Here are the key parameters I want in this bench:

- Sturdy: It needs to be strong

- Big: I want to have room for my stuff.

- Good shelves:

- Form fitting: Make room for things like my scope, AWG, and chunky PSU but don't waste space!

- Lots of space for hand tools

- Component rack: Store 15+ boxes housing various sorted components

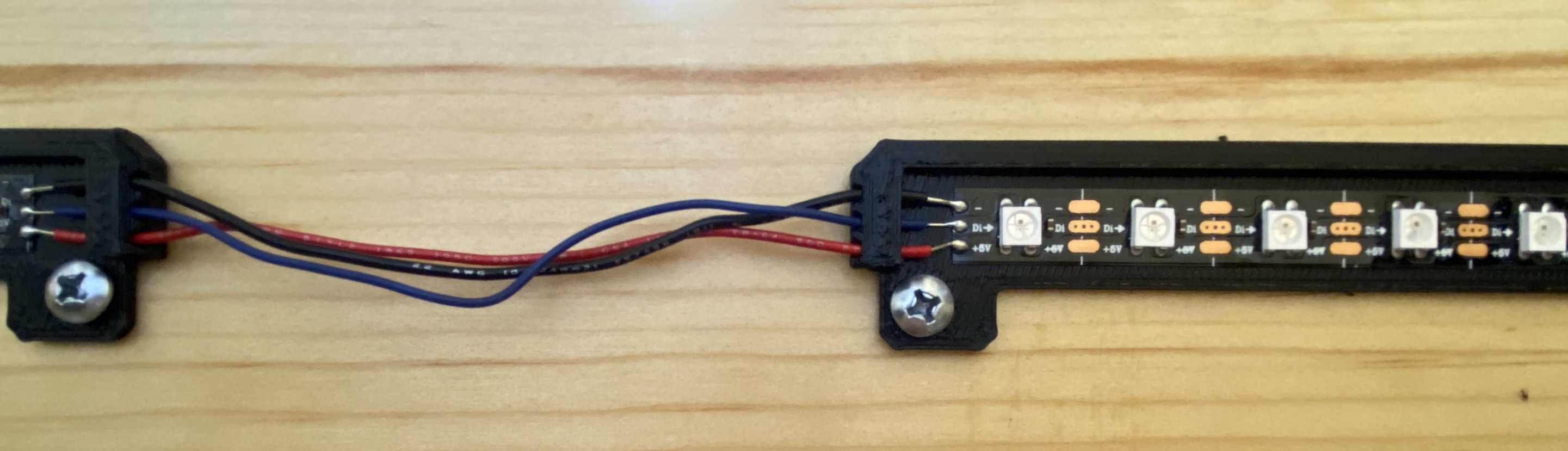

- Lights: I installed LEDs on my current bench - I want the same (or better - stay tuned...) here.

- Integrated Electronics:

- Lights: I already talked about this

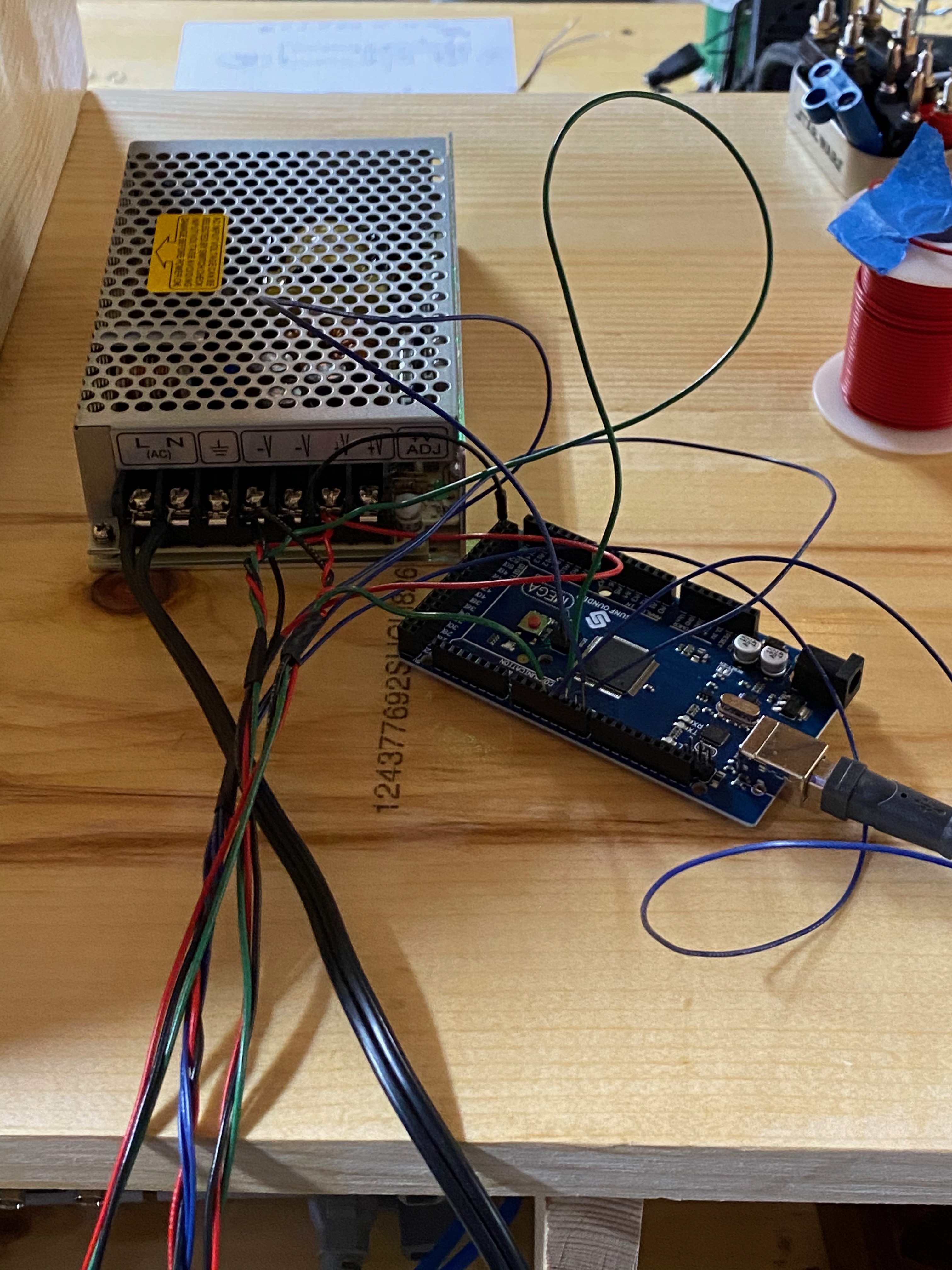

- 12V DC bus: I build a lot of smaller devices which run on 12 V. Keeping a ton of wall warts around is a pain. Plus most of the cheap ones seem to use really crappy SMPS which are quite noisy. Having one big beefy 12V supply lets me ditch these for a better one & cut down on some wires.

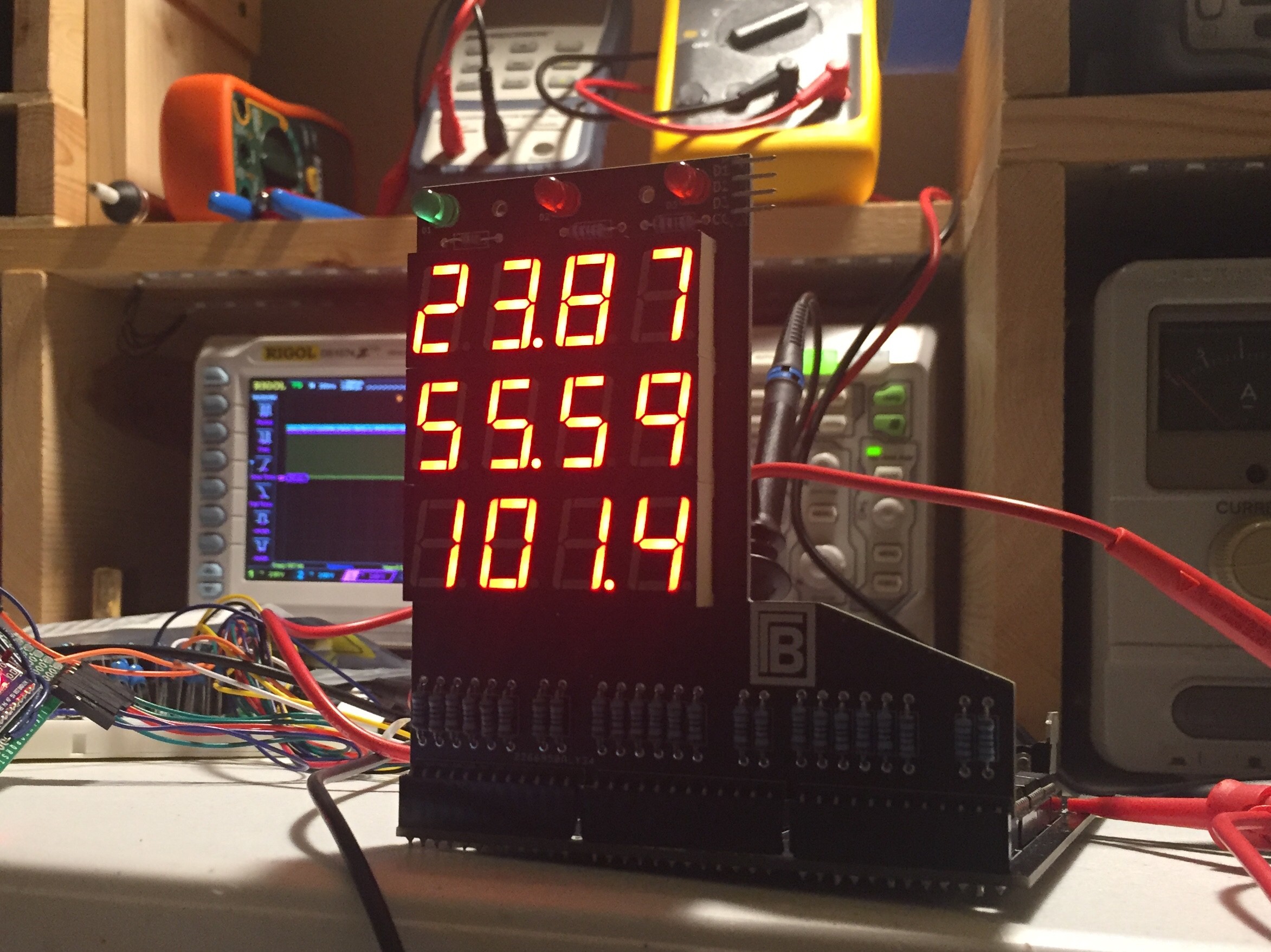

- Equalizer: I'm often either listening to music or building audio electronics. Installing one of the equalizers I've already built makes sense.

- Flood lights?: I drop tiny parts all the time. Putting some flood lights on the bottom to light up the floor when needed could help.

- Thermometer/hygrometer + data logger: Okay I can't justify this one. But why not

- Tool mounts: On my previous benches I 3D printed some structures to mount specific wires, tools, etc. I use them daily and plan to make more for my new bench.

Grant Giesbrecht

Grant Giesbrecht

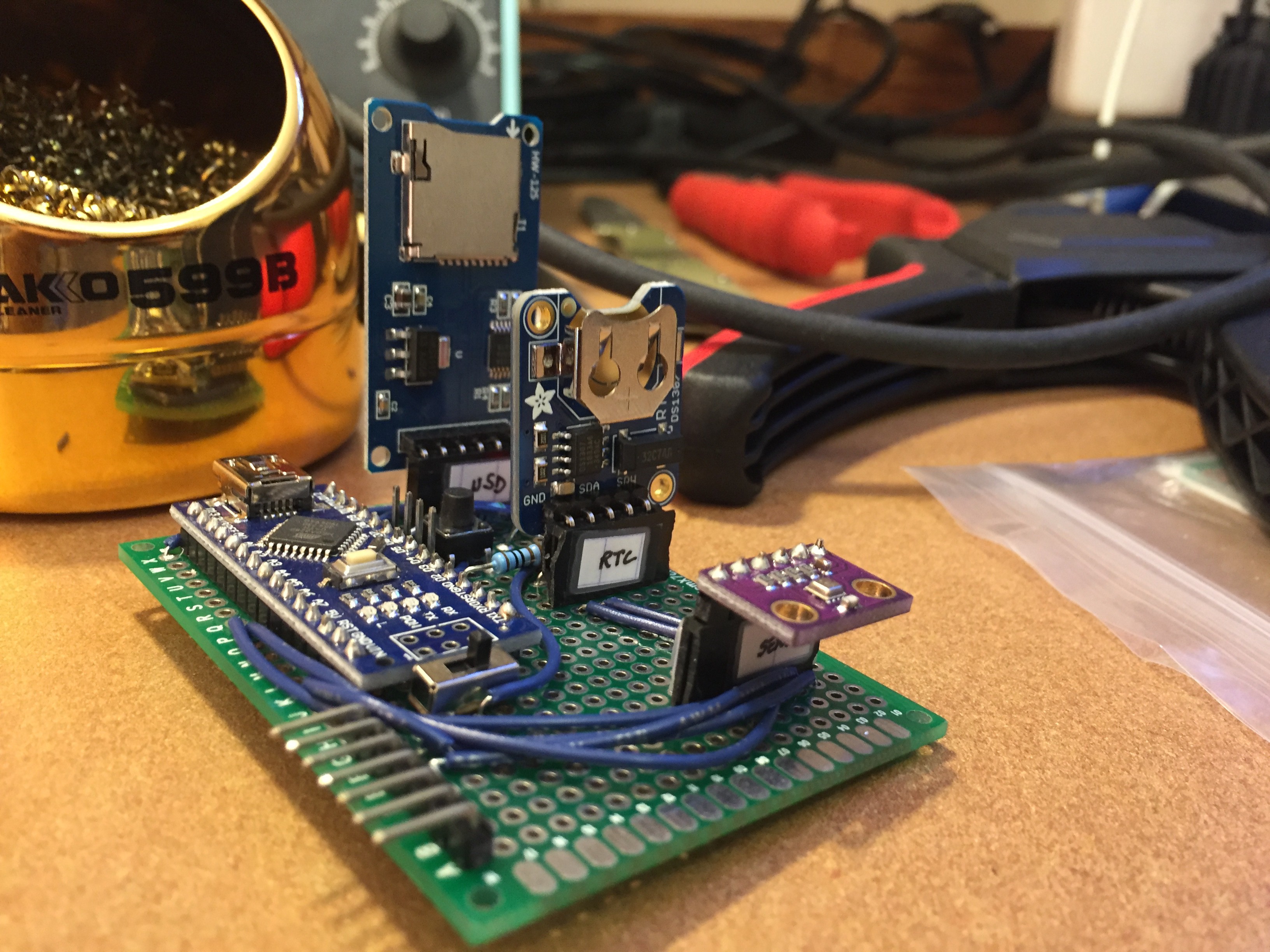

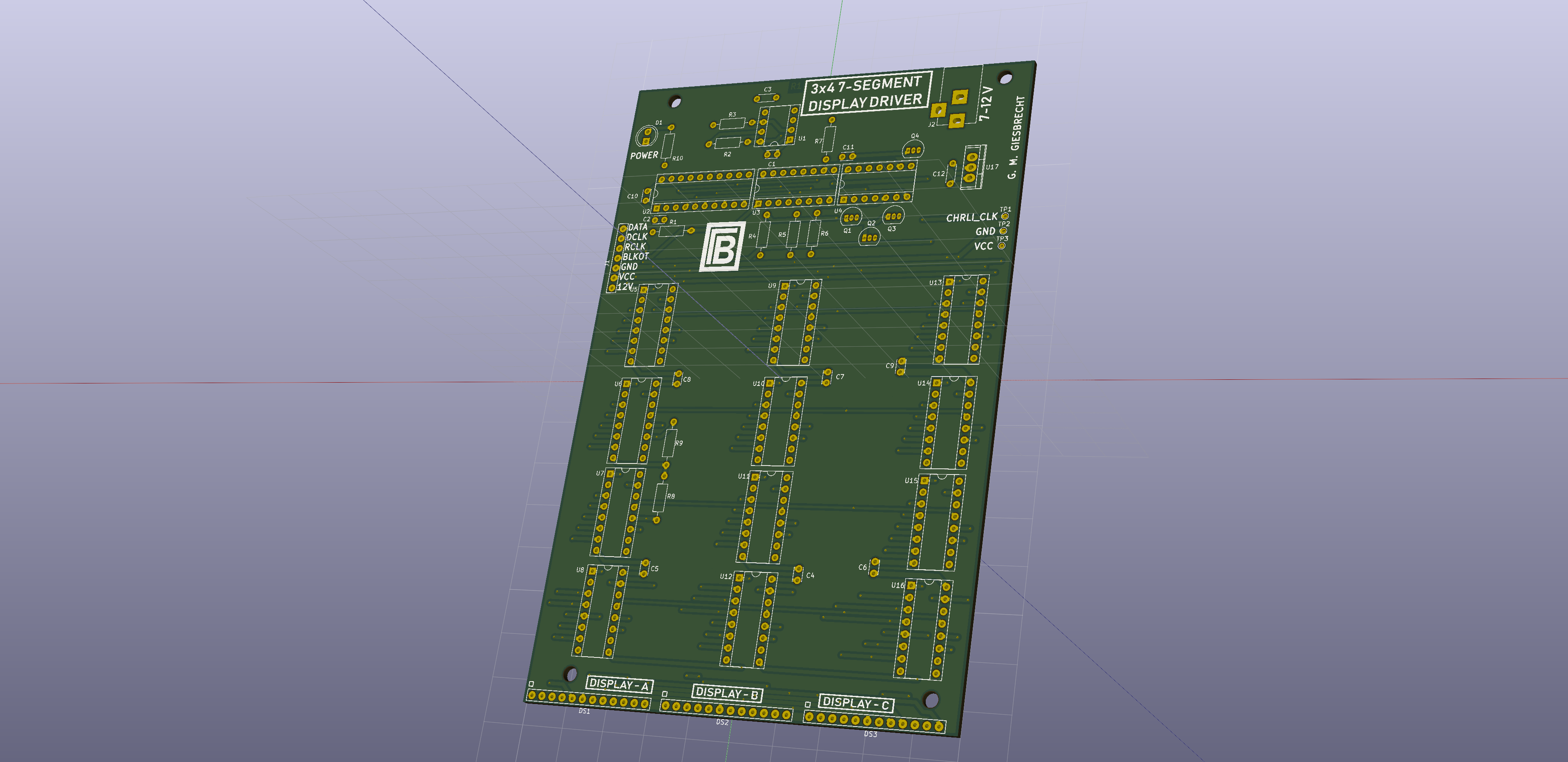

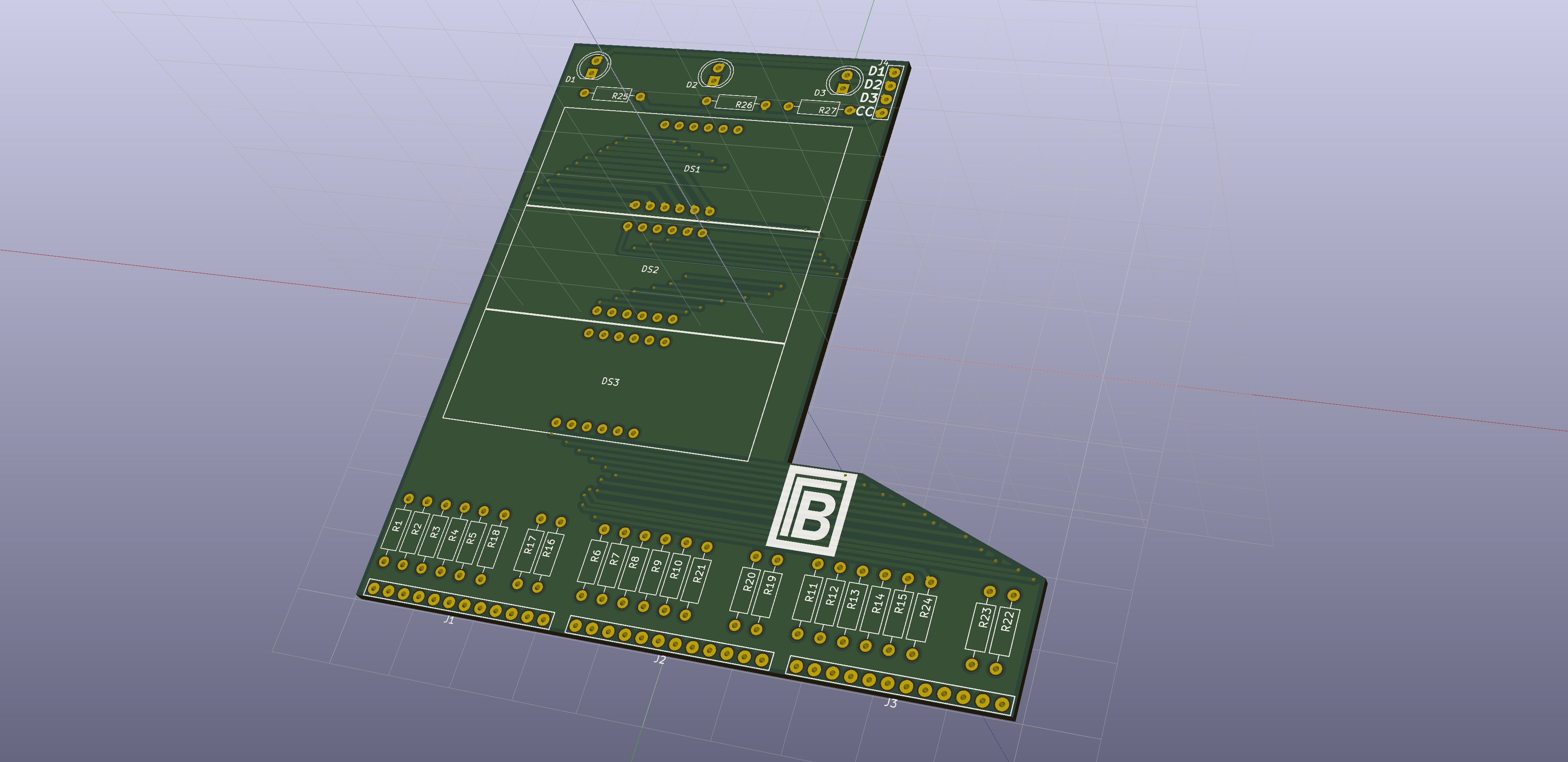

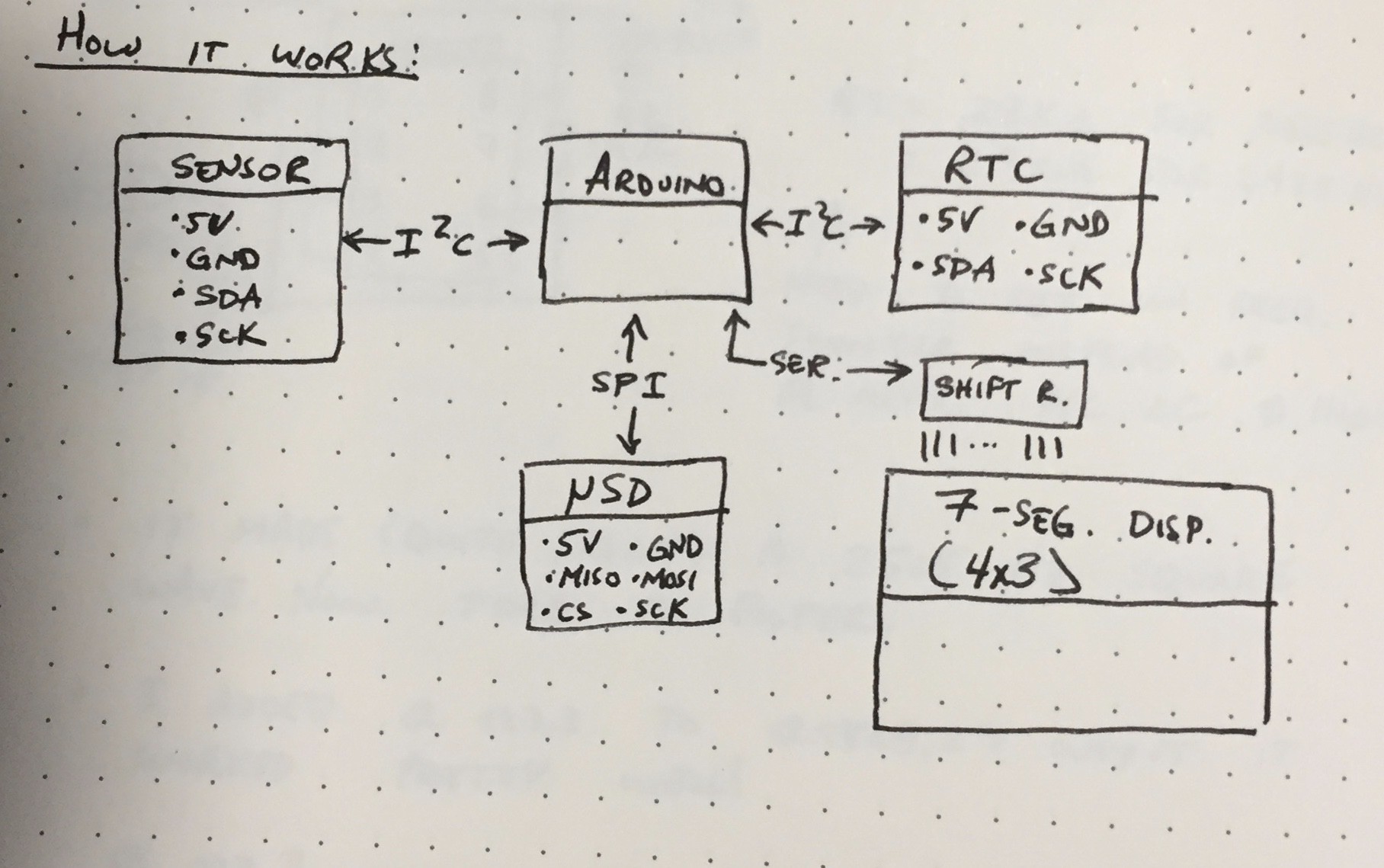

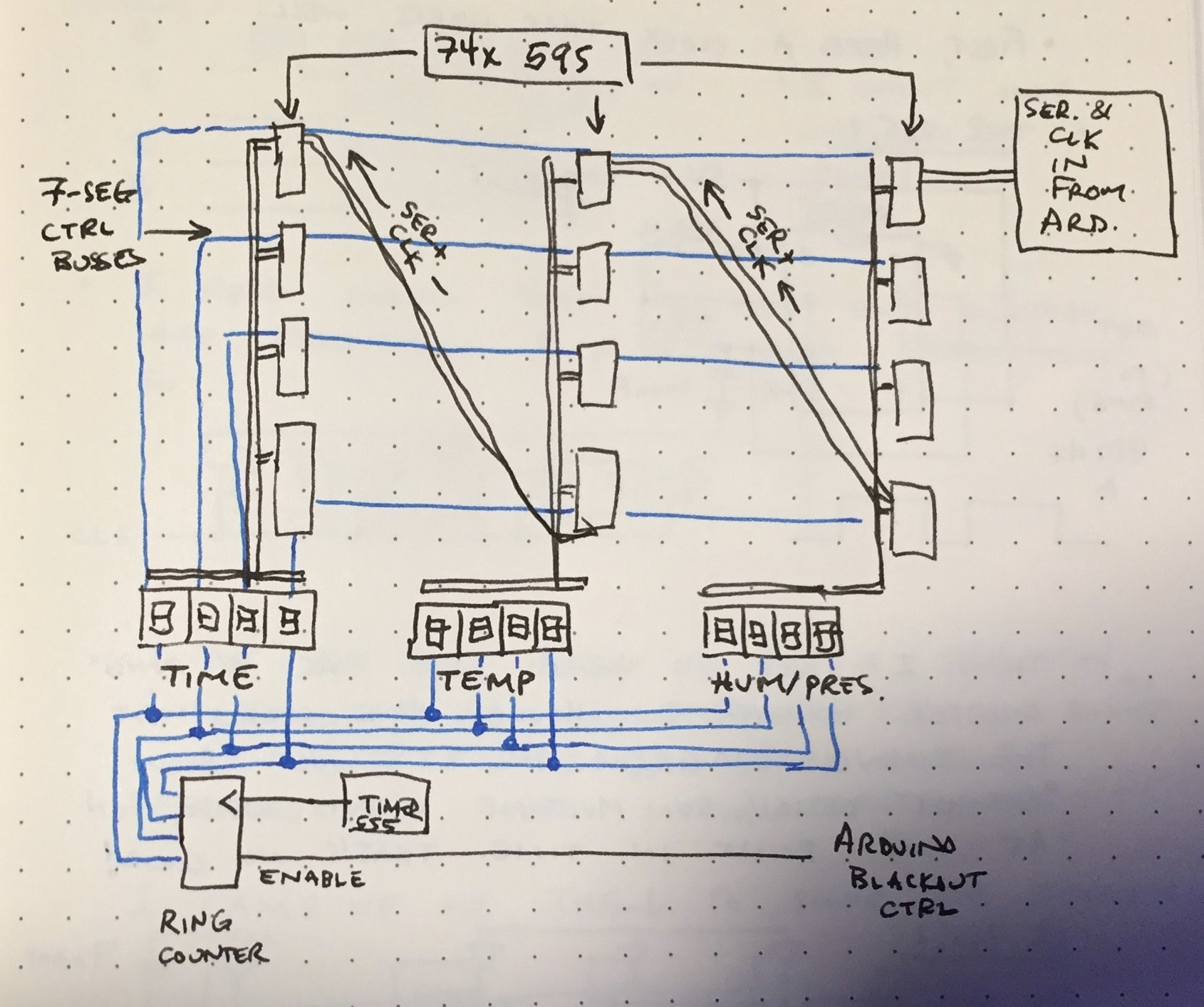

This board also has the real-time clock, MicroSD card module, the sensor, a push button (w/ debouncing circuitry) for cycling through error codes on the display, a switch to disconnect Arduino power, and a power LED for the Arduino.

This board also has the real-time clock, MicroSD card module, the sensor, a push button (w/ debouncing circuitry) for cycling through error codes on the display, a switch to disconnect Arduino power, and a power LED for the Arduino.

I wrote an Arduino sketch which you can find on the project's GitHub repo. Because I don't have the display driver board yet it's still a work in progress, but it can read the sensor values, log them on the SD card, and report them to the serial monitor.

I wrote an Arduino sketch which you can find on the project's GitHub repo. Because I don't have the display driver board yet it's still a work in progress, but it can read the sensor values, log them on the SD card, and report them to the serial monitor.

David Hopkins

David Hopkins

Michael

Michael

Jorj Bauer

Jorj Bauer

JF

JF