I planned to build a midi harp (cheaper, no need to tune it and intersting project).

It will be made with composite material but wood is used for now, till I get the final hardware configuration.

I want to keep the touch for the harpist, so I didn't want to use touchless strings (like laser ones).

I wanted to use both string strengh and capacitive touch. I was wrong with capacitive touch ( 10 times much to get a reading compared to analog reading and 99 % efficiency (not enough !!! ) so I gave up with this.

I used piano strings first (because I needed conductive string for capacitive touch) but they were not smooth enough. I went on guitar strings (painted with silver to improove conduction : useless now). I think the project will work with nylon strings.

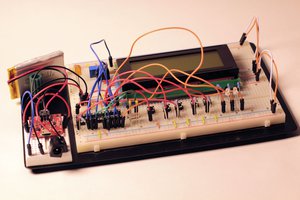

The project is powered with powerbank, I want it to be autonomous.

From a software point of view on arduino : The code is not very long but I spend a lot of time on it (smoothing signal from amplifier, analysing strenght curves to know when to trigger midi events, etc.).

Some work also on string strenght. In other words, how to keep the harpist touch (i.e. the more the string is pinched hard, the more the sound is loud even if physical string tune has changed during the night).

Next step is to build pedals : not a big deal from a technical point of view, but I have to find time to achieve it.

James Kingsbery

James Kingsbery

The Feature Creep

The Feature Creep

Myrijam

Myrijam

Mike Szczys

Mike Szczys

I’m in the planning stages of building a cimbalom-style (https://en.wikipedia.org/wiki/Cimbalom) MIDI controller, and your approach looks like the best one I’ve seen. Like the harp, the cimbalom doesn’t need pitch detection, just amplitude. Unlike the harp, cimbalom strings are played on both sides of the bridge, so I would need double the sensors. Since strings are struck with hammers, a heavier string might be OK. Any idea how much tension the strain gauges can withstand?