Introduction:

Energy is one of the crucial resources for any business. Rising energy costs, increasing demand, volatile energy markets, and strict enforcement of government policies are some of the propelling factors that have led many organizations to find smart ways for monitoring, controlling, and saving energy. Monitoring energy usage across your whole organization is a daunting task and often ends up in silos of data. In today's connected world, the energy future will be inexorably linked to Internet of Things (IoT). The need of the hour is an intelligent Energy Management System (EnMS) that can contribute towards cutting the costs, improving efficiency, and meeting your energy demands.

IoT Energy Management Solution (www.ssla.co.uk) is the panacea for customer's woes and an enabler of digital transformation. Our solution can be utilized to better manage your energy consumption patterns in commercial and industrial sectors by taking complete control of your energy data at a fundamental and granular level.

Objective:

"Energy savings are realized through enhanced visibility. Data visibility drives appropriate energy saving actions, thereby achieving organizational objectives." Our intelligent energy management system (www.ssla.co.uk/product/iot-evaluation)is designed to optimize energy consumption thereby improving utilization, reducing costs, predicting maintenance needs, and increasing the reliability of energy assets. It meticulously acquires energy data which can enable enterprises to illustrate dynamic performance against defined targets to identify deviations. This in turn, will ensure well managed and controlled operation to deliver the most energy & emission efficient level of productivity.

Importance of Energy Measurement for Monitoring

Measurement can range from only utility meters for small organizations up to complete monitoring and measurement systems connected to a software application capable of consolidating data and delivering automatic analysis. It is up to the organization to determine the means and methods of measurement.

Measuring energy data is a key component for implementing an energy management plan. To be done effectively a manager needs to:

- Establish an energy data measurement system;

- Designate staff in charge of monitoring energy use;

- Ensure proper use of energy measuring instruments and ensure safety of meters; and

- Provide energy data in a complete and timely manner.

Designating staff members to implement energy measurement is important to creating an effective system. Preparing a document that details ways the company measures energy is essential.

Although measuring energy data only reflects "overall consumption" rather than energy efficiency, it is still fundamental to evaluating energy efficiency and energy-saving opportunities.

Companies should measure energy consumption by considering:

- Overall energy consumption.

- Energy consumption of power lines and departments

- Energy consumption of office and production equipment.

Implementation of Industrial Energy Monitoring

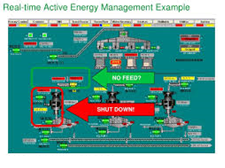

Energy efficiency monitoring and benchmarking are important for energy management, as they enable decision makers to identify improvement opportunities and to keep track of the effects of their decisions on energy use. Monitoring and analysis of the energy consumption of machines and support and manufacturing processes is the first step towards increasing energy efficiency. Insufficient monitoring may result in companies not being aware of their potential for profitable energy investments. Moreover, monitoring of energy consumption of the enterprise supports the judgment as to whether anticipated energy savings could be achieved or not.

Monitoring also helps to identify the most energy intensive processes. In this section all aspects of energy monitoring such as data collection, analysis, presentation and measures of performance will be covered. This section also analyses existing techniques for data collection, analysis, display, performance measures.

Data collection

Collecting data with standard method is very important. One of the recent standards for data exchange device is ELB-REV4 (www.ssla.co.uk/product/processor-evaluation)which was used to monitor energy consumption. Energy consumption data can be gathered using statistical data, energy audits, energy balance sheet, questionnaires. All big industry companies and energy providers are collecting historical energy consumption for statistical data. Energy audit includes, survey and analysis of energy flows for energy conservation in a building, process or system to reduce the amount of energy input into the system without negatively affecting the output(s), identifying the sources of energy use and the interactions with weather, occupancy and operating schedules. Data collection using energy balance sheets, where it shows the relevant energy input and output and break down of energy used in various processes to identify the “energy centers”, which may then be analyzed for energy saving potential.

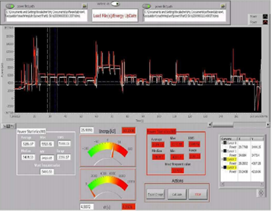

Energy Profiles Analysis

Typically, Machines consist of several energy consuming components which generate a specific energy profile when producing. Analysis of energy profiles from different temporal production levels provides detailed information about energy consumption and helps to identify problems and potentials for energy efficiency improvement.

Conclusion

From the reviews and case study mentioned it is proven that the energy management standard is a powerful tool, to adopt and implement desired energy efficiency and energy use reduction. The energy management system should be integrated into the overall development strategy of the company development with strong commitment as this will resolve the problems of strategic management, including strengthening the company’s market position and engaging in new strategic economic areas, growth of the enterprises competitiveness, the use of new energy sources, including the alternative sources of energy, the organization of new business processes, as well as the restructuring of the company in the light of the energy management systems. Government support that includes incentives in implementing the standard is essential and important aspect in promoting and encouraging the use of energy management system standard among industries or companies.

ensafatef

ensafatef