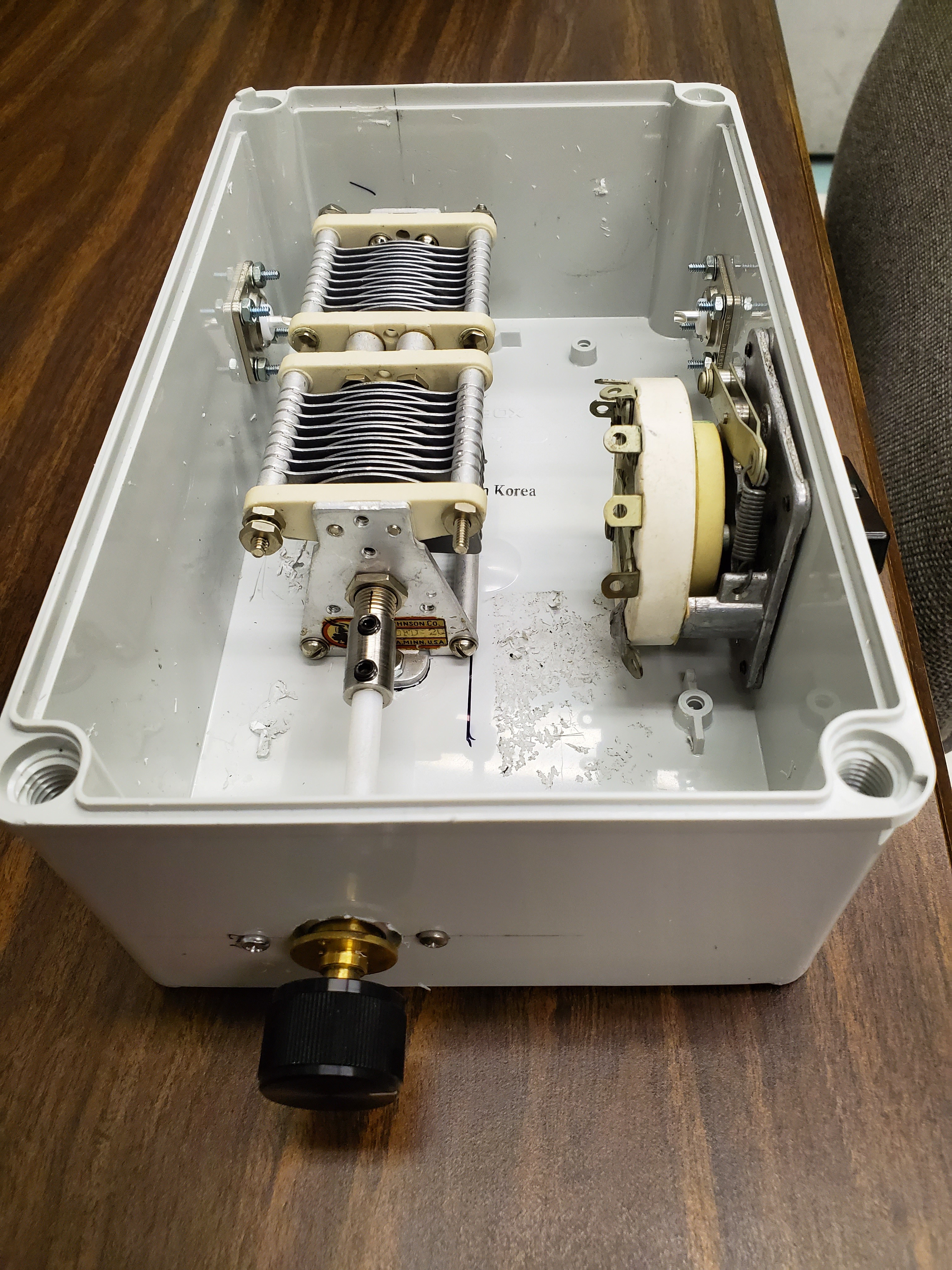

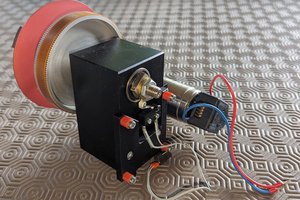

Check the log files for most of the details. The basic mechanical design is completed. The manually-tuned antenna performs very well. I have used it often for POTA (Parks On The Air) operation.

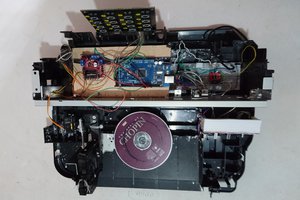

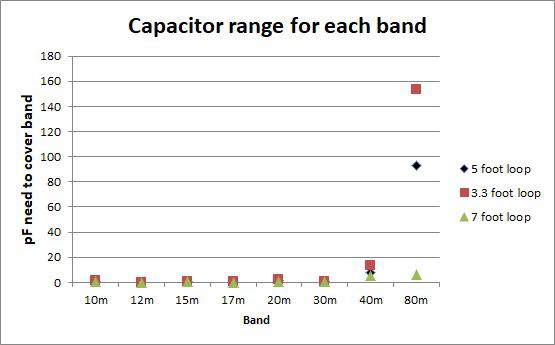

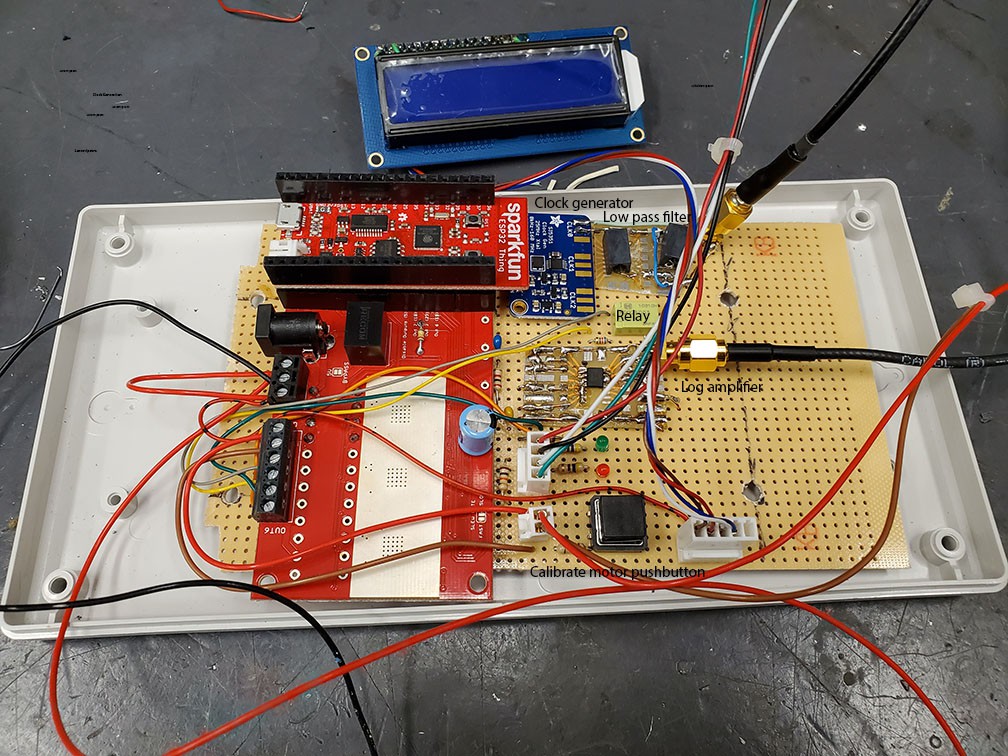

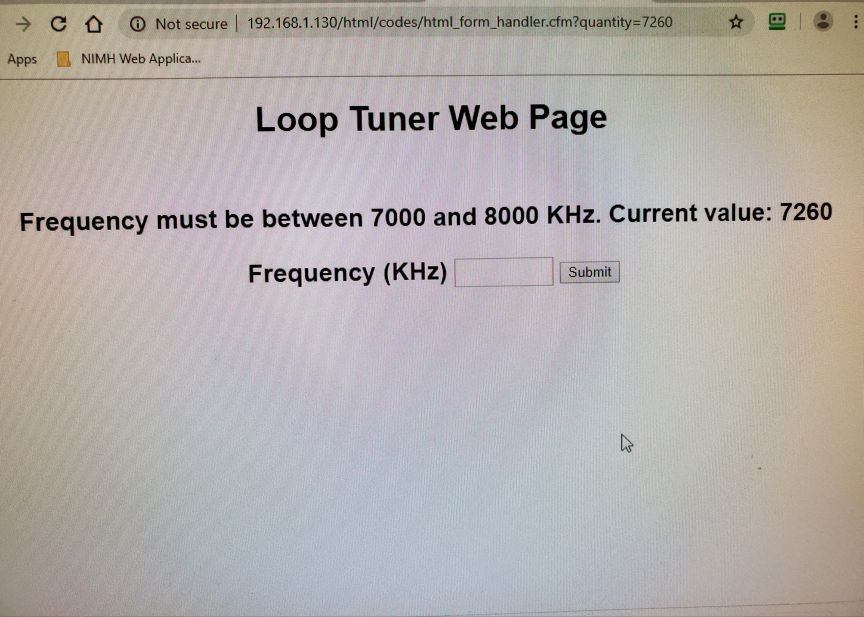

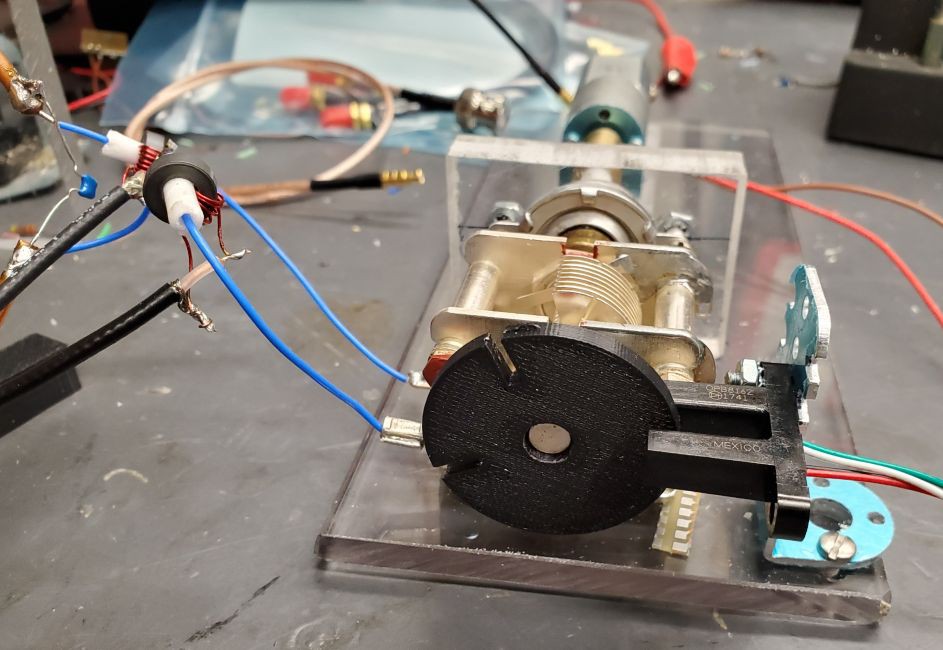

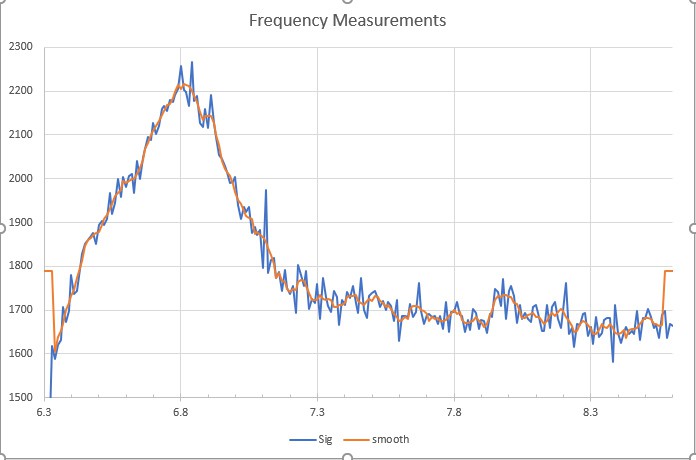

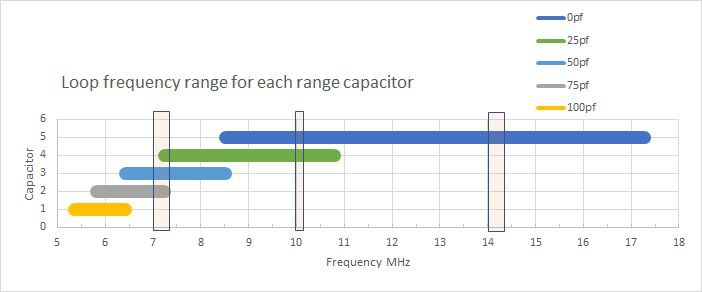

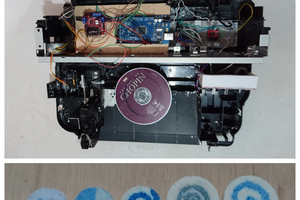

The automatic controller is able to autonomously tune a model of the the loop antenna. The model is a variable capacitor and large inductor on the test bench. The tuning circuit is able to find a resonant frequency selected through its Web interface. However, the automatic tuning has not been incorporated into any of my final loop antenna designs. The circuit is well worth studying and the design ideas work, but I changed direction. I started designing my own high voltage variable RF capacitors. See my other projects. These capacitors are motor driven, so someday I will return to autonomous tuning.

Andrew Mitz

Andrew Mitz

JP Gleyzes

JP Gleyzes

Guillermo Perez Guillen

Guillermo Perez Guillen