This project is an excerpt from the main writeup here:

https://salvagedcircuitry.com/olympus-12mm.html

The rear element on my 12mm f2.0 olympus lens was a bit too dirty for my tastes, and I could not get it as clean as I liked with compressed air and a cleaning cloth, so I decided to take the lens apart. The disassembly went smoothly and I was able to remove the metal mount and plastic lens spacer in just a few minutes. This gave me full access to the rear element. Then I saw the one thing that haunts every lens technician: a torn flat flex ribbon cable. It's not uncommon for flat flex cables to run completely throughout a lens, never to be seen again. Roger Cicala posts fantastic teardowns of such lenses on Lensrentals.com. These flat flex cables are not easy to source as a repair part from any consumer lens manufacturer, unless your best friends with the lens manufacturer. Often, these ribbon cables are custom cables with varying trace widths and can't simply be replaced with off-the-shelf flat flex cables from digikey or lcsc.

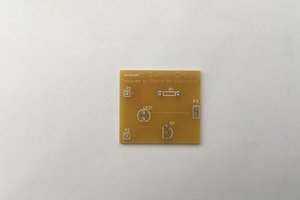

Luckily, I tore just the lens mount flat flex cable. These cables tend to be short and easily accessible, not requiring a complete disassembly of the lens. The way this lens is designed, the mount cable is actually soldered down to the main autofocus PCB instead of using a latched flat flex ribbon connector. I was debating whether a quick-and-dirty soldering job or a full flex PCB replacement would be a better way to repair this lens. After all, I could simply peel back the polyamide coating on the flex PCB and solder in some 28awg bodge wires. I decided to just redesign the flex PCB instead so there is a replacement part out in the wild. If I made the mistake of tearing this cable upon lens disassembly, there is a good solid chance that other folks will rip this flex PCB as well.

Keeping the open nature of this repair, this part was designed completely in KiCad, a fantastic open source PCB making utility that anyone can download and use. This PCB was designed in KiCad 5.0 and this KiCad file is free for anyone to use. The pad spacing is dimensionally correct, and a caliper was used to measure spacing and trace pitch. Of course, this flex PCB may not be a 100% perfect fit and I will only know when I get the flex PCBs in the mail. I added two positioning holes for the micro four thirds lens communication block as well, to ease in resoldering the lens mount connector.

Let me know what you think!

Anthony Kouttron

Anthony Kouttron

paulusjacobus

paulusjacobus

danielcanaday

danielcanaday