As an Industrial designer, I probably got a different approach than other RepRap contributors, which are often mechanical or electrical engineers. With this log, I want to communicate how decisions are made from a designers perspective.

Complexity and Material

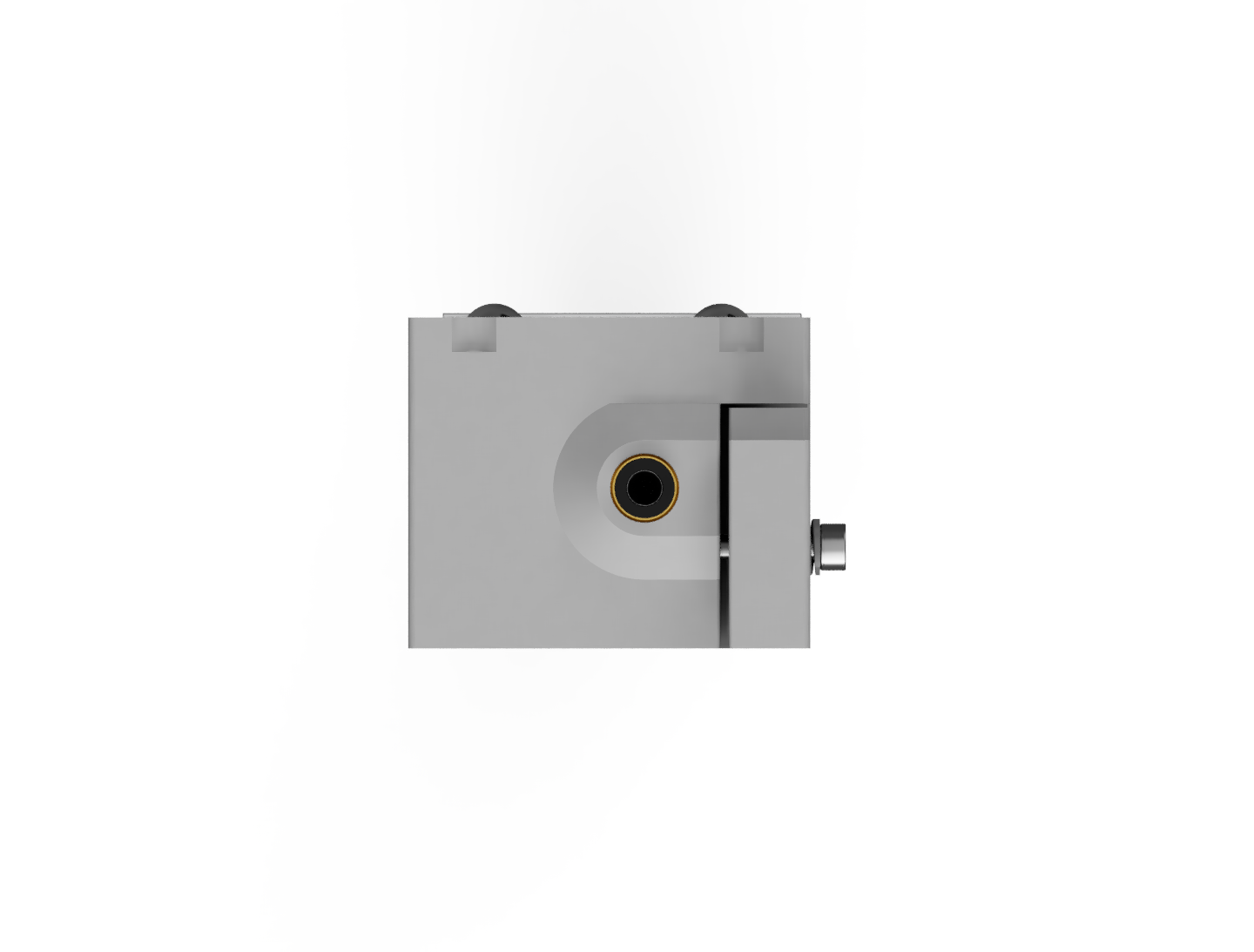

3D Printer are visually complex machines, and in my opinion, there is no reason to increase the complexity by unnecessary ornaments. Many printers are taking the extra effort in hollowing and sparing areas, often in an ornamental fashion. Many times the origin does not stem from functional aspects but our visual habits. Mass-produced, injection-molded products look like this. Injection-molded parts need to maintain a specified wall thickness, and its weight is purely dependent on the outer shape. And CNC milled objects are carved out of solid material, which adds a lot of weight when it's not hollowed. But 3D printer work different, FDM printed parts are almost hollow, and it's the perimeter and solid layer which adds most weight. Just think about it, three perimeter weight the same as three lines of infill, which can be several centimeters depending on the density. Therefore a cutout or excessive contour is not worth the effort in most cases. Sometimes structure can add stability (like the groves on a can), but it needs to be purposefully deployed.

Unity

Proximity is one of the gestalt principles, which are a fundament of design theory. The principle says that objects which are close together, share the same characteristics, and point in the same direction are forming visual groups. There is another design theory called "product language," which goes beyond that and imagines objects as subjects which speak a visual and tactile language. A group of buttons could say, "We control the same things, so we are close together." Braun did this masterfully in the 60s and 70s, the well-known calculators used the same buttons in a rectangular array, but four different colors are grouping the buttons in layers of interaction. I used this knowledge to create modules which appear as a unit inside the printer.

Blocky Design

When these thoughts are applied, the result is somewhat "blocky." It may look a bit plain, but it reduces visual complexity and makes adjustments and customizations very easy. The Fusion files are now open to everyone, and the hurdle for modifications should be low. The blocky design in combination with bevels is also a good indicator for the print orientation.

Marc Schömann

Marc Schömann

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.