This has been an exciting week with more people from Fox.Build joining the project. We had 4 out of 5 of us at the space on Friday working through the design. On top of that, our muse Dr. Erich Styger has joined our team and gave us some insights on the improvements he has been making and the things he would do differently.

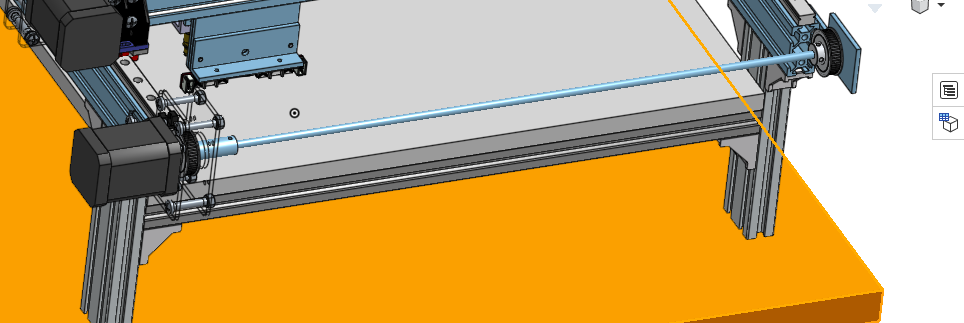

Of those items, the second y-axis is getting the most attention. Since it rolled so well, we thought the second y-axis motor was not necessary. Erich mentioned that he added one but it was hard to sync the movement. So he recommended using stepper motor with a shaft out that back that is connected to the second y axis. We decided to follow this advice but we are trying to turn the first y axis motor around and make a coupling shaft between the two axes. We will start with just supporting it on the far side with a brass plate. Having the 3D model is great because I can reference the model and design this part the right way the first time. At the makerspace we got a huge donation of metal and now shopping is as easy as going to the basement and picking out what we need. Here is the metal rack.

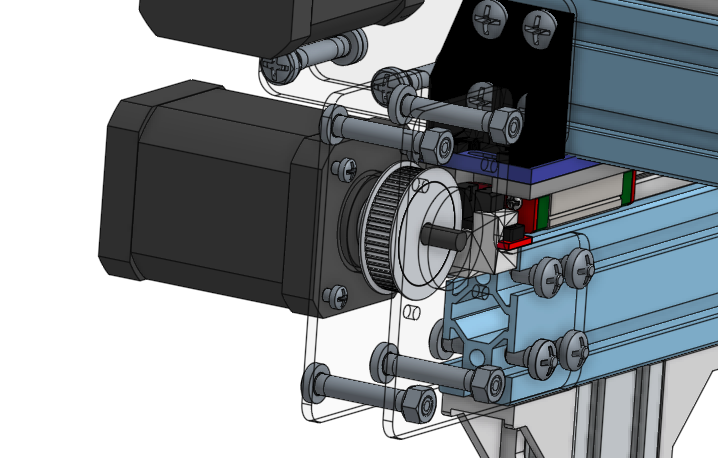

Here is what it looks like when we flip the motor. I am a little concerned that it might interfere with the cable chain when we get that set up but for now, we will flip it. I have to give some props to our CAD system of choice Onshape. We noticed the timing belt was rubbing on the sensor and was on bit of an angle. To avoid wear on the belt and inaccuracies from the angle, it was decided the bracket had to change. I changed it in context, using dimensions from the assembly. I just changed the sketch while seeing how it was looking and final model adjusted including the mates. An all this on a free CAD system that I can run on my Linux box. Here is what it looks like after the motor is raised and the motor turned around. I can see the top of the pulley is about the same height as the sled top bracket that holds the belt.

Here is how it looks with the shaft, the shaft coupler, the additional pulley and the brass shaft bushing.

Here is how it looks with the shaft, the shaft coupler, the additional pulley and the brass shaft bushing.

shane.snipe

shane.snipe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.