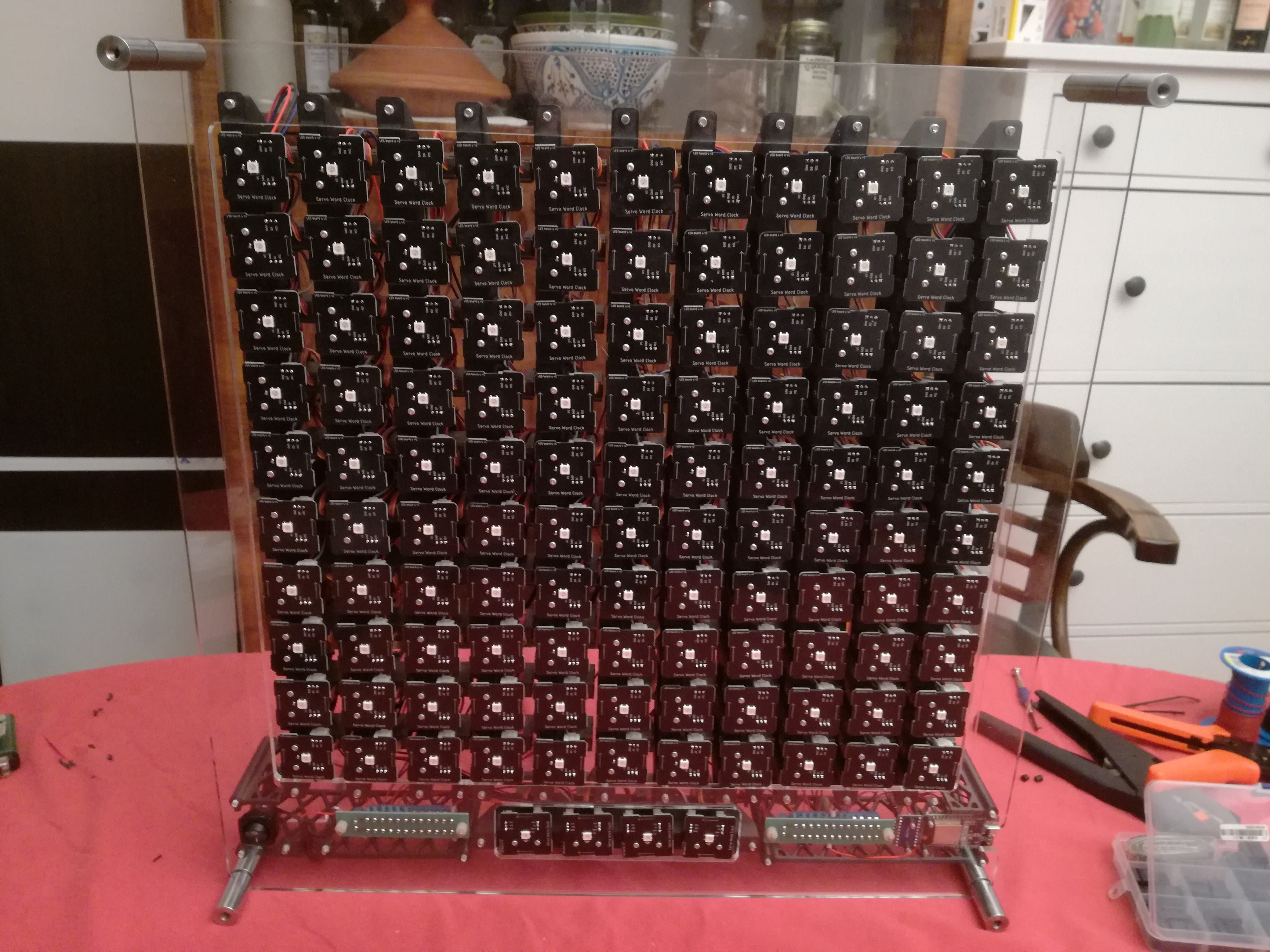

Compared to version 1 we succeeded in making the following improvements

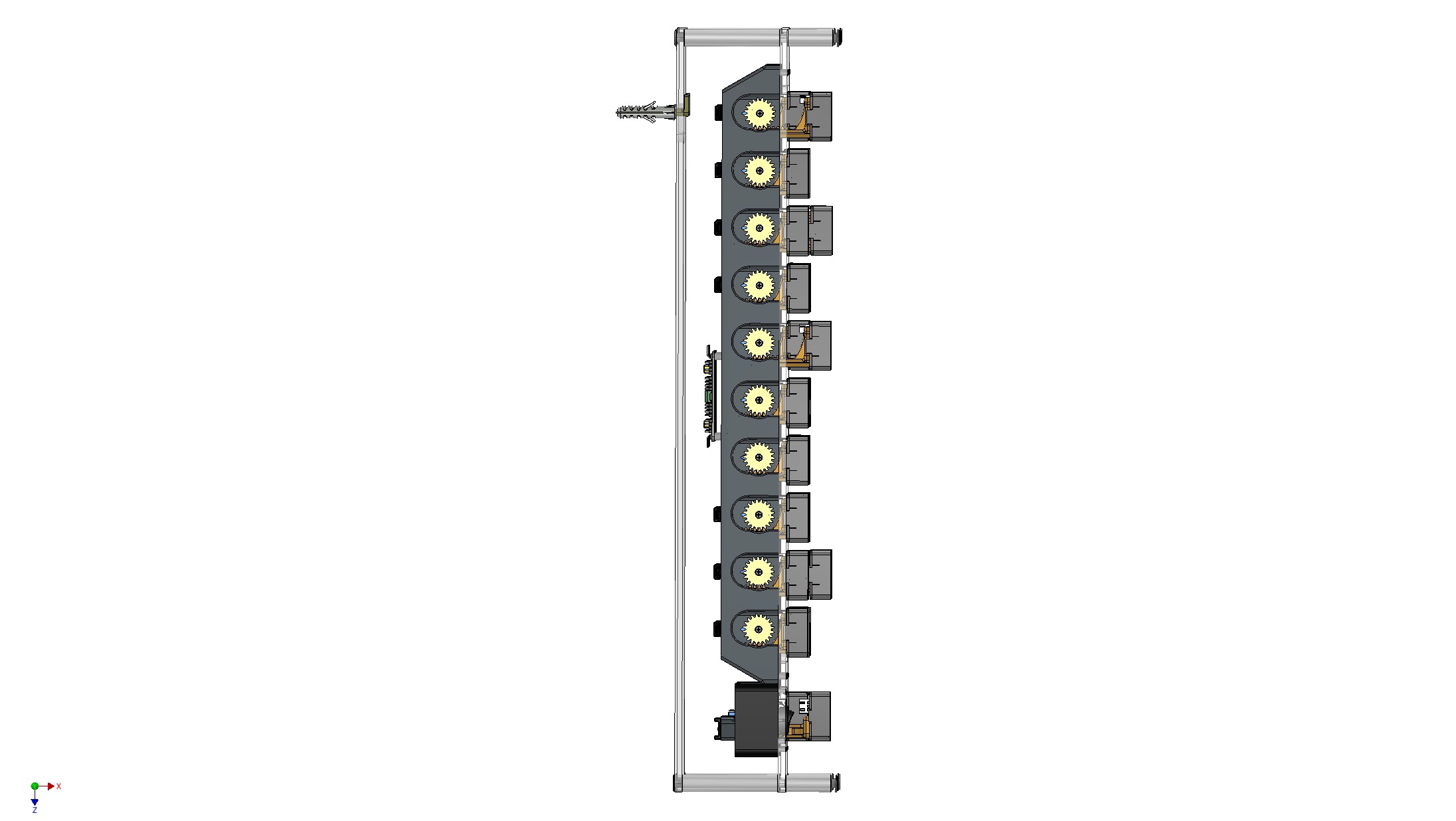

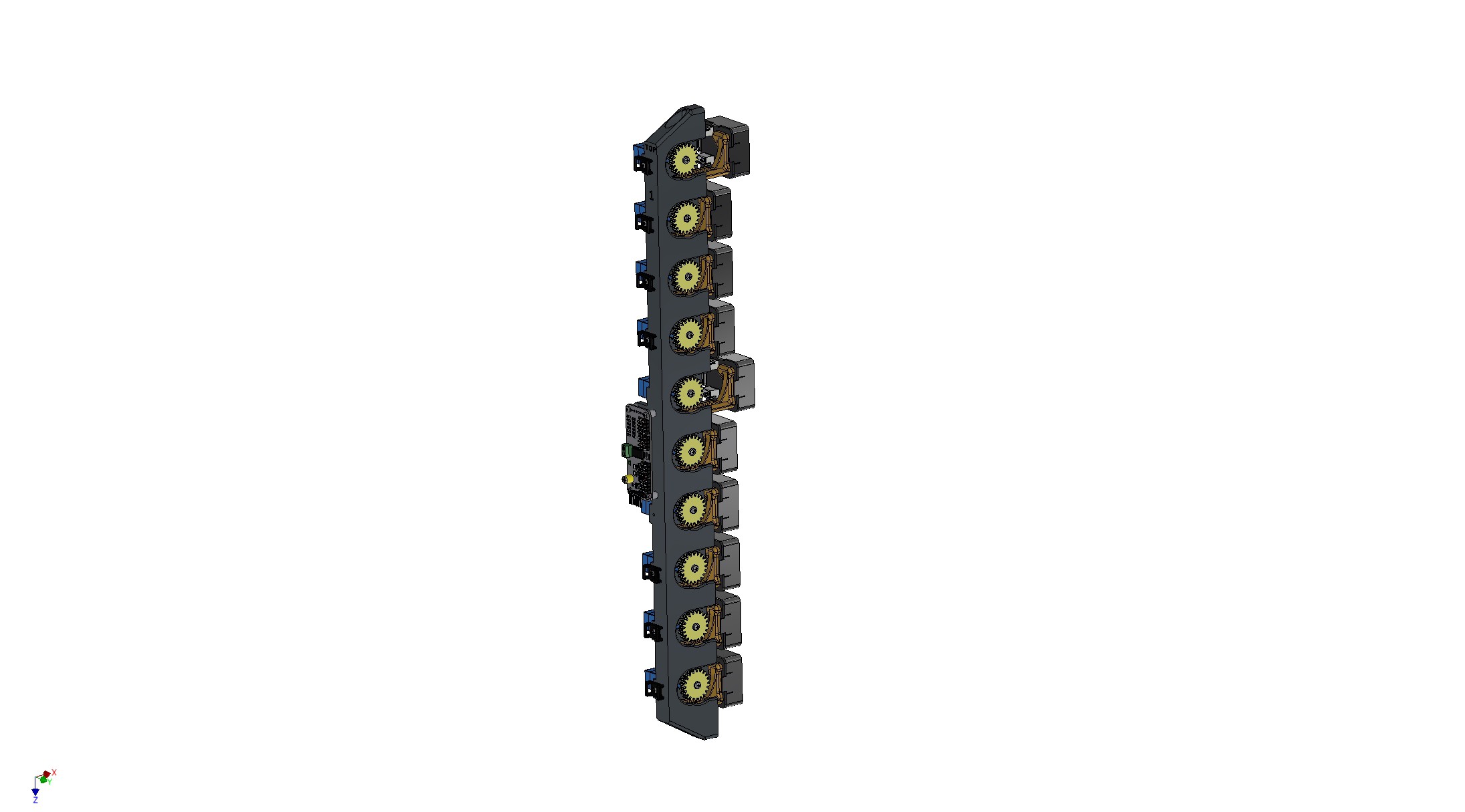

- reduction of 3D-printed components from ~800pcs to ~320pcs

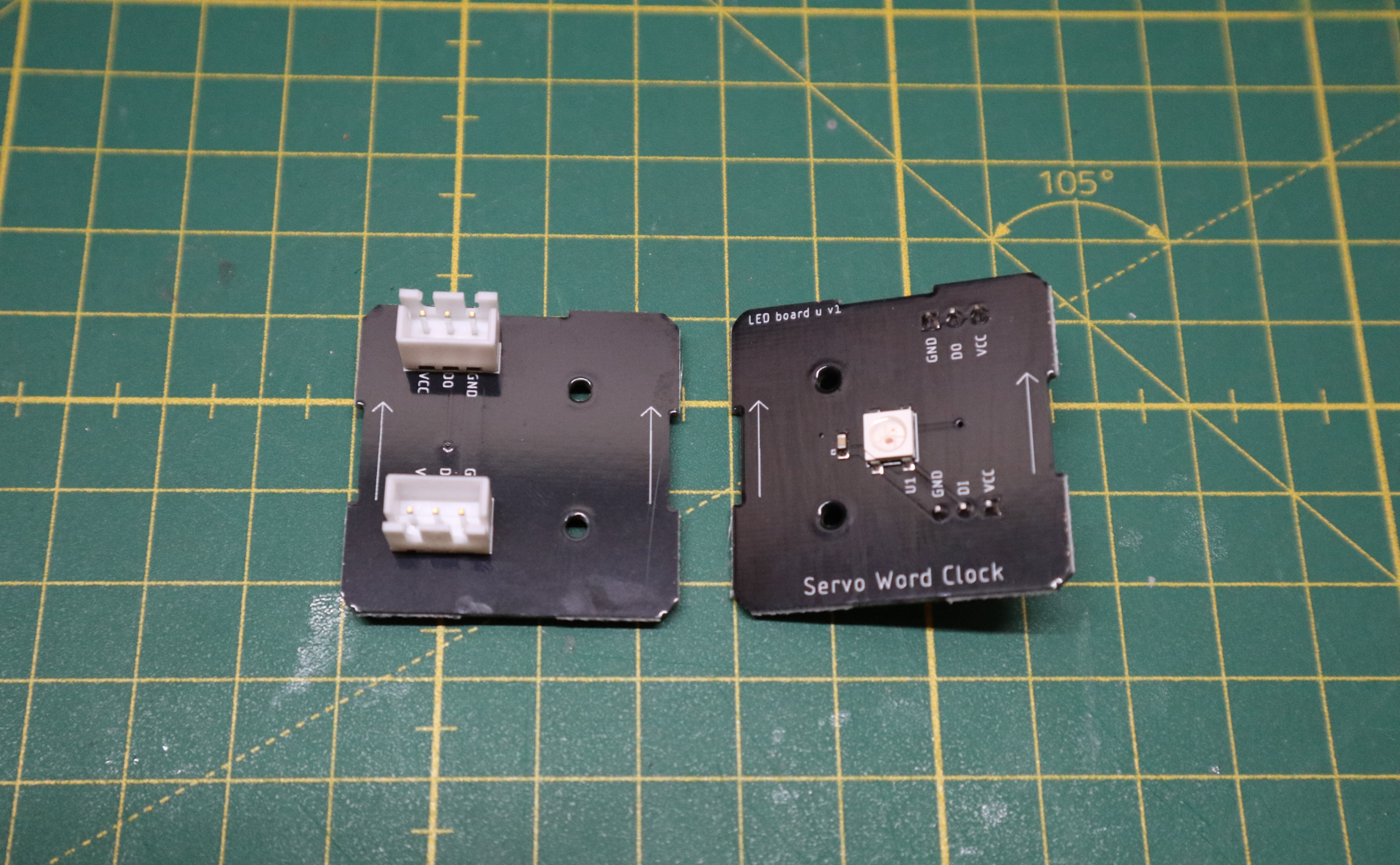

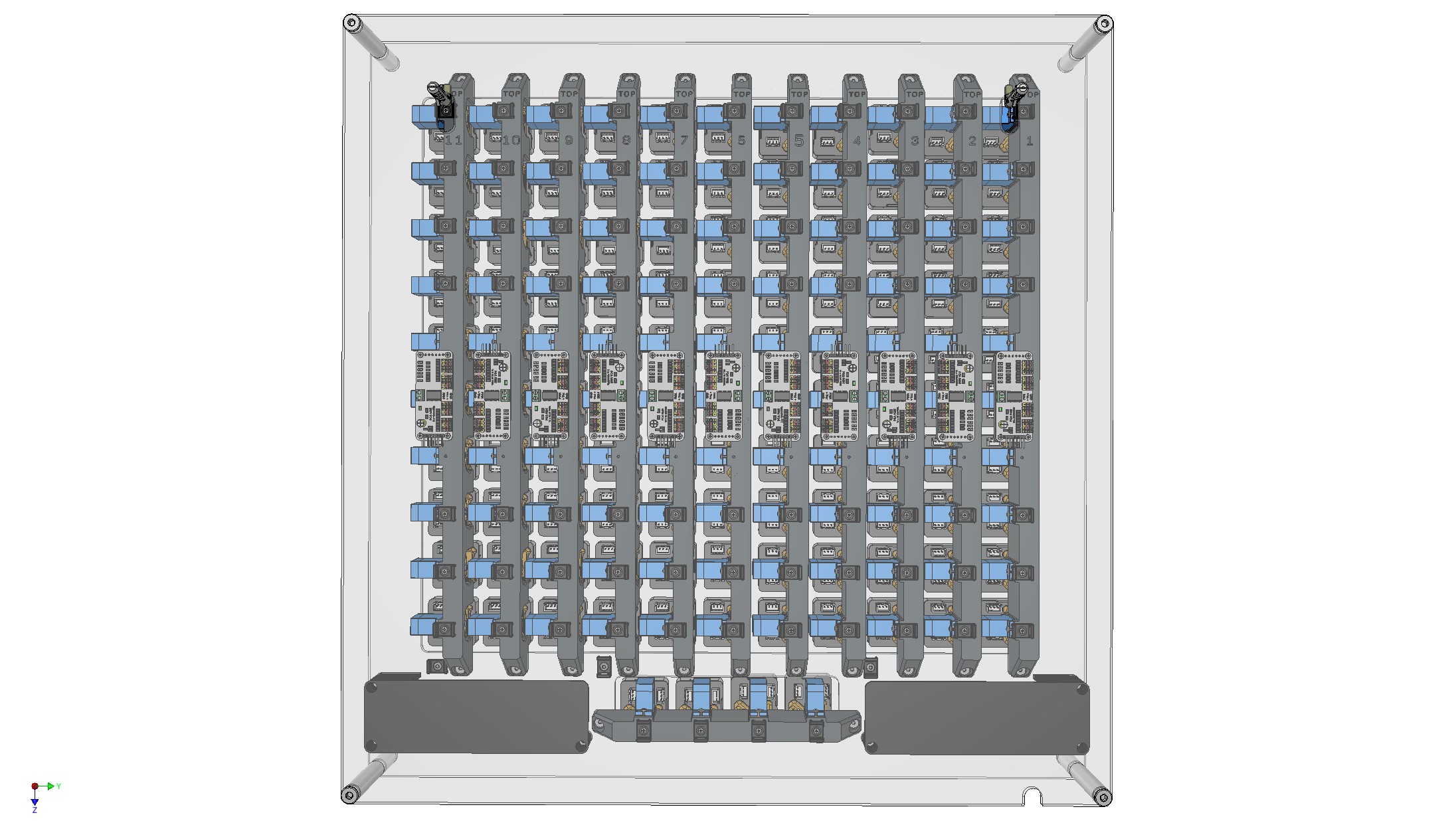

- custom PCBA for LEDs (no cutting and gluing of WS2812B strips)

- custom cables for LED connections with JST connectors (no preparation and soldering of wires)

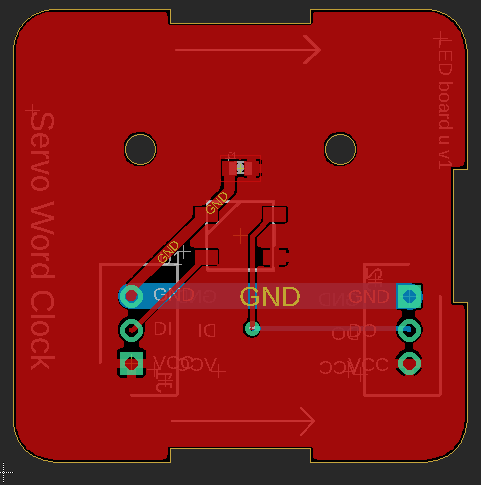

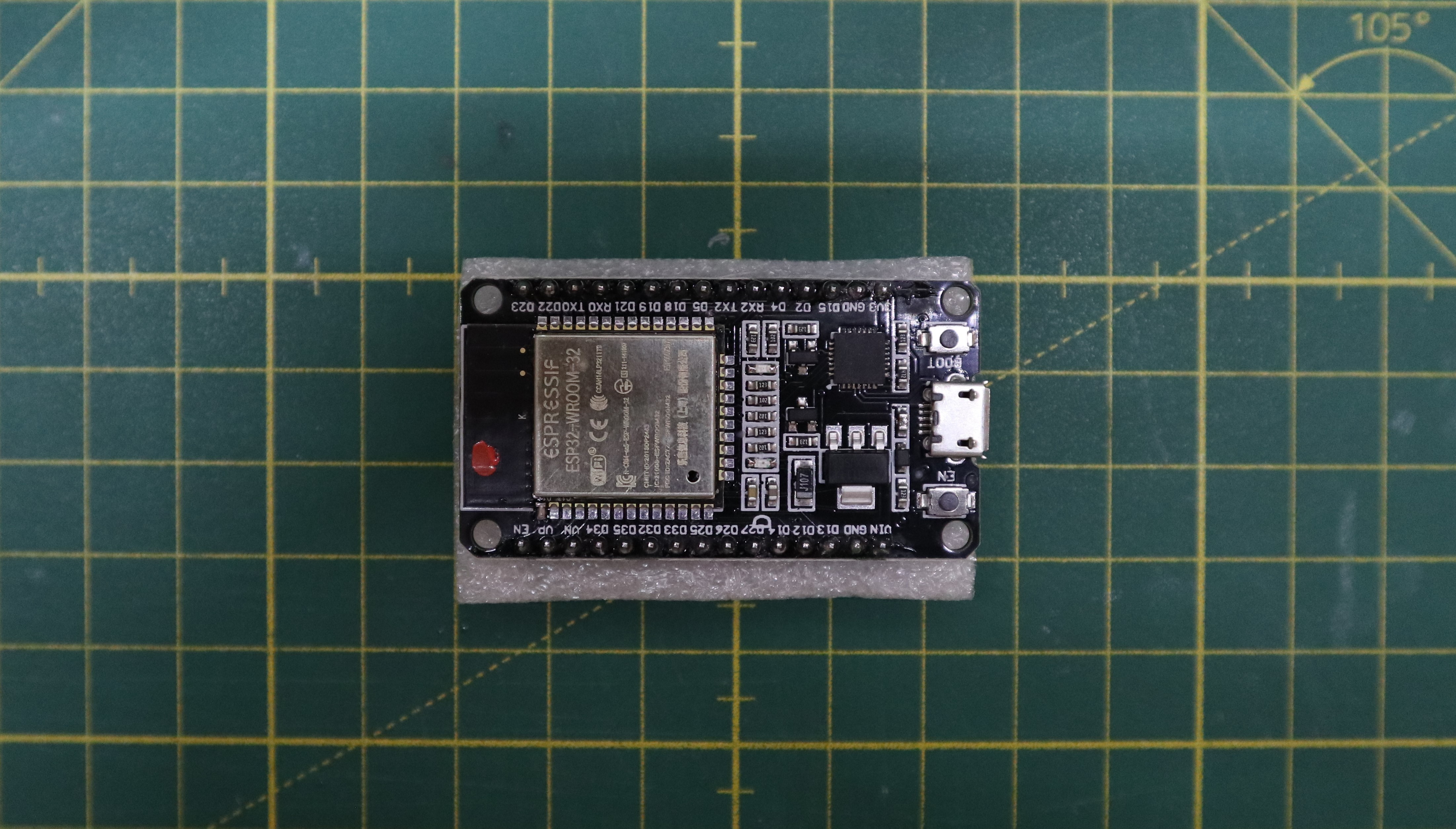

- custom PCB for main electronics

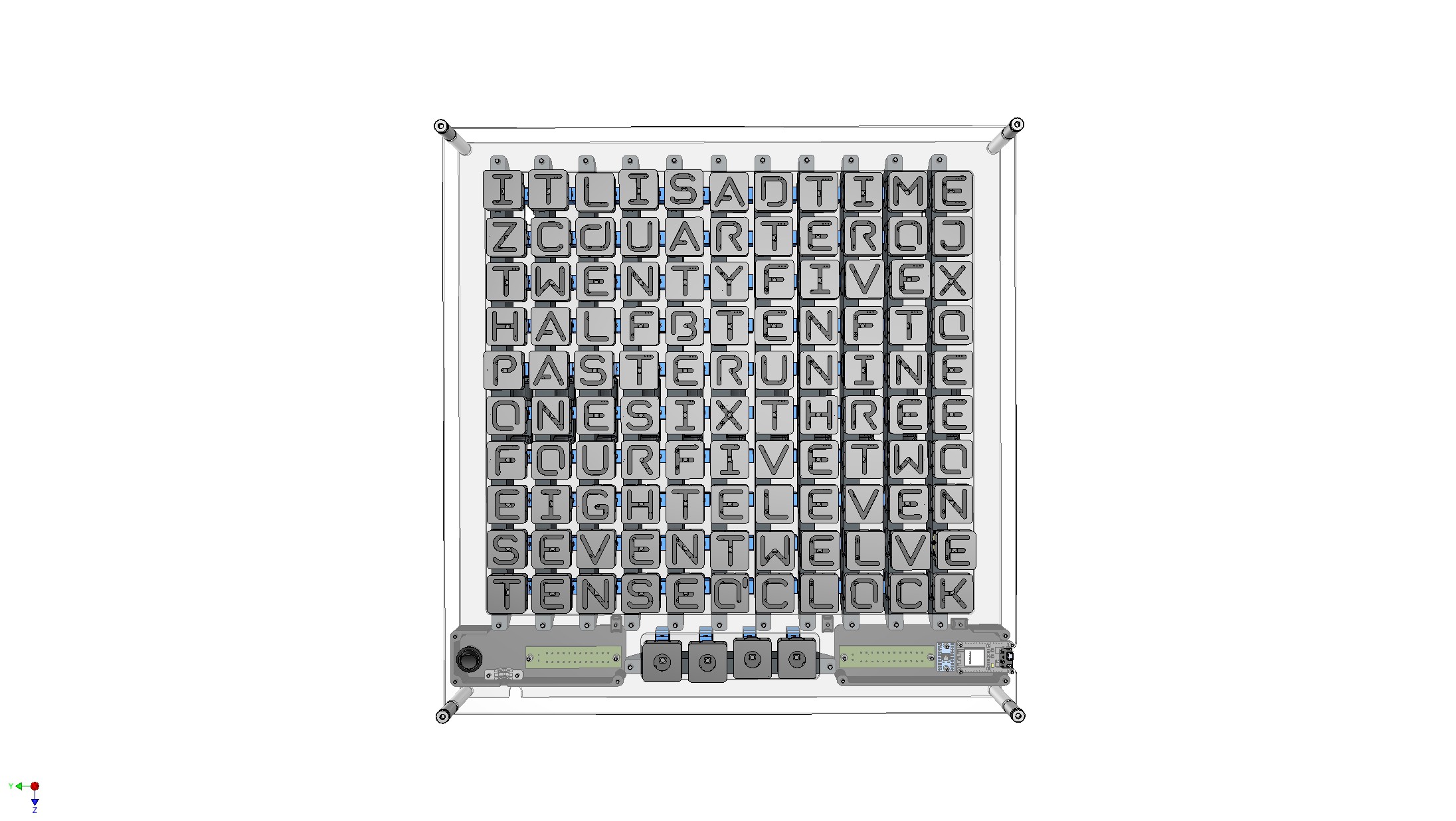

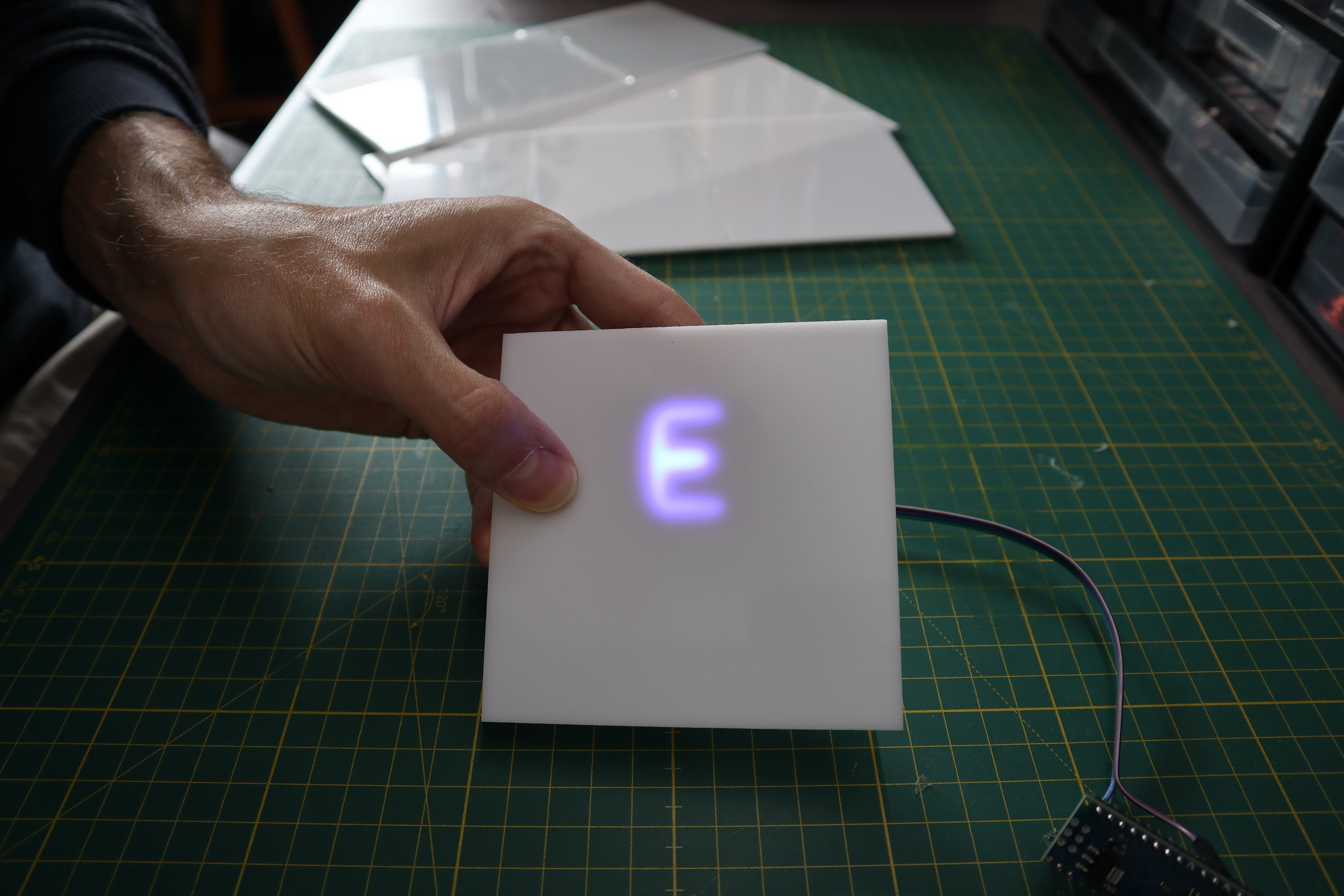

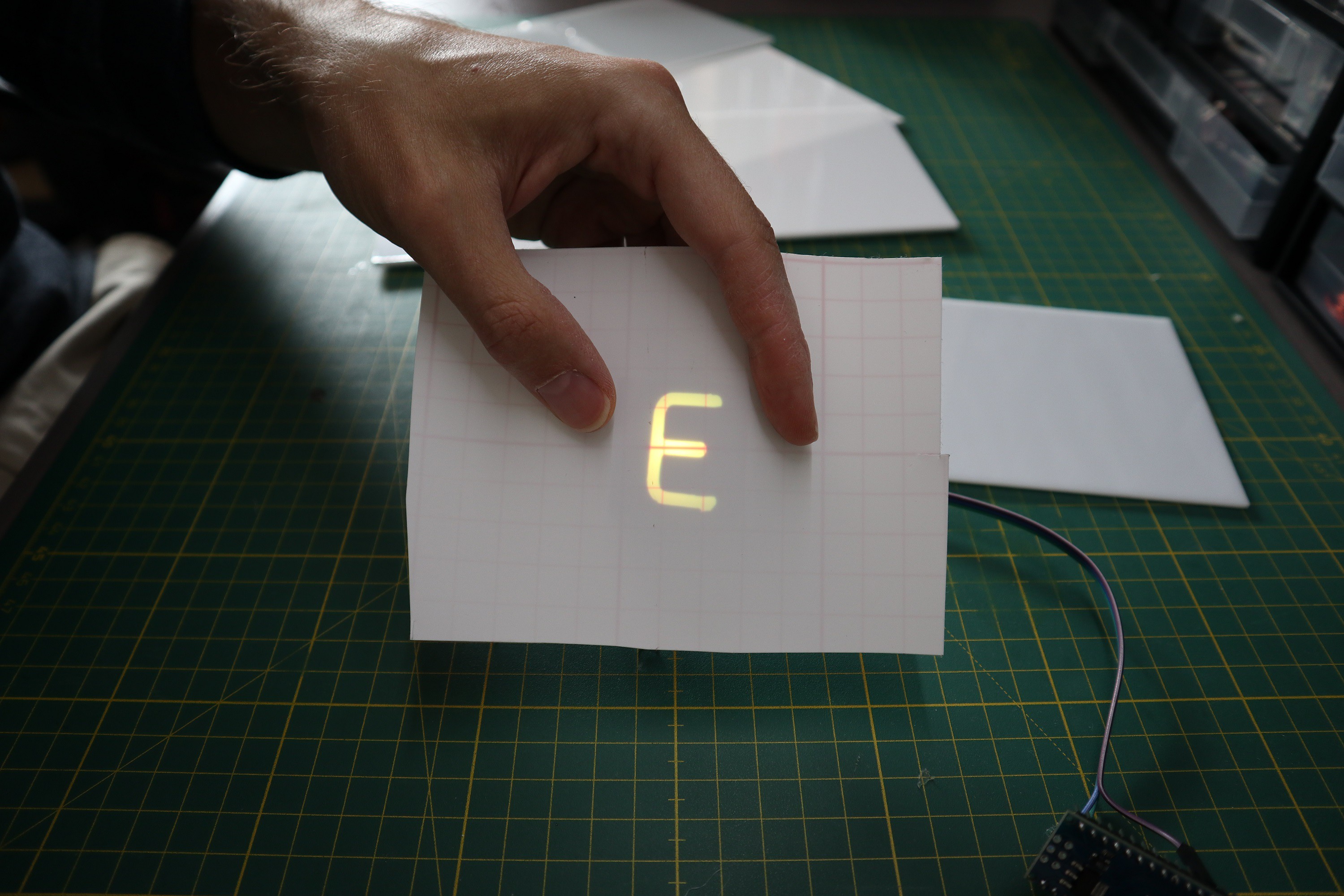

- improved alignment of letters

- greatly improved cable management

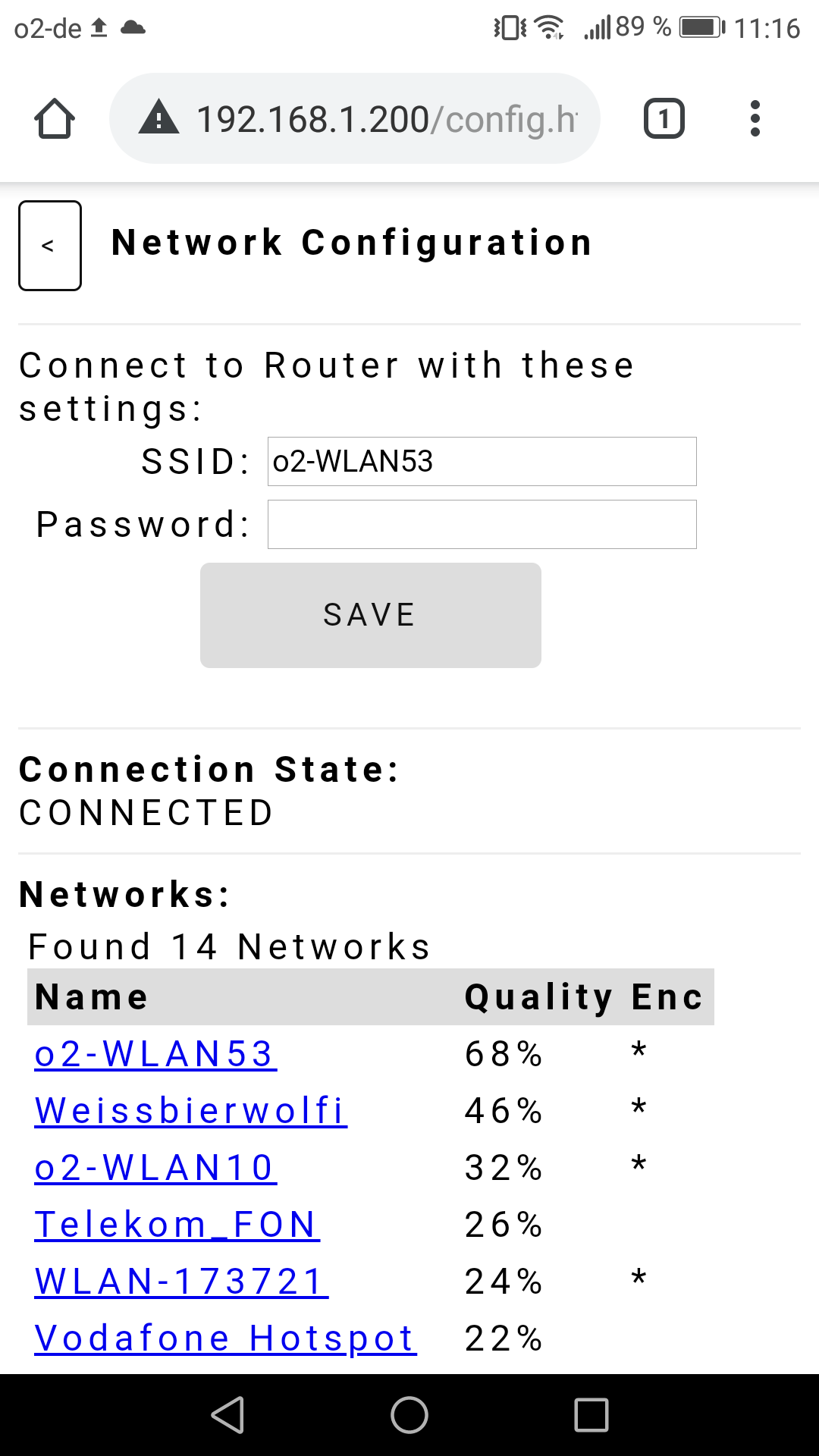

- WiFi connectivity

- time updated via NTP server

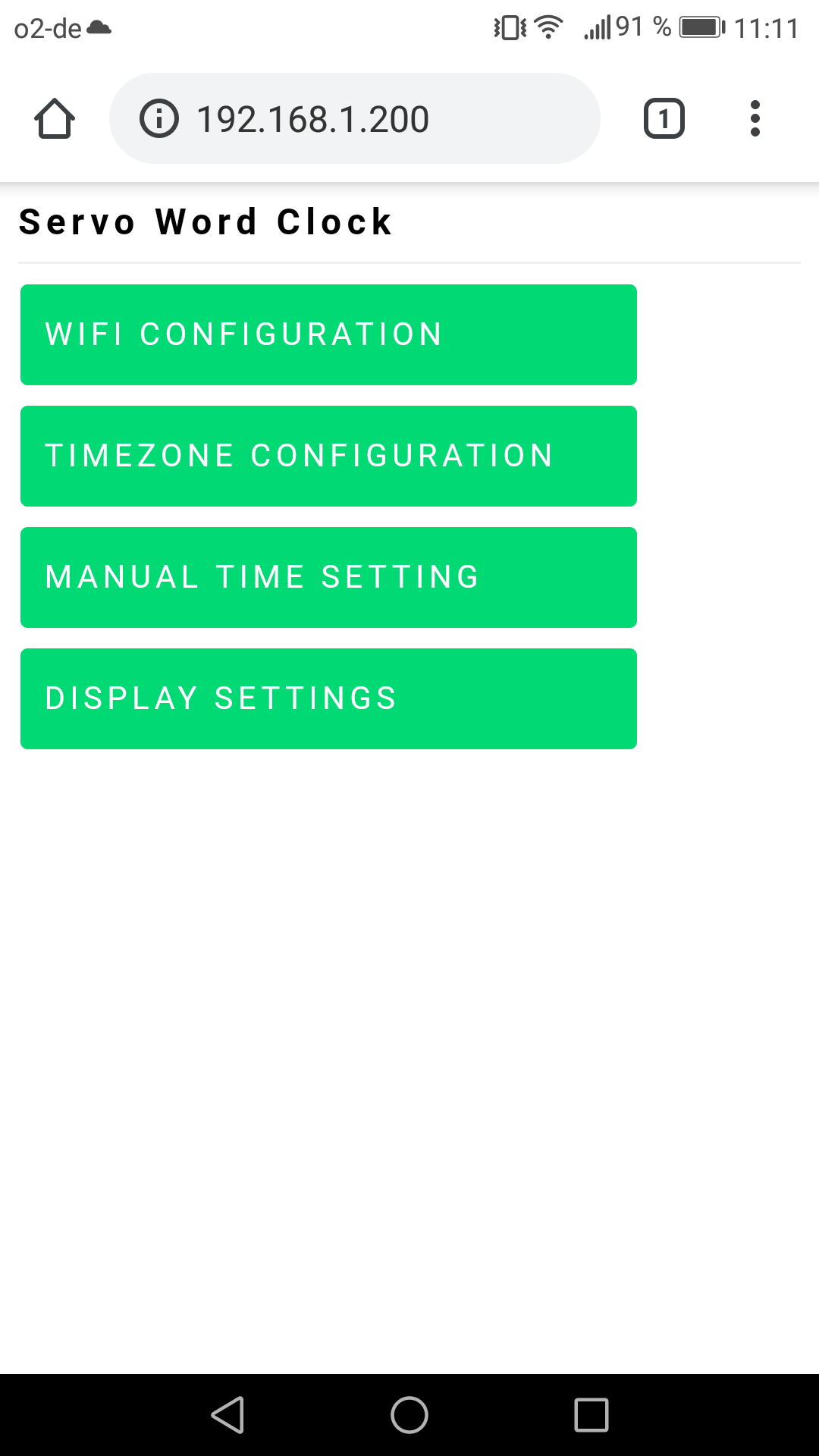

- control clock functions via web app (time setting, LED colors, brightness, transition effects, sleep mode, ...)

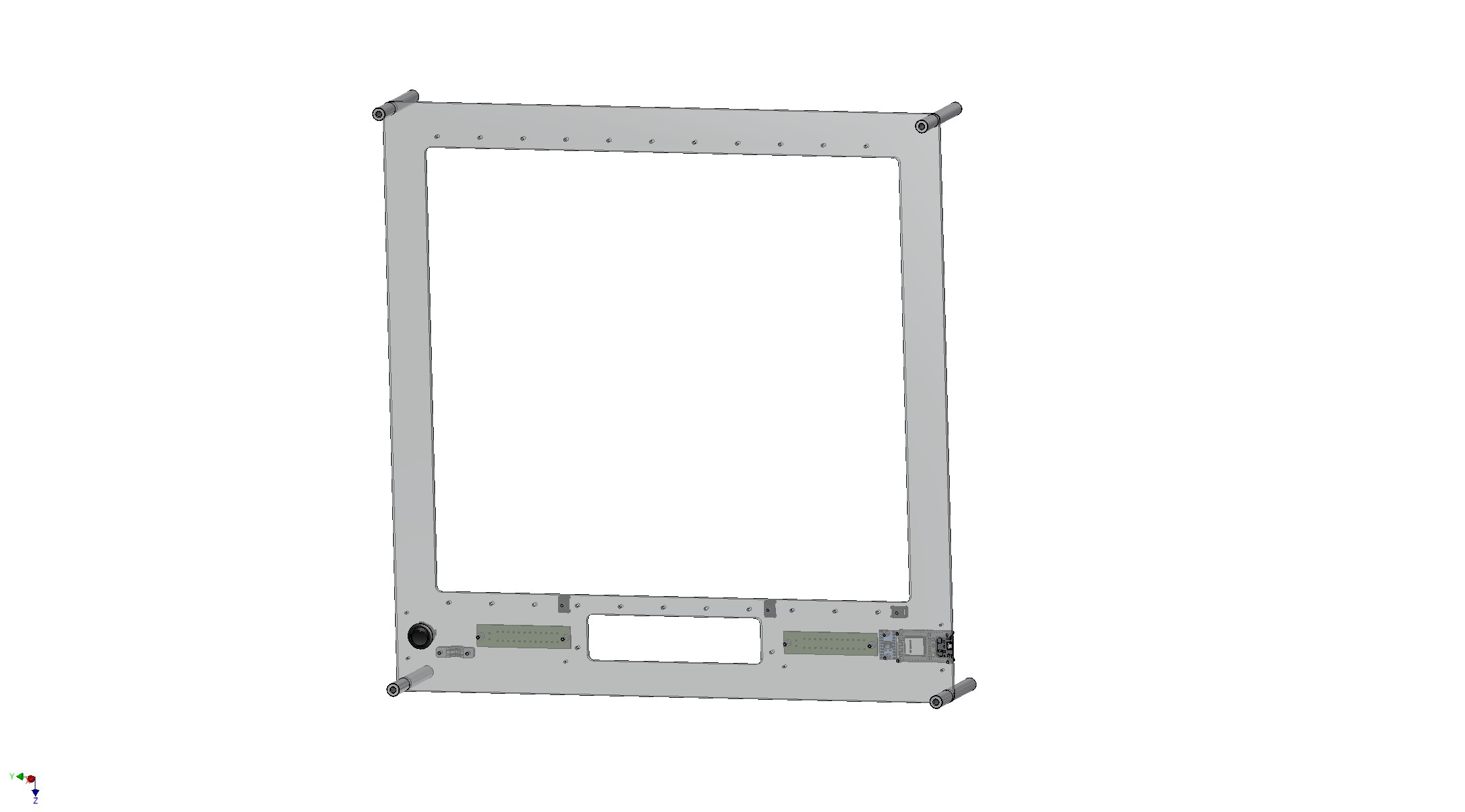

- minimalistic design based on laser cut acrylic

- quieter servos due to reduction of travel speed

Moritz v. Sivers

Moritz v. Sivers

Keith Elliott

Keith Elliott

Lex Kravitz

Lex Kravitz

Andrew Cooney

Andrew Cooney

Gorloth

Gorloth

That is some seriously awesome design! I loved the v1, but this is on another level. Congratulations :)