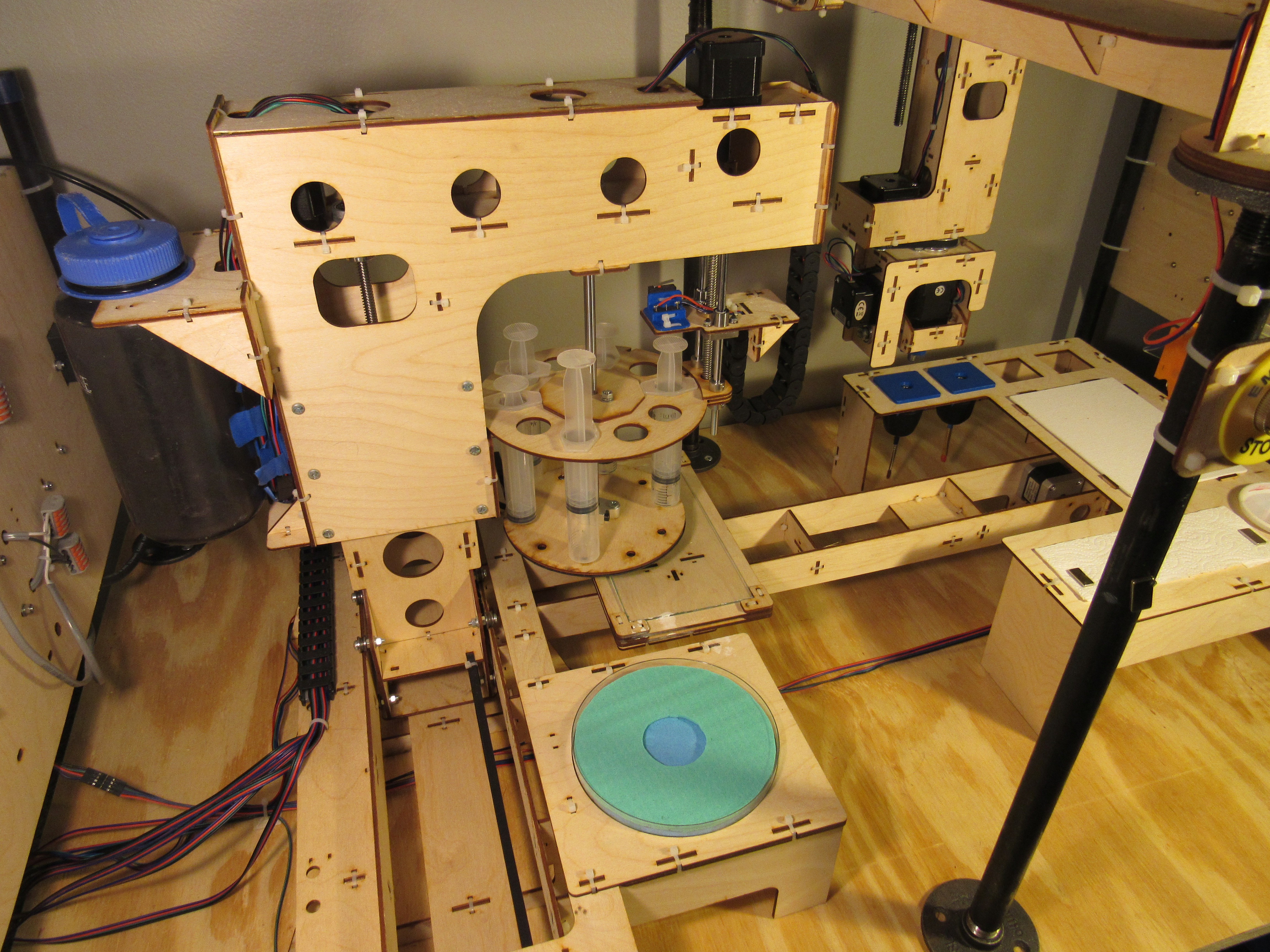

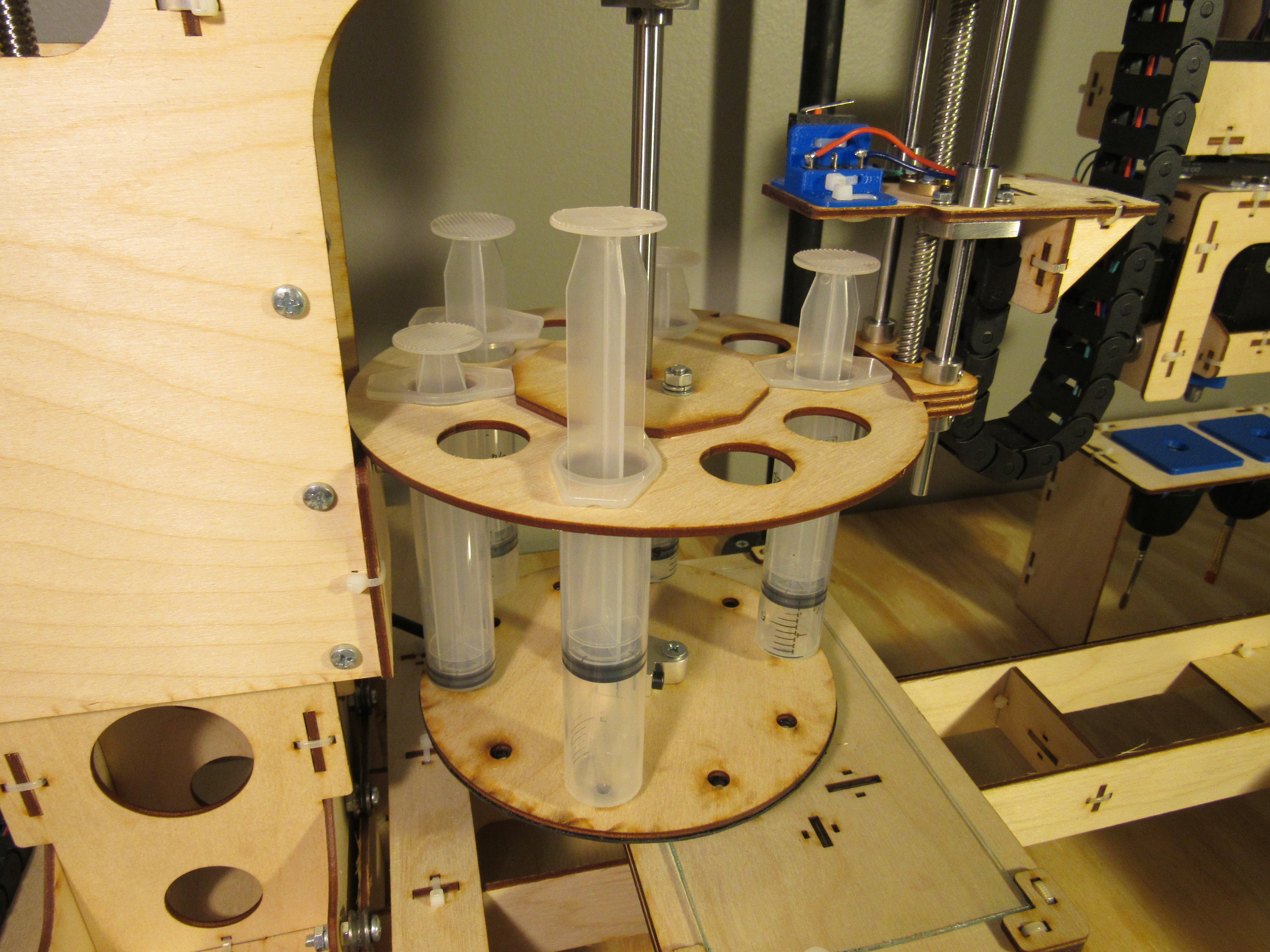

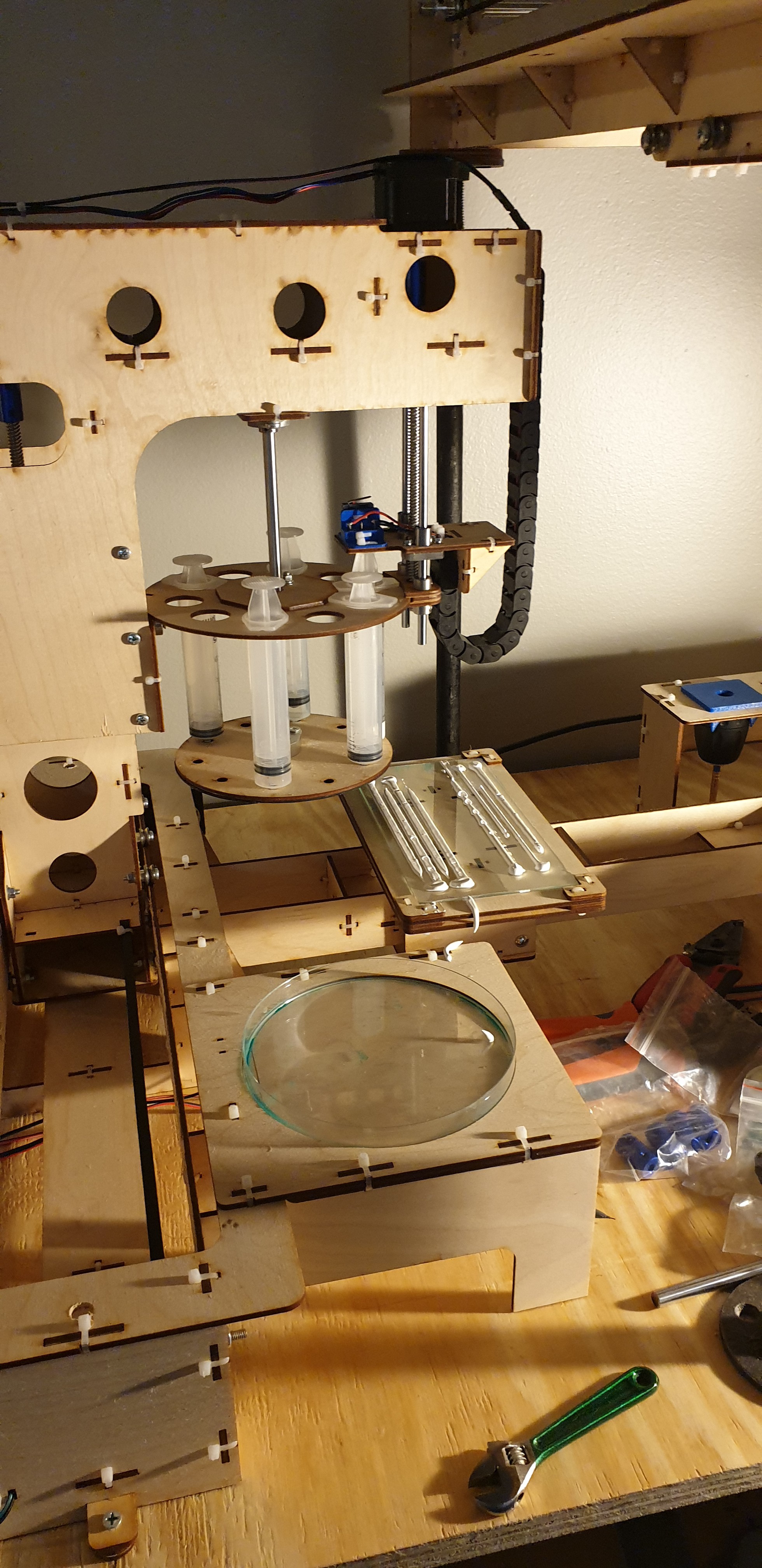

"Paint management" refers to the processes involved in dispensing and storing paints during the cnc painting operation. The paint management system developed for the proof of concept prototype is comprised of a three axis positioning system, a syringe carousel and push plate, a paint palette, and a water dish. The three axis positioning system is used to dispensed paint at any location on the palette. The syringe carousel allows up to ten syringes of paint; one per paint color. The syringe carousel rotates to position syringes under the push plate. The push plate presses on the syringe plunger to dispense paint onto the palette. After use, the syringes are returned to the water dish so the paint doesn't dry and clog the tips of the syringes. The palette is made of glass so it can be cleaned easily using a metal scraper.

In theory, the paint management system will determine how much paint to dispense and where on the palette to put the paint by following this process. After the user has converted a bitmap image to paint strokes, another programming script determines the total paint stroke distance traveled on the canvas for each color of paint and each paint brush. Each paint brush has a predefined (determined through testing) parameter on how far it can travel on the canvas before needing to be reloaded with paint as well as the length of paint bead required to reload the brush. From this information, the length and color of each paint bead that needs to be dispensed on the palette to complete the painting can be found. Another script will map out how to place the variable length beads of paint within the available palette size. This map will be converted to the gcode instructions that get sent to the paint management system microcontroller.

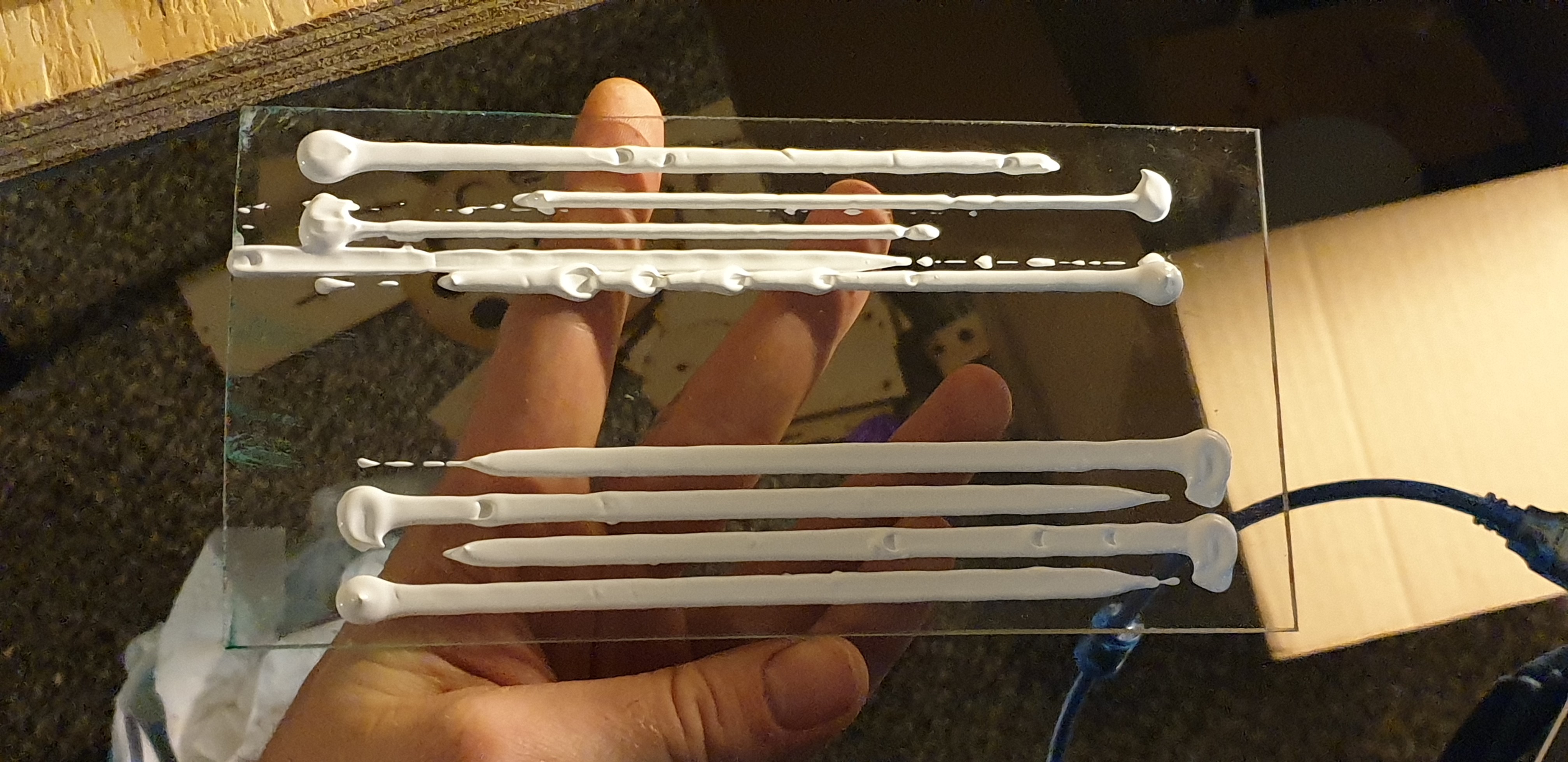

Turns out that acrylic paint is thixotropic (viscosity decreases with an increase in shear stress). When I commanded the machine to dispense paint and move all in one single movement there would be a delay before paint would start coming out of the nozzle. After the movement was completed the syringe continued to dispense paint. See the rows of paint at the top of the palette in the images below. I eventually figured out how to create uniform beads of paint by dispensing a little bit at the beginning and including a short delay so the paint could begin to flow before staring the movement. See the rows of paint at the bottom of the palette in the images below. It still needs some work but after a few months of designing and fabricating the paint management system I considered it a victory.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.