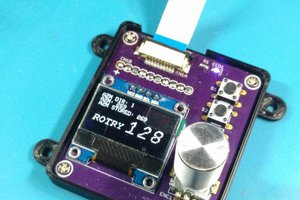

IOTON MICRIO MPU Quick Start and Hello World

This video is about very basic IOTON MICRIO functionality. How to connect devices, program system via EDITOR, control it via USER DASHBOARD and via E-mail messages.

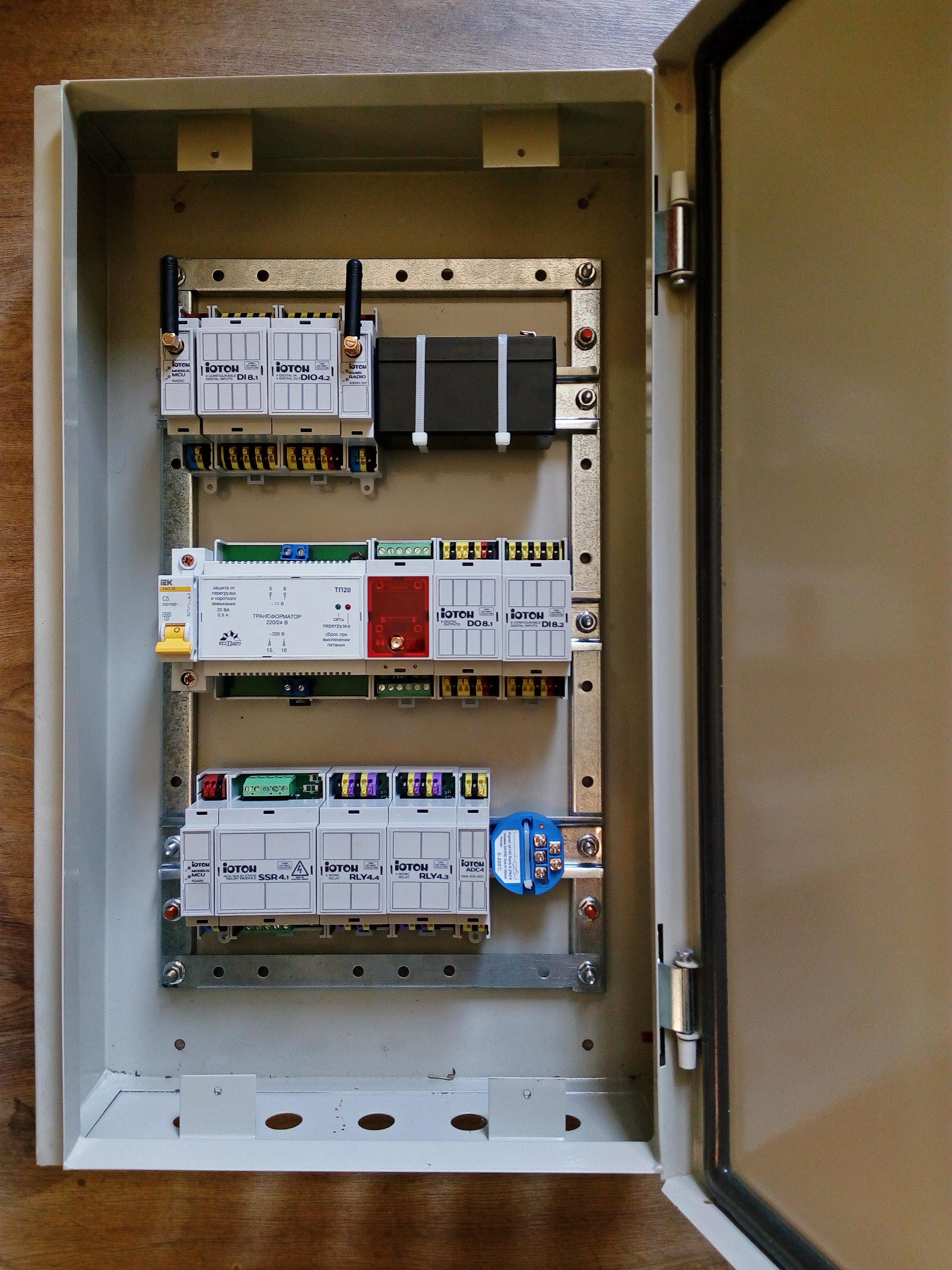

IRL

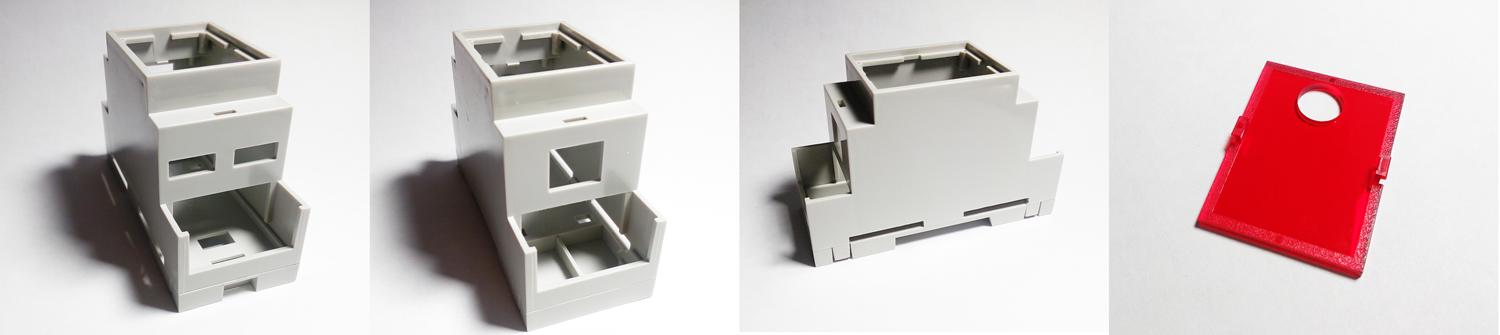

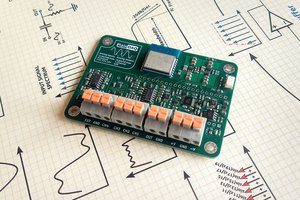

Some modules (not all).

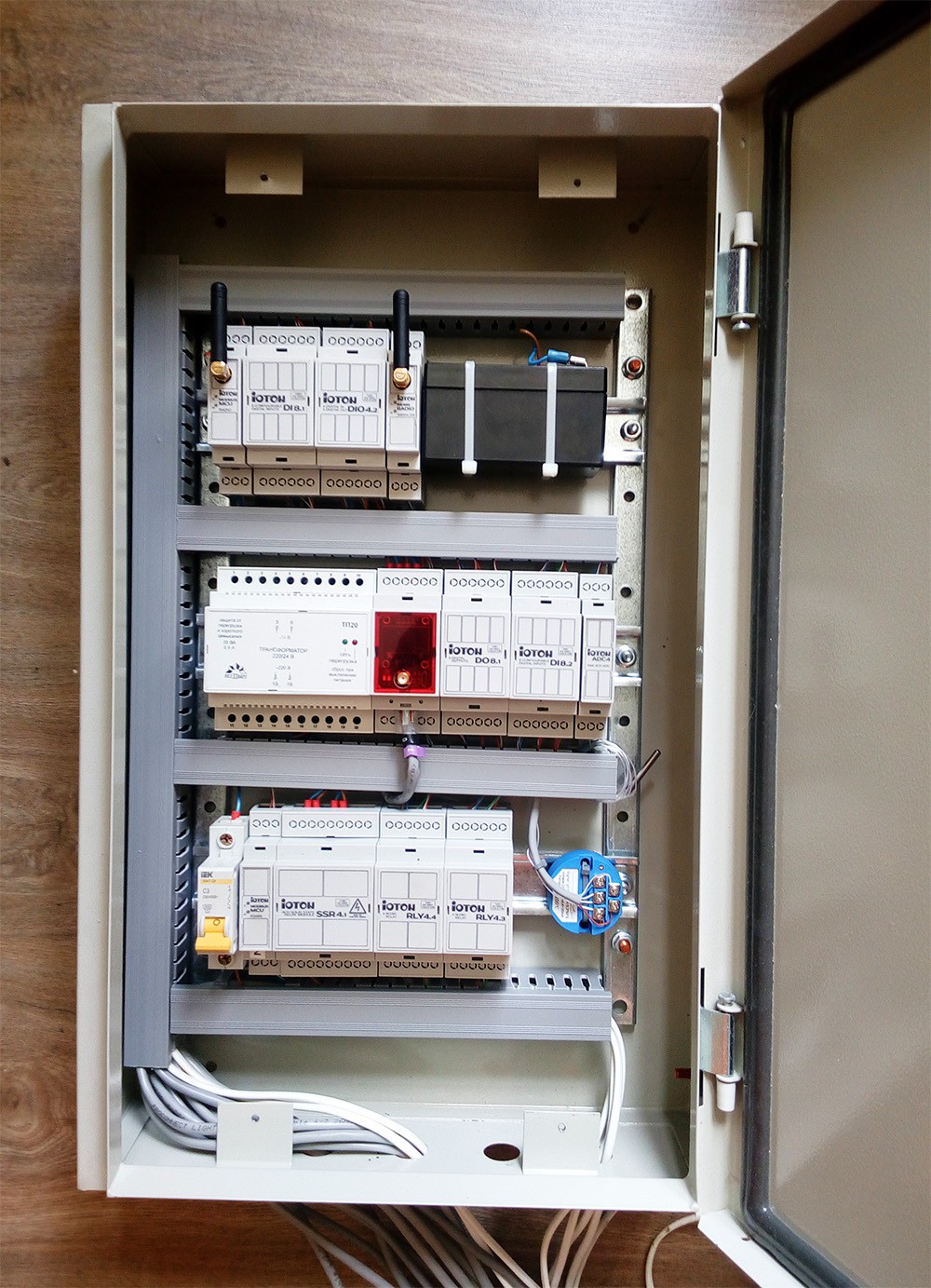

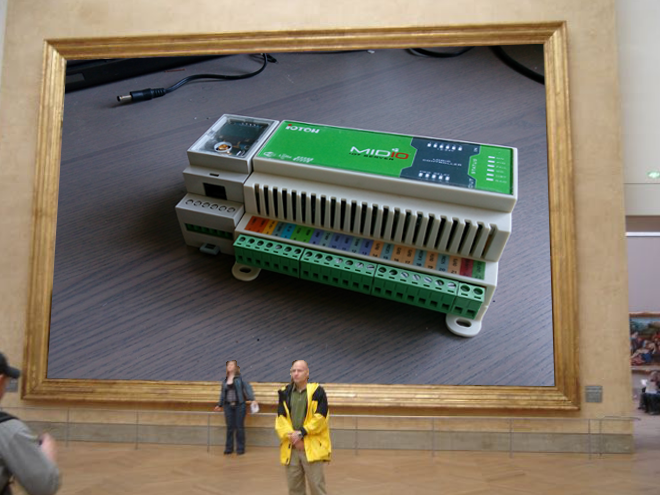

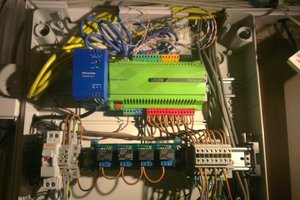

Before I start the project description let me introduce the first industrial project on IOTON MICRIO equipment.

My old school friend is the CEO of company produced bioreactors. For one of his projects he asked me to make a system to control 3 big fans (on/off by schedule) and one pump motor. RPM for this pump motor must depend on atmospheric pressure and temperature, and calculated with the interesting formula (I can't post it here because of NDA). I solved this problem in one day. IOTON MICRIO MPU takes atmospheric pressure and temperature data from the INTERNET and control motor by MODBUS protocol (RS485 PHY). On this moment system works around 3 months w/o any problems. The schematic is simple:

HOW I DID IT ALL

Please, excuse me for any errors in the text, English writing is not so simple for me.

Base principles:

At first, I identified five base principles for the whole system:

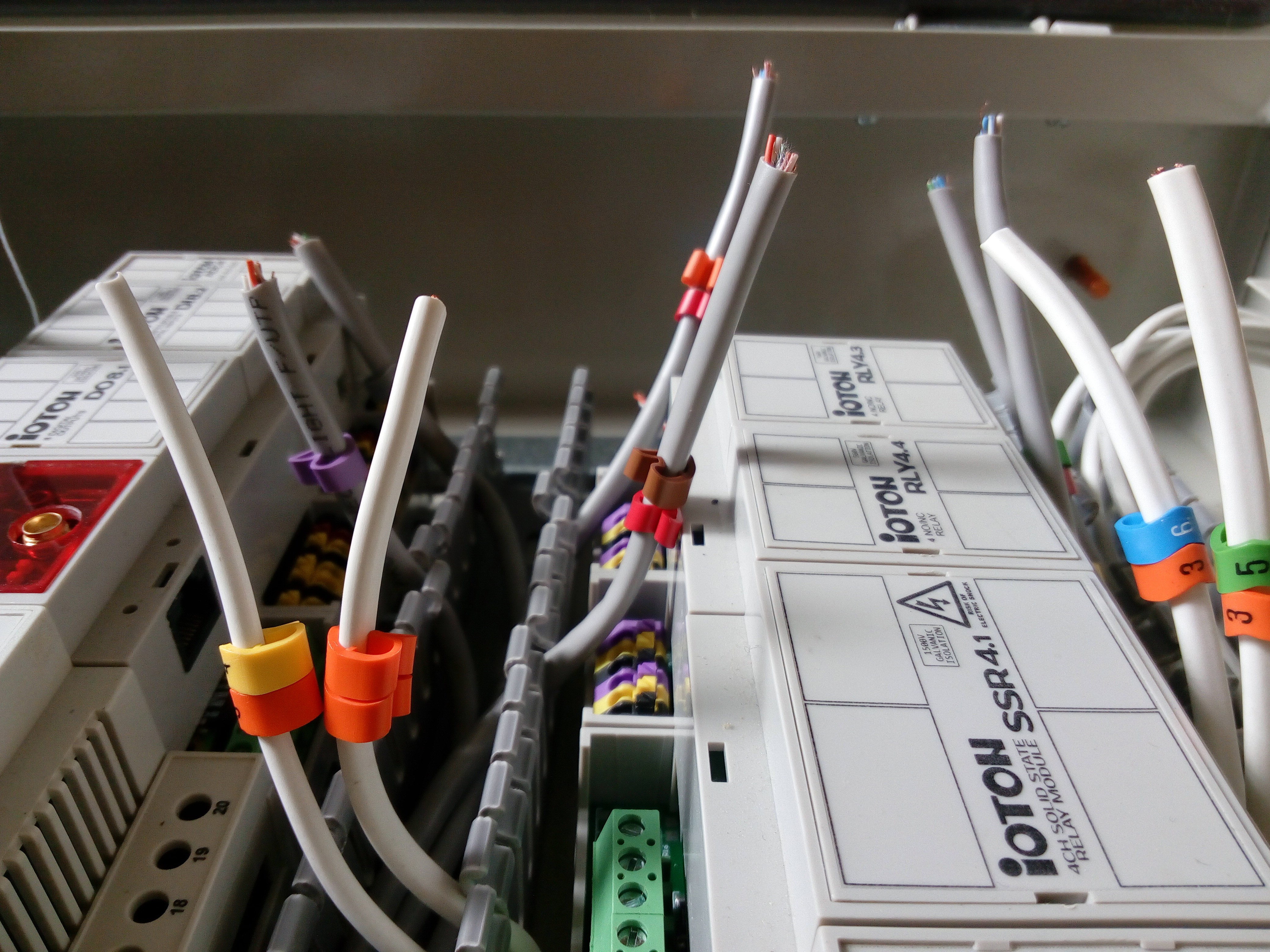

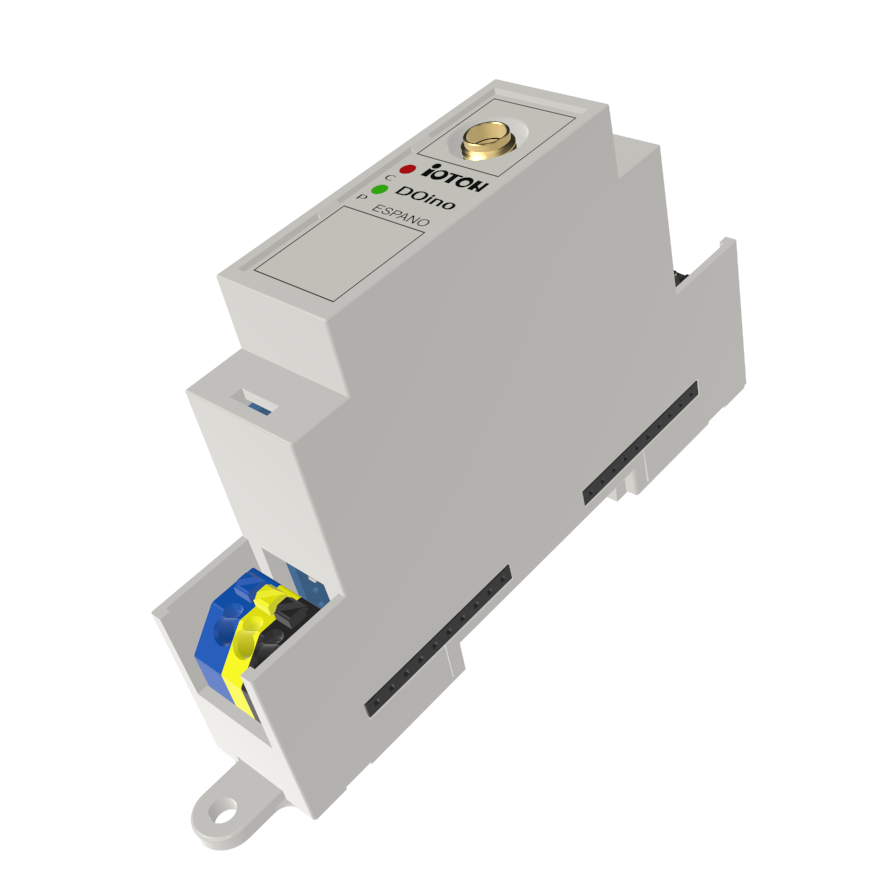

1. Any input or output must be galvanically, optically or mechanically isolated from the Microprocessor Unit (MPU)

2. Keep the size as small as possible.

3. Keep it simple, stupid.

4. Reliability is more important than functionality.

5. All modules must be cross interchangeable.

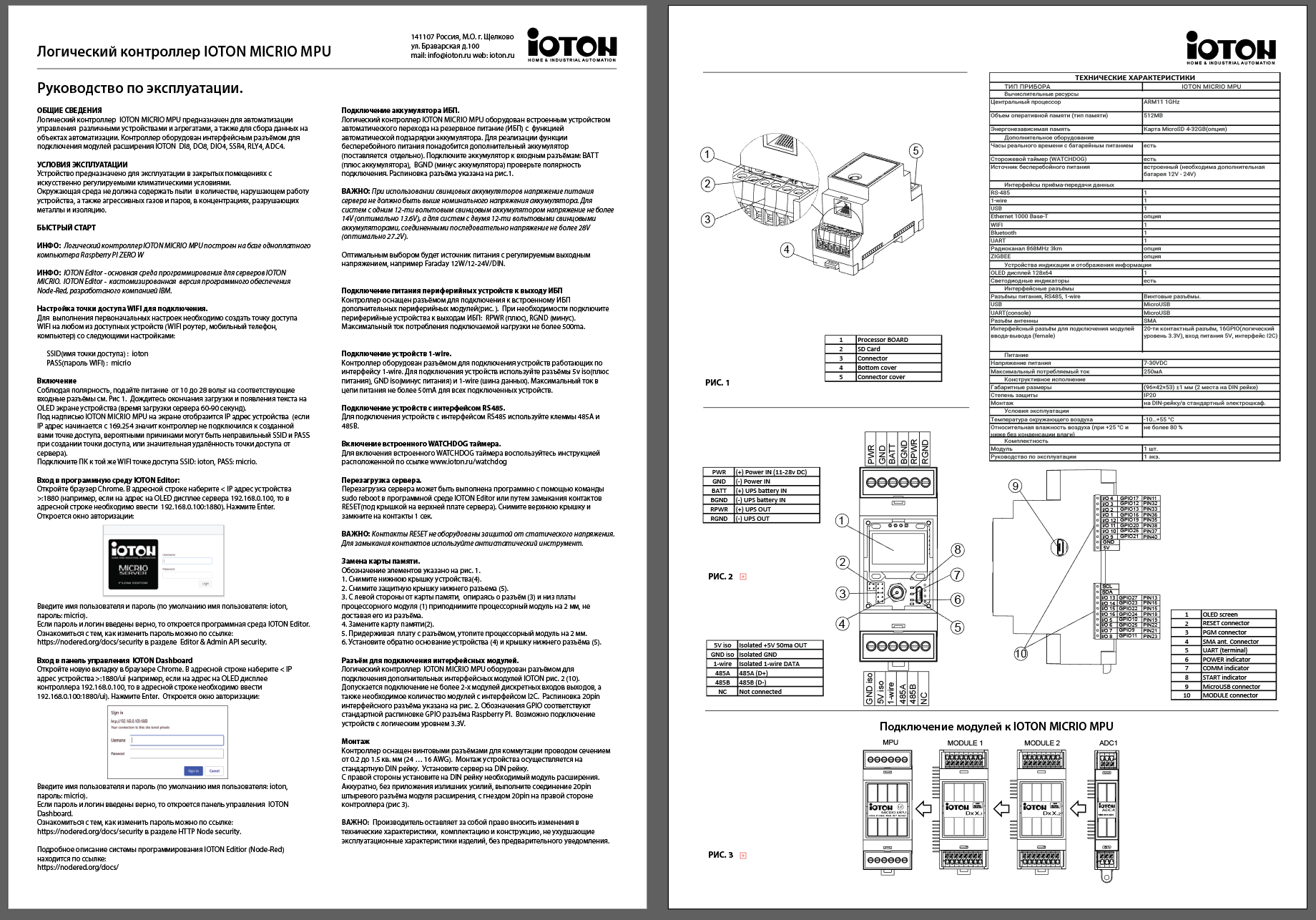

Programming environment:

Luckily I found Node-Red from IBM guys. It's a really great and simple programming environment for the IOT devices. It works flawlessly on Raspbian and has great support from developers on their forum.

Schematics:

It was not so challenging for me. I have enough experience in it. Also, I have experience with repair different models of PLCs so I know base principles for safety, reliability, and functionality.

A little challenge was to find the solution for RS485 and 1-wire galvanic isolation. I used an isolated DC-DC converter and Analog Devices transformer isolators.

Andrey V

Andrey V

CriptasticHacker

CriptasticHacker

Ian Norton

Ian Norton

Alperen

Alperen

kelu124

kelu124

Excellent project. A lot of work done. The idea of using NODE RED adds value to your project. We have a similar idea (M10CUBE) but it has a different concept. Being in Automation for more that 35 years I can appreciate your design and the work done. The DIN rail approach is very good indeed for using it in industrial enclosures.

I am trying the pdf files but all are in Russian? Is anything in English?

Our idea M10CUBE https://hackaday.io/project/171770-m10cube tries to cover both worlds in an practical package. Please join us to exchange ideas.