As of 08/1/19 A Grasshopper definition has been built which generates frames for metal 3D printing, lasercut files and easy customization.

This is a Wallfacer Design project.

Thank-you: Electron Microscopy Sciences of Hatfield PA, ......

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

As of 08/1/19 A Grasshopper definition has been built which generates frames for metal 3D printing, lasercut files and easy customization.

This is a Wallfacer Design project.

Thank-you: Electron Microscopy Sciences of Hatfield PA, ......

HingeStapleType.3dmOnly dependency for MicaSunglassesGenerator12.gh3dm - 606.63 kB - 08/01/2019 at 22:29 |

|

|

MicaSunglassesGenerator12.ghAnnotated glasses frame generator for grasshopper in Rhinogh - 47.44 kB - 08/01/2019 at 22:28 |

|

|

BaseEightGrasshopper.ghTemporary; but usable. Custom frame generator.gh - 47.14 kB - 08/01/2019 at 18:55 |

|

|

lensexplorer11print.3dmTest 3D print, no nose bridge (this will be a fitting model) hinges use spring wire, not sure if it will work yet.3dm - 4.47 MB - 06/11/2019 at 19:53 |

|

|

CADCAMProductionStandards.pdfReference for casting requirements.Adobe Portable Document Format - 3.37 MB - 06/06/2019 at 20:23 |

|

|

Psychedelic Mica Wave-Plate Camera Filter project fork!

Since the housings are pre-built I am able to easily bring these to market, so they are for sale on Tindie now! I'm planning on putting them in a few local stores as well.

The filter works amazingly! Color intensity and schema are very easy to control.

Water can generate some incredible colors.

Subjects like automotive photography offer opportunities for unique color tuning.

Or extreme shifts:

Pastels are easy to pull off too:

The lens materials allow for a very high amount of visible light transmission allowing for easy operation in low-light situations.

Easily manage glare and intense highlights:

I'm excited to see who ends up picking up the first couple filters and what they end up doing with it!

Using two rotating filter holders I made a tuned variant of the mica and polarized effect.

Each filter holder is about $6.00 so not exactly cheap, but they are well made and deliver pretty impressive results. The major downside is that they are pre-branded.

I'm definitely placing a small order, enough to make maybe 4-5 of these assemblies to then sell on Tindie. Right now I think they'll just come in a small lasercut box, nothing too fancy. Filter adapters can be used for other lens sizes, I'll have a link.

I still need to do some experimentation but I've been using a UV filter pre-stage, then the linear polarized filter, then the mica. Auto-focus was slow without the UV filter but that could be for a number or reasons and I honestly haven't logged enough time for a conclusive result. This might be because the mica filter uses "reflections" to produce its effect, this is then colorized the best I can work out and then flattened by the UV filter. Not having the UV filter might be decreasing the focus time since the sensor is looking at a reflection (or at-least a remaining component not modified by the mica plate.)

Its worth noting that right now I am using the V5 Mica (medium quality) which seems to have around a 80-85VLT (Visible light transmission) rate. The V1 is much better, but I want to cut those filters out on the laser cutter rather than by hand. I might offer an choice between the two since there is a decent price difference in the raw materials.

Now for some comparative images; they will be unfiltered then filtered:

---

---

---

Hopefully these give you an idea of what kind of color palettes to expect and what will be affected. This particular filter has a bias towards purple in the center of the frame, this is very obvious when you shift the target artifact off center in the window, the color will change. Blue section to the right, pink to the left of frame:

When I head into the city next I'll likely get a wider range of example photos.

I finished the packaging and included written material:

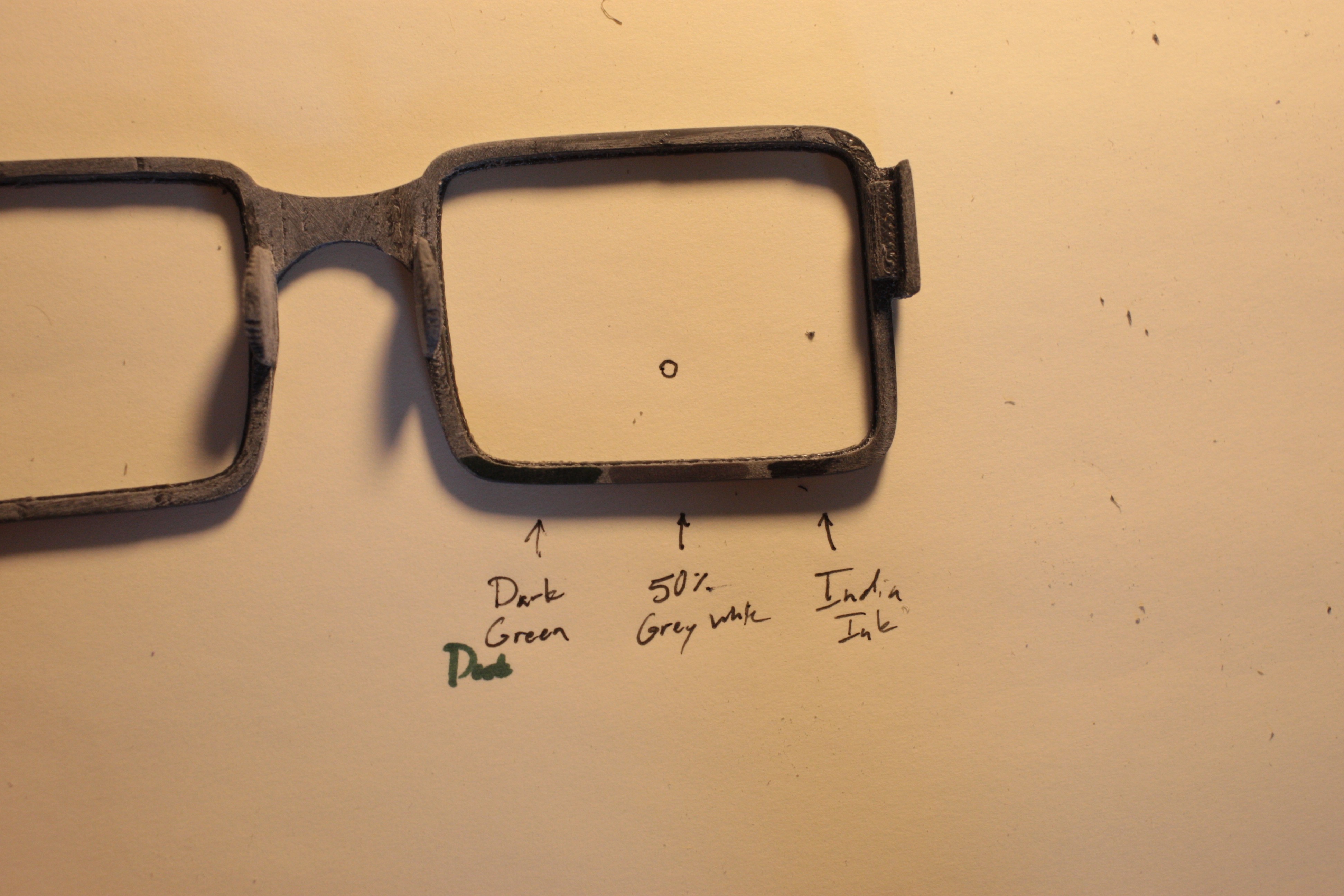

The prints came out well:

I then got the laser-cutter settings dialed in for cutting the mica. Thankfully this works though, could save a lot of tooling costs.

I also cut the polarizing film after correcting some dimensions.

I screwed up cutting the next mica sample.

Assembly was relatively easy.

I haven't removed the films, cleaned anything etc.

I need to figure out the nose pads still.

Compared to the previous prototype, the lenses are small but the viewing region seems comfortable.

The shown model dubbed "Rund" has the most stiffness of all current designs and so I went with it first.

Using a combination of the frame generator and direct modelling I was able to create multiple functional iterations in a relatively short amount of time.

I am trying to replicate some of my common manual command strings in grasshopper.

Derived:

Modified definition:

and from the back;

Pads are undecided.

Lens profile and pads:

I'm planning on making a module to generate the arms for at-least the current hinges.

I still think that bent wire makes sense for the arms; its very easily scaled. At-least six manufacturers in the area could do what I need.

https://www.thomasnet.com/eastern-pennsylvania/wire-bending-services-5616-1.html

Still no quote back for metal printing the old prototype, I'm going to send over the new design now prior to even test printing on my end due to lag time! Not how this should be... Anyways, hopefully things get sorted out soon.

I'm going to print the new models in plastic soon for testing. The nose pads for all of them seem to be the big deciding point.

A video tour of functions and usage; still under construction but helps explain a lot.

The generator for the 4th generation prototype is nearly complete.

This system will serve as the basis for the first release of purchasable designs.

A video tour will be conducted tomorrow explaining the architecture and details.

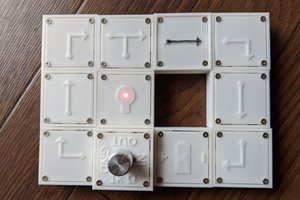

A modular glasses builder is being made in Grasshopper for Rhino.

It incorporates logical bounds and high customization with deeply interconnected systems.

Essentially, you manipulate the lens shape and it makes a pair of glasses automatically based on the shape; then you can tweak every other variable as you see fit.

The system is tailored for metal 3D printing at the moment.

John Cecil and I went to the North pop-up-shop today to demo the Focals.

First contact

The inspection

Overview:

Wearing

I had a lot of trouble seeing the screen until I tried on John's pair and got it calibrated. There is very little perspective, but colors look good. Refresh rate seems okay? I noticed some strobe effect, but mainly as the eye looks around.

Definitely looks better from the side.

Scanner for sizing:

After some processing, a 3D model for sizing. They had me wear a head band to keep stuff away from my ears.

Huge charging case.

Tortoise shell frames:

Lots of people stopped to ask questions:

Overall; we both agreed that as much as these really seem to work, they're not quite there yet. At-least for me, I think that only true AR or spatial computing will convince people to make the jump. $600USD+ is a too much for what is really just a perceived .25" see through smartphone or smart-watch screen. I did try to access the language learning app, which was thankfully easy to find and activate.... but, it took too long to boot (over five minutes) so I had to give up. The pop-ups were pretty distracting, maybe more-so than a normal phone even. The controller was surprisingly easy to use. Other people might not see the display but they will definitely notice some weird eye movement. John noticed that the projector got a little warm during use, but it seemed within normal limits. Knowing the realities of producing something like this, the price is probably fair while something like Magic Leap is actually under-priced. Considering the market; North is probably safe for now, but as more products come out North will have to expand their devices functionality or suffer getting left behind.

Following photos are from John Cecil:

Nice!

The end result:

------------------------

Linear build process:

Sanded frames

Cleared arm pivots and test painted, then painted.

Then the lens assembly:

Testing:

Following two images are with same lighting, but variation in polarization.

Finally putting that HdP to use haha.

I'm still working on the arm design, thankfully it's easy to work with.

Ended up lengthening the arms.

I ended up tweaking the arms a lot, ended up drawing them into an arch.

Finished.

The third prototype printed successfully.

I had to dissolve support overnight.

The resolution is still pretty terrible, but it'll work. I just have to do a bunch of post processing.

More sanding of the interior surfaces needs to be done.

I need to buy wire of the correct gauge and quality, superglue and I need to print off the lens templates (forgot again while I was at work!)

Then I can assemble the model.

The new prototype; Stapler.

I recorded my design work. Two parts.

Part two:

Change nose-pad shape. DONE

Open up arm wire diameter to 1.6mm+ DONE

Extrude half blind input by: .6mm (proportional to edge of arm support expansion. DONE .6mm

Eliminate arm-notch: <Switch to staple design> DONE

-------------------------------

Prototypes take an hour on average to process using current printer. Too slow.

Lens fitting and orientation is all done manually right now.

Only way to speed that up is with expensive tooling.

Goal: limited release in about 4 weeks.

Note; this is part two of this video, I needed to think about a design decision and to switch to no audio for a bit.

I have decided to go with a staple type arm, I will completely remake the arm supports so that the arm cannot flail outwards. I’ll make an illustration after showing the model. Here we go.

Running low on ram.

Not filleting any further, makes more sense to do by hand.

Create an account to leave a comment. Already have an account? Log In.

Micas high heat resistance would actually make it an excellent material for close proximity to a high heat source like a light-bulb. Mica lamp shades are actually somewhat common, made of a composite of shellac and mica flake.

Become a member to follow this project and never miss any updates

Benjamin Blundell

Benjamin Blundell

WalkerDev

WalkerDev

Polarization capablity looks like it could be a potential luminaire component. Might be a cool follow up project to make a lighting fixture with a non-halogen light source since heat resistance is an issue.