The oven gives you a bunch of informative feedback over serial about its current operation. For example, here's the output from a reflow process:

Reflow Started

Profile Settings (1)

PreHt: 100°C, 80s

Heat: 180°C, 220s

Ref: 240°C, 30s

RefKp: 240°C, 30s

Cool: 50°C, 80s

Channel 0 PID Preheat

P: 50.28

I: 4.78

D: 166.72

Channel 1 PID Preheat

P: 96.98

I: 26.96

D: 210.38

Channel 0 PID Heat

P: 97.00

I: 25.97

D: 168.54

Channel 1 PID Heat

P: 44.30

I: 6.56

D: 201.32

Channel 0 PID Reflow

P: 38.12

I: 2.15

D: 200.13

Channel 1 PID Reflow

P: 43.01

I: 6.73

D: 400.31

Mode,Seconds,SetPoint,TC0,RateTC0,PWMOut0,TC1,RateTC1,PWMOut1

PreHt,0,46.09,45.13,223.39,95.79,46.92,232.26,0.00

PreHt,1,46.82,45.00,-0.62,100.00,47.04,1.04,0.00

PreHt,2,47.59,45.00,0.83,91.11,47.17,0.41,18.85

PreHt,3,48.31,45.42,1.45,2.51,47.88,0.62,0.00

....

Heat,83,100.24,99.71,1.04,0.00,100.83,1.04,0.00

Heat,84,100.63,100.62,0.41,30.46,101.62,0.62,0.00

Heat,85,101.04,100.92,0.21,77.28,101.96,-0.21,87.07

Heat,86,101.44,101.17,-0.21,100.00,102.21,-0.62,100.00

....

Ref,304,180.41,179.79,1.24,0.00,179.83,0.83,0.00

Ref,305,182.57,180.25,0.21,100.00,180.75,1.87,0.00

Ref,306,184.85,180.62,0.41,100.00,180.96,-1.24,100.00

Ref,307,187.02,180.58,0.83,100.00,181.25,-0.83,100.00

....

RefKp,403,240.00,238.33,1.04,0.00,238.46,0.62,0.00

RefKp,404,240.00,237.92,-1.66,100.00,236.83,-2.90,100.00

RefKp,405,240.00,236.87,-1.45,100.00,236.87,-0.83,100.00

RefKp,406,240.00,237.46,0.83,30.11,236.21,-1.04,100.00

....

Cool,434,238.44,238.58,-1.24,94.78,239.96,-1.45,100.00

Cool,435,235.88,238.50,0.00,100.00,239.58,0.41,100.00

Cool,436,233.20,237.92,-1.45,100.00,238.71,-1.24,100.00

Cool,437,230.65,234.21,-3.73,100.00,236.87,-3.32,100.00

....

Cool,762,50.00,50.33,0.00,100.00,54.96,-1.66,100.00

Cool,763,50.00,47.71,-2.90,0.00,52.88,-3.32,100.00

Reflow Complete

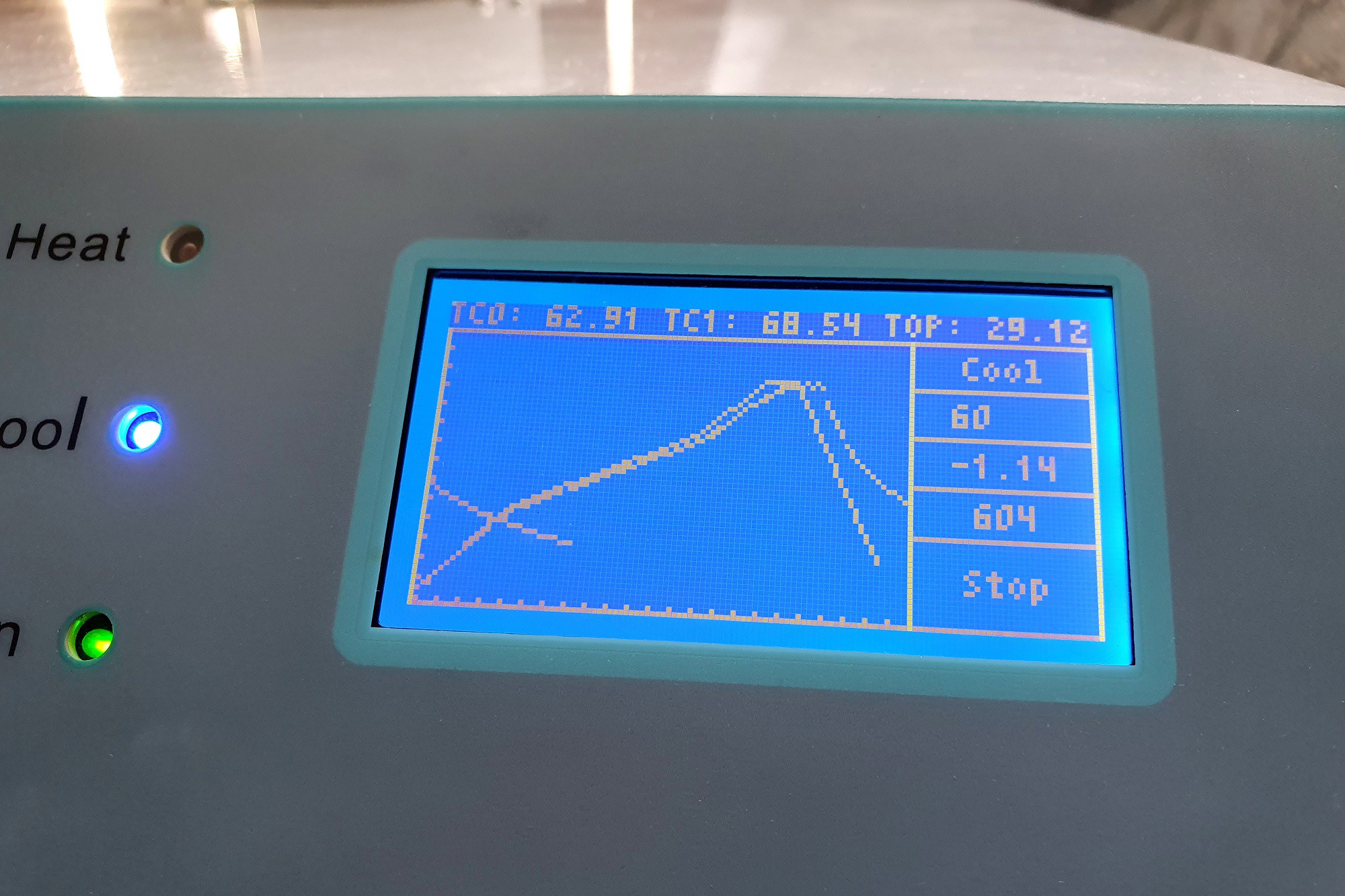

The LCD display also gives you a nice little overlay of the current reflow process, which shows how well it fit the curve:

As you can see, while the oven does struggle a little to keep up with the steep ramp rate required in the reflow phase of this profile, it does get relatively close (despite lagging a little). Tweaking the ramp rates of the different stages will yield fitter results.

The graph will overflow to the other side as well (as you can see with the cooling cycle tail).

Edit: something in the back of my mind from the start was the built in thermocouples not getting as hot as the boards themselves, which is a common problem with IR based ovens. This is more extreme that first thought as a black test PCB got up to 290oC during the reflow phase. As I feared, we are going to have to either create different modes for different PCB colours, or move/swap out the thermocouples to have them contact the boards.

This is tricky, since we have a tray that slides in and out and there are two thermocouples for each zone. Maybe a third thermocouple is required to offset the actual temps (using the built in ones to control PID rates for each zone)? Maybe we can have fixed metal plate that we can permanently have thermocouples attached to on the tray. I think moving to thermocouples on the board is the way to go however as it removes a lot of the guess work.

Blecky

Blecky

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.