So why to use hobby servo for rotation?

It is light and available. I do not have the hollow shaft Nema9 stepper.

Analysis.

The one and only Arduino hobby servo that I had in my house had a rotation range of about 170 degrees. So not quite enough, need at least 180 degrees.

I studied that some people are able to extend the range of their servos with adding some resistors in series with the feedback potentiometer. Tearing down the thing showed that unfortunately in my case this was not the option, the feedback potentiometer track was physically just 170 degrees and no more. So the stock servo with no modification or with small modification is not doable.

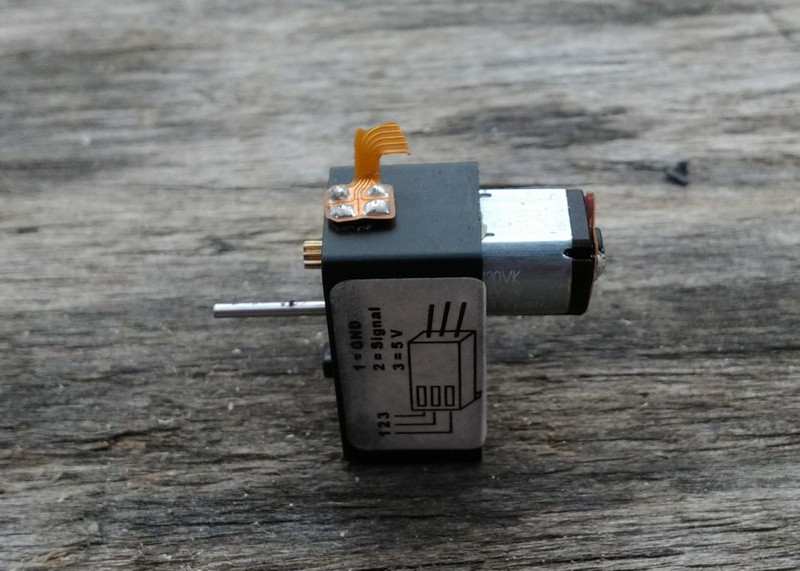

But it still have the nice gearbox. I ripped out the feedback potentiometer and control chip from the servo. Replaced the motor with longer shaft version form the old Canon compact digital camera and had the flapped shutter added to the shaft. Installed the optical counter also from the old camera to count the motor movement. And put together the Arduino Nano and H-bridge to control all this thing.

Arduino simply receives the „step“ and „direction“ commands from the motion controller and drives the motor same amount of steps in the commanded direction. This way I can preserve the stock OpenPnP and Smoohieware operation and only simulate the stepper. Ended up with 5.4 steps per degree resolution. It probably slips a little but hopefully not enough to matter within a single maximum 180 degree rotation. Tricky part is aligning the speeds so that the rotation is actually finished in time. So I is a dirty hack. But works for now, at least until something better comes along.

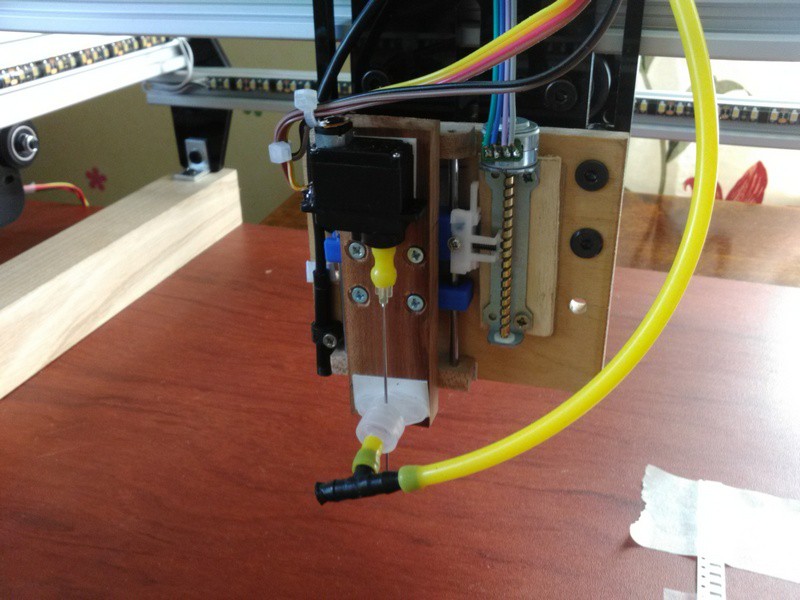

Servo is connected to the needle with just a little piece of silicon tube, same that is used for the vacuum line.

Here is a little video of it in operation.

And yes the board have a scratch on it. This is because while adjusting strip feeder length I accidentally pushed "home" command and it dragged for the X0;Y0 without first raising the nozzle. Still the same needle though, those things are quite tough.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.