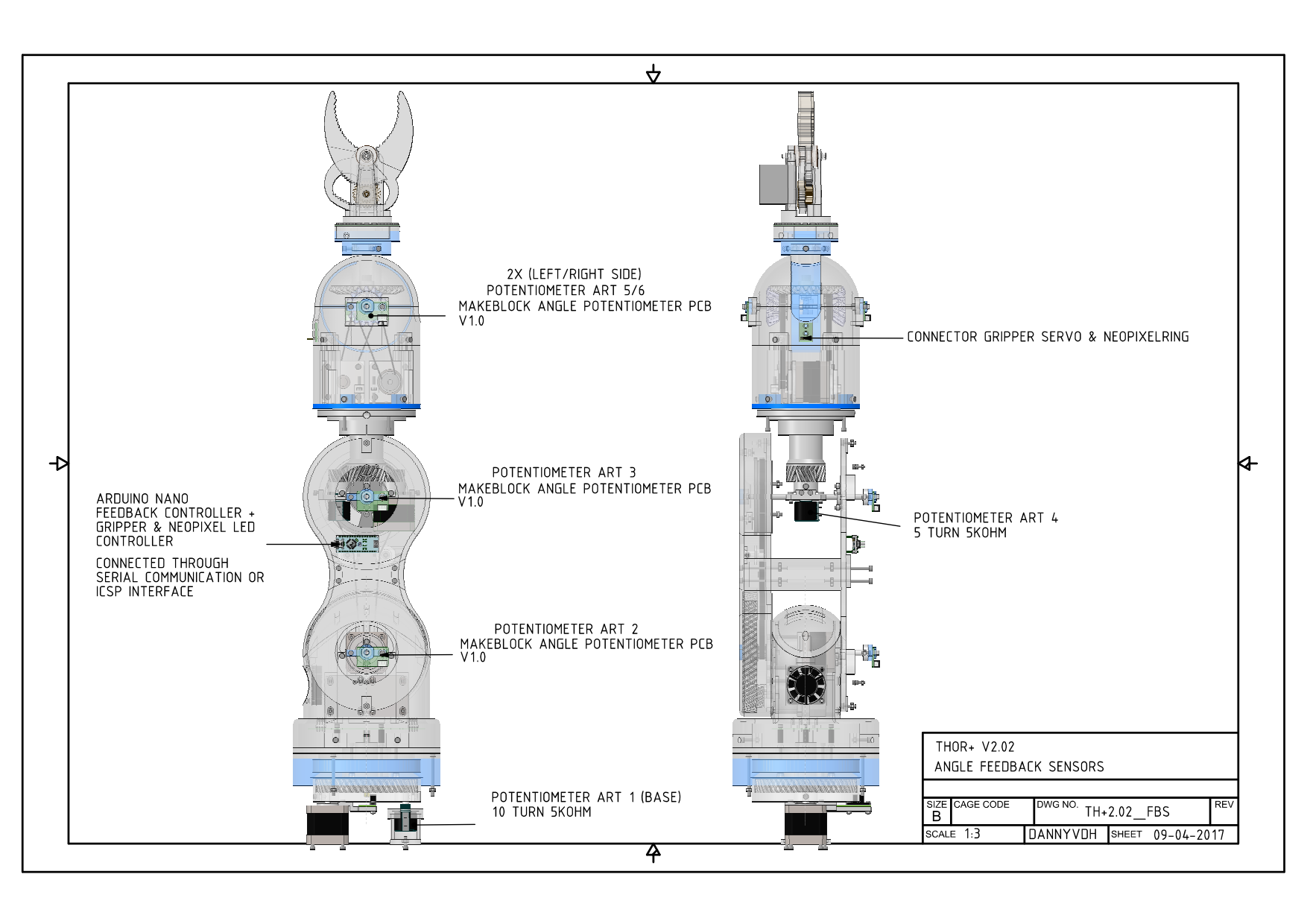

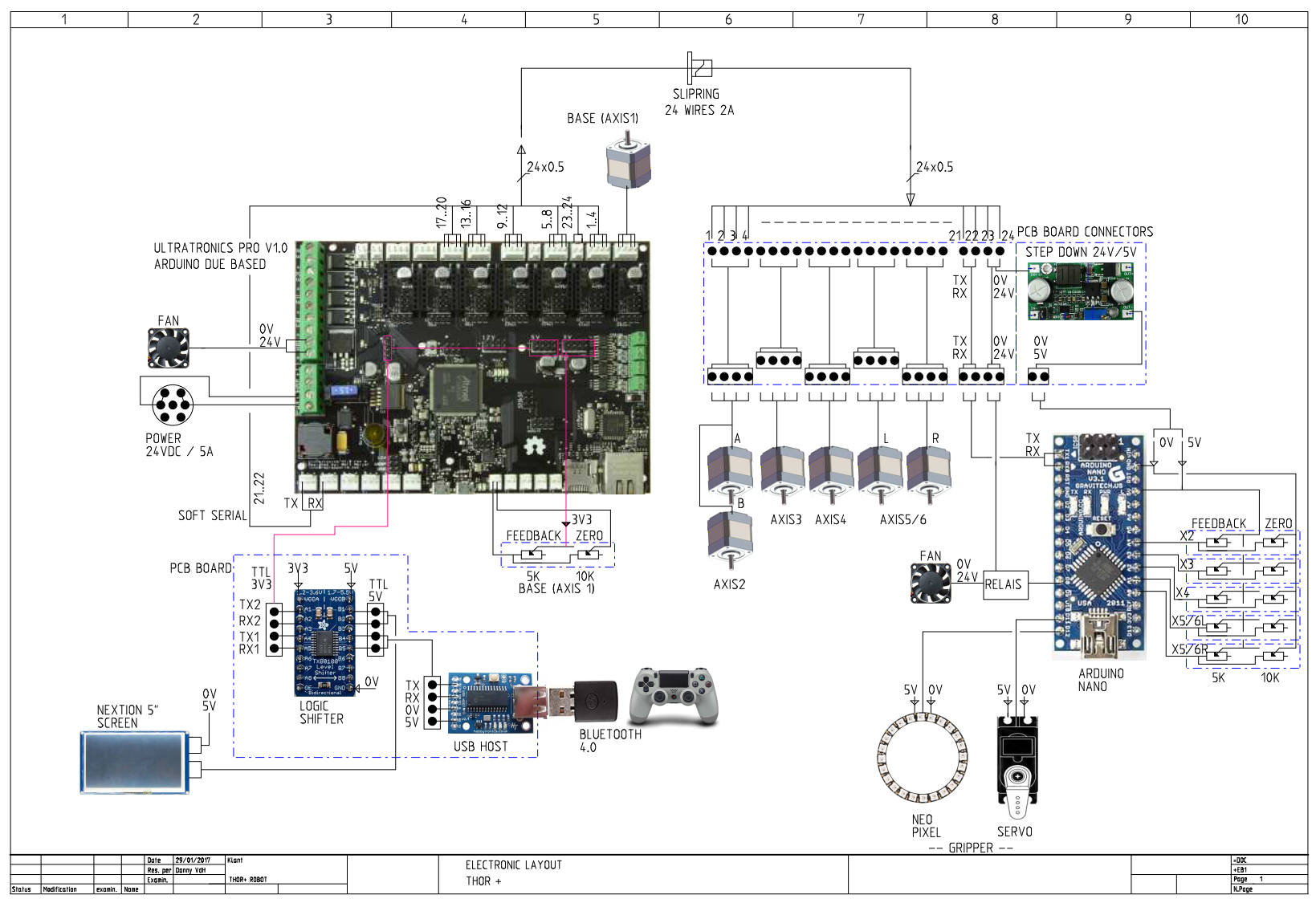

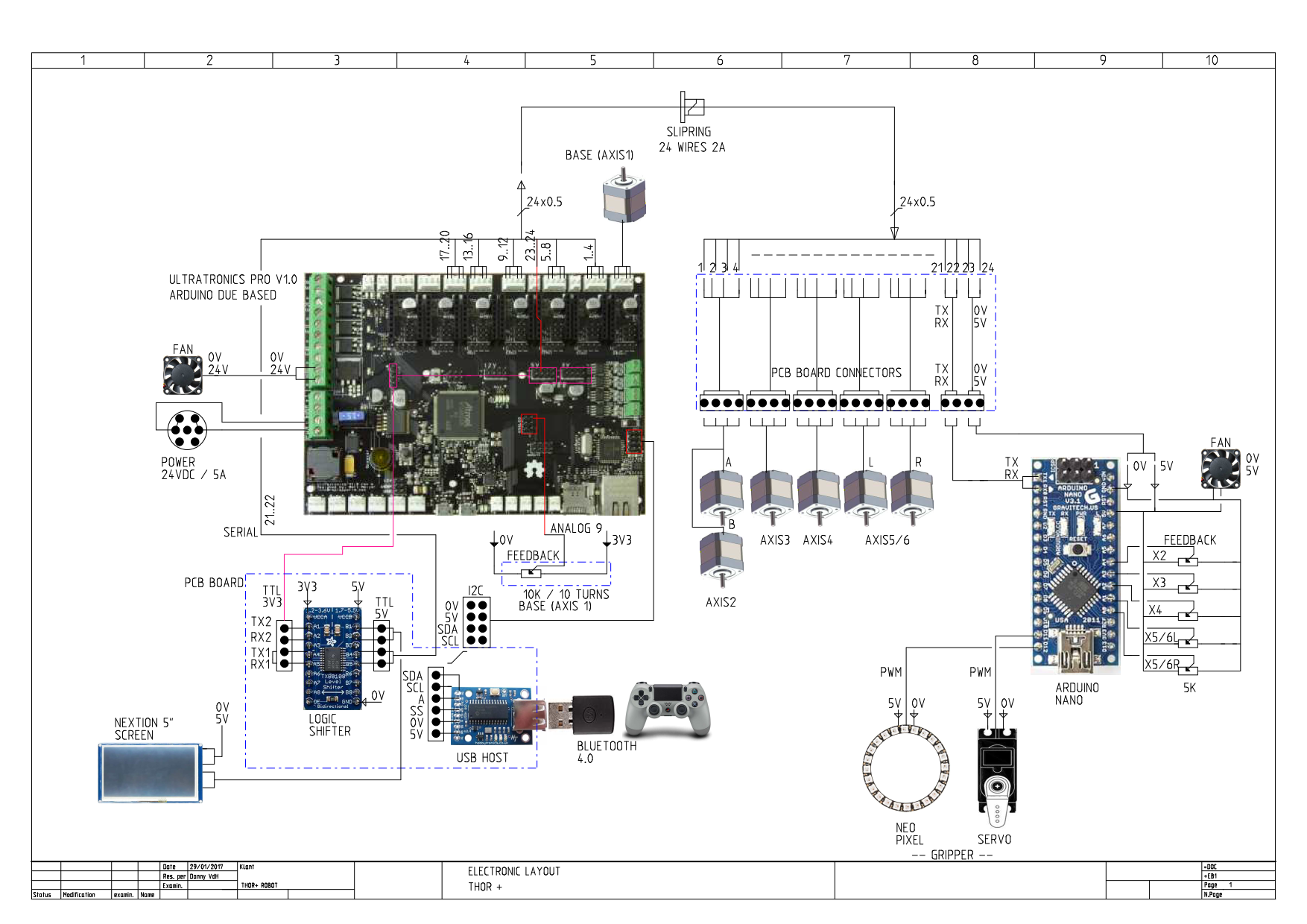

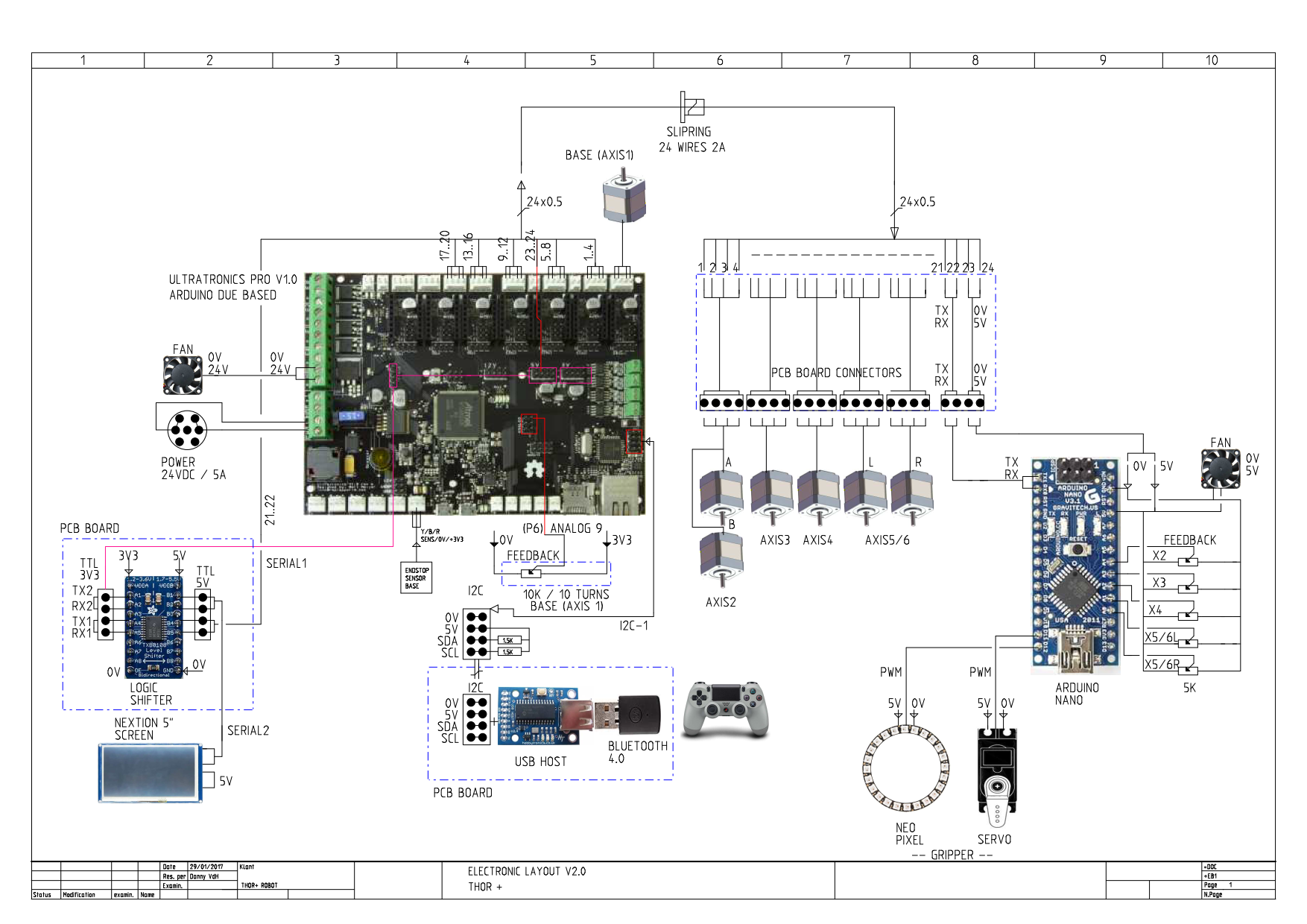

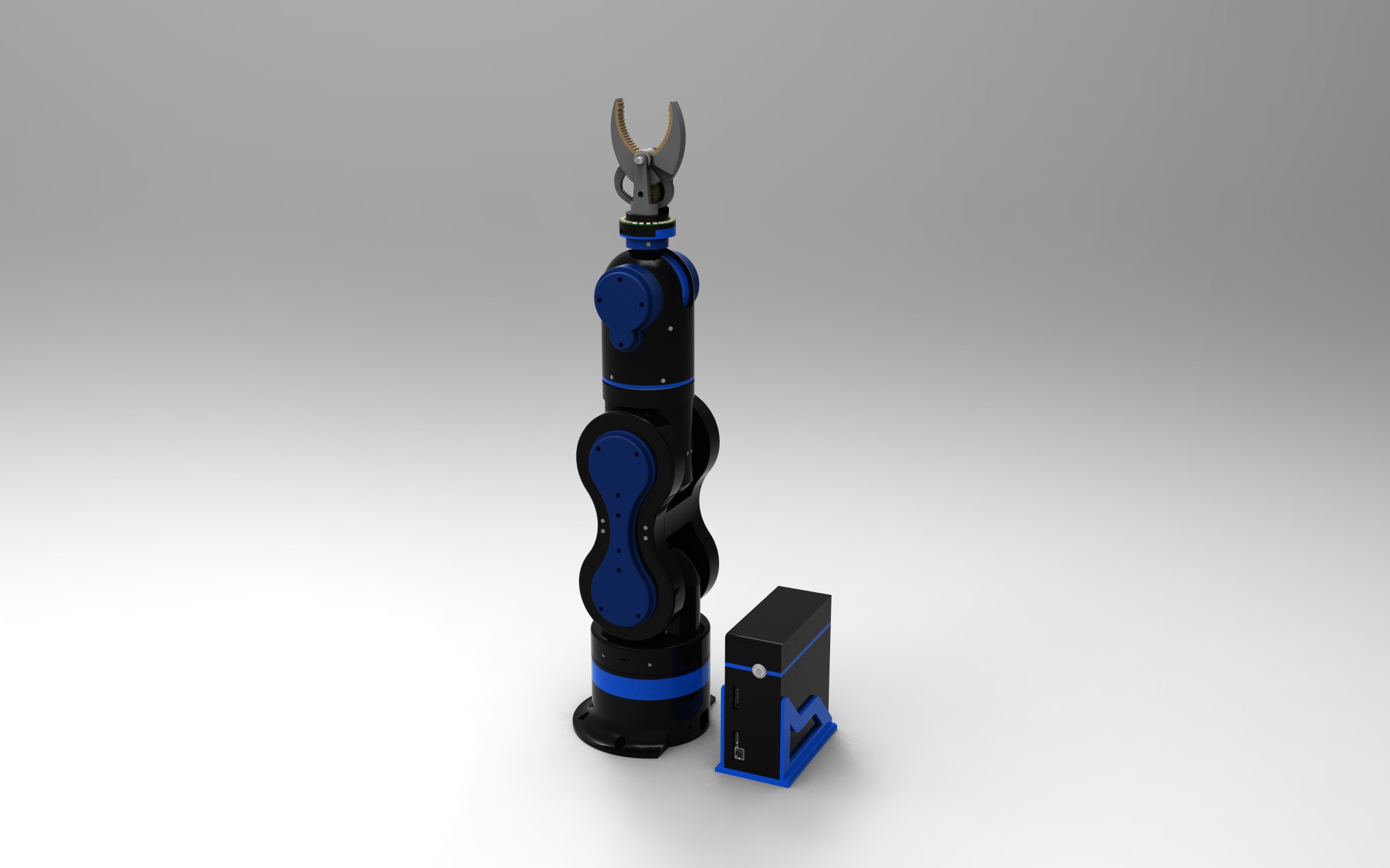

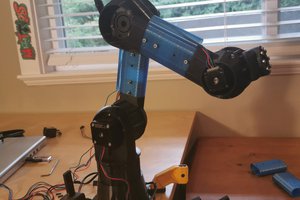

This project is based on the THOR robotic arm project from AngelLM and will be a version with lots of add-ons and especially modified for a wide range of 3D printers with a smaller print area.

Also it is my intention to improve a lot of things to the robot his hardware and software.

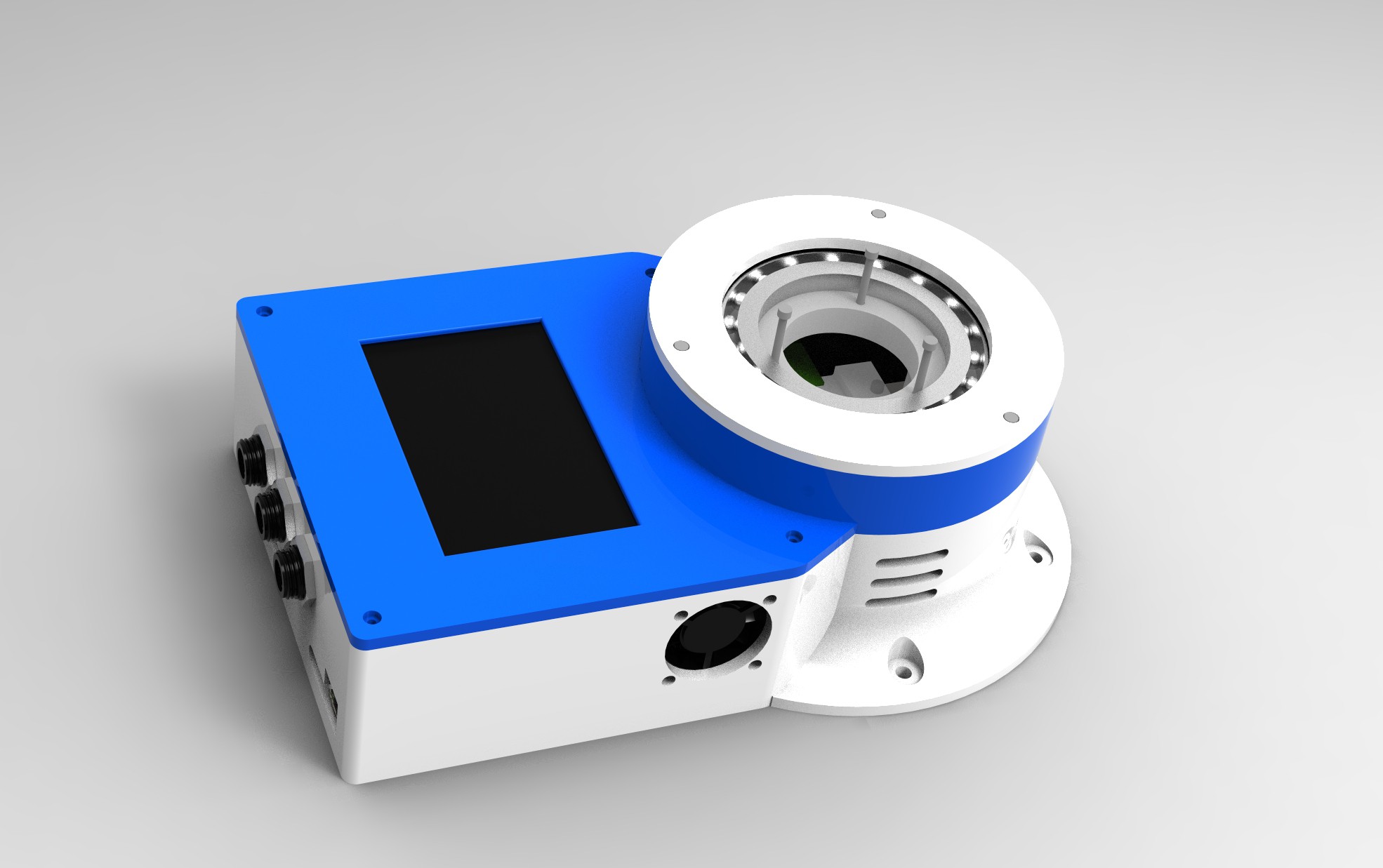

I am working on a graphical controller that works on PC,MAC and later on mobile devices.

You will have the possiblity to make al the movements on the controller without the need of the robot.

Ones everything is working on the GUI controller it can be transfered to the robot arduino controller

board, with the press of a button and some digital inputs you can run the sequences you programmed in the GUI controller.

There will be a hand controller to move the robot manually and store the points, afterwards you can send these points to the graphical controller. It will be bi-directional programming.

In a further stage the axis will be recorded into the controler so movements can be simulated be moving the robot by hand and can be replayed afterwards.

It's a lot but this will be my challange in the next comming days...months :-)

Any feedback is welcome!

I will send my regards to AngelLM for the original nice designed robot called 'THOR' , without him I could not started this SUPER project!

Everything stays open source, like everything should be...One for All, All for One

All software programs to build the robot are free to download

dannyvandenheuvel

dannyvandenheuvel

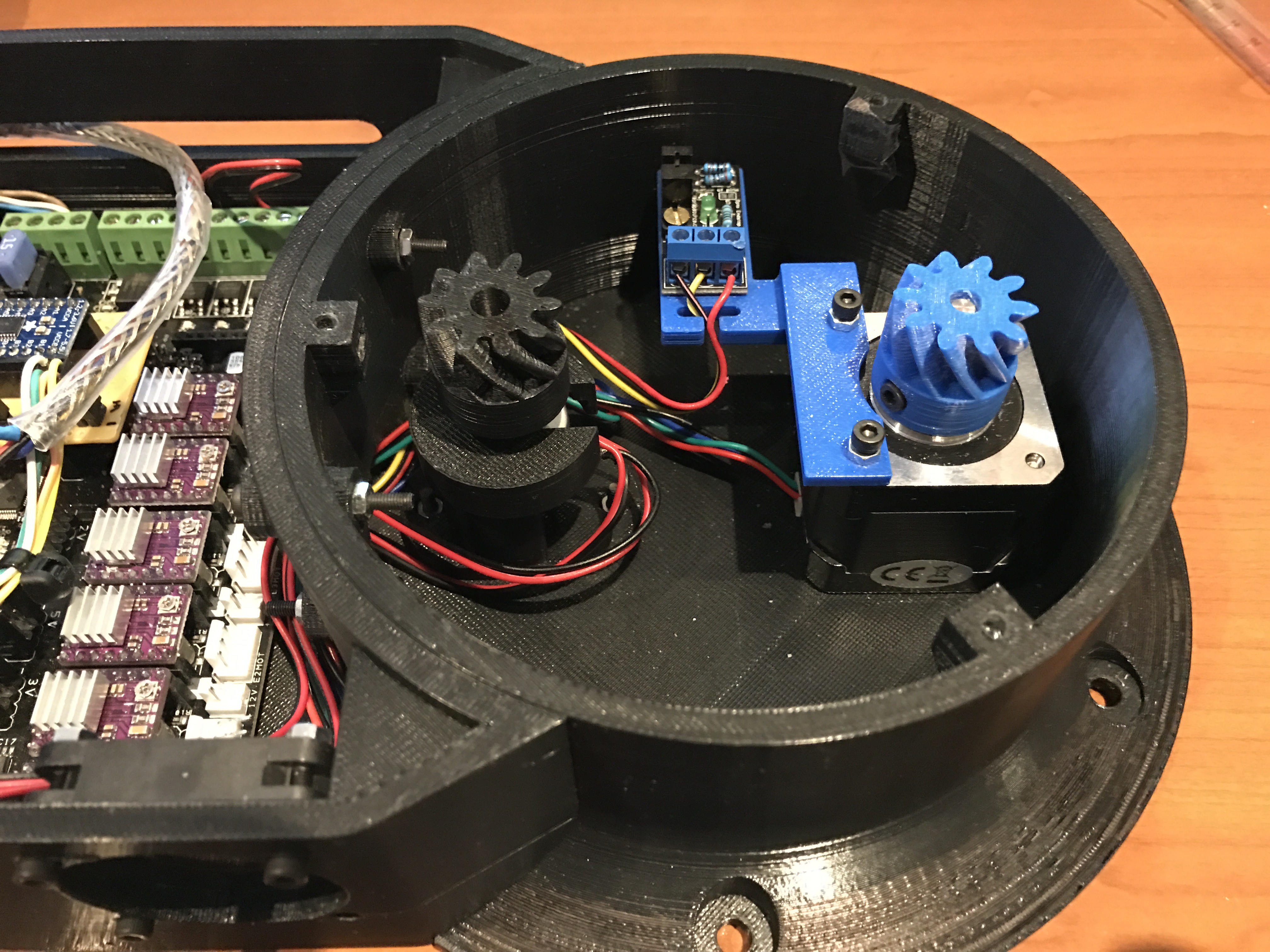

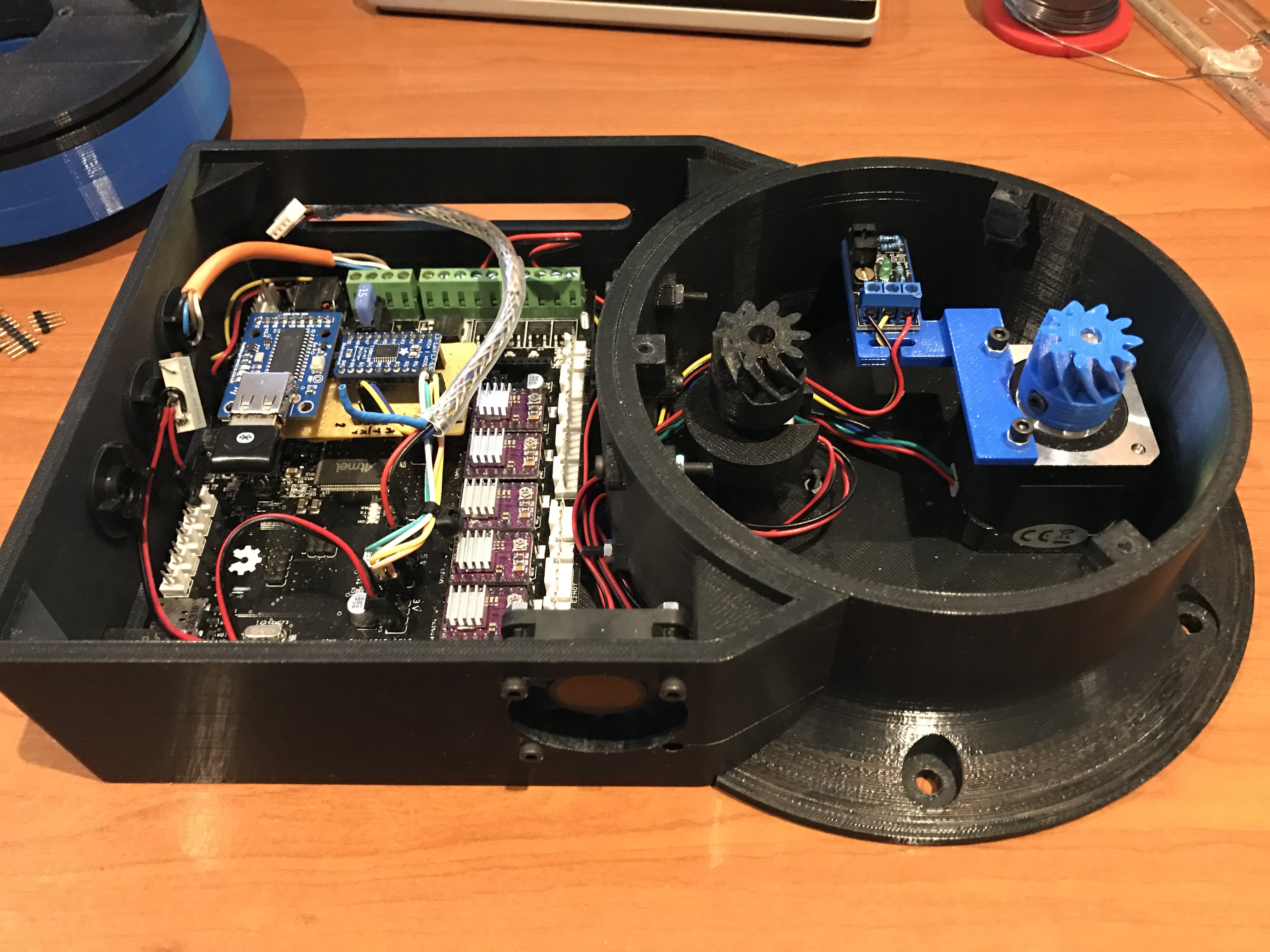

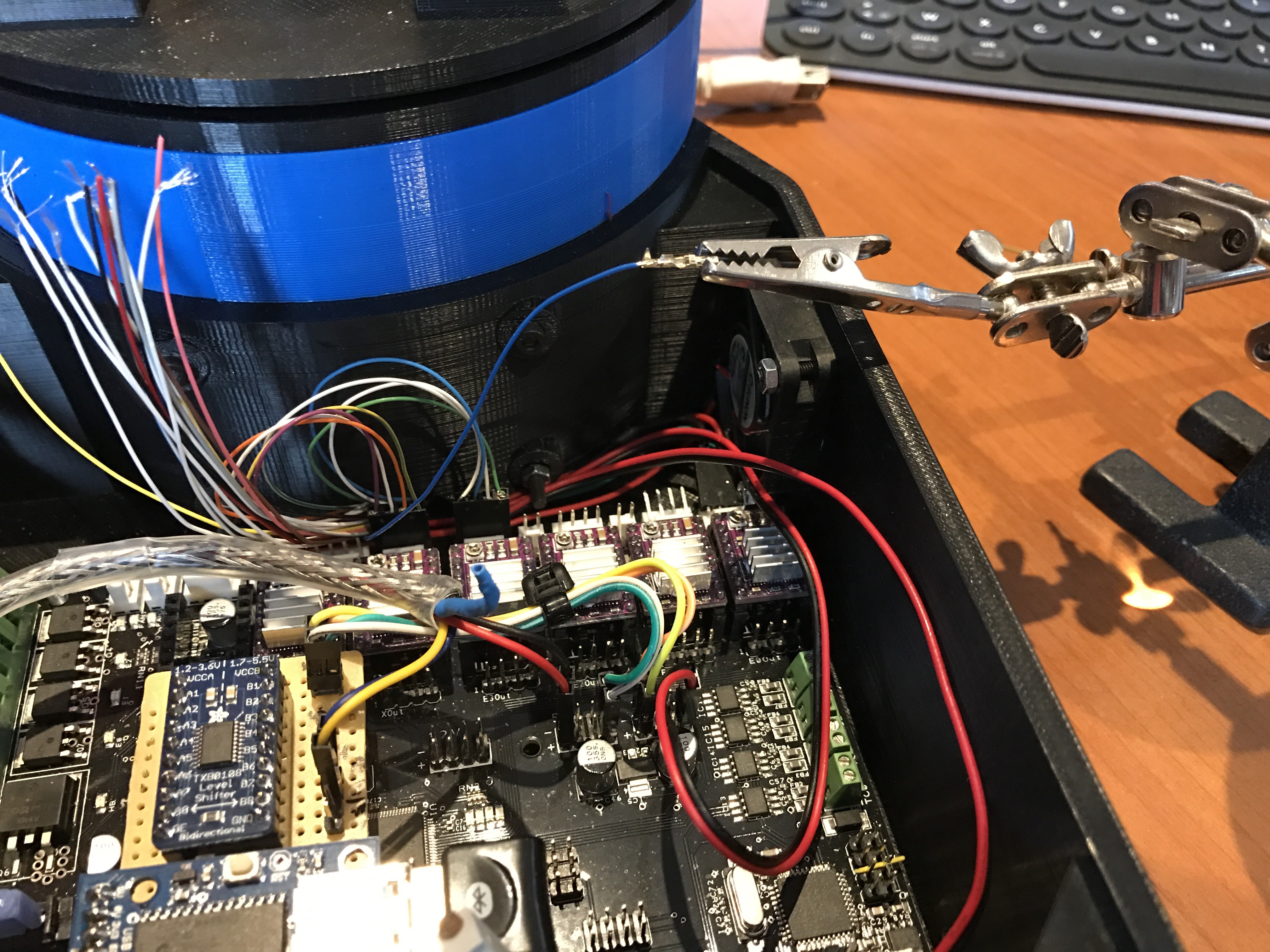

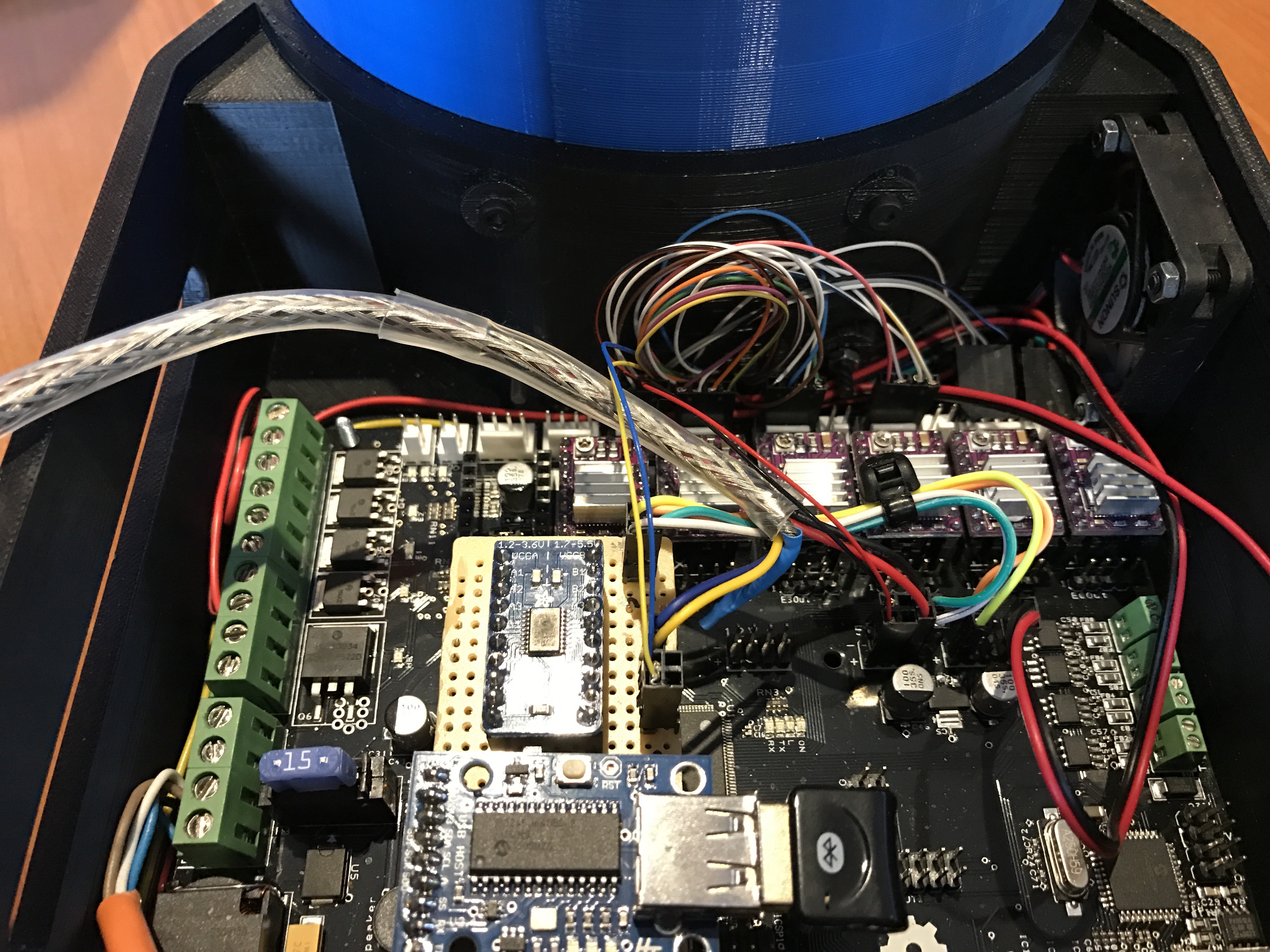

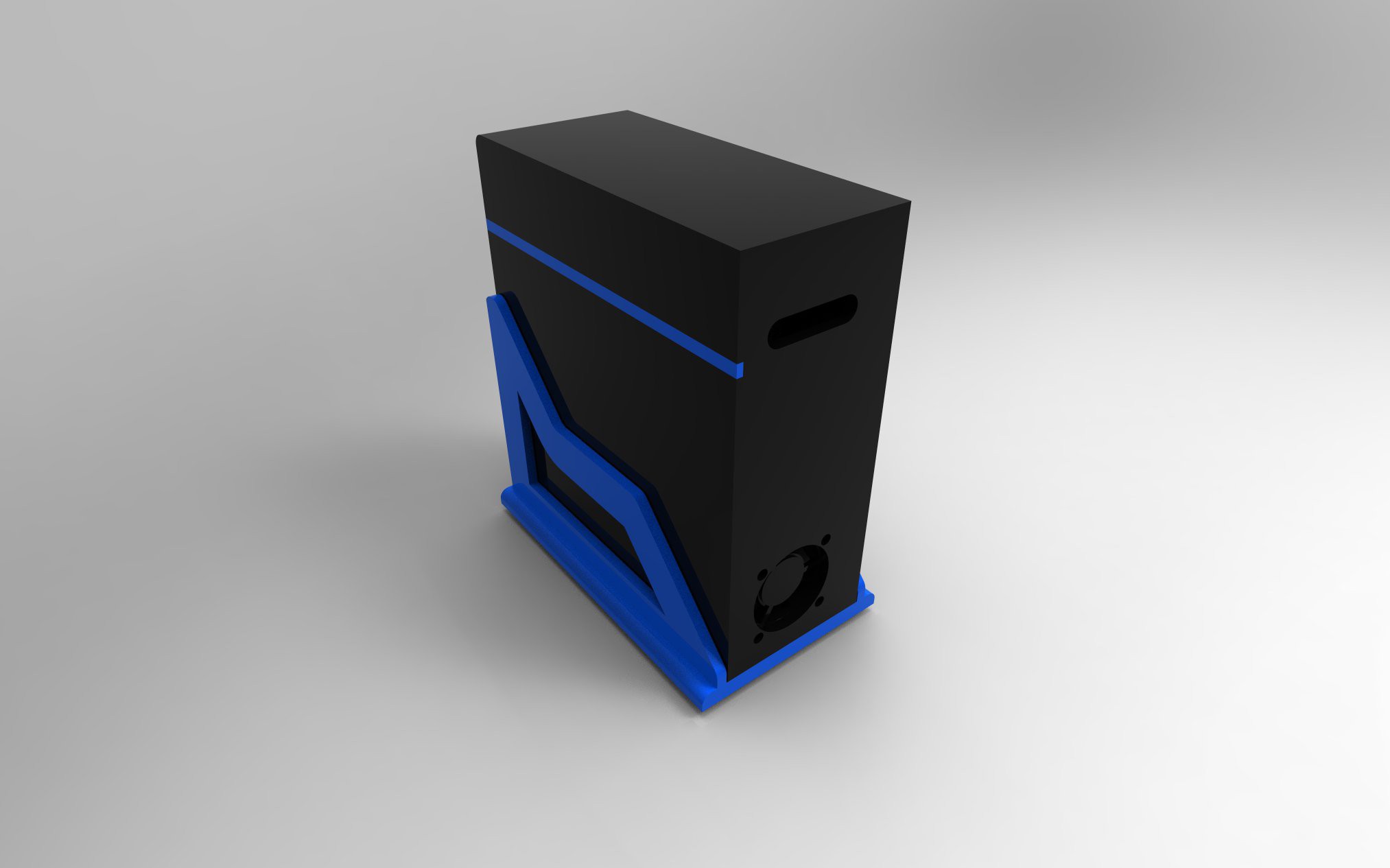

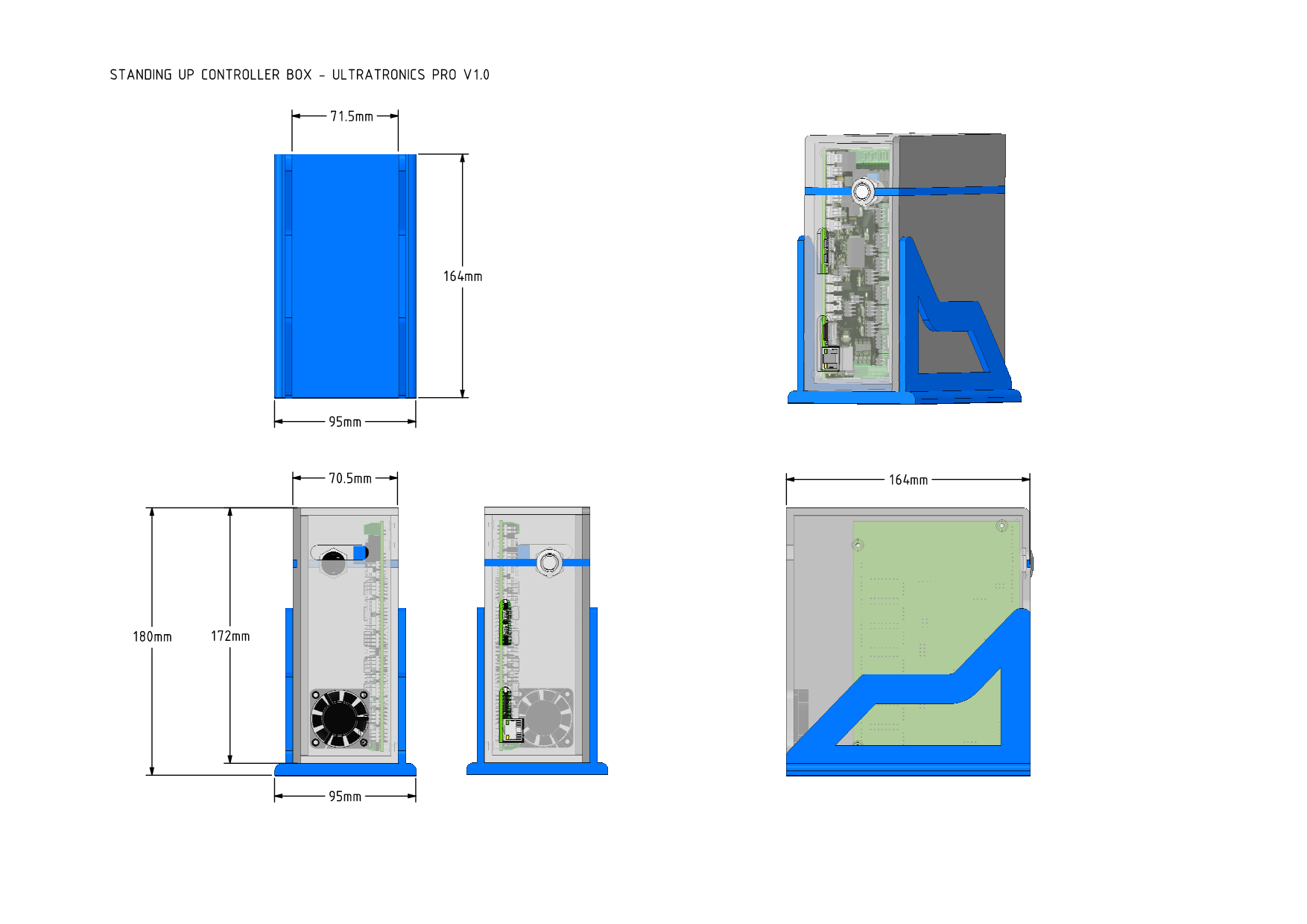

For all those wanted a seperate controller box, there's room enough for the ultratronics pro V1.0 board, if you want a empty holes box, just ask!

For all those wanted a seperate controller box, there's room enough for the ultratronics pro V1.0 board, if you want a empty holes box, just ask!

If you want some dimensions, no problem :-)

If you want some dimensions, no problem :-)

Guillermo Perez Guillen

Guillermo Perez Guillen

Mihai Oltean

Mihai Oltean

Mattias

Mattias

Hi Danny, I'm playing around with the Linux-compiled GUI, and it's pretty good so far. One thing I would add in though for us that dislike sliders and want faster accuracy, would be to allow typing in the degrees for each axis instead on sliding a slider bar around.

Keep up the great work!