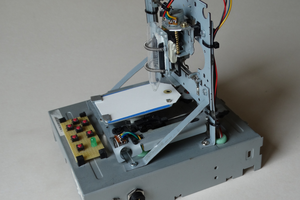

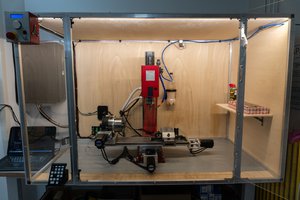

On the hardware side, this machine possesses two degrees of freedom (X and Y directions). Take into account that as this CNC machine doesn’t have a Z axis, the pen will continuously touch the paper, so it is recommended for continuous line art projects, such as this. You can also replace the pen with a laser to convert this machine into a laser engraver/cutter, although this last modification will require some small modifications on the electronics side as well.

On the software side, this machine uses “Universal Gcode Sender” and the “GRBL” for the Gcode sending and parsing steps, respectively. For generating amazing continuous line art, I recommend the following “StippleGen” program, which generates TSP art and that can be converted into Gcode commands via Inkscape program.

Daniel

Daniel

Fabien-Chouteau

Fabien-Chouteau

Federico Virdia

Federico Virdia

Adrian Prinz

Adrian Prinz

Recommend shaft drive stepper motor, Nema17, 59Ncm, high quality.

https://www.motiongoo.com/index.php?route=product/product&product_id=73&search=17HT19S4200C1