Thanks to Platformio I switched back to Marlin 2 because the compile times are much better than those of the Arduino IDE.

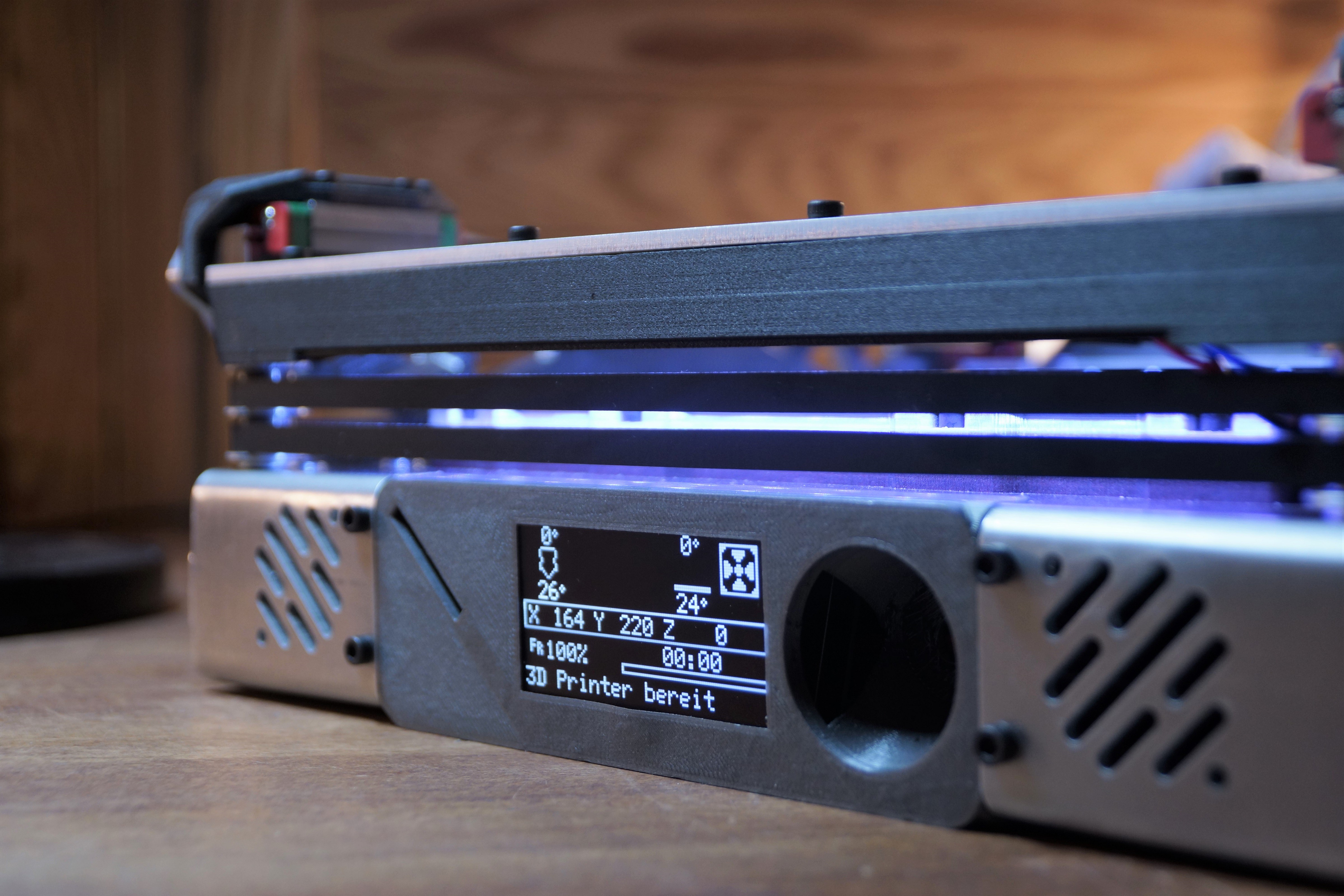

The printer now has a 12x12cm silicone heatbed, and I was able to install the OLED display.

The whole display controller assembly (3D-printed part) still needs some modifications because, at the moment, not all components fit.

Reinforced Z-slider

I reinforced the Z-slider with another 3mm aluminium plate which I screwed onto the old Z-slider. Unfortunately, my tapped screw threads weren't very precise so that I couldn't use all screw holes to join the two parts together.

With the new reinforced Z-slider, the printer is now at all Z-heights above the printbed rigid (no Z-flex when applying extra load in Z-direction).

When The Nozzle moves under the printbed, the Z-flex starts to increase.

Which for the printing process is unimportant, but can be a problem when homing to Z min (could result in homing position inaccuracy).

Backlash

The Z-axis has backlash, which I didn't aspect to happen because the axis has a preload due to the scissor lift and the weight of the upper construction.

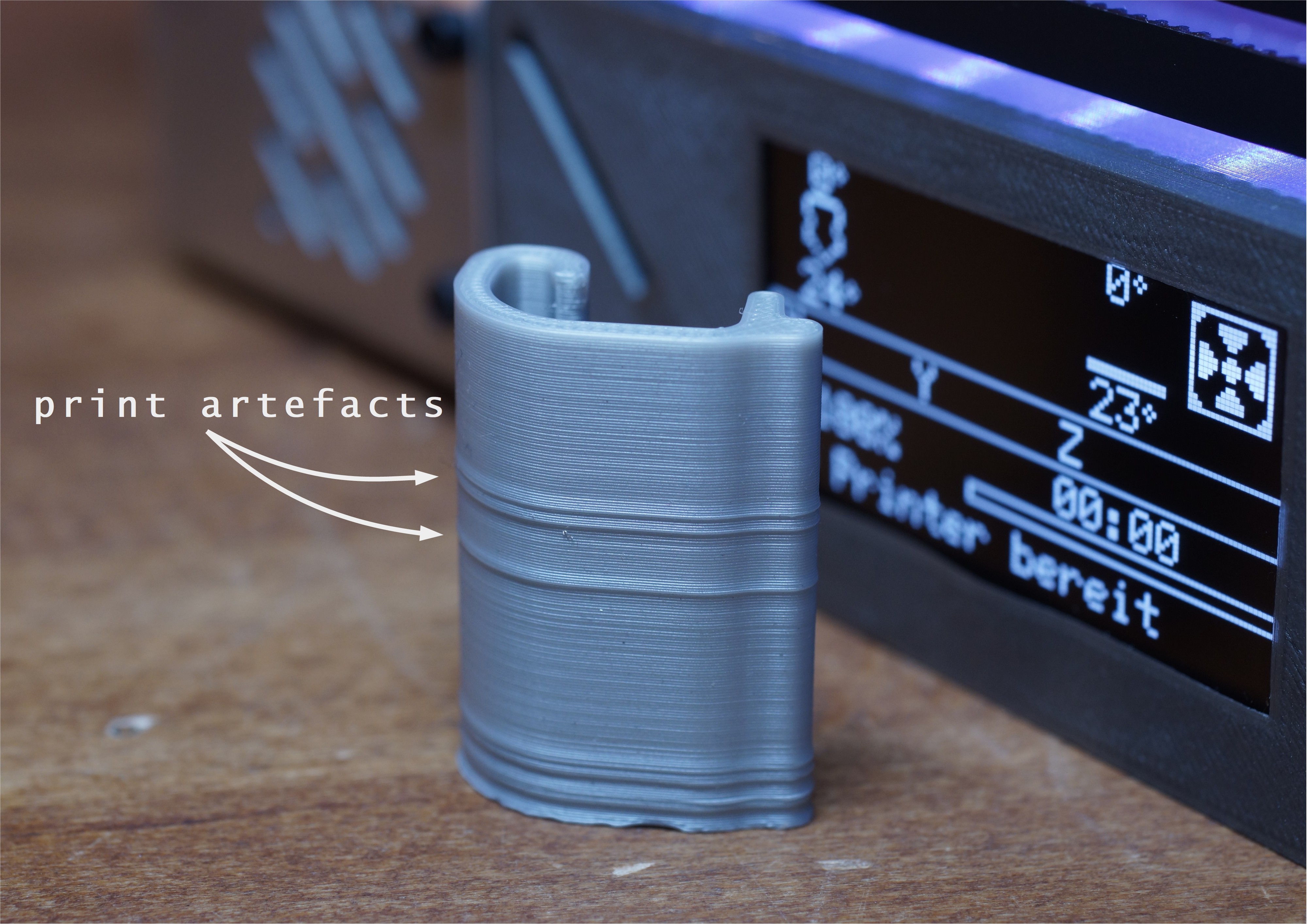

The backlash caused the print artefacts in the first layers, which I mentioned in the last log because the standard PrusaSlicer Gcode moves the printhead at first some millimetres above the printbed before the printer moves downwards and then starts printing.

To solve the problem, I have changed the Gcode so that after homing, the printer moves only upwards, which is a short term solution, but backlash limits the possible features of the printer. Z-hop and auto bed leveling will be not usable.

Even homing is hard with backlash, for more accuracy I'm pushing the upper construction manually downwards before homing, to eliminate the backlash.

I tried the backlash compensation feature in Marlin, but it didn't work very well since the printer moves slightly upwards during the compensation process.

The next thing that I want to try is to improve lubrication because I think there is already enough preload to prevent the backlash.

Maybe some of you have any ideas on how to solve that problem.

Print quality

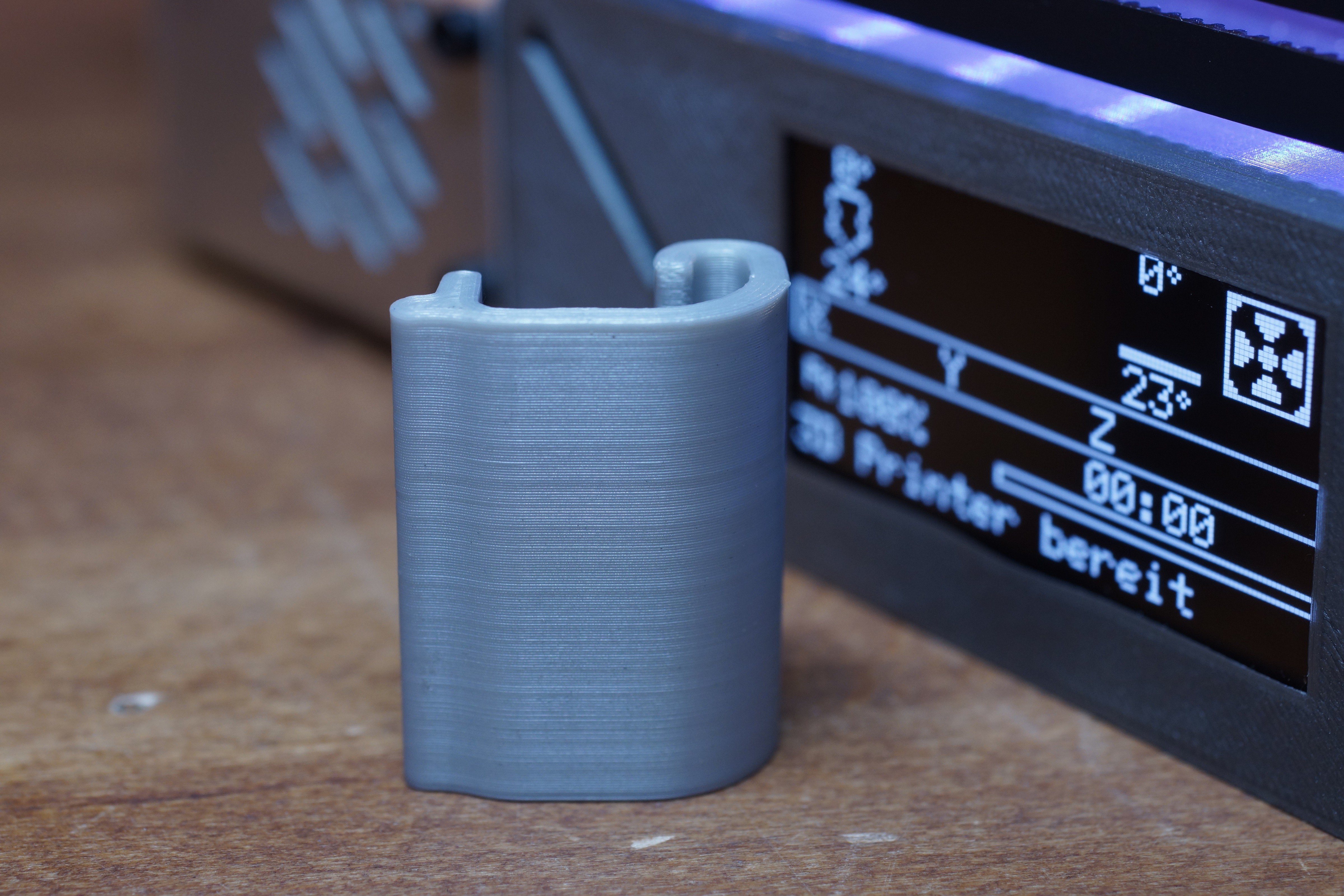

Print quality looks good. Some test parts are getting weird print artefacts from which I don't know where they come. But I think this is not a Z-axis problem. I increased the belt tensions, which improved the problem. When I print with slower speed, the artefacts are mostly gone. But I'm still not sure what exactly is causing these artefacts. Feel free to write a comment If you have any ideas.

Malte Schrader

Malte Schrader

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.