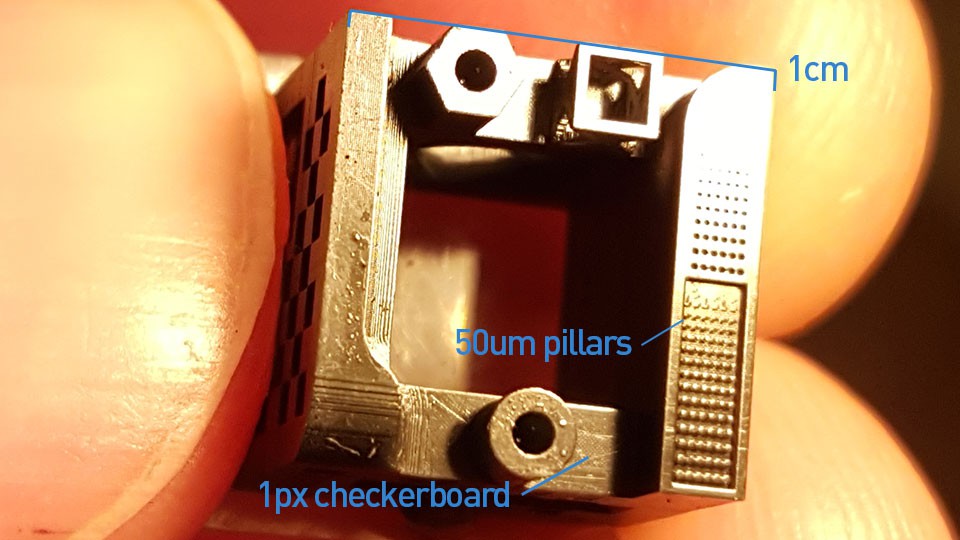

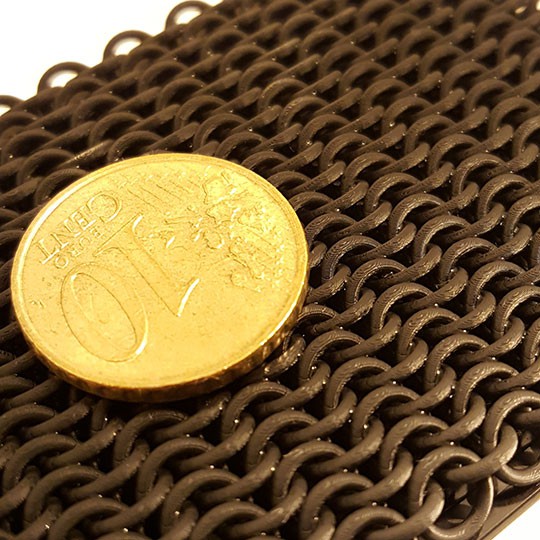

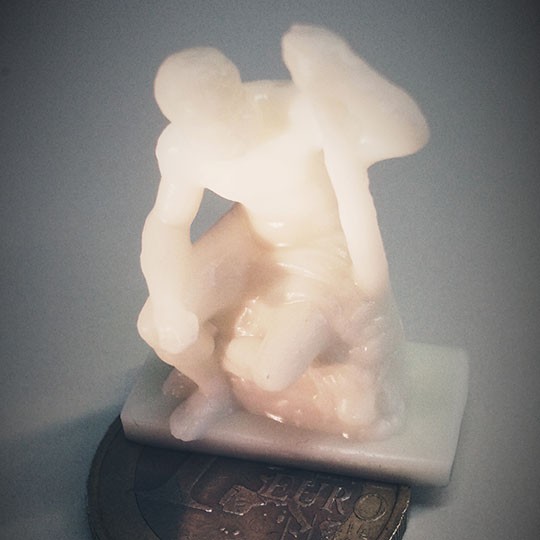

There are lots of cheap SLA printers out there but in this project I was trying to go primarily for quality of the resulting prints. Of course the budget was not unlimited but since some people pay thousands of dollars for other hobbies I figured it's worth a shot.

So here we go.

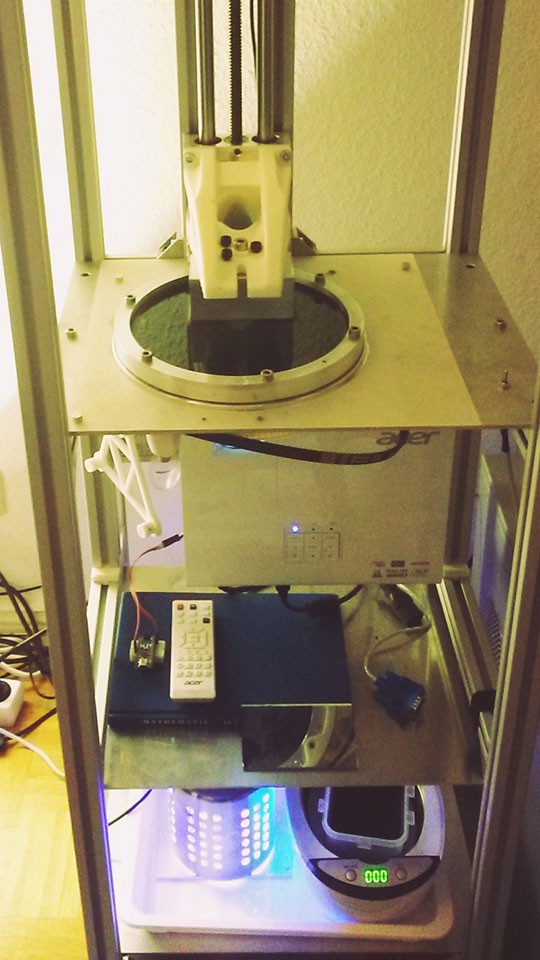

I've been going through several iterations over the last few Years. I first started with an ACER H6510BD Home Cinema Projector and Windows based Creation Workshop as the control software. Also the first iteration used a Sanguinololu as Motor controller.

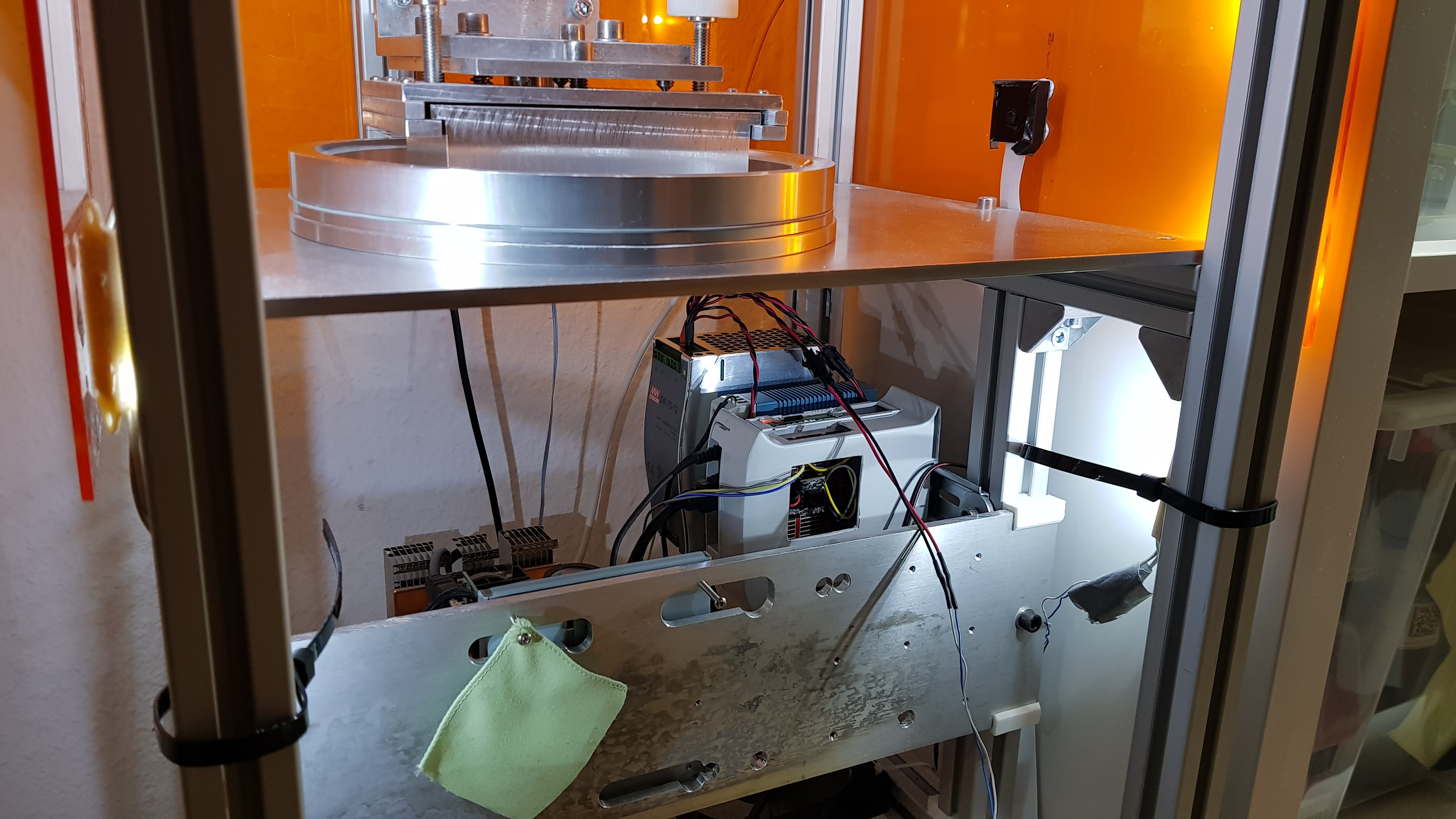

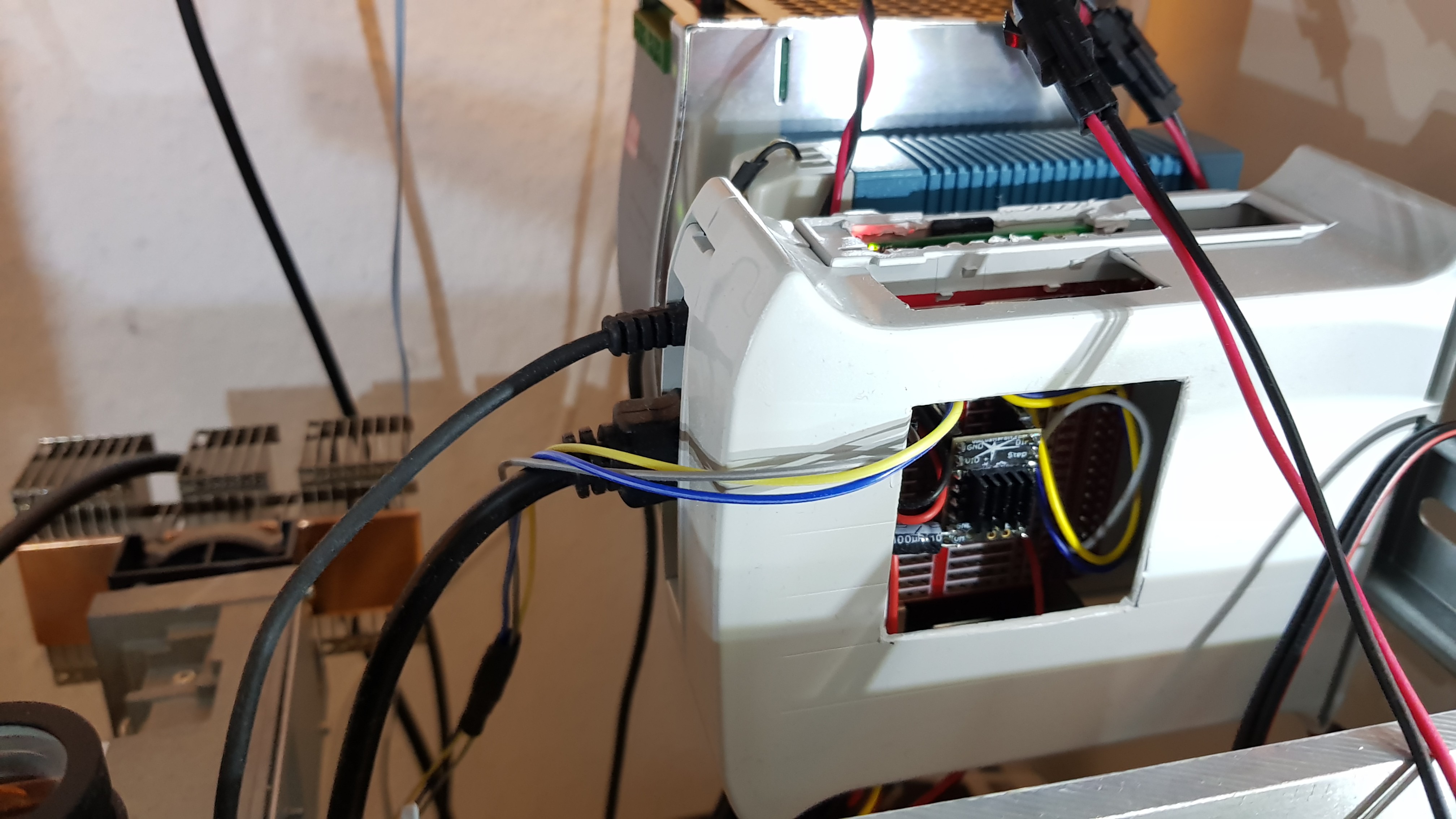

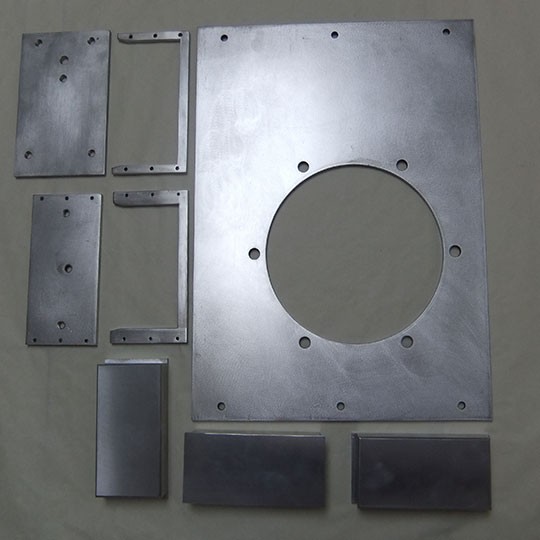

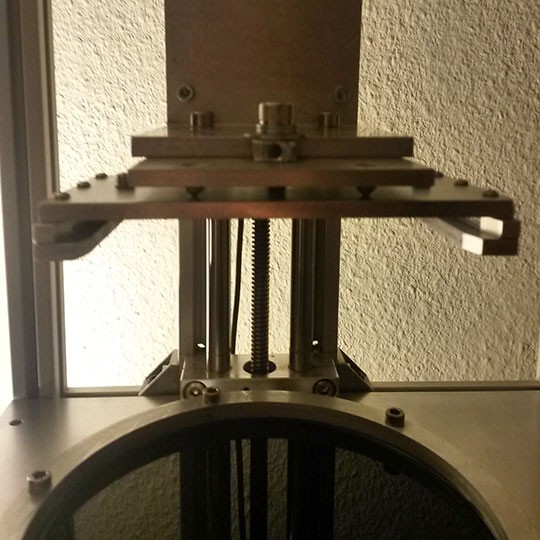

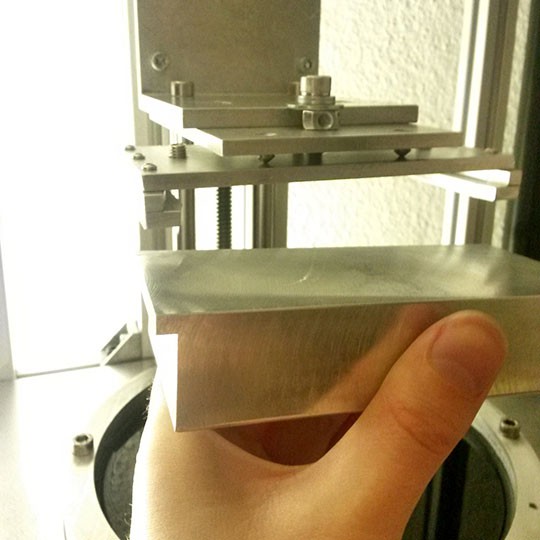

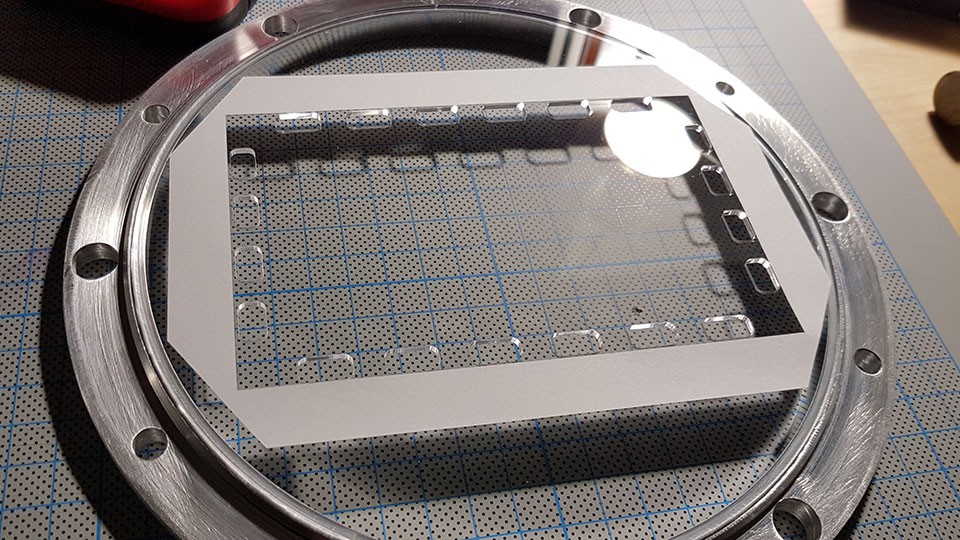

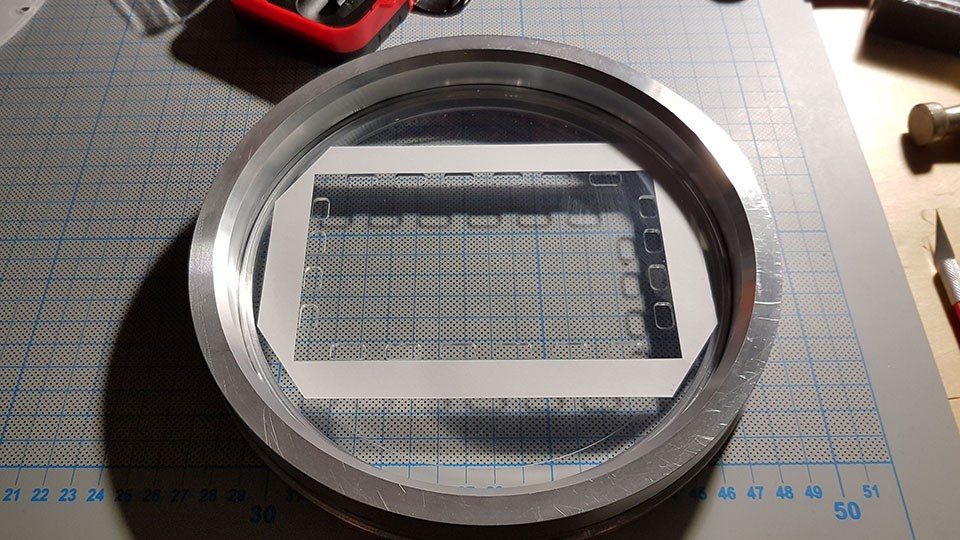

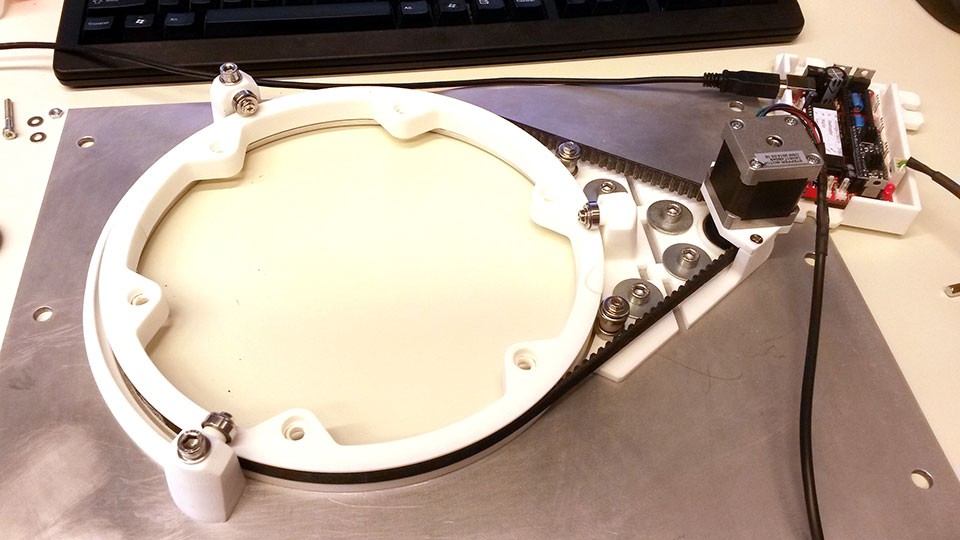

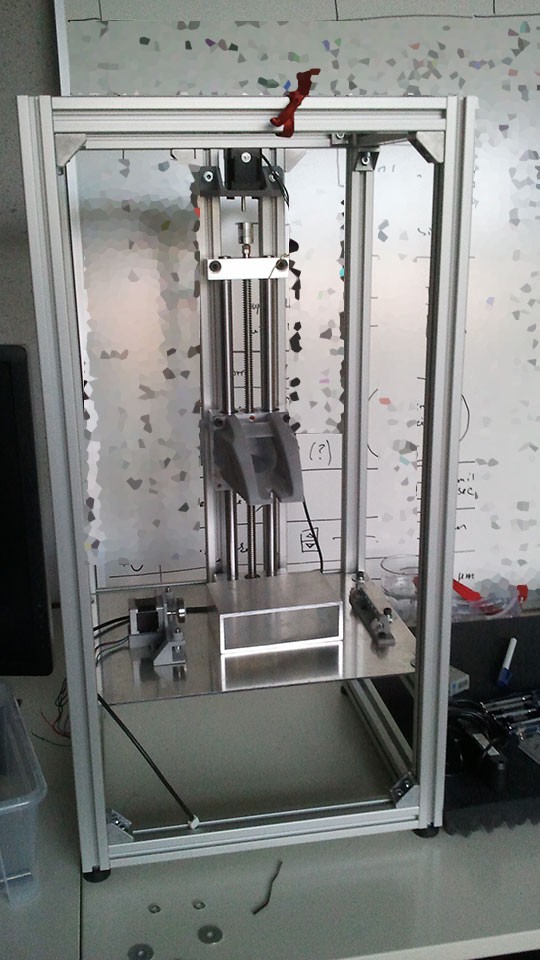

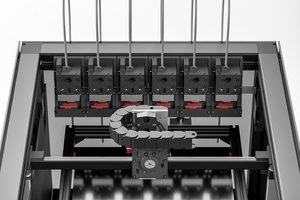

At this step all electronics have been replaced by better performing/optimized stuff and most 3D printed parts by machined parts:

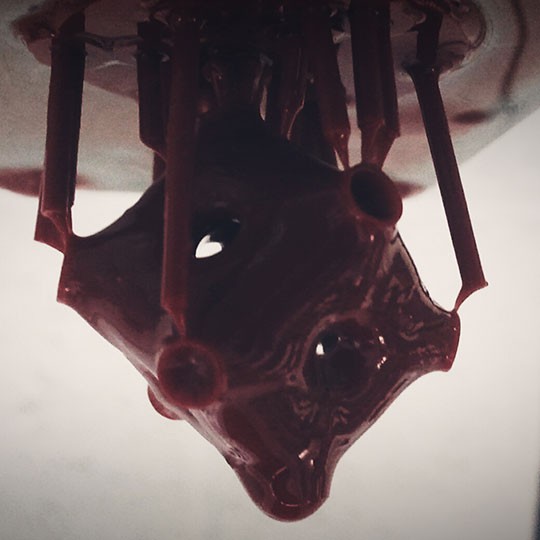

- Professional UV DLP Light Engine (1080p)

- Raspberry Pi 3 with NanoDLP

- Trinamic stepper controller

Szabolcs Lőrincz

Szabolcs Lőrincz

alexwhittemore

alexwhittemore

Joseph Marlin

Joseph Marlin

Marc Schömann

Marc Schömann