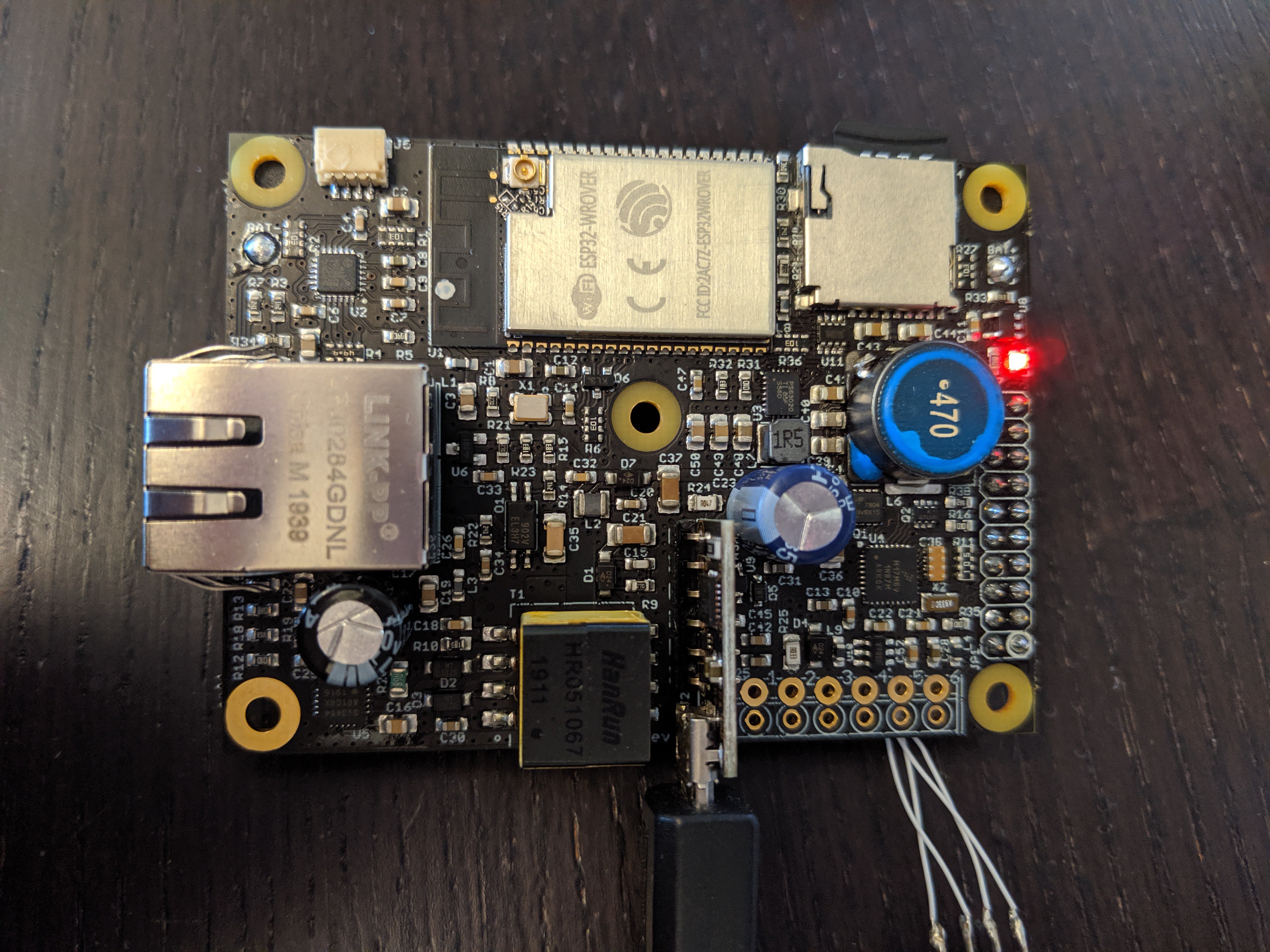

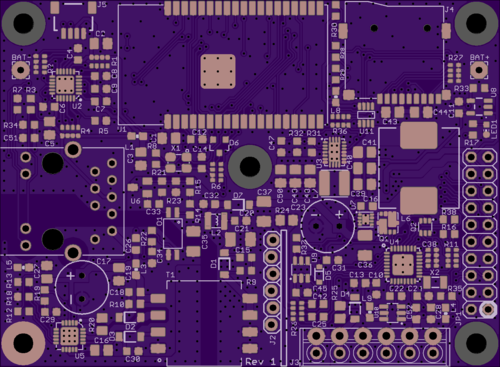

The design as implemented from the original idea has the following features:

Processing system

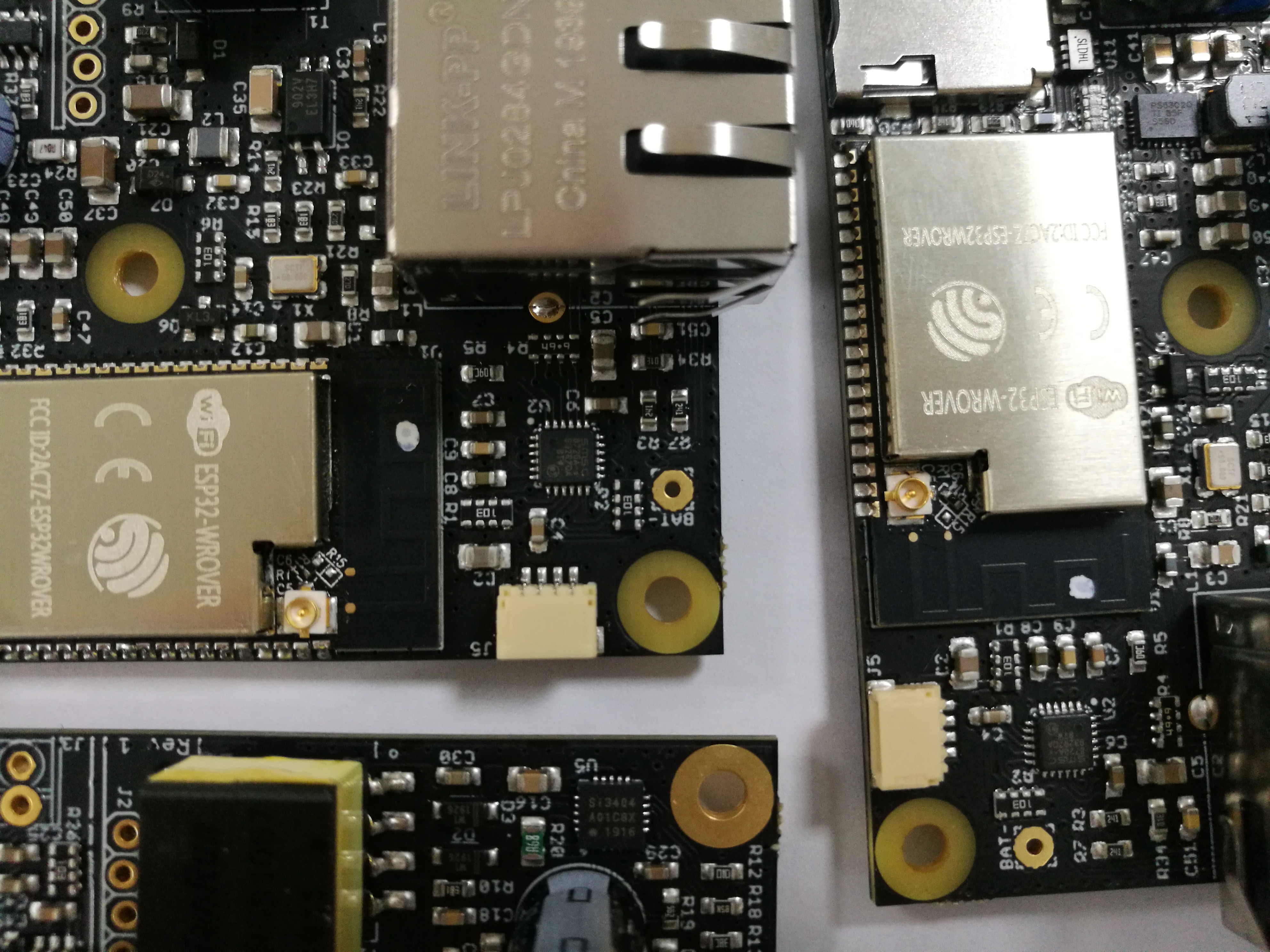

- ESP32-WROVER-I module with 4 MB Flash, 8MB PSRAM and external U.FL antenna connection

- Micro SD card slot for data storage

- Separate NXP MKL17Z32VFM4 ARM Cortex-M0+ charge / system controller allowing ultra low power sleep with various wake events including RTC

- Charge / system controller fully configurable by ESP32 over I²C bus

Power

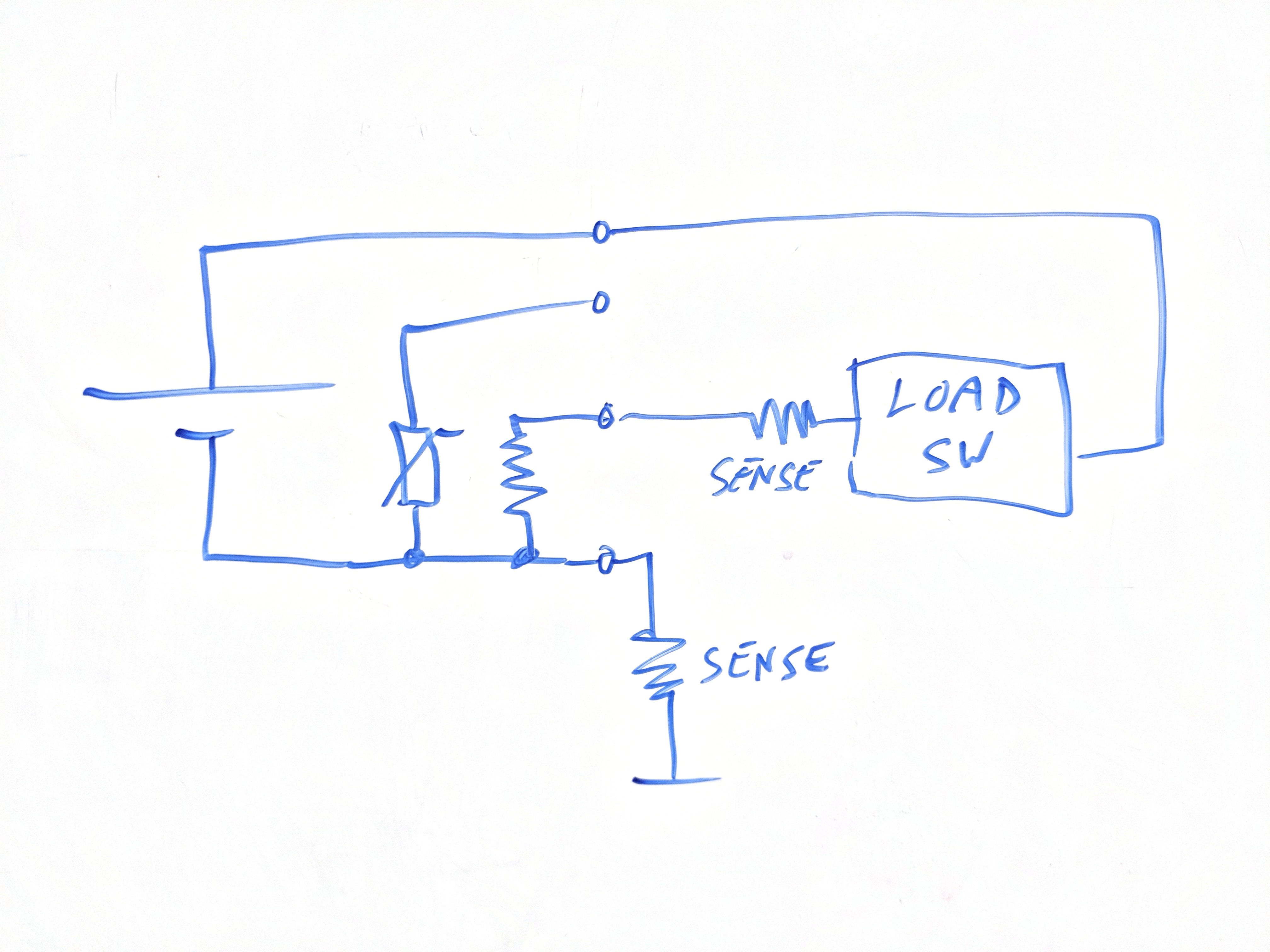

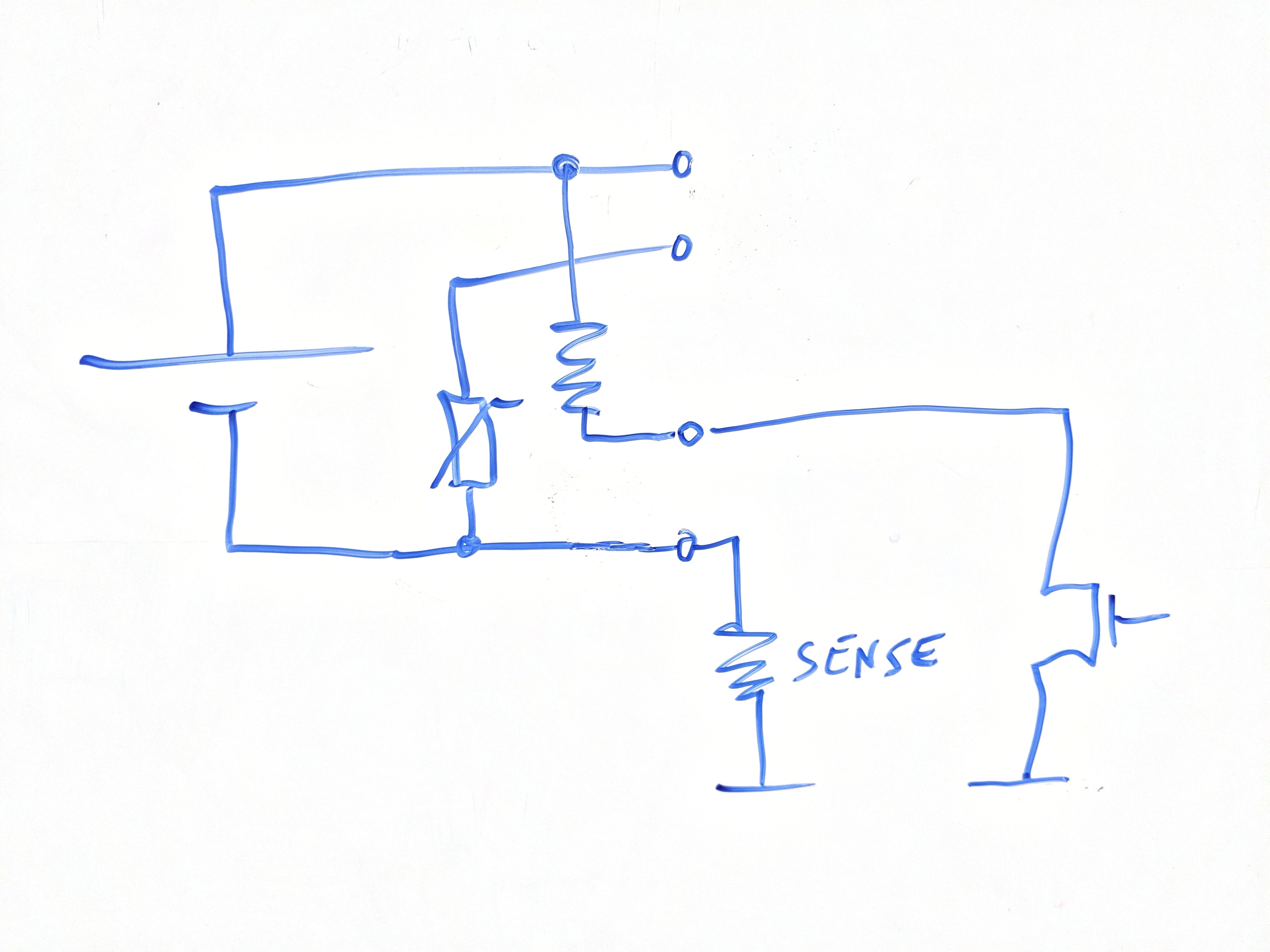

- Battery-backed: either by LiFePO4 cell or Lithium Titanate (LTO) cell for highest reliability due to predictable power on/off behavior and buffering of erratic input power

- Long life with typically 2000+ cycles at 100% DoD when used with LiFePO4 cell

- Extremely long life with typically 10000+ cycles at 100% DoD when used with LTO cell

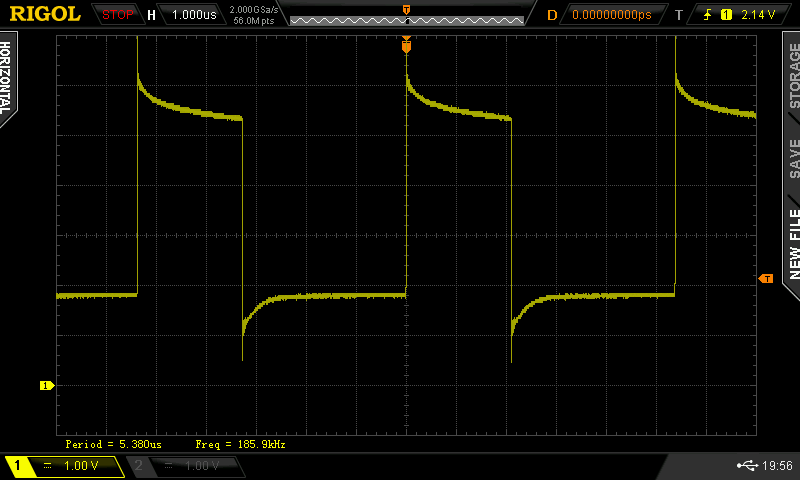

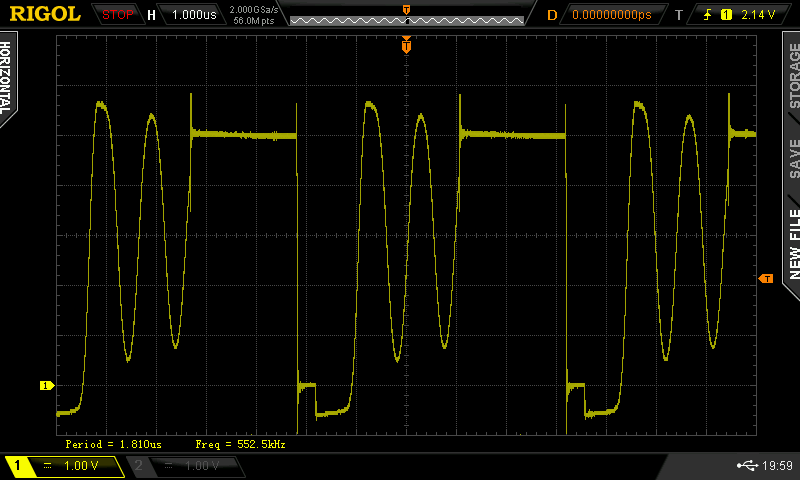

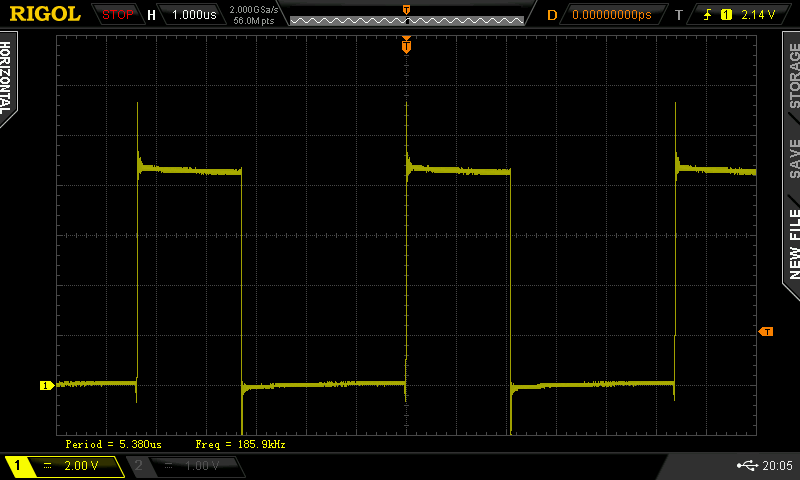

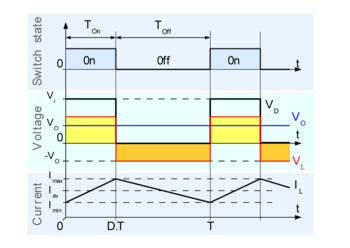

- MPPT charger to efficiently extract the most energy from a connected external power source

- Convenient battery and external power connection with screw terminal block

- On-board 18650 battery option

- External power option DC 5V - 30V

- External power option solar panel 5V - 30V

- External power option micro USB 5V through optional wESP32-Prog module

- External power option isolated Power over Ethernet IEEE 802.3af

- OR'ed external power inputs can be present simultaneously

- Integrated buck-boost to provide regulated 3.3V to the ESP32 system

Connectivity

- WiFi 802.11 b/g/n using external antenna connected to the U.FL

- Bluetooth 4.2 with Low Energy (BLE)

- 10/100 Mbit Ethernet

- GPIO header with UART, I²C, SPI, etc.

- Sparkfun Qwiic connector allows easy solder-free development using existing Qwiic modules

Physical

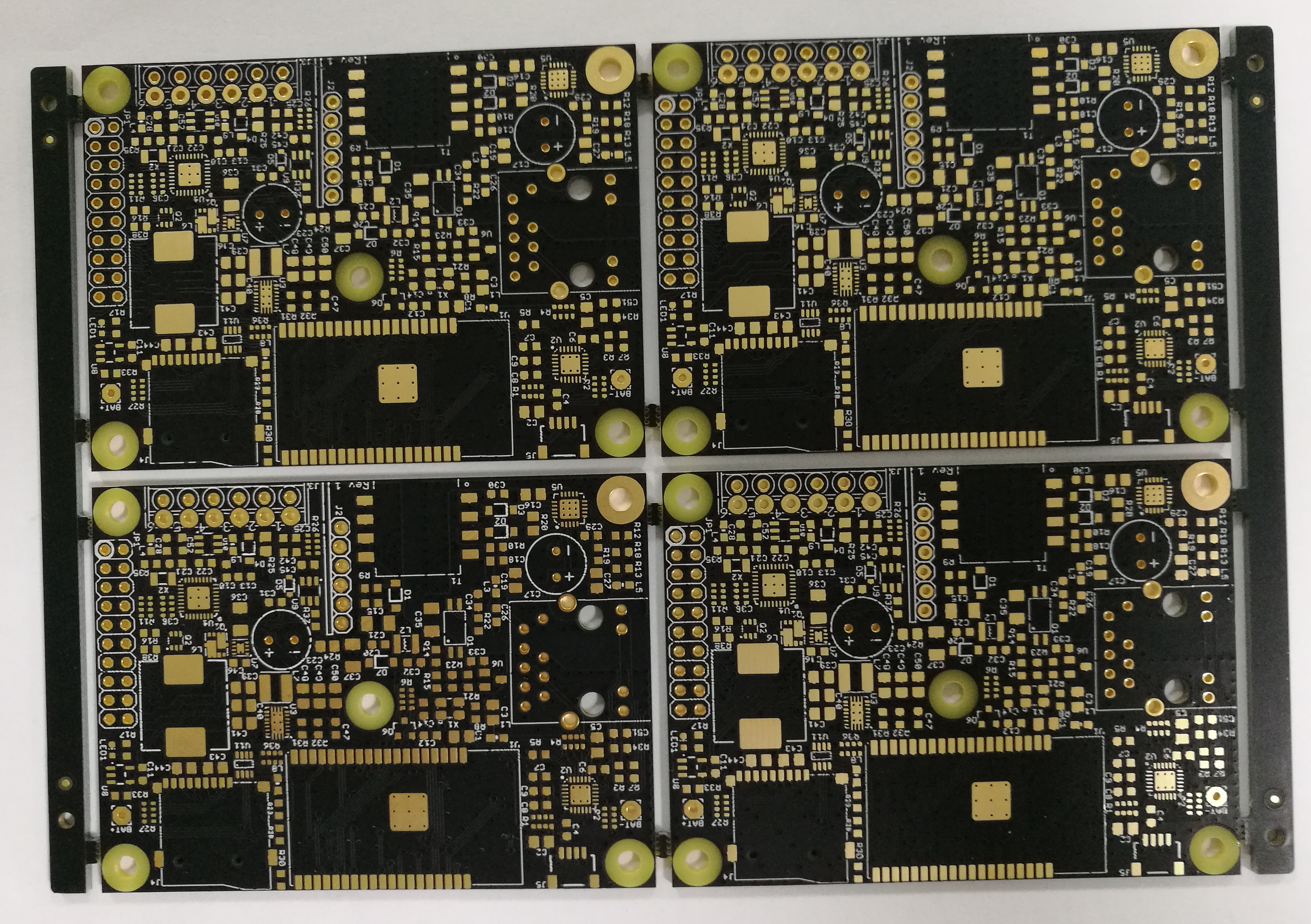

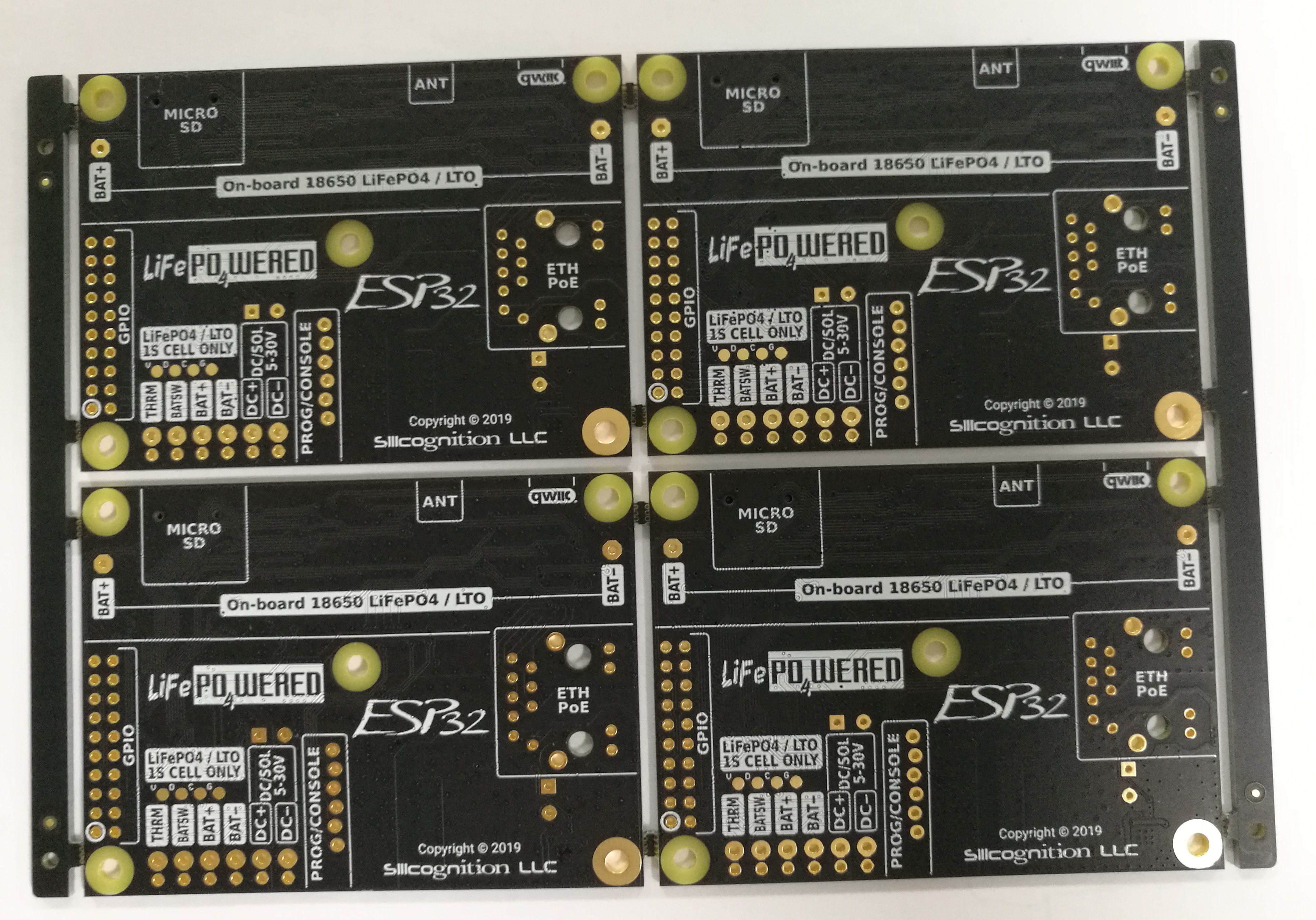

- Compact 75 mm x 55 mm PCB

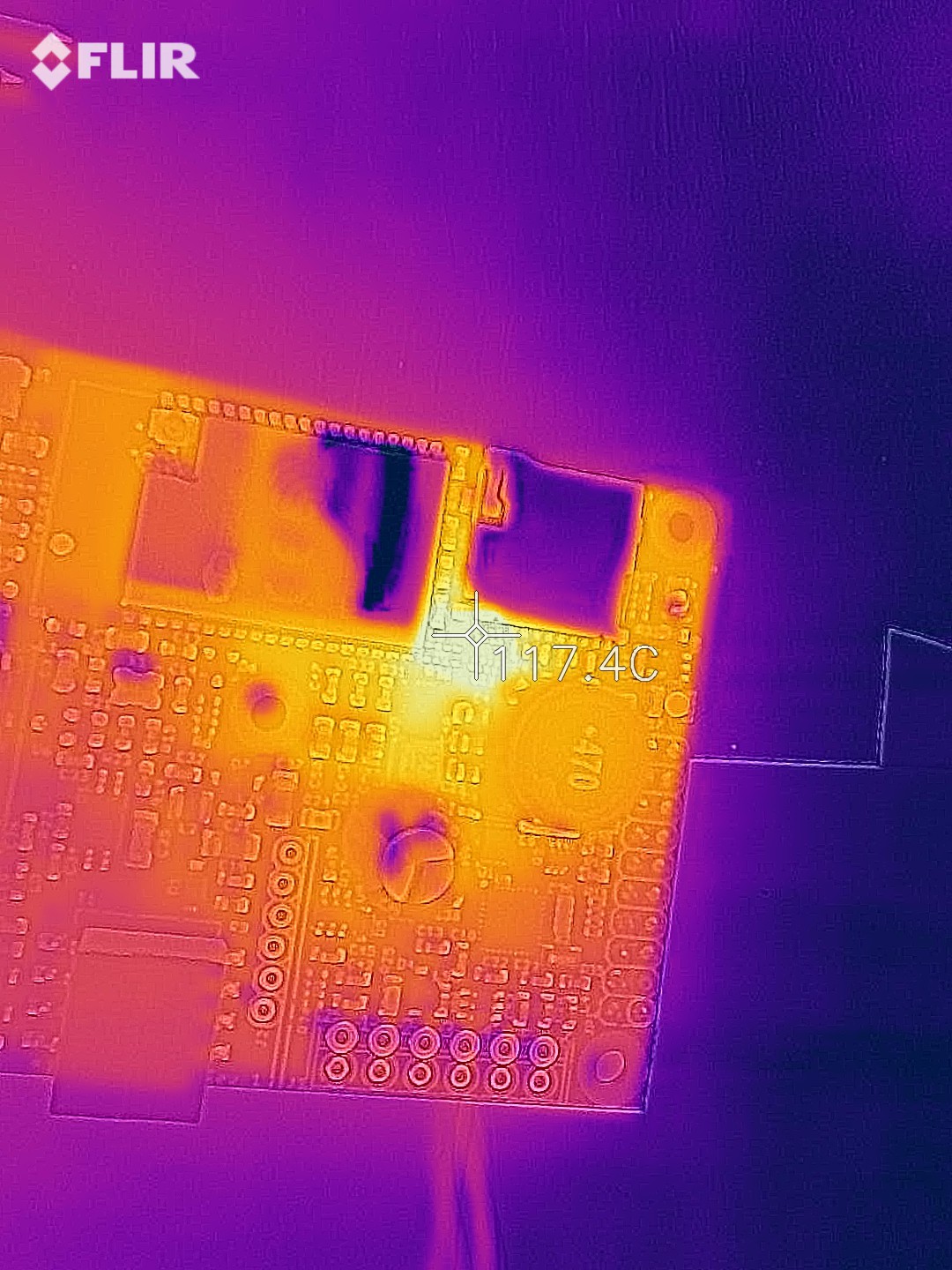

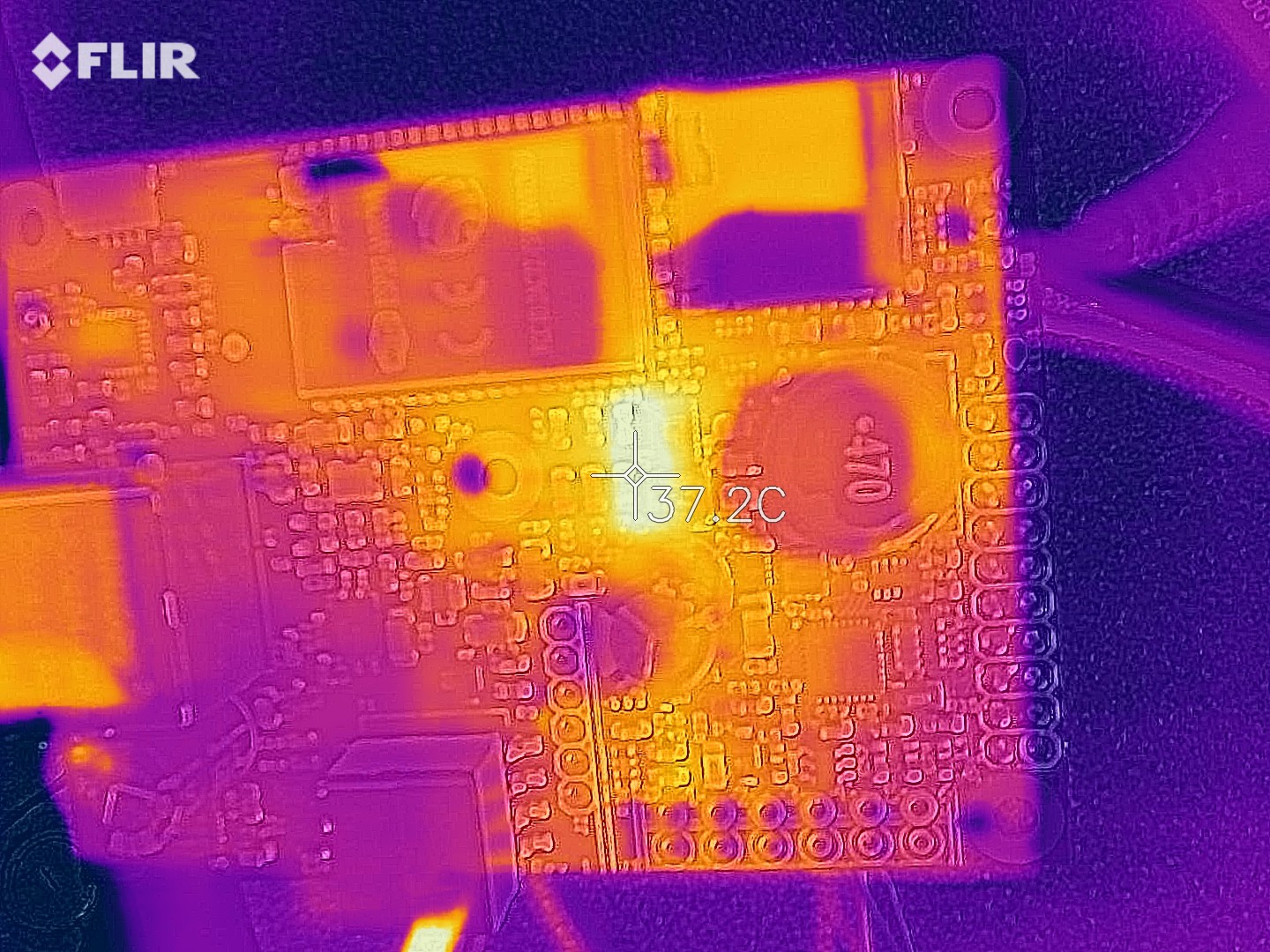

- Designed for wide -40°C ~ 85°C temperature range

- Battery heater option for charging LiFePO4 in cold temperatures (not needed for LTO)

Patrick Van Oosterwijck

Patrick Van Oosterwijck

David Scholten

David Scholten

Dan Julio

Dan Julio

This is an exciting project, I ESPecially like the use of LTO batteries to complement a Solar panel. Excellent! Were you able to get this board working? I'm trying to do something similar, minus the PoE, which I now want having seen yours!