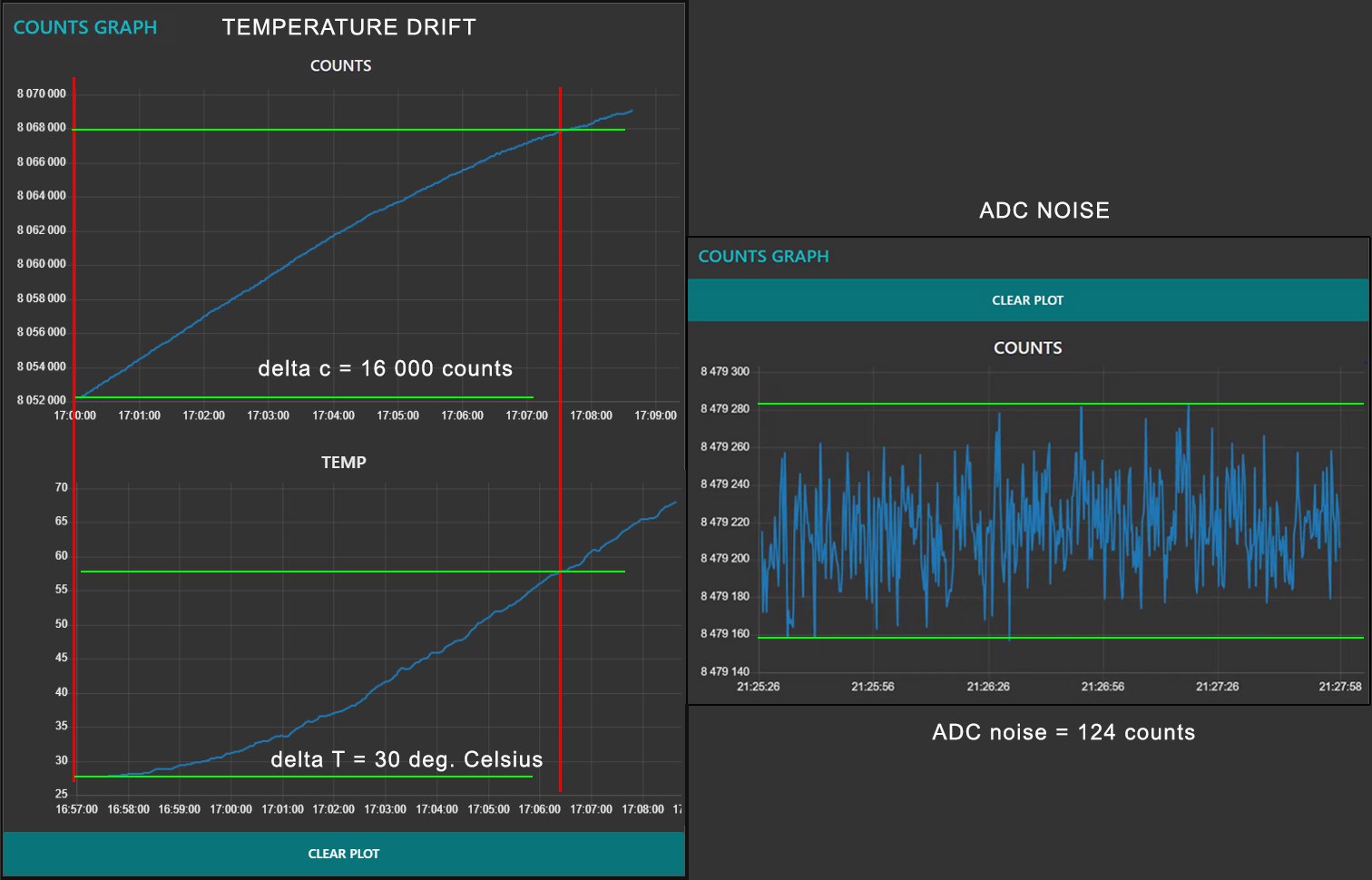

Yesterday I did preliminary load cell temperature drift test.

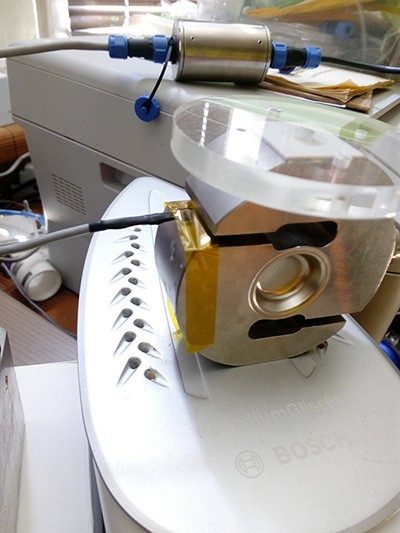

Here my test setup:

I understand it's not so accurate setup for measurements(I need thermal chamber for accurate measurements) , but let's look on the results:

As you can see I have 16000 / 30 = 533 counts temperature drift for 1 degree Celsius. It's more than 4 times higher than noise, and it's unacceptable for accurate measurement.

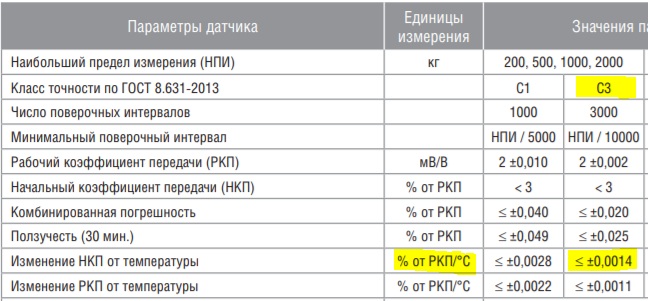

I use expensive hi-class (C3) load cell. Let's calculate how the load cell meets specifications.

C3 - accuracy class

Temperature effect on zero balance TKzero must be less or equal +//0.0014% for 1 degree Celsius from the full scale.

My ADC has 24bit resolution, so the number of counts = 2^24 = 16 777 216 and calibrated exactly for this load cell full scale

Temperature drift = 533 counts

So:

TKo = 533 / 16 777 216 / 2 * 100 = 0.0016%

It's slightly higher then I see in the specification.

Let's calculate temperature drift error in grams. I use 200kg load cell which works in both directions (tension and compression) so it has 400kg full scale.

TKo = 533 / 16 777 216 * 400 000 = 12.7 gram/1 degree Celsium.

It's significant error in measurements. That's why I did all this project!

Why it's significant error? Because the standard deviation with filtering (20 values mean) only 0.65 gram for 400 000 gram full scale load cell.

Sensitivity balance of the load cell also have temperature drift (TKc - Temperature effect on sensitivity balance).

I will try to test it next time.

Andrey V

Andrey V

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.