I designed and began testing the next version of the kinematic laser mounts. I took a few components from the previous design and started brainstorming modifications. I decided to attach the flexible mount to the rear component holding the screws instead of requiring a front component. This greatly reduces the size of the module.

Initially I designed the flexible part that could be 3d printing, which I think would be easier to get working. I completed the part and soon after getting the 3d printer ready, I started to reconsider. The whole goal was to make the second prototype easier to manufacture and 3D printing 12 flexible parts for each harp was going to take a lot more time than the first prototype. I went back to the drawing board and came up with a design to test.

3D printed design idea

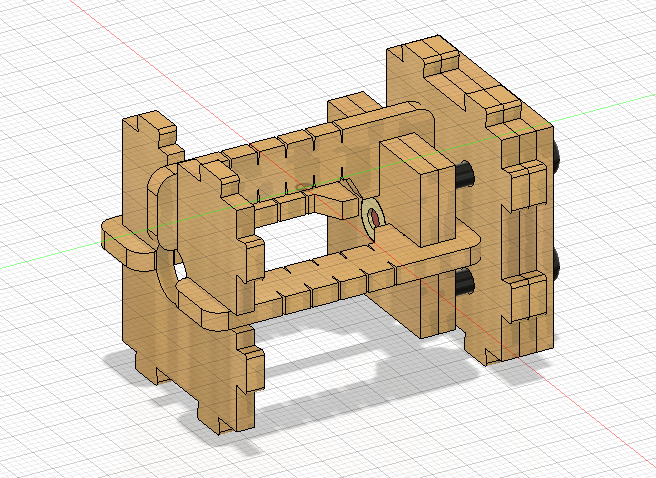

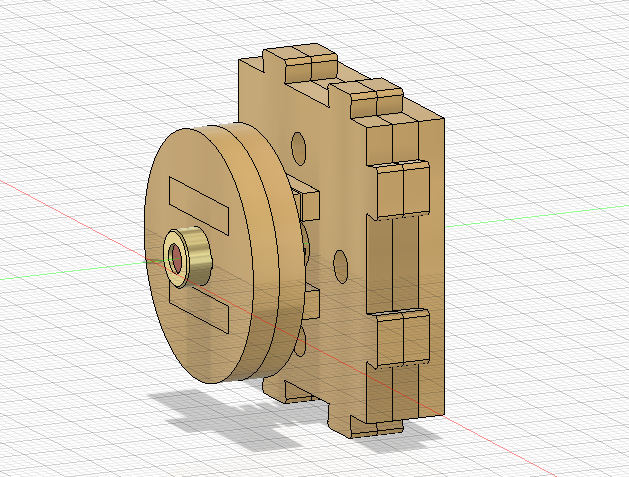

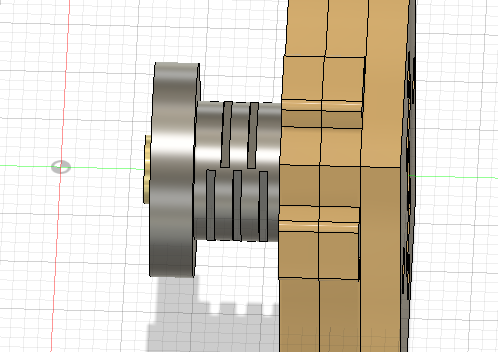

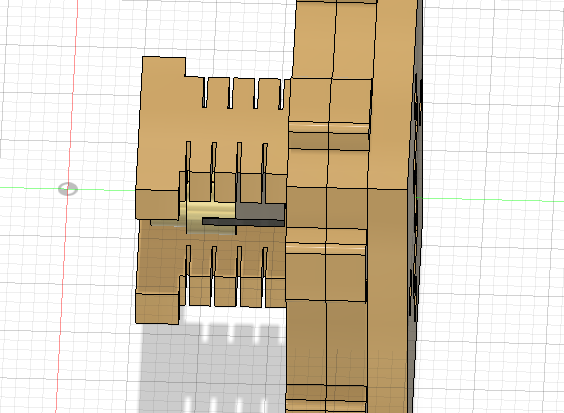

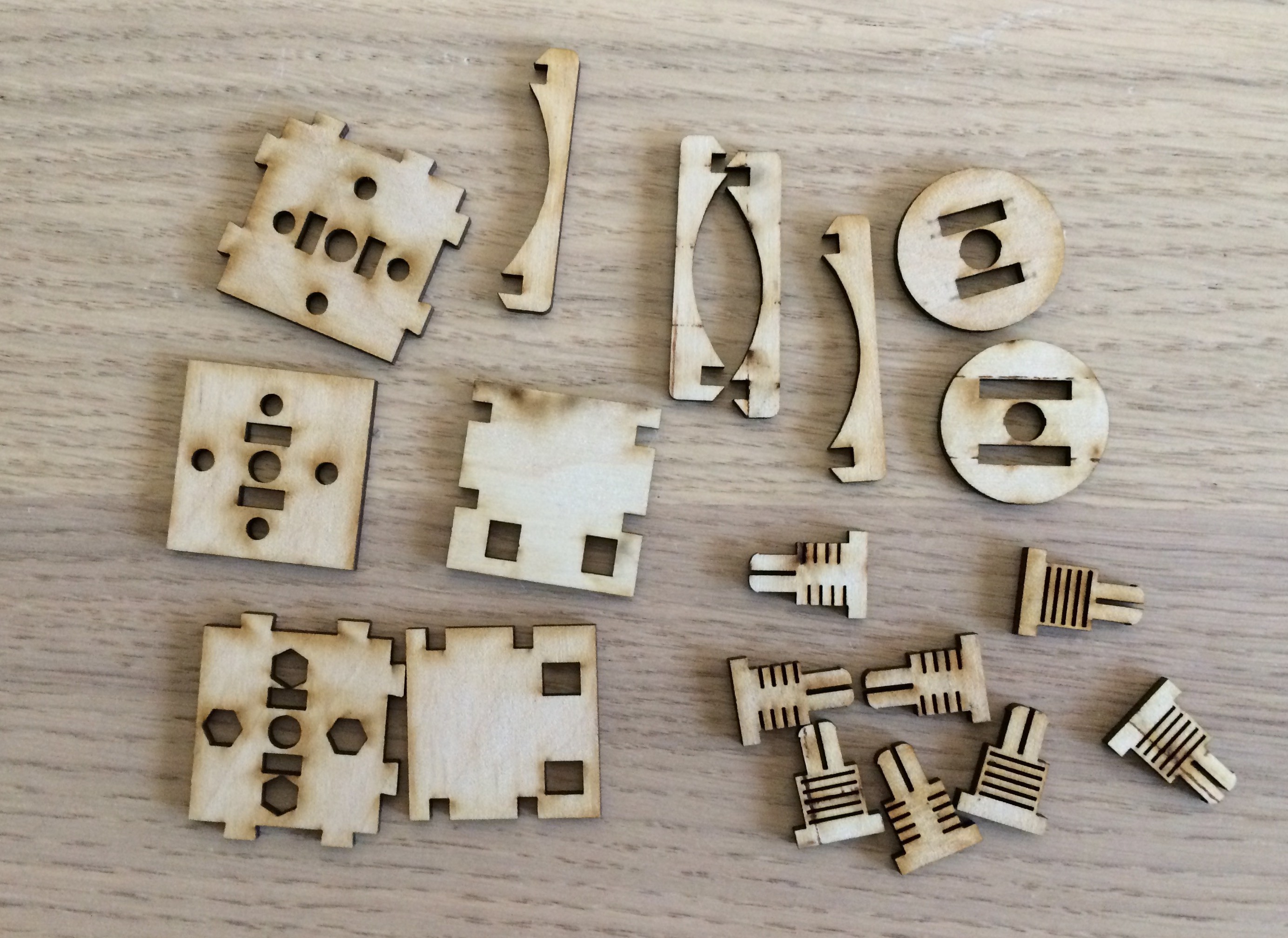

Lasercutting design idea:

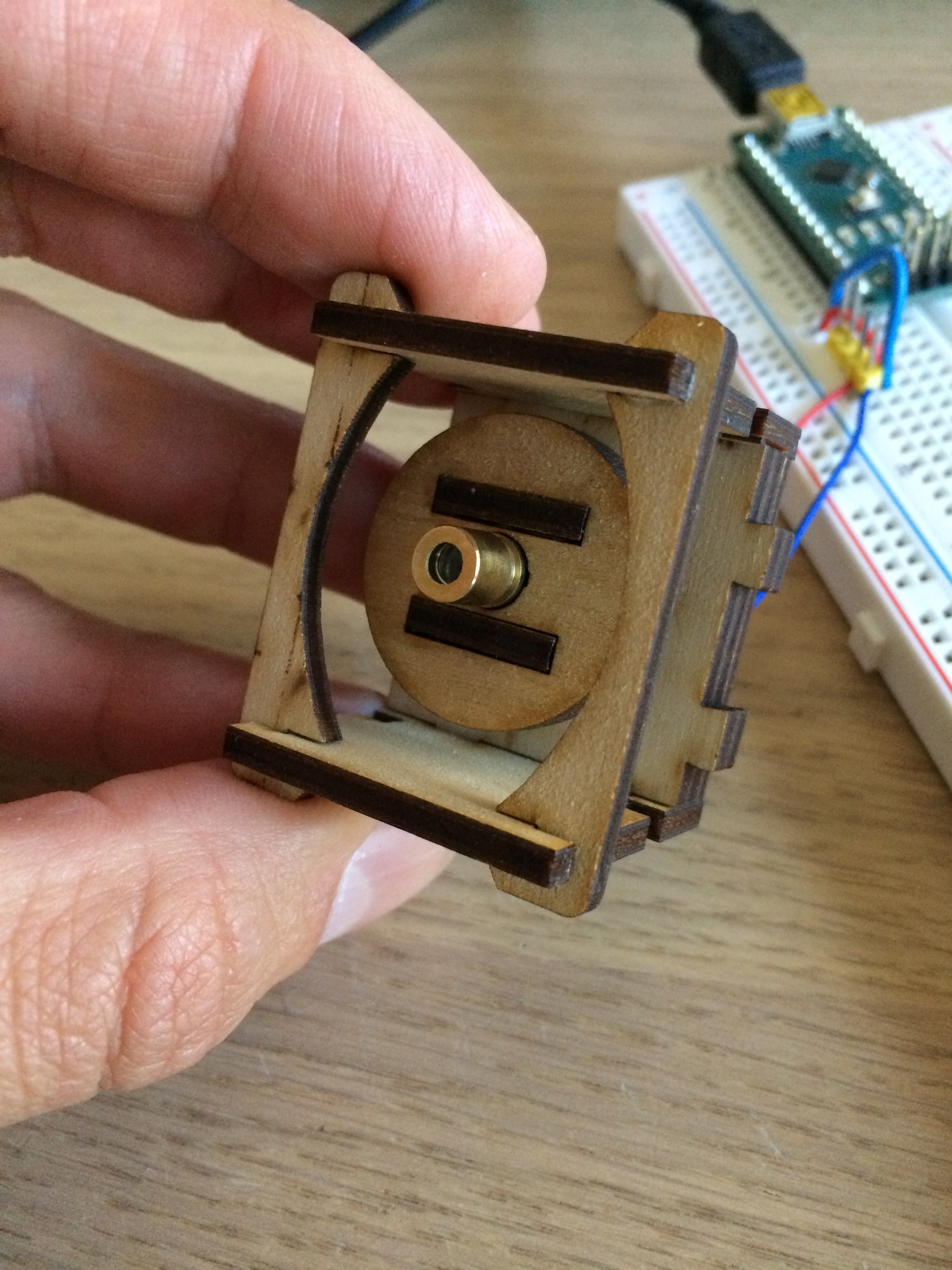

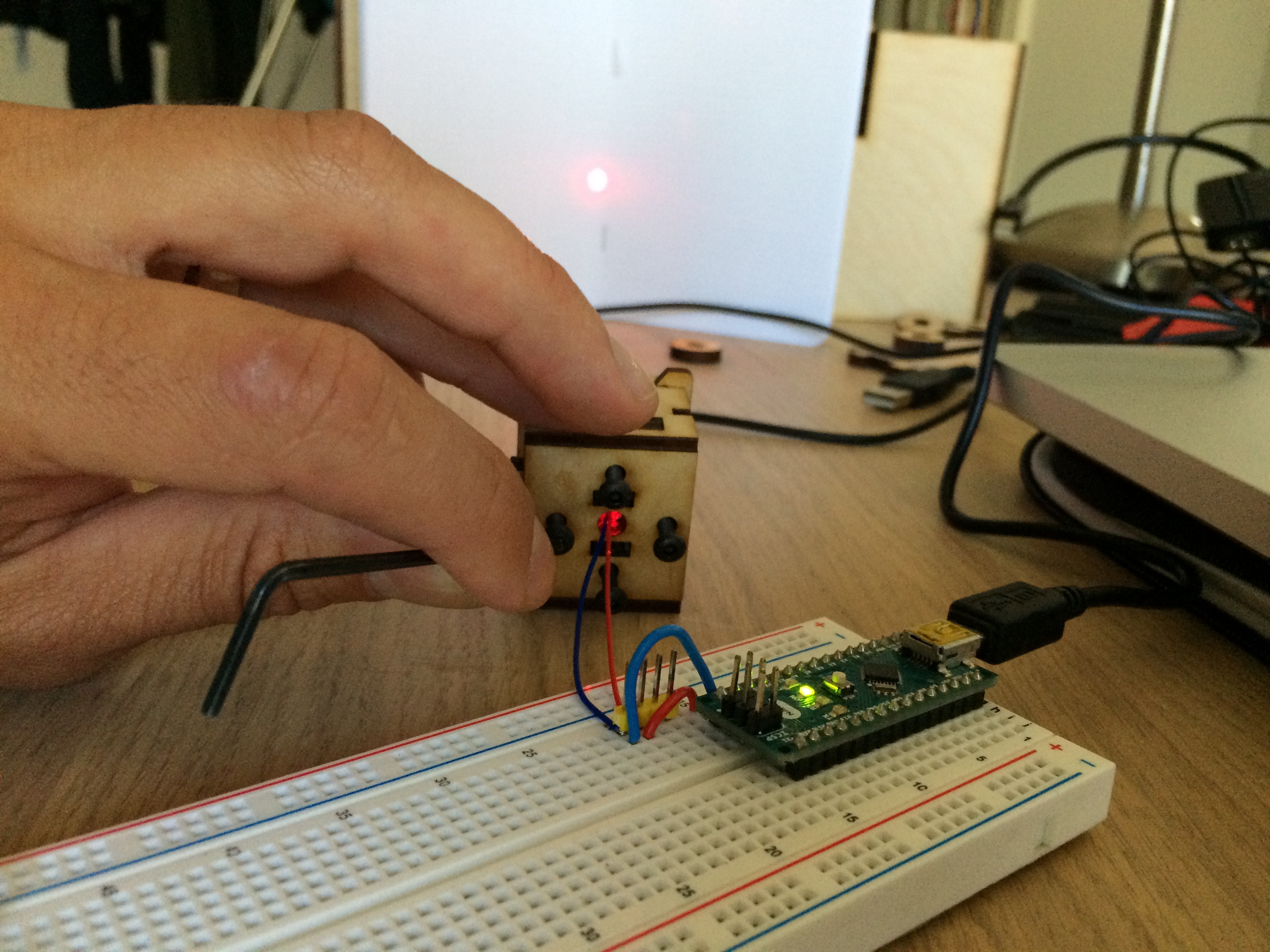

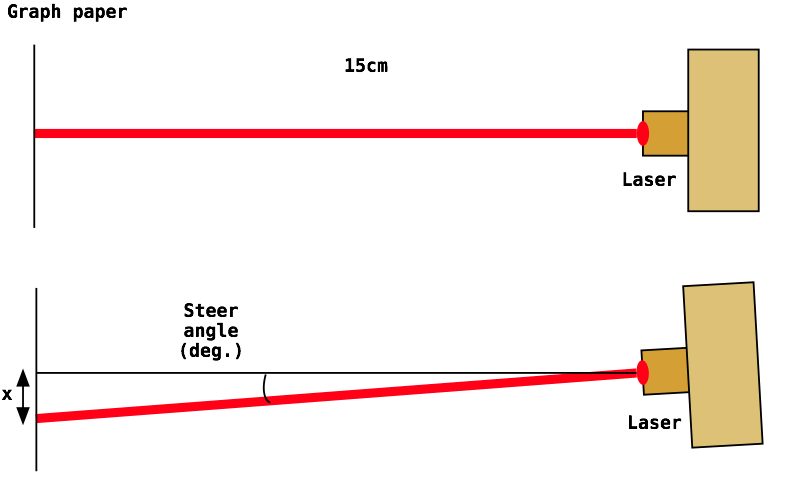

After finalizing the design, I laser cut the parts and put together a small test assembly. I then tested the alignment range (i.e. the angle the laser can be steered out of the mount) by placing graph paper 15cm from the laser mount.

By calculating the displacement of the beam on the graph paper, I can calculate the steer angle. The steer angle helps me to figure out if the mount is working well enough because I know roughly what is required for the laser harp. Here is a diagram showing the calculation.

I am able to adjust the beam around +/-4degrees in one direction and +/-1.5degrees in the other direction. I am getting close with this mount, but I need to make a few more tweaks before making a bigger test. Once I am happy with the mount, I will build up a layer and test it.

Jonathan Bumstead

Jonathan Bumstead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.