With the motion sensor selected, it’s time to think more about the overall design of the transmitter (TX).

It might seem strange, but for a lot of projects, and certainly this one, the design actually starts from the battery. After all, the battery dictates a majority of space , and careful consideration about the chemistry, shape, and capacity is needed in order to achieve the best balance between cost, performance, and manufacturability.

Broadly, we have rechargeable and single-use batteries. Obviously for this application we want the TX unit to be rechargeable so the user doesn’t have to swap batteries all the time.

And for rechargeable batteries, popular ones include Nickel-based such as NiCD and NiMH. The former is very toxic, and both only provide 1.2V per cell. So that means for a 3.3V system, either a step-up converter or multiple cells are needed, not good for the cost.

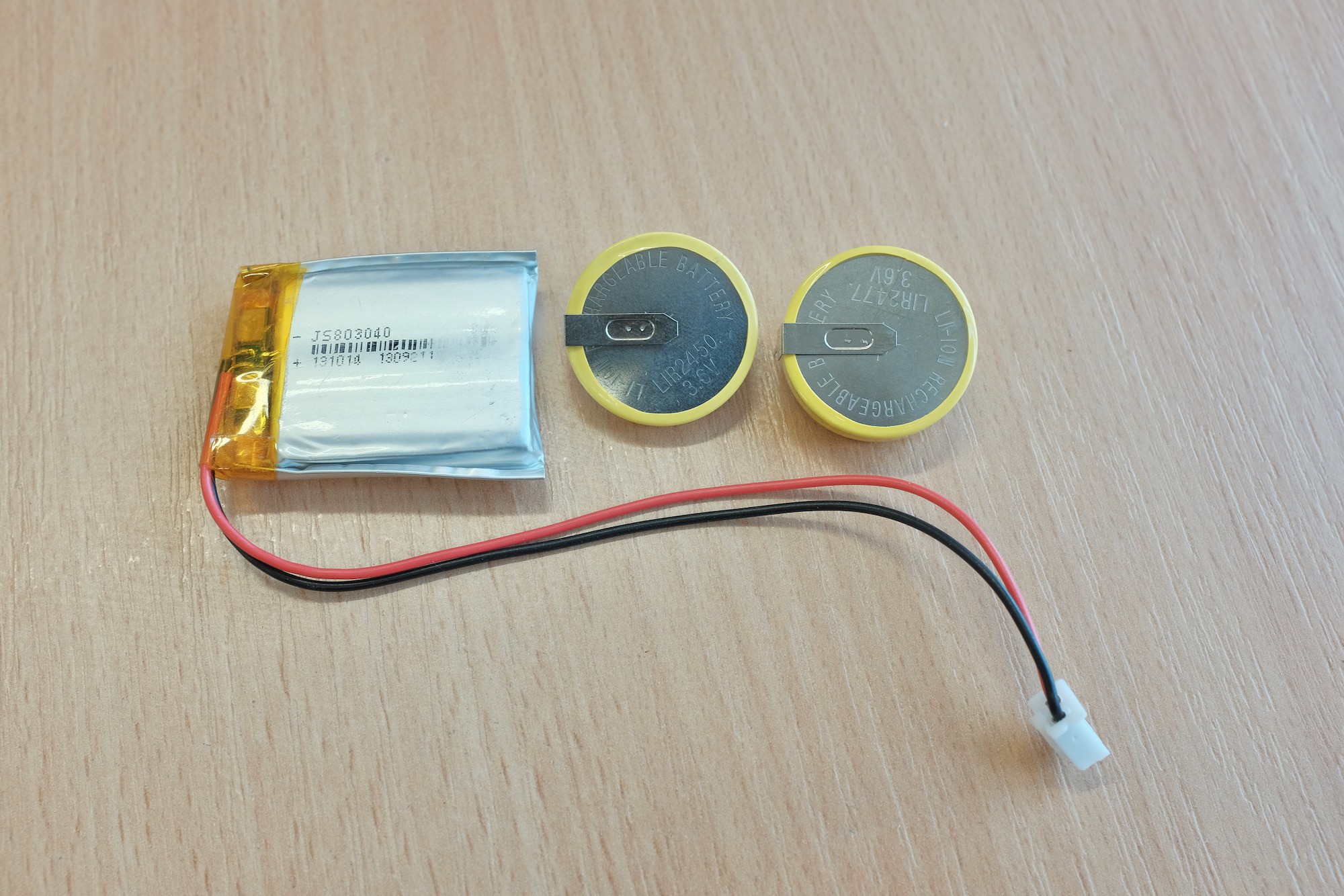

And so we come to our old friend LiPo battery. Used from everything from smartphones to drones, they are available in a massive selection of shapes and capacities. I spent hours going through listings on ebay aliexpress, and ended up with two contesters. Coin-battery or a small LiPo pouch cell:

The pouch comes in a number of difference sizes, the one I have is 500mAh but there are some smaller ones around 200mAh. The coin cell comes in two sizes, LIR2450 and LIR2477, both have the same diameter but the latter is thicker. As a result LIR2450 has a typical capacity of 100mAh while LIR2477 has 150mAh.

The pouch cell seems to be more space-efficient, since it doesn’t have the metal enclosure of the coin battery. On the other hand, it does mean it is more prone to accidental damage such as crush and puncture. And for a small production run of a few hundreds, securing the battery will involve either making a proper enclosure with a battery compartment, or using adhesive to fix it to the circuit board, neither are unnecessary complexities. Additionally, the two battery terminals will need to be either soldered or mated with a connector. Former is a bit of extra work, latter adds cost and takes up valuable space on the circuit board. Plus, two battery wires dangling isn’t a neat sight to behold.

That’s where the coin cells starts to shine. The metal shell means it’s stronger and less likely to break, and since I managed to find some with attached pins, it is much easier to solder, eliminating the use of a connector and dangling wires. The spacing between the terminals also leaves an ideal amount of PCB real estate for components. Meaning the finished product will have a clean and professional look.

dekuNukem

dekuNukem

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.