Progress Report:

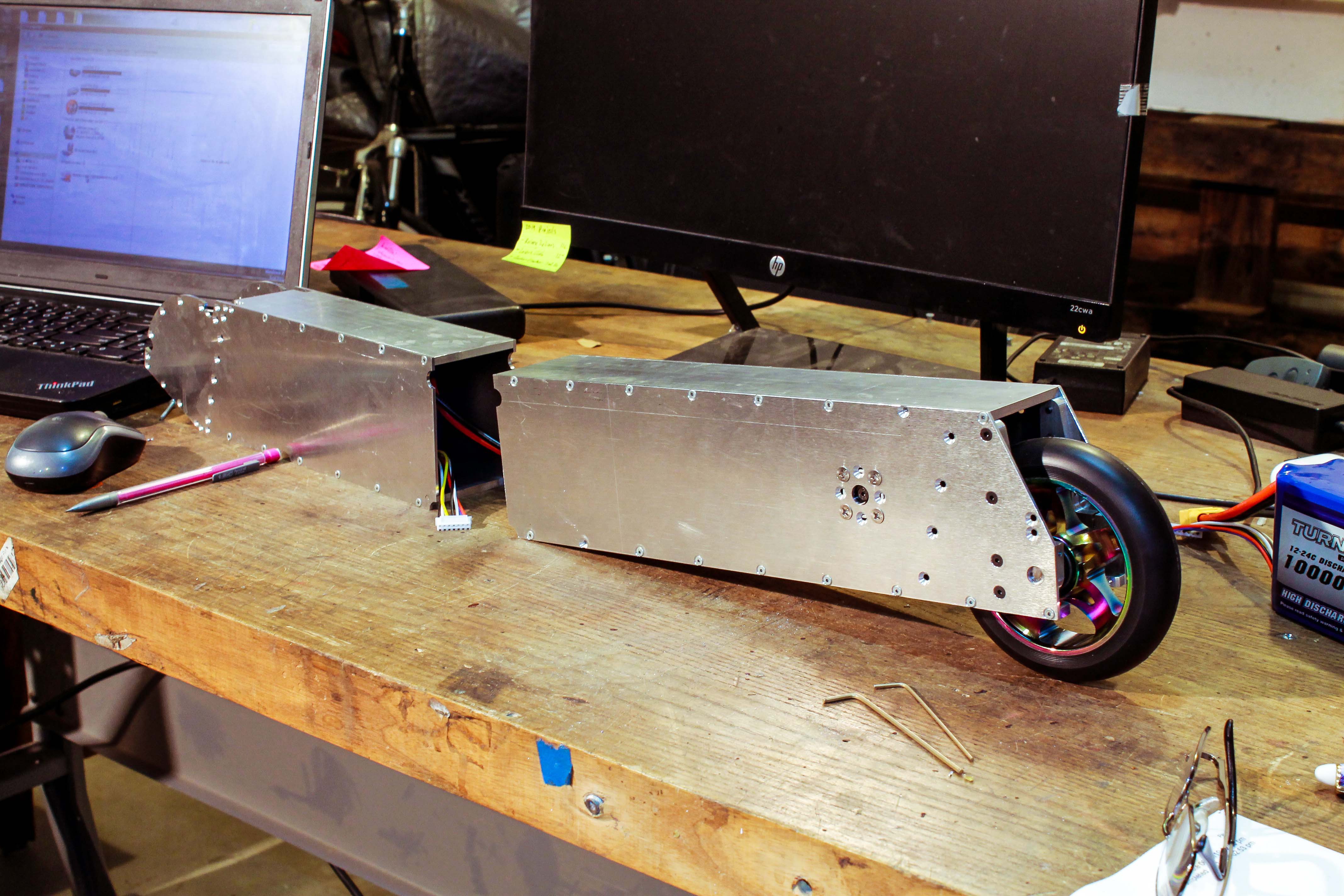

The machining is underway and the decks are beginning to take shape.

Here the rear axle supports are being milled. These parts clamp either side of the rear axle and distribute the load while also allowing the belt tension to be adjusted then locked in.

Why start with Milling?

I chose to emphasize milling in the prototype stage for the following reasons:

- Milling itself works as both a low-volume and mid-volume process.

- I can use strong materials.

- Milling generally produces good results on the first parts.

- Milling lends itself to threaded fasteners, which is like giving myself an "undo" button as I navigate assembly!

- Milling has many relatives in NC-controlled cutting family. By starting with milling, I can more readily bring part designs to contract manufacturers with other cutting capabilities. For example, I would really like to see the deck frames become laser-cut tubes. Maybe someday!

Mike Thielvoldt

Mike Thielvoldt

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.