BikeOn is a device that converts any bicycle to electric and back in seconds. No tools or skills required. Just attach the device to the wheel of your bicycle and it becomes an electric assist.

Creating a product that is useful, practical, aesthetically pleasing and stylish was very challenging. It had to be practical in several areas which included:

Aesthetically pleasing and stylish products are often a key to successful brands (along with other aspects, such as usefulness and practicality, for instance). In our view that is especially important for digitally native vertical brand, which we are building.

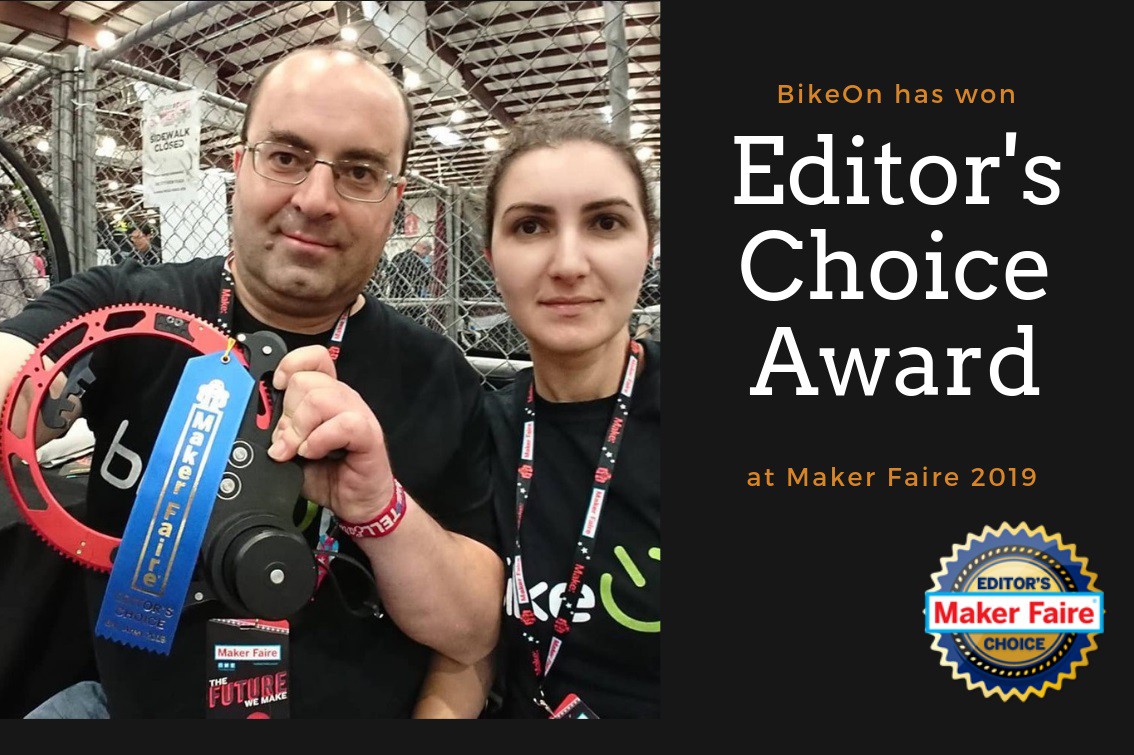

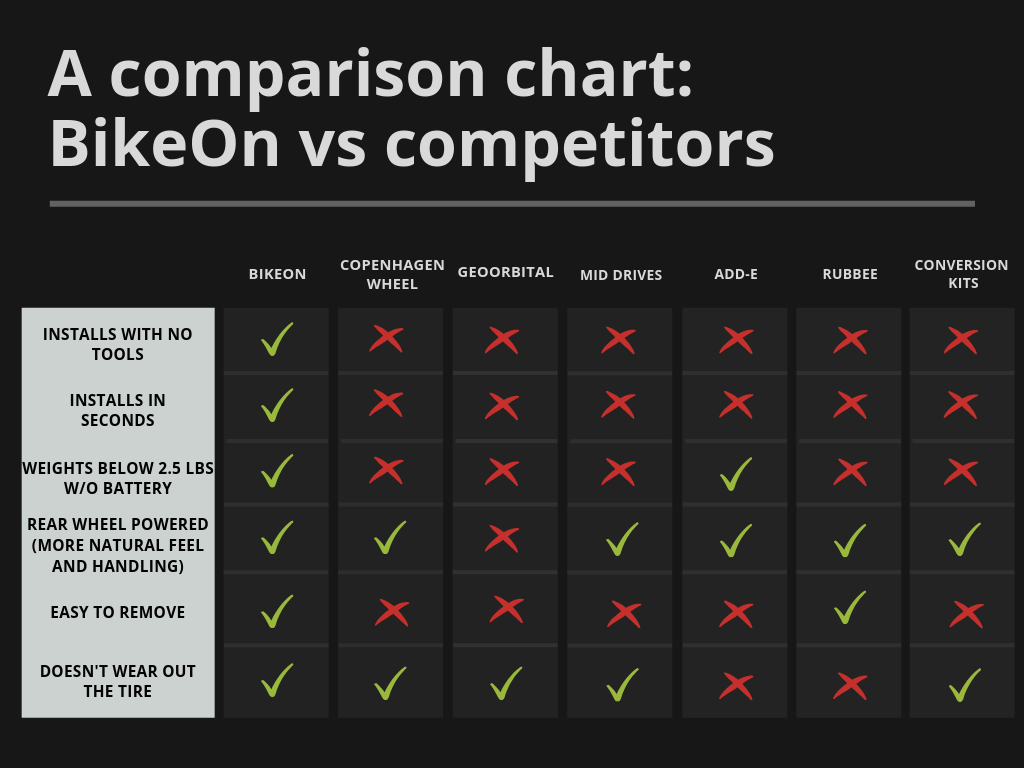

BikeOn is the only device on the market that combines ease of installation and removal (in seconds, with no tools), compact size, and low weight (below 2.5 lbs). Our algorithms ensure the smoothness and ease of ride. Because it powers up the rear wheel, it also provides very natural feel and handling of the bicycle.

One of the challenges on the technical side was to find a concept and a form factor that would physically fit most of the bicycles. Bicycles of different brands and builds (and even different production year) have very little in common. Frames, wheels, wheel lacings, cranksets and all other bicycle components vary greatly in size and often shapes. There are some common dimensions agreed upon by manufacturers, but not many. We have managed to find a way to bypass most of the constraints yet keeping the design within desired specs and parameters

We have been developing BikeOn for over 5 years. In the course of the development, we have made over 70 different prototypes. Each of them led to a different set of decisions and changes. We have tried to compress that 5+ year process in this submission and highlight the most significant choices and decisions we have made. Those decisions can be partially seen in our logs and project details section (see Design portion below)

BikeOn is set to solve two major issues:

When we first started working on BikeOn, there were 5 things we would not compromise on:

- easily attachable and removable, with no tools and skills;

- universal (works on most bicycles);

- nice looking;

- lightweight;

- reasonable cost for the end user.

It was pretty ambitious, no wonder it took us more than 5 years of research and development :)

First, we started developing our own electric motor concept, because at the time, we thought that it is the way to achieve a sleek design we were looking for. It took us 2 years of research and development to steer in the direction of buying a motor, integrating it into the design and concentrating more on other aspects of the product.

The other problem was how we attach BikeOn to the wheel. At first we worked on attaching it to spokes of the front wheel. Here is a video showing the prototype of those times.

However, we did not like that solution very much, we knew it was not “the best”. Firstly, because it is always better to motorize the rear wheel rather than the front, due to safety concerns and much more natural handling of the bicycle; and secondly, because we didn’t really like the idea of applying direct force to spokes due to mechanical stability issues.

So we kept thinking and iterating, and came to a design solution that would allow BikeOn to be attached to the rear sprocket. That’s when we knew that we eventually got something really good.

In this concept BikeOn sits on one of the strongest parts of the drivetrain member - the sprocket.

Part of the housing comes in contact with the chainstay tube from the bottom and works as built in torque arm - no additional parts required for that.

Yes, this design was not as sleek as our ideal vision of ring shaped motor with nothing sticking out. But on the other hand, the motor is half hidden/covered by the chainstay tube, so we were fine with that compromise.

The sensor group blends in seamlessly in this design. We always wanted to use the best available set of sensors and one of them was the torque sensor. It measures the chain tension and allows the device to work in unison with the rider. It gives superior experience and that’s what we were looking for! Other sensors, such as gyro and accelerometer, come to complement and add to the torque sensor.

The ease of removal of BikeOn is a useful feature for some, but undesirable for others. That's why we will be introducing a lock, which will work seamlessly with BikeOn to prevent theft. Stay tuned!

BikeOn is fully ready for production. We are engaged and work closely with our manufacturing partners and we’re getting ready to produce the first batch in a few months.

BikeOn is made of simple metal and plastic parts, using such widespread techniques as stamping, extrusion, plastic molding.

It can be fully assembled and tested by minimally trained workforce. The assembly and testing do not require any complex fixtures and take very little time thanks to the semi automated testing procedures, developed by us.

We are bootstrapping the project and we will be profitable from the very first batch, so that we can reinvest the profit back into production and ensure fast growth. BikeOn has been designed for manufacturing from very beginning and currently we are building a robust supply chain that will support fast growth.

PLAN FOR DEPLOYMENT

We are currently working on the first batch of 30 units. These will be sold to our early adopters for testing and feedback. After that we will start making larger batches, increasing batch size each time. We plan for a crowdfunding campaign right after one of the early batches.

Here is a list of our competitors. For more details on each of them, please see the video below. It’s not an exhaustive list, but more of a representation of competitors’ types and some companies:

Even though it is not a completely open source project, we have published as much of the project as we could without hampering further commercial development of the project. We’ve published the PCB layout of the electric motor controller along with the schematics.

We are grateful that our project has attracted the attention of so many folks around the world. We received and continue to receive an overwhelmingly positive feedback and support. That is one of the most amazing parts of our journey and Hackaday competition in particular.

Shushanik Khachaturian

Shushanik Khachaturian