I will not stress you with the usual catastrophic global warming stuff, you can read plenty about that online (here's a great article). However it's no coincidence that my love for electronics and efficiency drove my career straight into one of the fields that was promising a huge impact on that front: Electric Mobility.

This is the story of a journey that started a few years ago, when I and a friend with this same passion started a company to be part of this revolution, with big ideas for the future and small pockets.

But you have to start somewhere, so we tackled one of the most annoying problems we had as EV drivers: charging. You can charge your vehicle at home with an EVSE cable, but that's only a temporary solution as the charging rate is very slow (~10km/h) and it's usually not very safe as plugs in Europe are not designed for that kind of continuous load. This solution is also ugly and dumb because you can't control the charging rate and you easily trip the main circuit breaker if you use other loads in the house. Reducing the charging current when other loads are connected is a very basic feature, but at that time the only device offering it was the OpenEVSE. Even today, only a few brands offer this feature, and it's usually a quite expensive optional.

And while we're at it, why can't we also sync with our solar inverter and charge only when the sun is shining, if we're not in a hurry? Again, only an OpenEVSE connected to an OpenEnergyMonitor can do this. That's a very important feature as it reduces the overall pollution in the lifecycle of the vehicle, makes the user totally independent from oil companies and helps reducing the load on the grid, making transition to EVs easier for everyone.

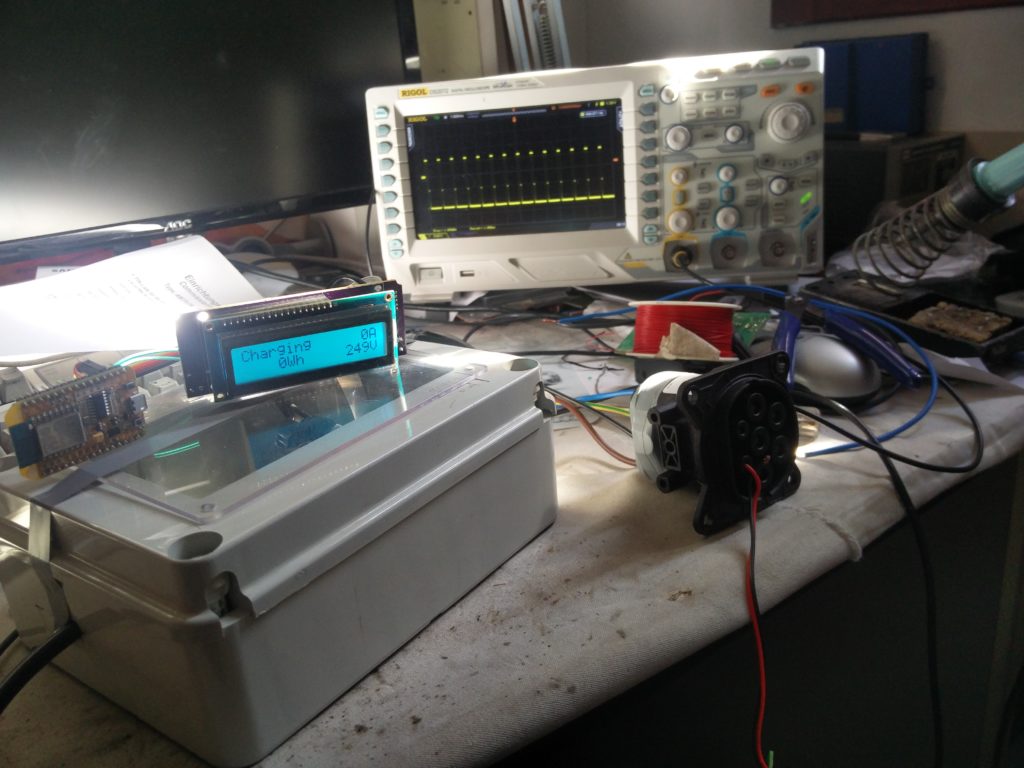

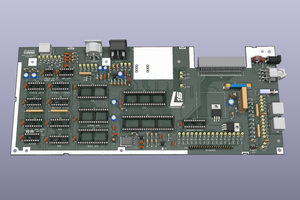

So we built ourselves an OpenEVSE, and we were happy for a while. But oh, there's so much to improve! It doesn't have ethernet (WiFi in the garage was very flaky), it was only single phase, and it looked (and still looks imho) too much like an hobbyist project.

We also had the chance to test some commercial products, and when one exploded on us we decided it was time to make things right. And the idea of Prism was born.

Other great and unique features that set Prism apart from the competition:

- Based on OpenWRT Linux:

- high security and constant updates

- easy development in any language (C, LUA, Python, PHP...)

- WiFi Access Point feature: very important to keep your car connected if your garage is underground

- Integration with Vehicle API, to customize charging based on vehicle state of charge

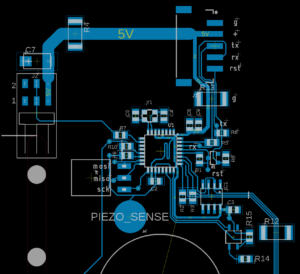

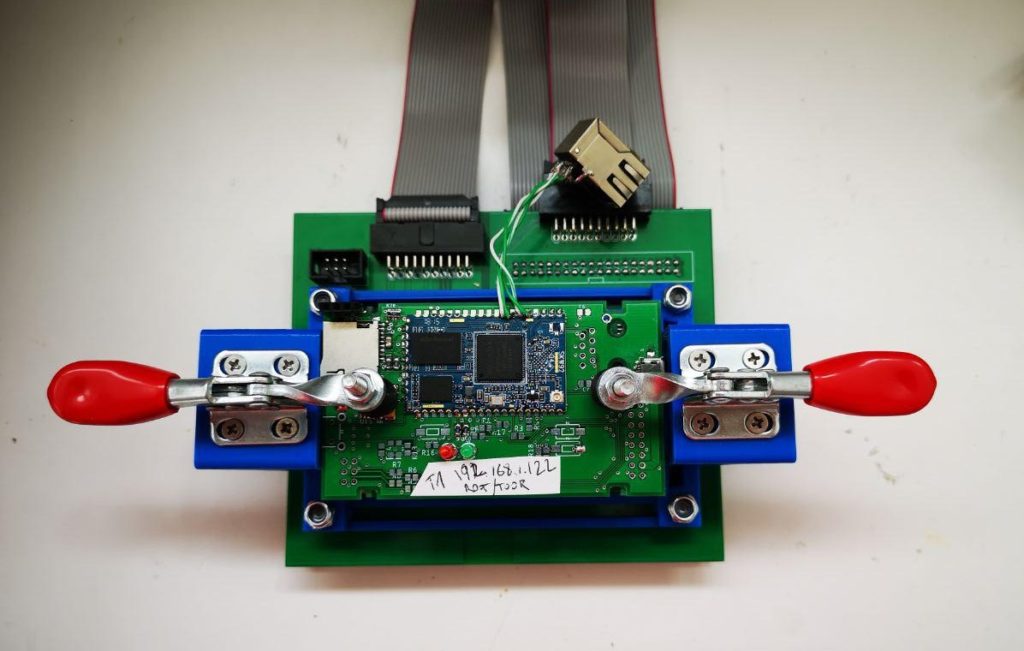

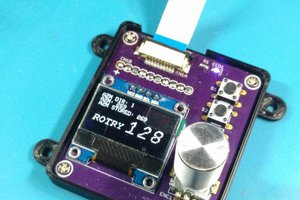

- Open and easily and "modularly" customizable: you can play with any part of it, e.g. if you're not comfortable messing with high voltage stuff, you can just play around with the cover module that still has access to all data and customize the user interface, or redesign only the Linux module to use your own SOC, or just code new features in any language without touching the hardware.

- One single prism can charge one or two vehicles at the same time

- Advanced energy monitoring can give unique insights into the EV charging system - especially useful for makers playing with this component

- Extra safety with integrated Ground Fault protection for both AC and DC residual current

- Oversized contactor for extra safety

General specifications are:

- up to 22kW charging power (3 phase) or 7.4kW (single phase)

- 400V AC (3 phase) or 220V AC (single phase)

- IP54 case (but by design we should be able to achieve IP64 or even IP67)

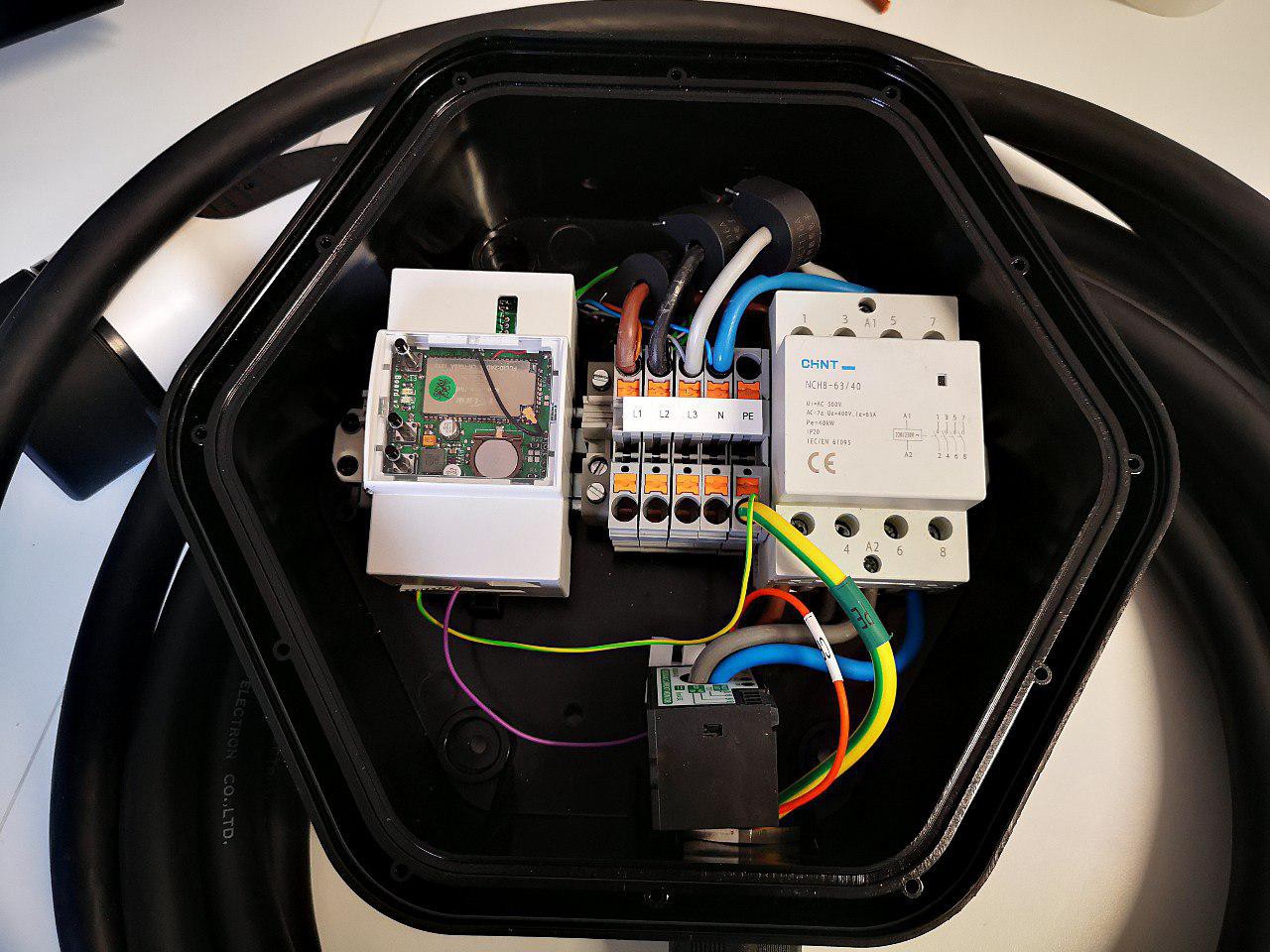

Here's the latest image of the prototype in its case:

Status of the project:

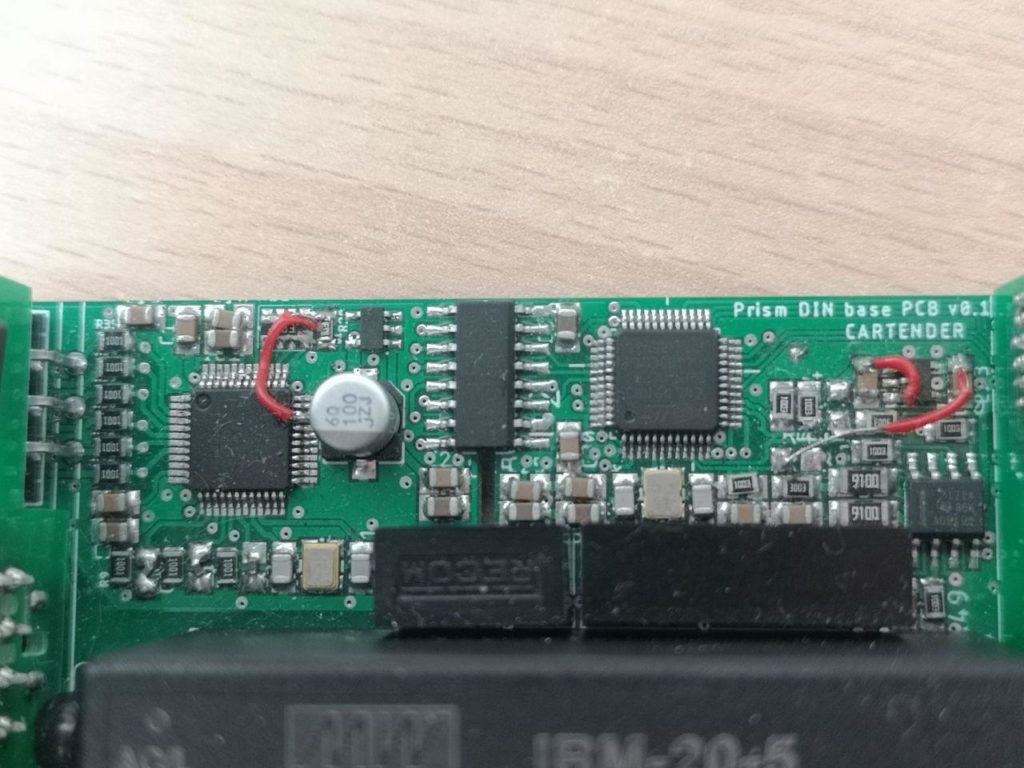

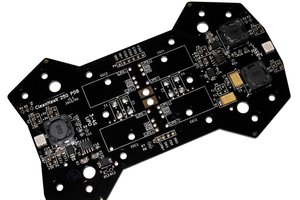

- The electronic modules are going into production - we received the first prototypes and we're testing them

- We finished the plastic case molding and will manufacture...

Mastro Gippo

Mastro Gippo

SukkoPera

SukkoPera

2bluesc

2bluesc

CriptasticHacker

CriptasticHacker

KingOfKYA(Travis K. )

KingOfKYA(Travis K. )

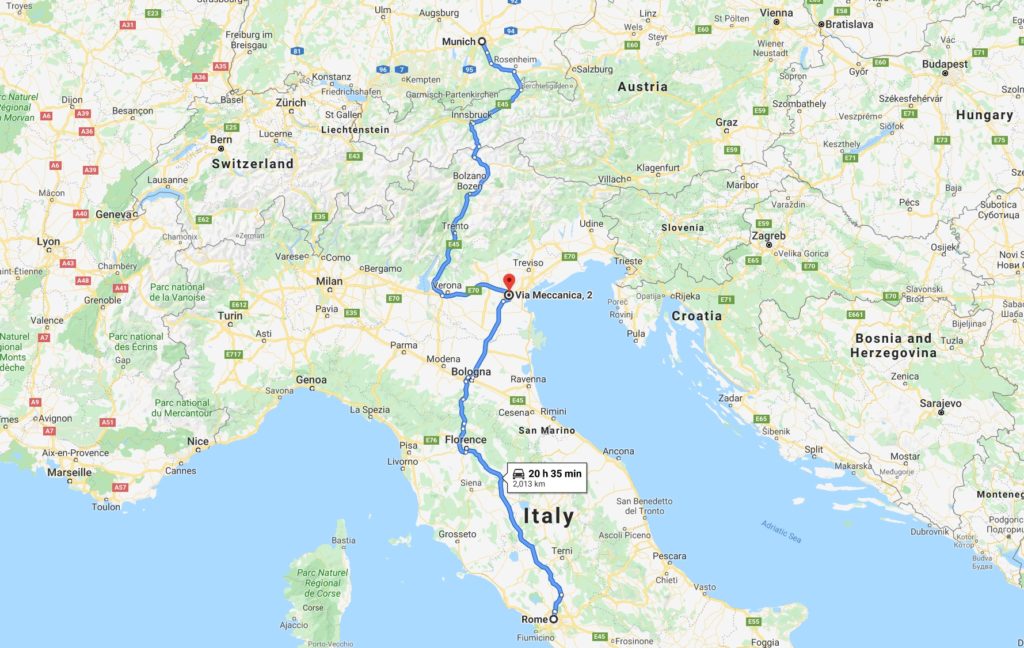

It was really cool to see Prism at Maker Faire Rome this weekend. I know the enclosure design was a painful process, but what you ended up with looks fantastic!