Complete Description Website ~ Hackaday Post ~ DIY Photography Article ~ Hackster.io Post

What Is A High-Speed Flash?

A high-speed flash is a photography tool used for high-speed photography (unsurprisingly). Photographs of bullets and other projectiles travelling at incredible speeds can be photographed using any camera (even a cell phone) with the help of a flash.

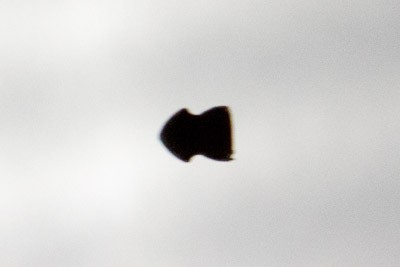

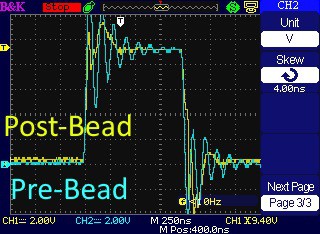

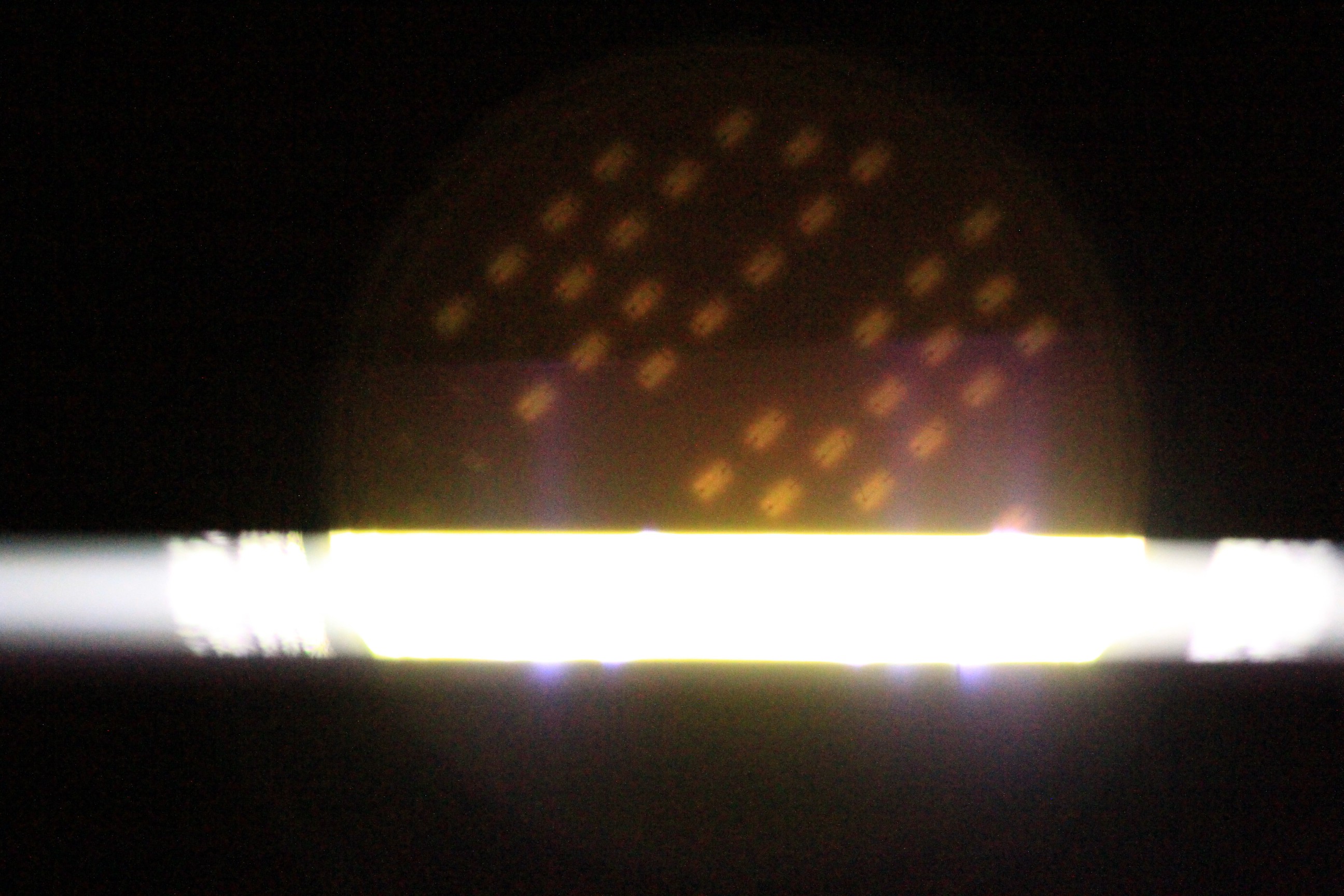

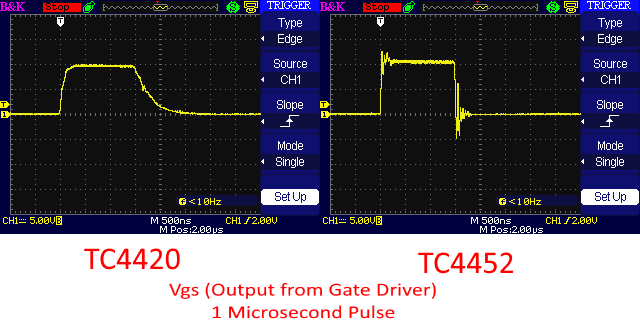

A normal camera flash is not fast enough to capture these images! Below is a comparison of a typical camera flash vs this high-speed flash (1-μs duration). Both air rifle pellets were fired from the same rifle, travelling about 280 m/s. This demonstrates the advantage of using a high-speed flash for high-speed photography.

Anybody Can Do It

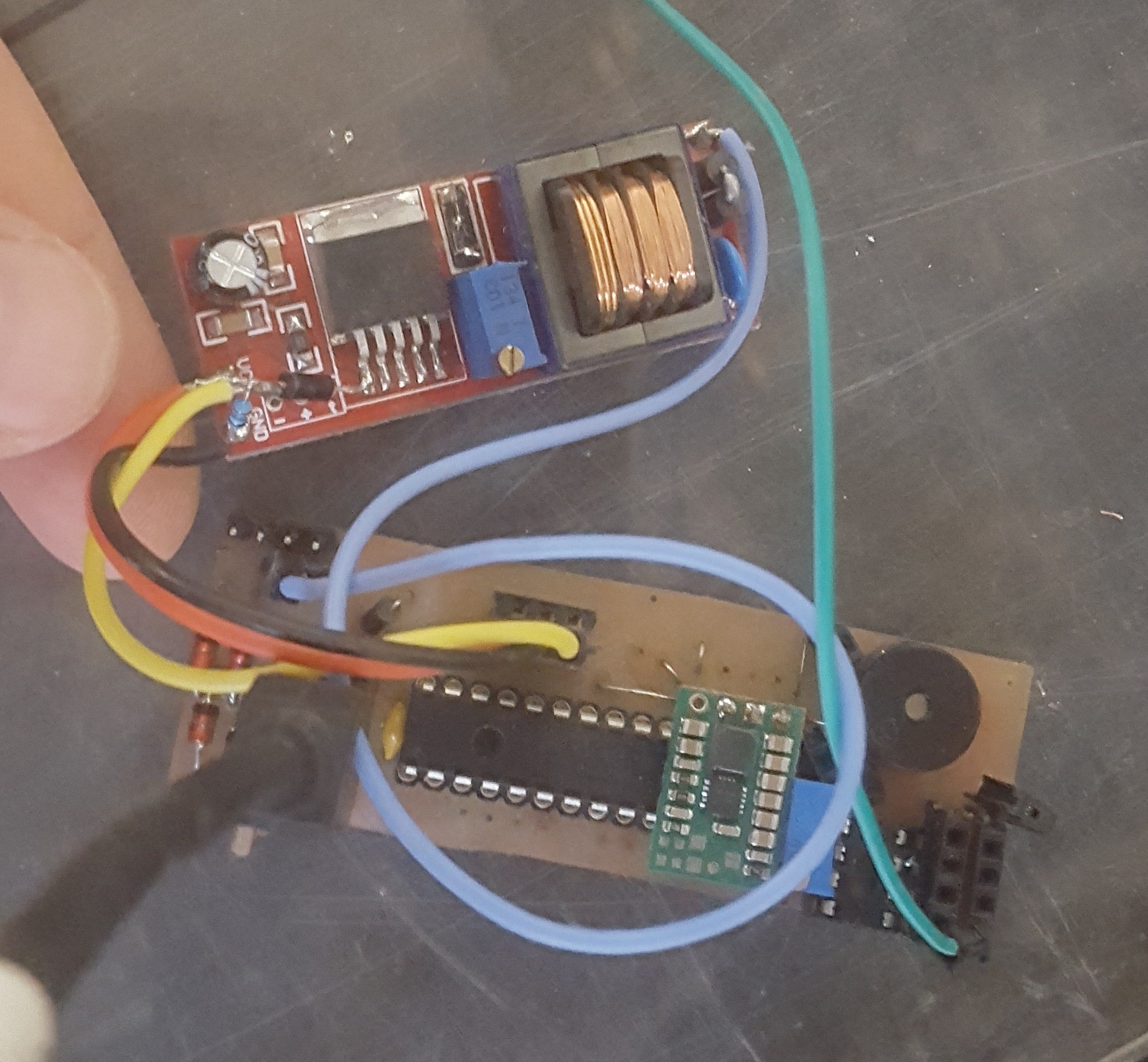

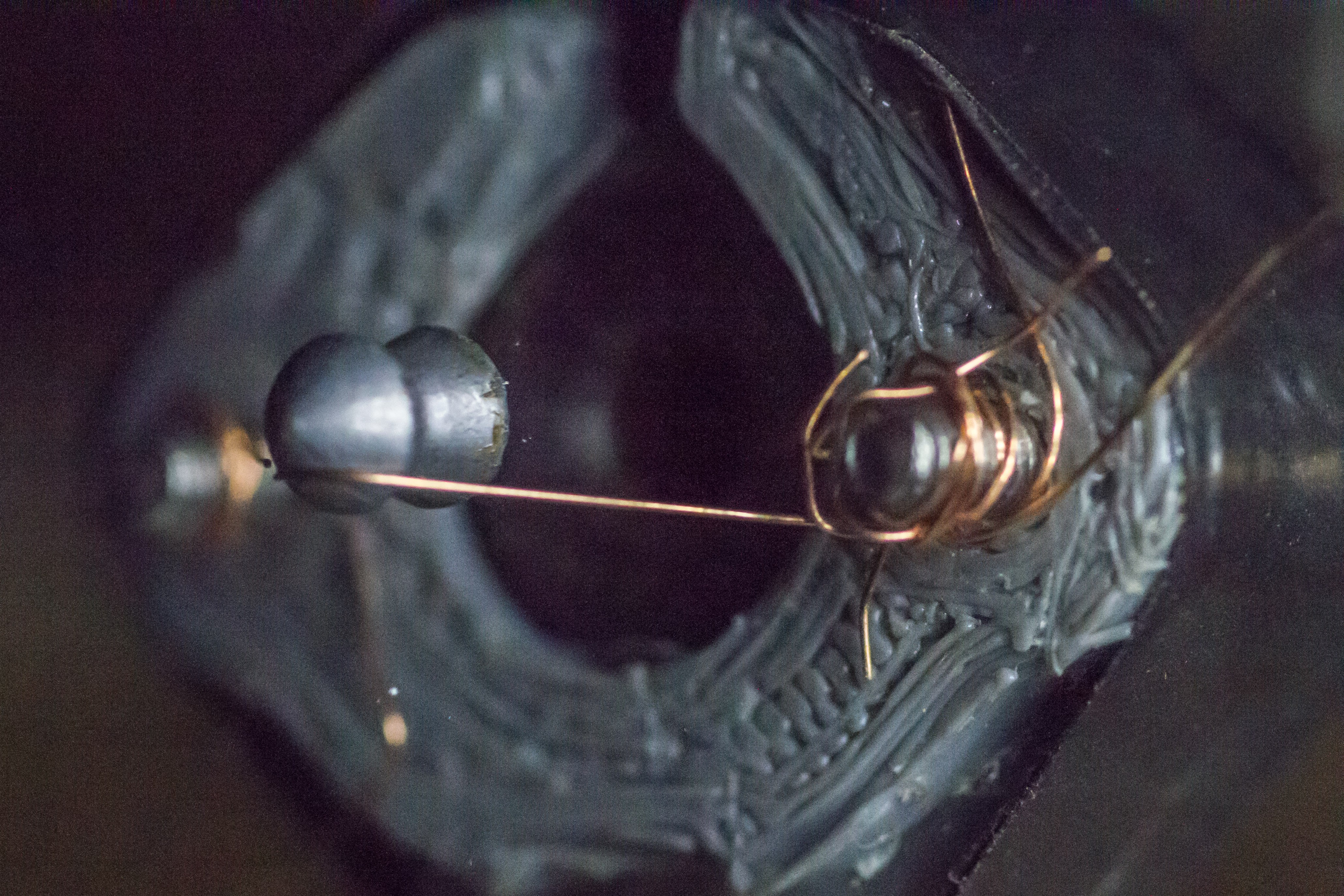

While typical camera flashes require a trigger system to fire, Edgerton is going to be equipped with a built-in tripwire trigger function. All you need is a camera, a projectile, and a piece of wire! The tripwire trigger works by placing a small wire strand in front of the projectile's path (usually in front of a rifle's barrel). The user enters a delay into Edgerton, and it will flash exactly that long after the projectile has broken the tripwire!

Edgerton can also use the same trigger system as a typical camera flash. This means it's compatible with DSLR's or wireless trigger systems.

Are There Alternatives?

High-speed photography is no recent invention. Doc Edgerton was already experimenting with high-speed photography in the 1940's, and has taken some incredible photos. He was known to use an Air-Gap Flash, which is similar to the Xenon flash tubes found in modern camera equipment. It unfortunately requires much higher voltage which could easily cause injury (SEVERE injury). While I didn't completely disregard the option, I eventually opted for a safer solution.

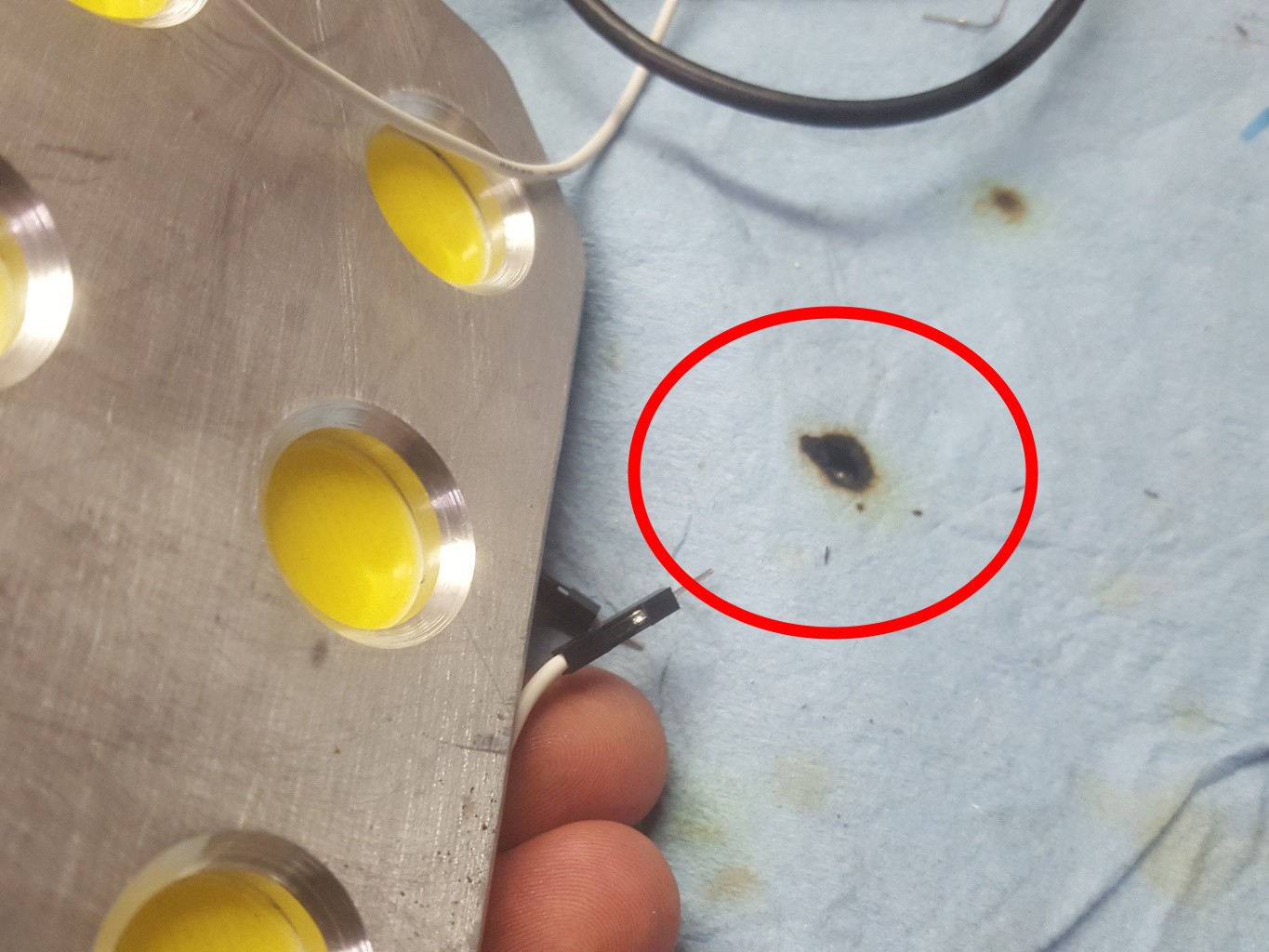

A recent kickstarter campaign (Vela One) offered a high-speed LED flash. It can produce flashes lasting 0.5 μs (microseconds), was not dangerous, but was priced about $1,750 CAD! A significant amount of development resources was put into this commercially-available flash. I've likewise conducted destructive testing with expensive components and put much time into developing the Edgerton.

Feature Set

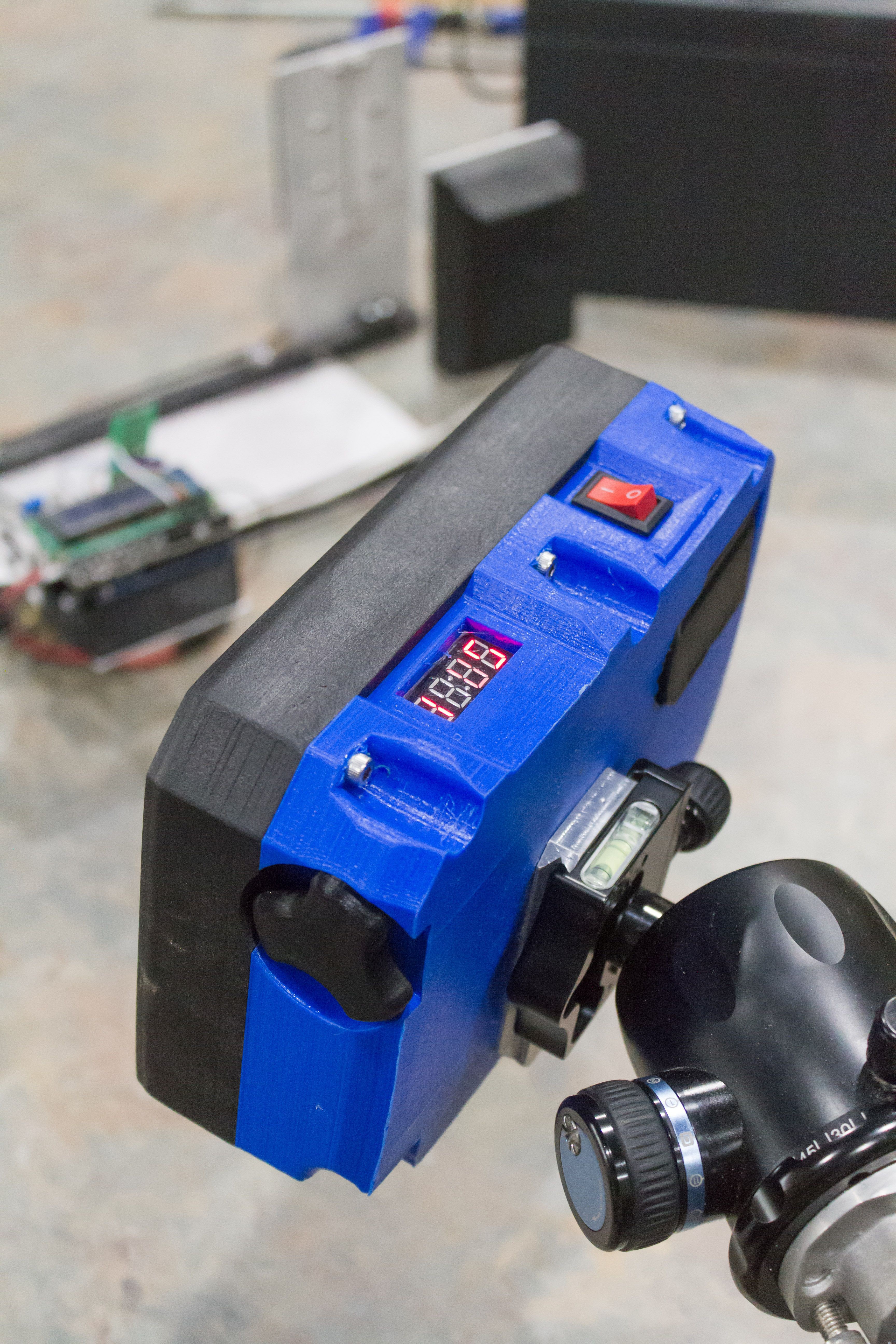

- Simple user interface consists of an encoder, 4-digit LED display, and power switch

- Tough plastic case for real-world use

- 3.5mm Jack for multiple types of external triggering

- Arca-Swiss mounting plate compatible with many tripods

- 1/4" threated hole for non-Arca-Swiss tripods

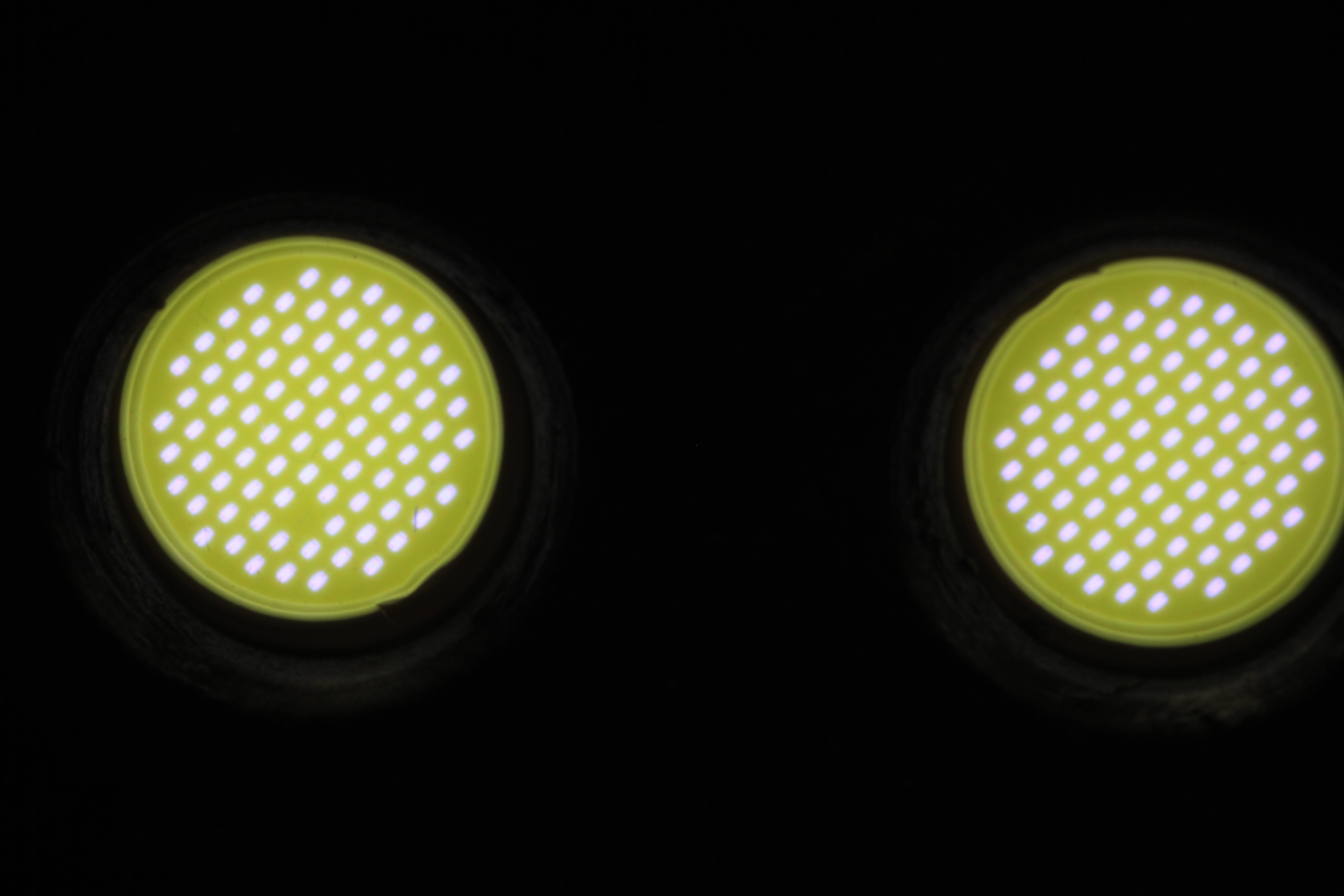

- 12x high-powered Cree LED's are capable of well-exposed images in one microsecond

Tyler Gerritsen

Tyler Gerritsen

Sam Ettinger

Sam Ettinger

Jakub Kaderka

Jakub Kaderka

Tim

Tim

Yann Guidon / YGDES

Yann Guidon / YGDES

Is this project still on going.