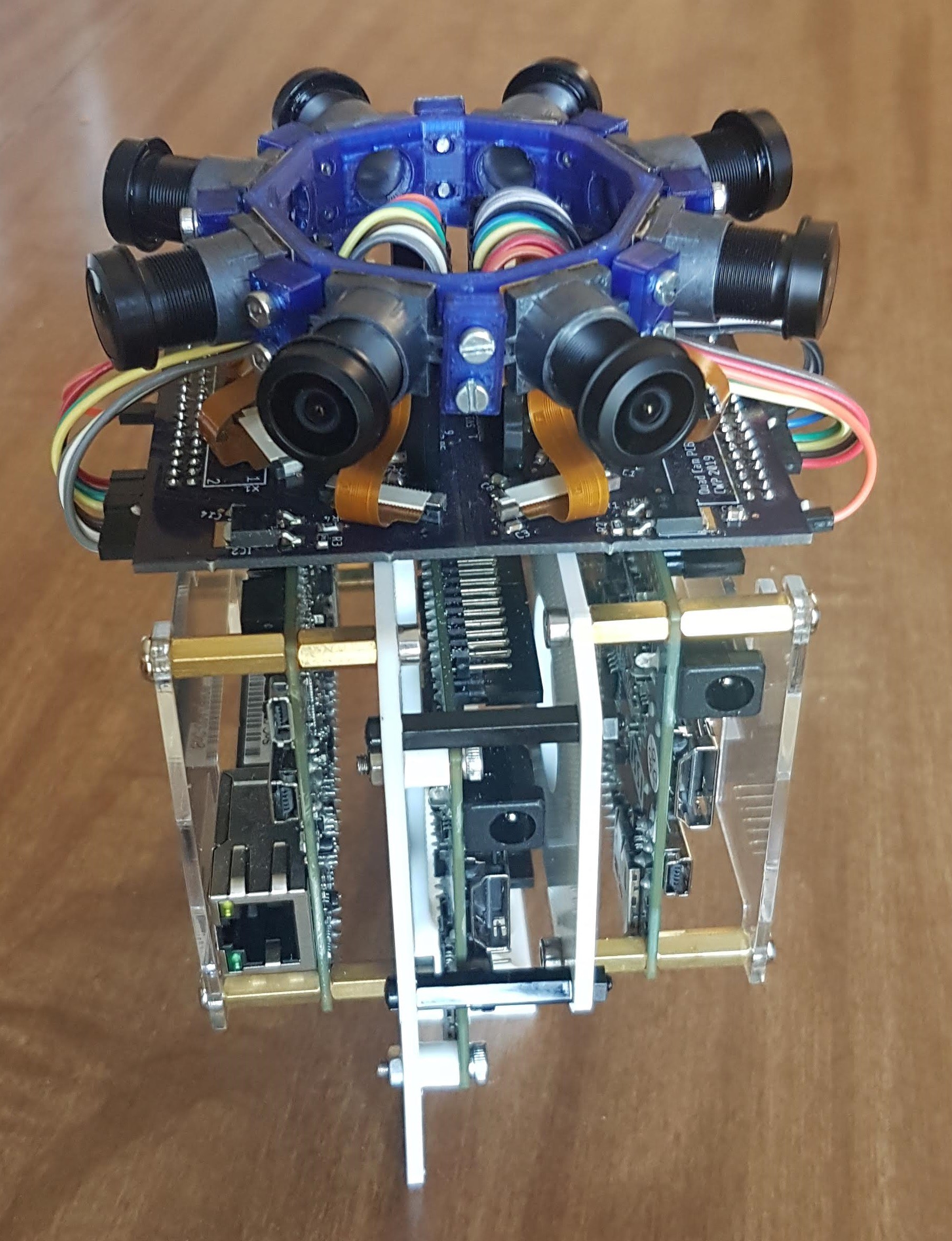

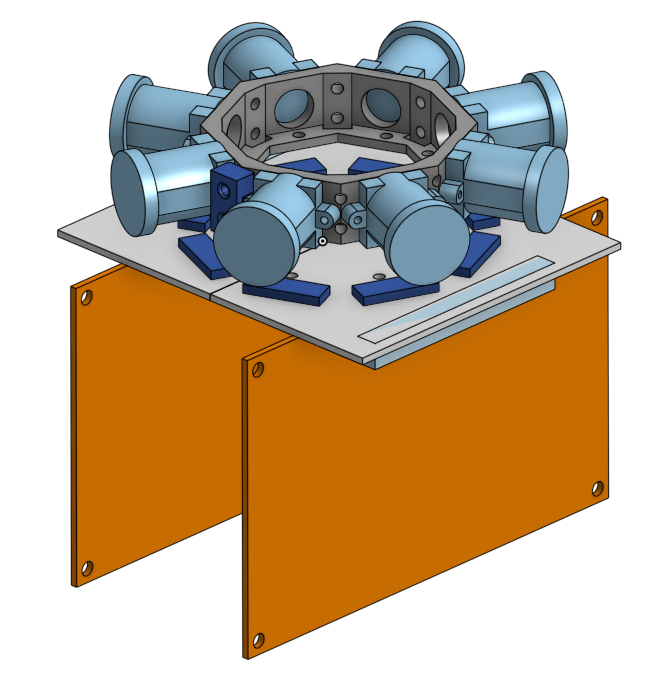

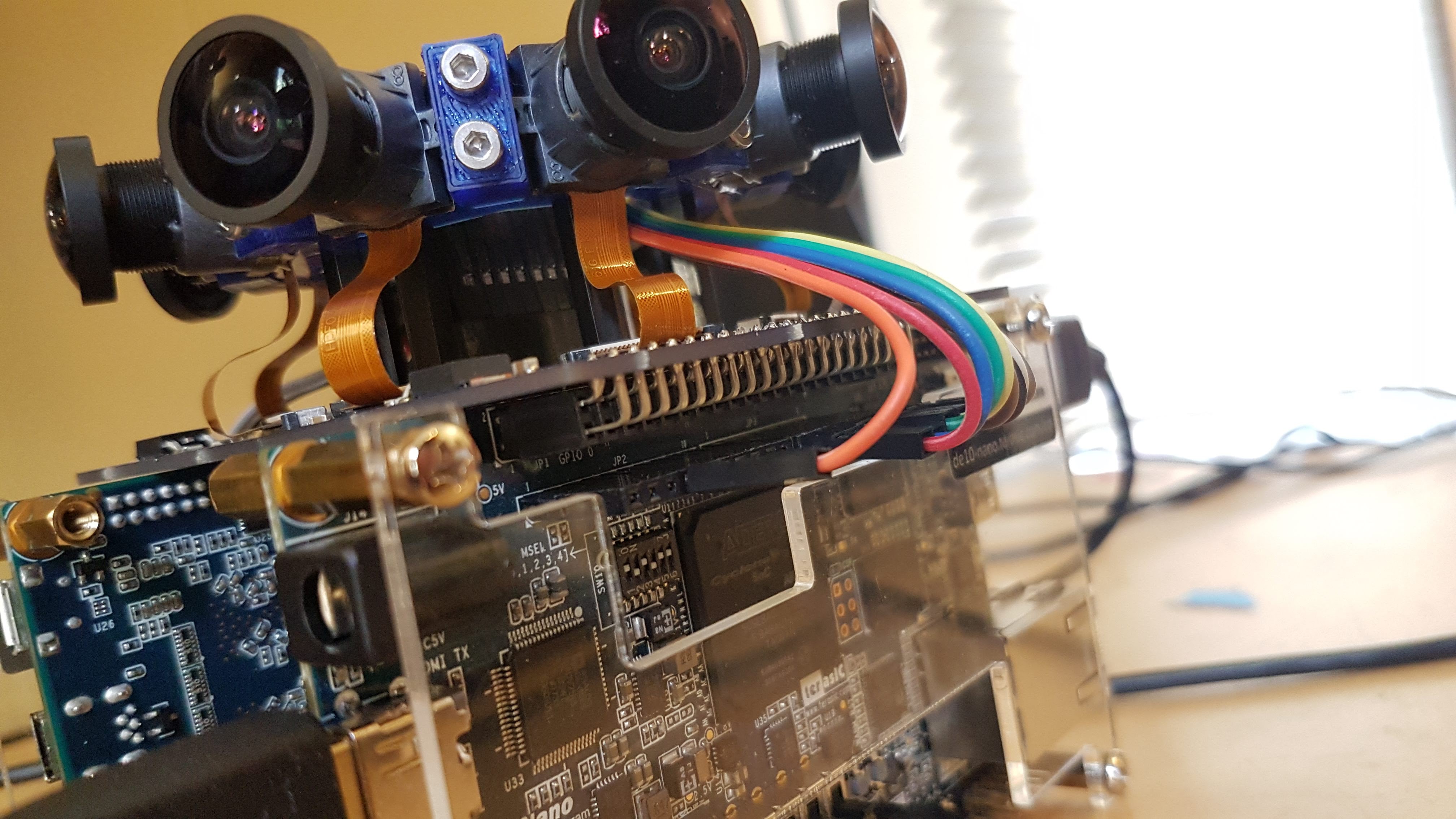

Here are the components of the project that I have successfully implemented so far:

- Camera I2C control

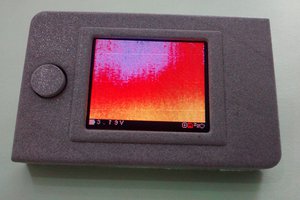

- Debayering module

- Camera image warping modules

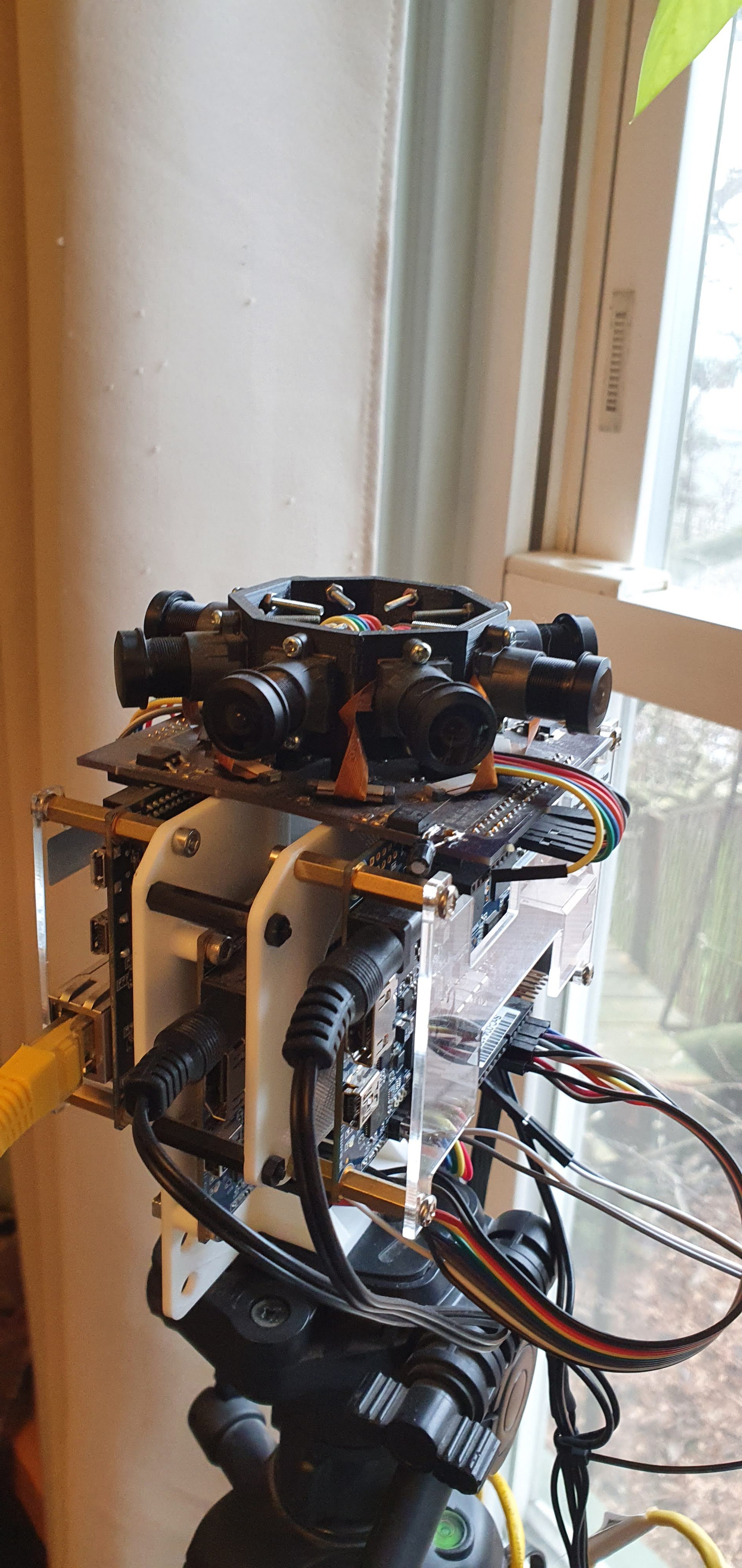

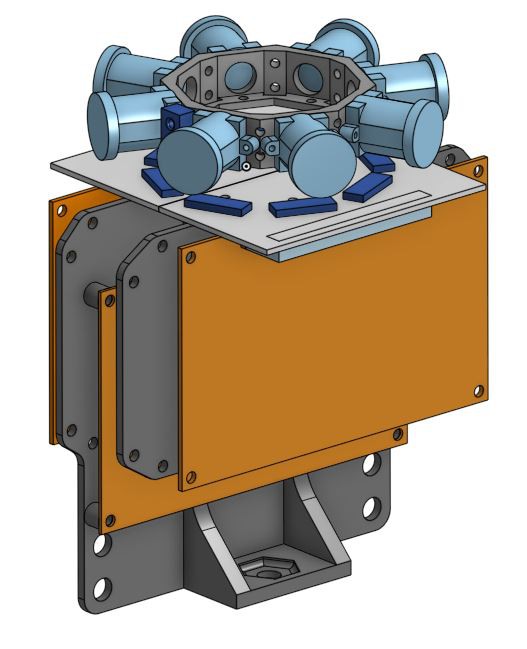

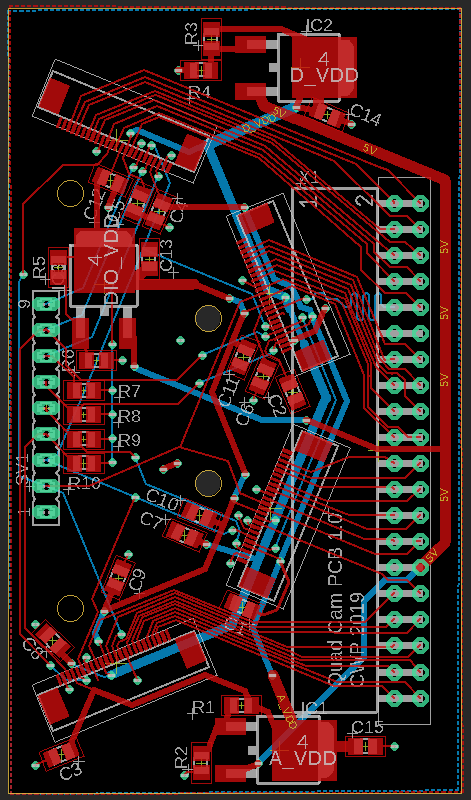

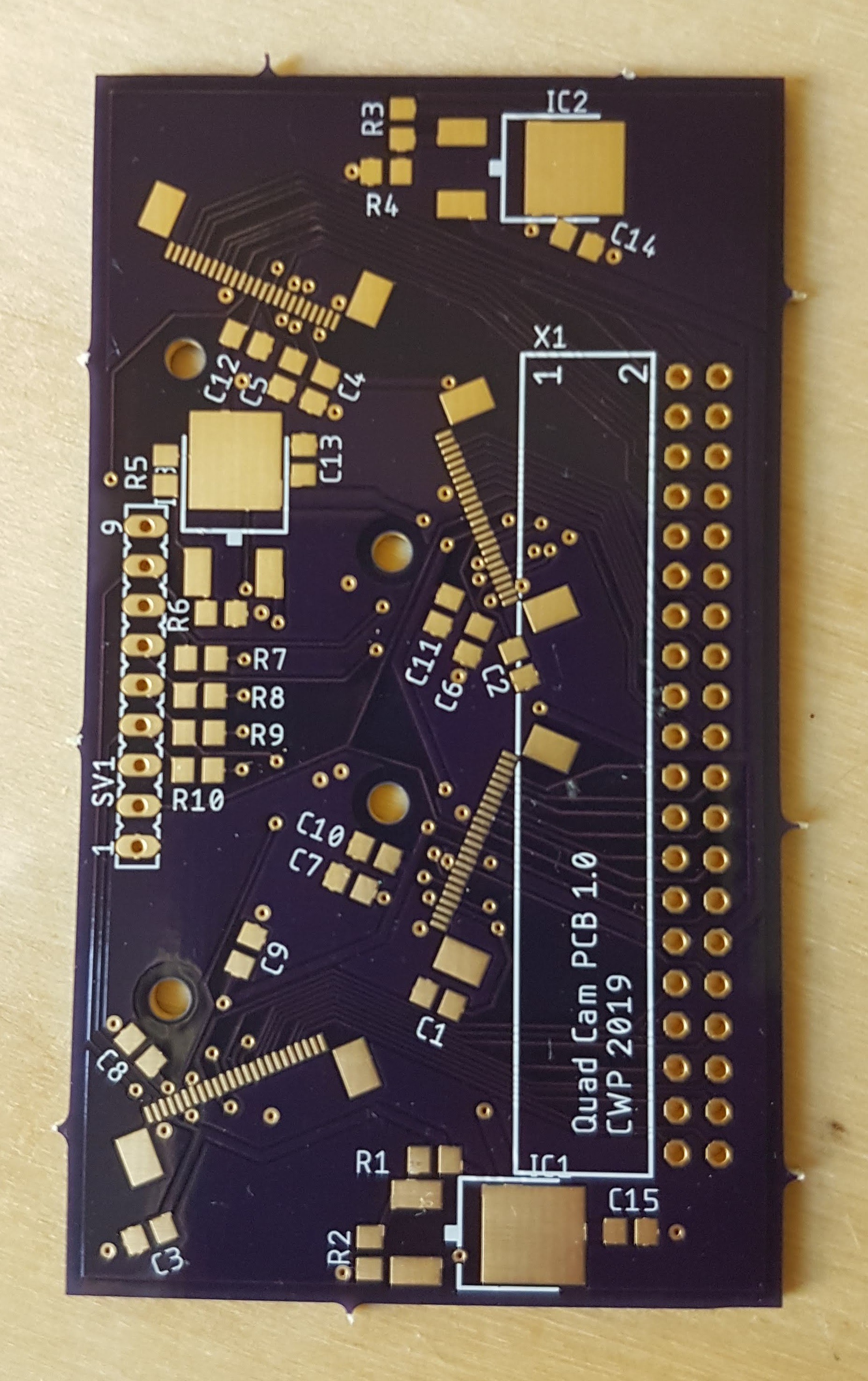

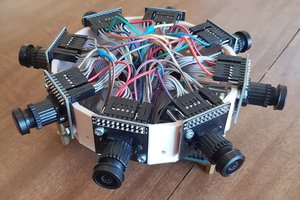

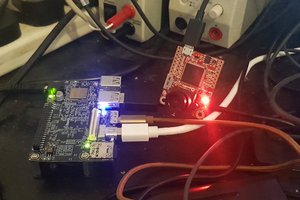

- Camera interface PCB

In progress/partially working:

- Block matching optical flow

- Grayscale conversion and downsampling

- Optical flow filtering

Not yet started:

- Jetson encoding software

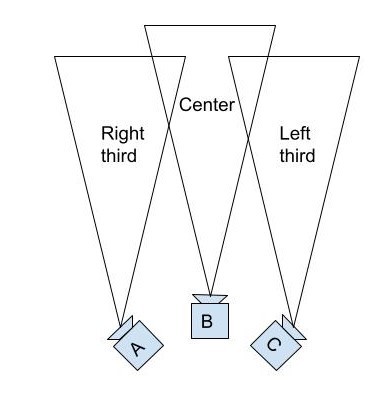

- Image stitching modules (uses optical flow map to shift pixels and create interpolated views between cameras)

- Data interfaces between FPGAs and FPGA -> Jetson (either use MAX 10M50 dev boards or some other parallel-to-CSI device)

Off-site resources

Image warping FPGA module GitHub repo

Block matching FPGA (the middle one) GitHub repo

C++ Code that runs on the image warping FPGA SoCs GitHub repo

alex

alex

Adam Taylor

Adam Taylor

x-labz

x-labz

Hi, Amazing work

Would it be possible to get the Quartus project files ?