This Saturday I have started selling my boards on Tindie. https://www.tindie.com/products/jaspersikken/aemblink/

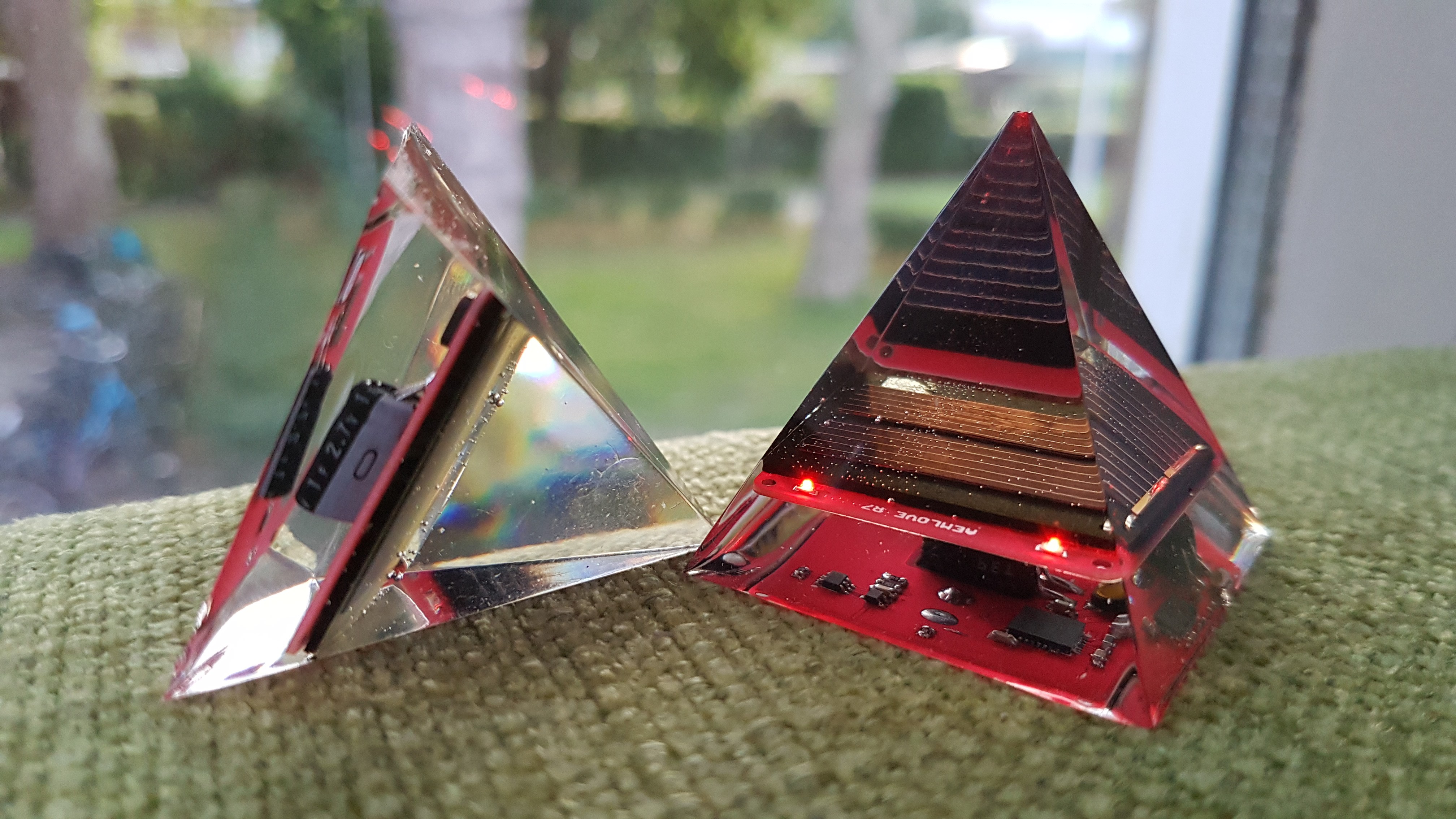

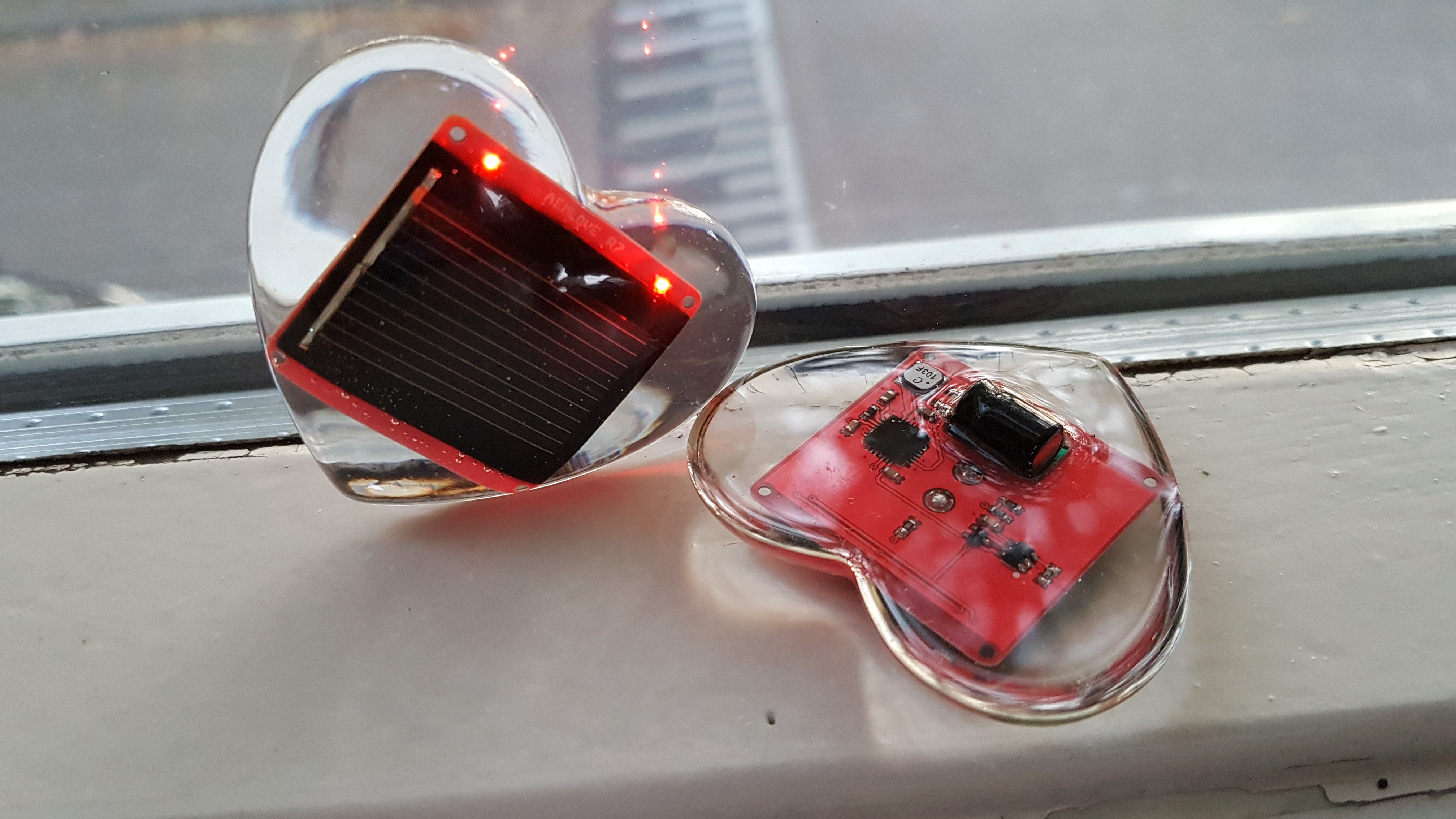

I have poured the PCBA with this epoxy into a silicone piramid and heart shape. The pouring is a delicate process. You need to work very clean, have everything prepared before actually starting. I have cleaned the silicone mold with water and soap and used a can of compressed air to blow out the water, then I have put the mold in the oven at 100 degrees celsius to dry further. On the table I have put couple sheets of protective baking paper. And put everything on it, the bottles of 2 parts epoxy, the bottle of UV stabilizer, a couple disposable cups, a couple wooden stirring sticks, a roll of kitchen towel, a kitchen weighing scale. And then I started mixing the 2 parts epoxy, 50g of part A, 30 grams of part B, 1 gram of UV stabiliser. To avoid bubbles stir slowly and in 1 direction, after 2 minutes pour the stirred mixture slowly in another cup, and mix again, this makes sure that the two parts are well mixed. Then to reduce amount of bubbles I slowly poured the mold 3 quarters full with epoxy and put the electronics slowly in. Then I filled the mold full. Using the stirring stick I tried to remove the bubbles. The curing is slow, you have about 15 minutes to finish, after a few hours it feels hard and after 24 hours curing is done.

It was quite easy to remove the epoxy from the silicone molds.

Jasper Sikken

Jasper Sikken

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.