Iteration #1

In our first iteration we used an arduino uno, a 600N electromagnet, a 5V relay, an arduino-compatible accelerometer/gyroscope breakaway board (MPU6050) and a solderless breadboard. We contained the device in a 3D printed case which we attached with nuts and bolts through holes drilled into the side of the trash can. The device is powered both by a 9V battery for the arduino and 4 AA batteries to power the electrmagnet., however due to the power demands of the system (largely the arduino itself) and the size of the system we decided to optimize through development of smaller versions. We learned that the contact between the steel plate on the lid and the electromagnetic base unit must be precisely engineered for a reliable locking action to occur. The attachment to the device to the trash can and the alignment of the electromagnet’s base and the armature plate on the lid had slight imperfections and irregularities that were updated in the newer models.

Iteration #2

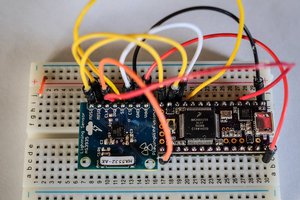

In our second iteration we switched from the arduino uno to the arduino metro mini and we used a solder-able breadboard to make the breadboard component smaller. These two changes drastically reduced the size of the case. The gyroscope component has not changed. Additionally, we changed the 5V relay to a transistor to help reduce power consumption and decrease the overall size of the assembly. Finally, the 3D printed case is now modular so that individual components of the design can be separated. The transistor also is connected to a single resistor that will ensure the device can be turned off when uprighted.

Iteration #3

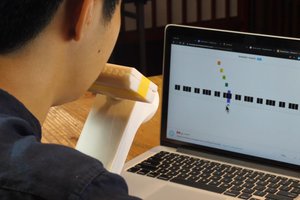

The team has decided to try an updated solution to our power dilemma. We have designed a custom PCB and we will begin soldering the components. In order to solve our power dilemma we needed to switch to a low power microcontroller (PIC16), the BMA400 accelerometer and the BMG250 gyroscope as each of these components uses significantly less power than our previous system. The new components will require additional capacitors and resistors that we will be soldering.

Things we considered:

We considered using an arduino trinket. At the time we were trying out the trinket we were using a 5V relay but the trinket did not have a 5V output so it was not functioning in our system. We then switched from a relay to a transistor to prevent the issue in the future. We have not revisited the trinket in our newer iterations but this could be an area to explore. As a student team, we also found the metro mini to work better with the constraints within our school.

We considered using button batteries early on but had issues with the power they could provide in our early systems.

We tested several electromagnets and the most success we have had so far has been with a rectangular 600N electromagnet. We tested several circular electromagnets (ranging from 100-300N) but these didn’t work as well within our system. We discovered that 200N is likely the necessary force that we will need however the additional surface area provided by the stronger 600N rectangular electromagnet

brian bloom

brian bloom

Shu Takahashi

Shu Takahashi

Alex M Sunny

Alex M Sunny

Ondřej Petrlík

Ondřej Petrlík

Thanks for your suggestion! We looked into various gravity features early on and didn't feel they served all our purposes. First, we wanted to be sure to not void the warranty. Second, we want to be able to update the device in the future with additional options controlled by the arduino. We are hoping to add in some new components this year (including more sensors).