-

1POST STROKE SPASTICITY REHAB HELPER

Bill of Materials

We use in the project the components

No

Q

Name

Description

1

2

Controller

Arduino nano R3

2

6

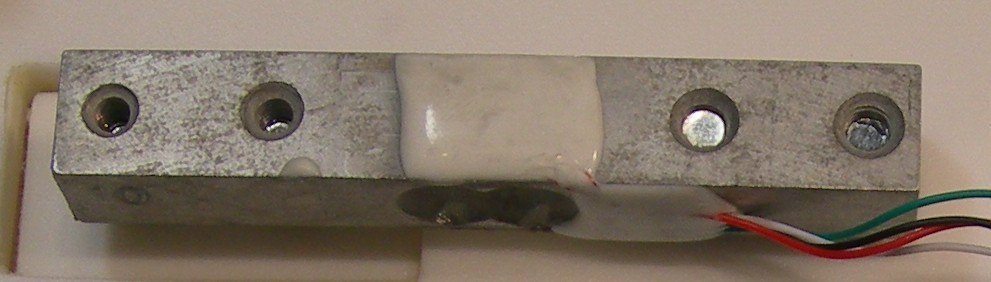

Tenzo Bridge

Pressure Sensor Scale Module

3

6

ADC fo Tenzo Bridge

HX-711

4

12

Servo mini SG90

Servo mini SG90 9g Tower Pro

5

0

Blue Tooth module

HC-05

6

6

Magnetic Snaps

3/4-inch size Magnetic Button Clasp Snaps

7

2

Shottky Diodes

Shottky Diodes 1N5817

8

2

3300 uF 16 V capacitor

Low ESR capacitor.

9

2

0.1 uF 16 V capacitor

Capacitor for high friequency noise damp.

10

3

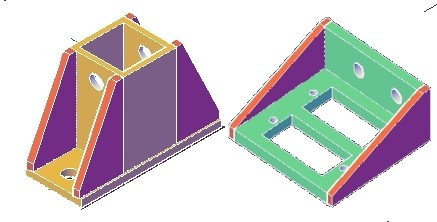

Low base for servo

3D printed or milled plastic components

11

2

High base for servo

3D printed or milled plastic components

12

10

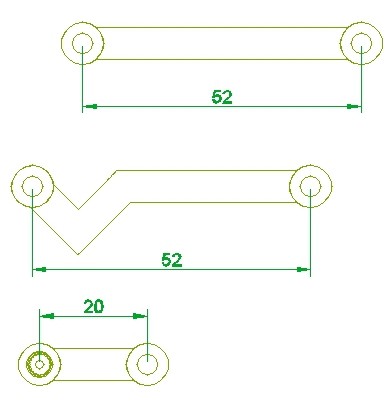

Servo mounted lever arm

3D printed or milled plastic components

13

6

Short node lever

3D printed or milled plastic components

14

4

Long node lever

3D printed or milled plastic components

15

2

Breadboard

Plastic Breadboard or other flat plastic

-

2Bill of Materials

We make some introduction about it.

- Controller Arduino Nano R3.x (992-ARD-NANO30NP) or any Arduino Nano R3.x compatible.

![]()

Servo SG90 9g Tower Pro. You can use any type of Servo. Please pay attention that some servos can have other control pulse parameters.

![]()

Magnetic Button Clasp Snaps

18mm (3/4-inch) size Magnetic Button Clasp Snaps![]()

Breadboard.We used plastic cutting board, but any flat surface can be used.

![]()

- Scale weight sensors 10 kG (or other)

![]()

- Controller Arduino Nano R3.x (992-ARD-NANO30NP) or any Arduino Nano R3.x compatible.

-

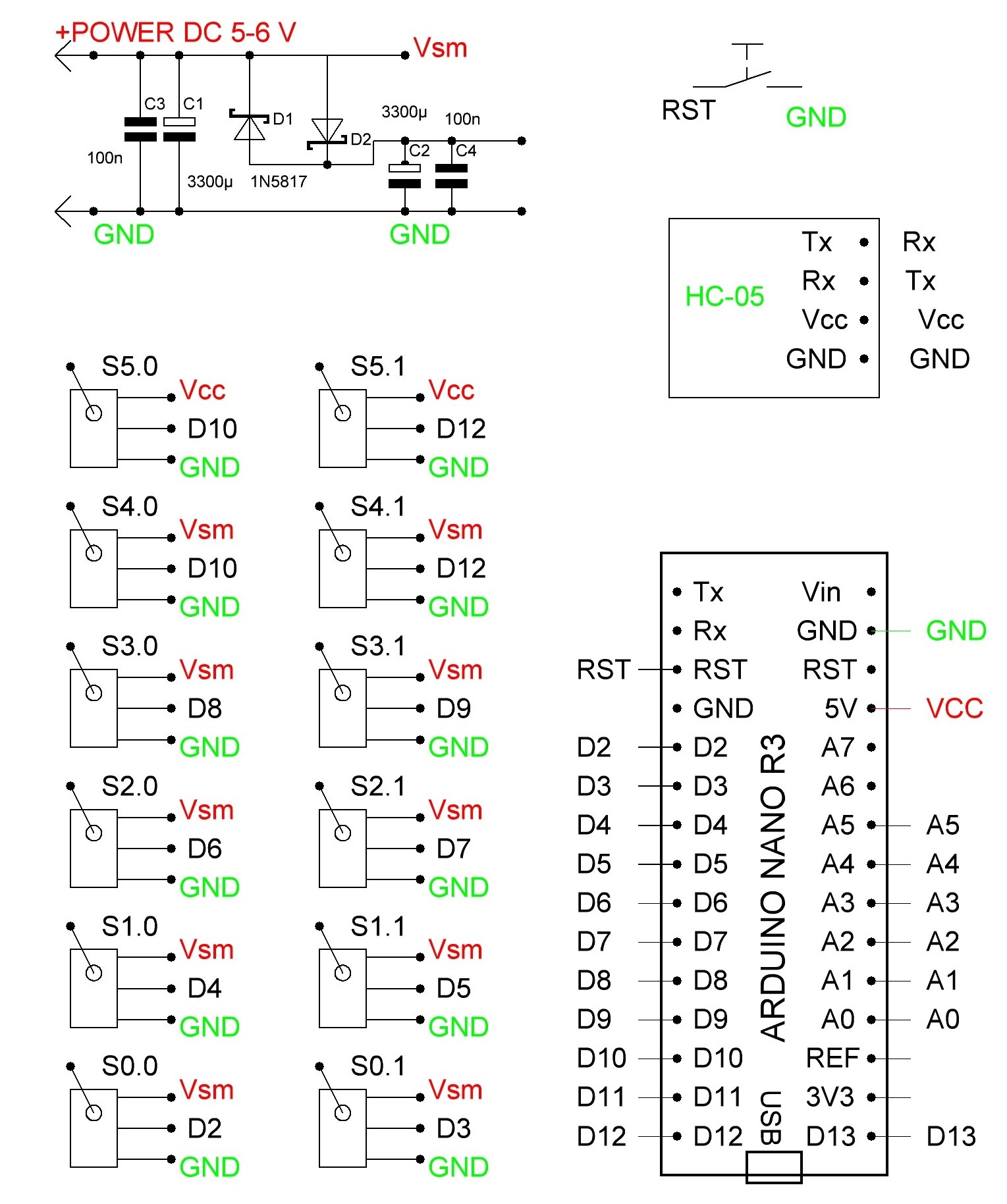

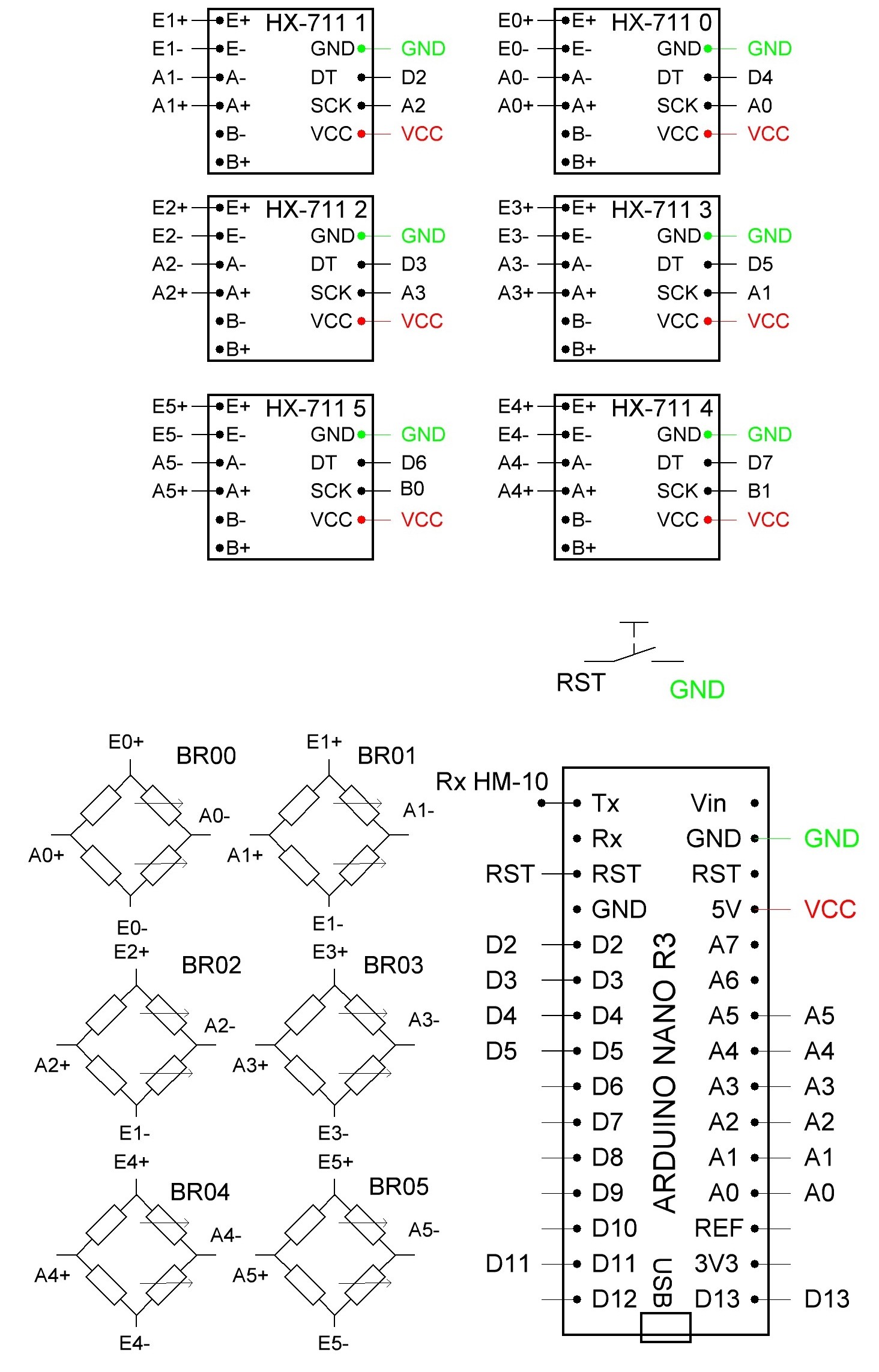

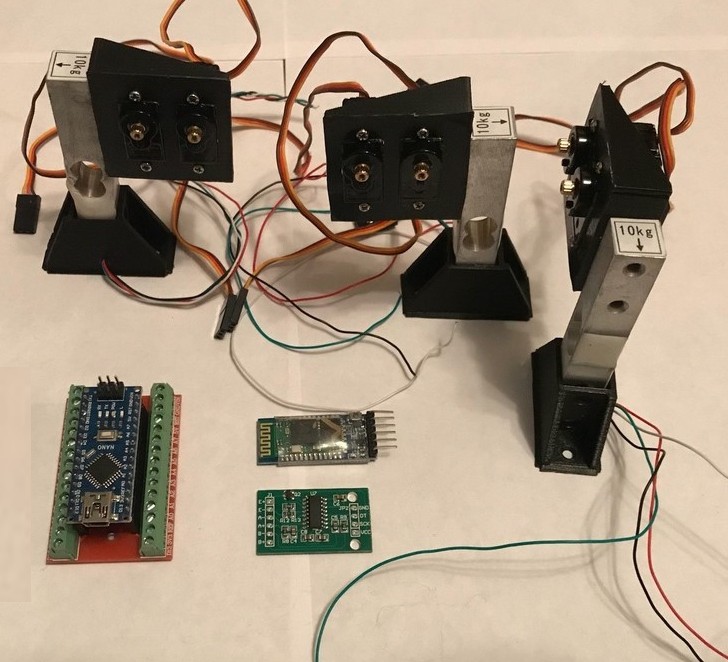

3Schematics

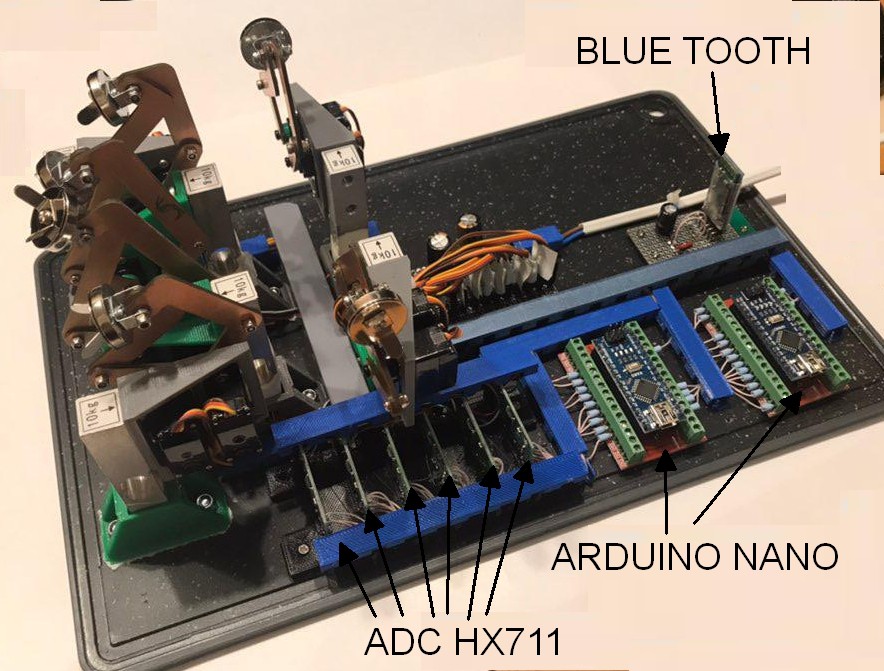

Schematics consists of two parts - 12-servo controller and differential dynamometer. For connection can be used USB or BT interface.

![]()

![]()

-

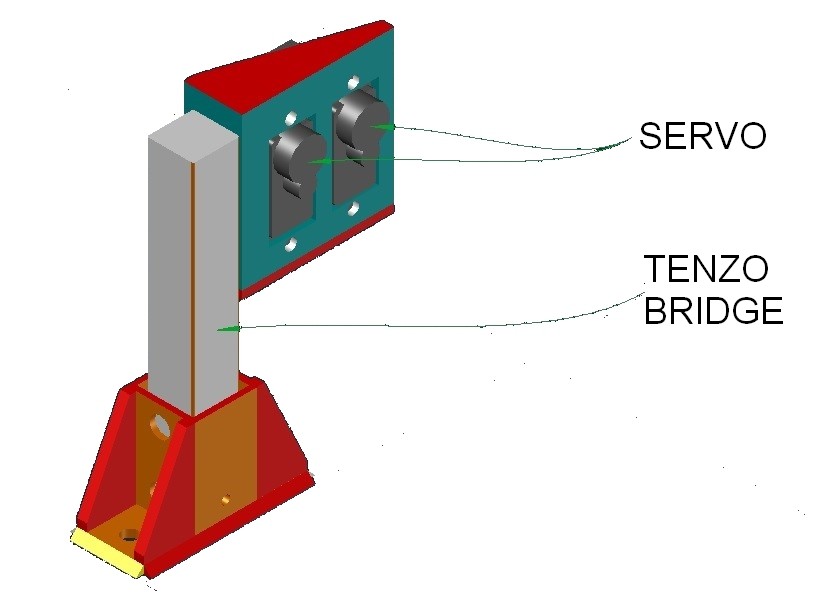

4Mechanics

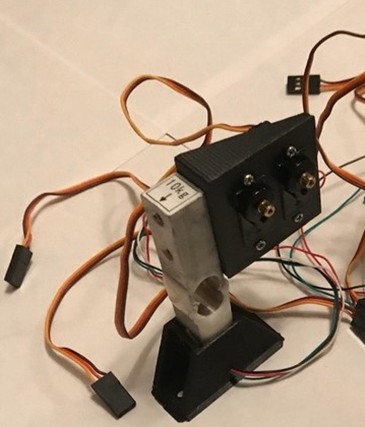

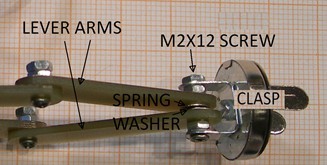

We use the simplest analogue servo. You can use any kind of servos. The bases, lever arms are shown in a figure:

![]()

![]()

![]()

![]()

-

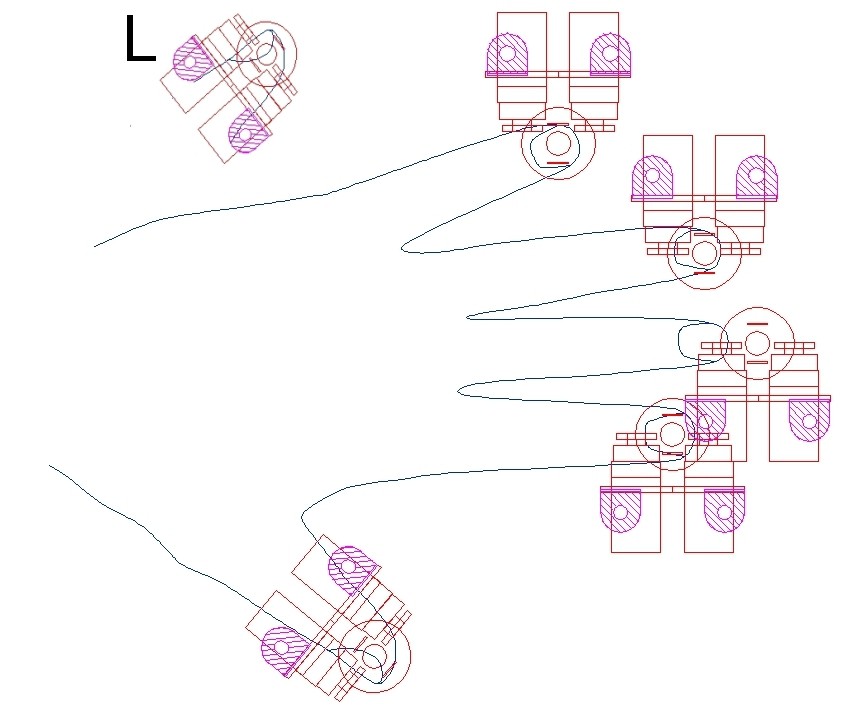

5Breadboard and Blocks

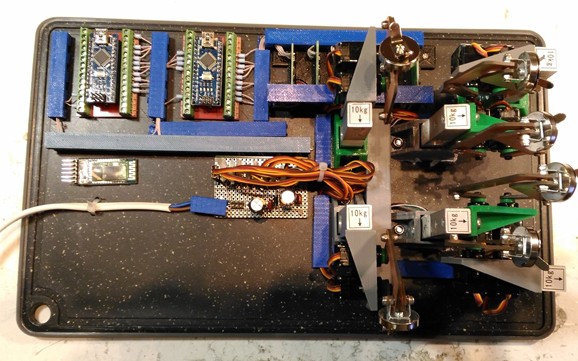

We took plastic breadboard and install 6 blocks on it, for example it is left hand drawing, L – for the right hand.

![]()

The size of components are defined by the servo in use. We made all drawings for Servo mini SG90 9g Tower Pro. Here is one block

![]()

We use 3/4-inch size Magnetic Button Clasp Snaps. It is screwed with two node lever arms so it can be rotated.

![]()

Here You can see the breadboard with installed blocks and fully assembled

![]()

![]()

-

6Programming

Program code is Arduino IDE compatible. You can download code from git hab https://github.com/DrOnkel/ReHabJr or Hackaday project file section.

BuildInstruction2.pdf This instruction

DifDinLCD.ino Arduino code for Diffirential Dynamometer controller

Dinamometr_Schematics.jpg Add files via upload 6 days ago

ServoMotorsSchematics.jpg Add files via upload 6 days ago

ServoRehab01.ino Arduino code for servo controller, USB control version

ServoRehab_i_06.ino Arduino code for servo controller, BT control version

Download the program to Your Arduino Nano using Arduino IDE. You can download it from arduino.cc .

The movement is defined by arrays MassX[8][2]. It contains 8 main points of finger base path. The movement between main points is calculated using linear interpolation. The full review of program code is in Program instruction.

-

7External Box and Hand Holder

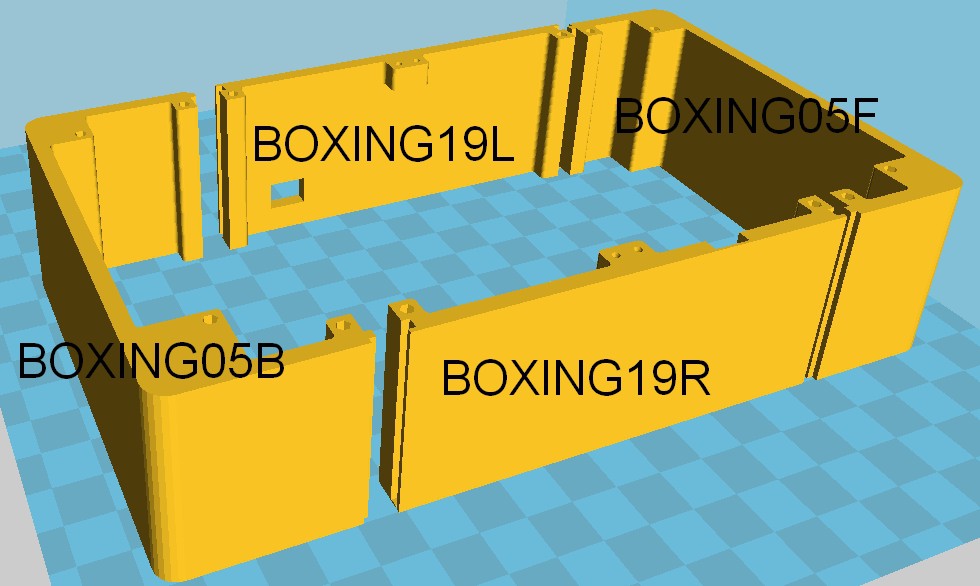

We construct 3d box for 3d printer. The box is bigger than 3d printer base and we devide the component by 2 or 3 parts. Here is 4 side parts of box

![]()

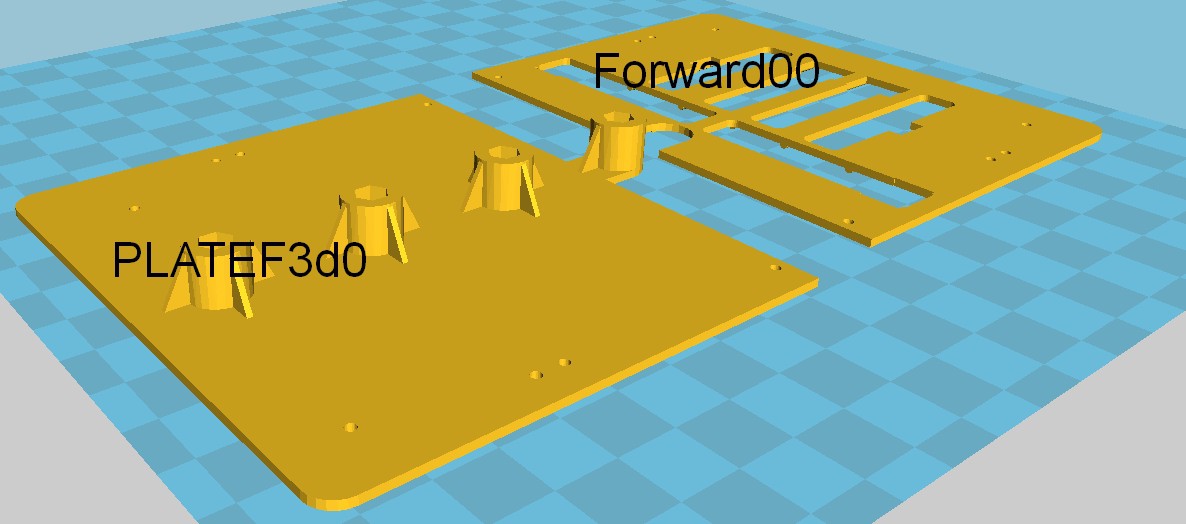

Here is top deck, we connect it to the sides of the box

![]()

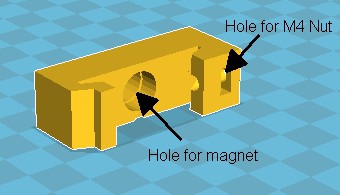

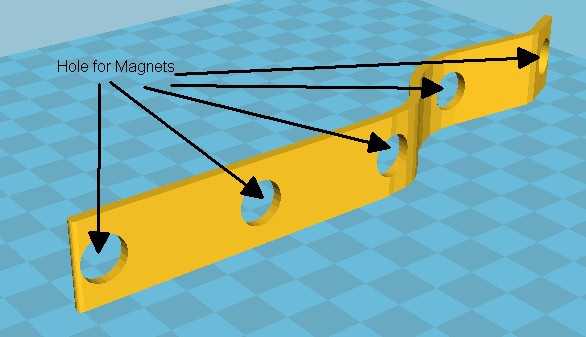

We hold the parts together. We use plastic DIN- rail (1) and magne holders (2)

![]()

-

8Hand Holder

Part 2 contains magnet for attaching hand holder with magnets too

![]()

![]()

We install this plate with magnets into han holder

![]()

![]()

![]()

![]()

-

9It works

![]()

ReHubJr Rehabilitation Helper

The open source 6- channel massage and differential dynamometer rehabilitation devise can be used for Post Stroke spasticity rehabilitation.

Sergei V. Bogdanov

Sergei V. Bogdanov

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.