We could say the process was started with the question: What simple, reasonably consistent and repeatable and processes is available at the Lab? Laser cutting of course. There are CNC mills and 3d printers but with laser cutting, once you have a predetermined shape, it basically becomes a "push a button" task. The next step, acrylic bending is not too complicated and I am planning to make a bending jig out of MDF soon.

We could say the process was started with the question: What simple, reasonably consistent and repeatable and processes is available at the Lab? Laser cutting of course. There are CNC mills and 3d printers but with laser cutting, once you have a predetermined shape, it basically becomes a "push a button" task. The next step, acrylic bending is not too complicated and I am planning to make a bending jig out of MDF soon.

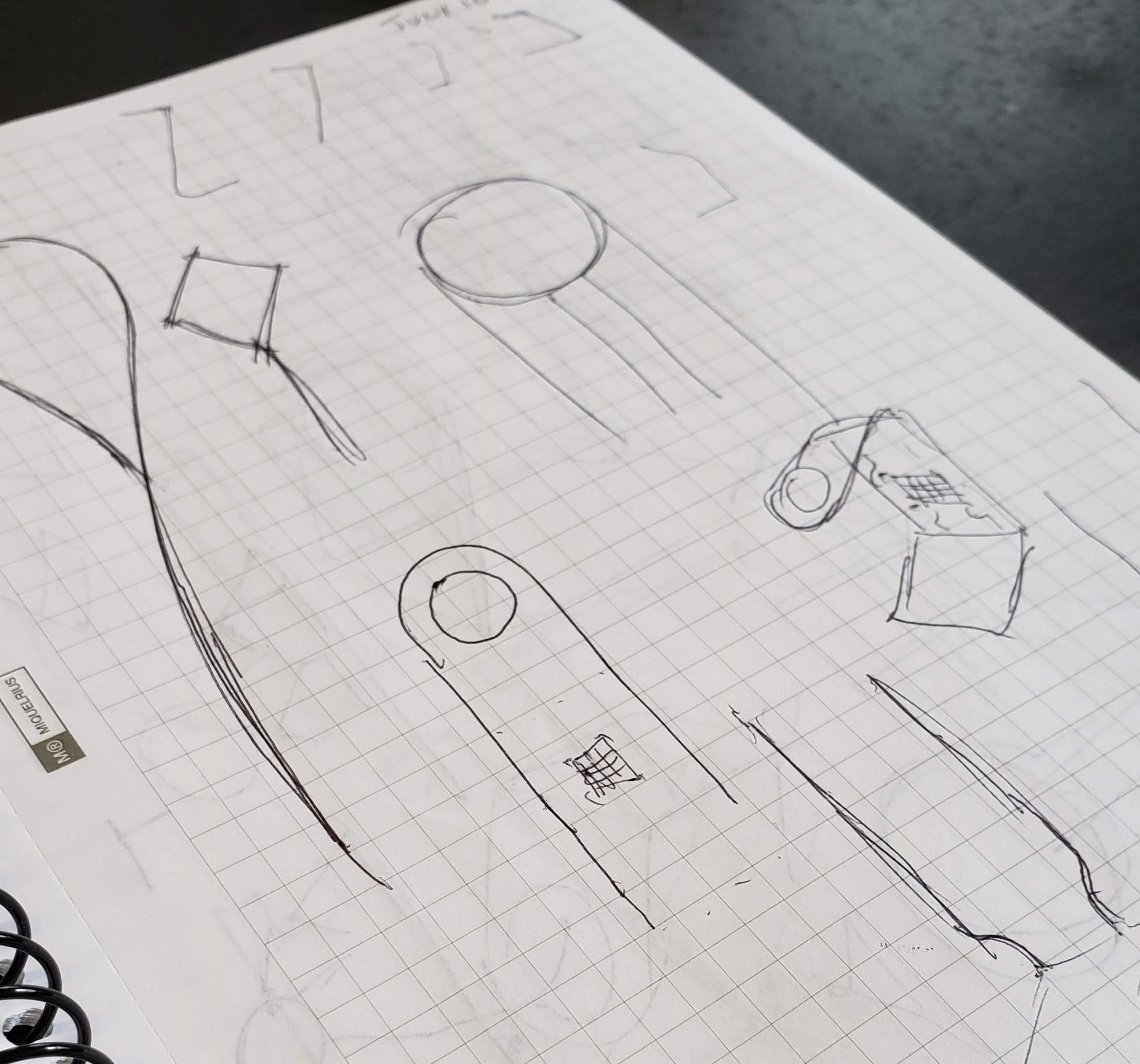

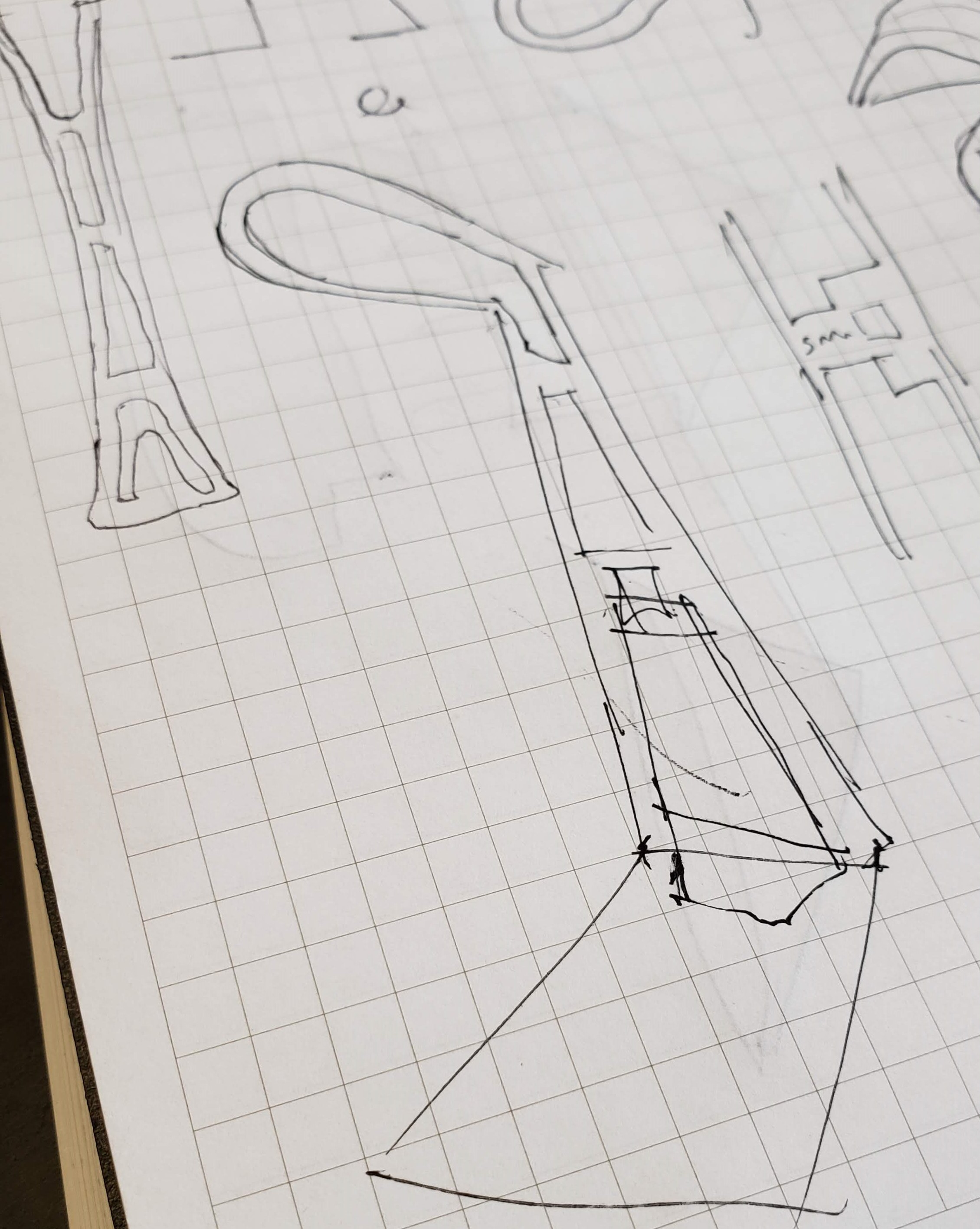

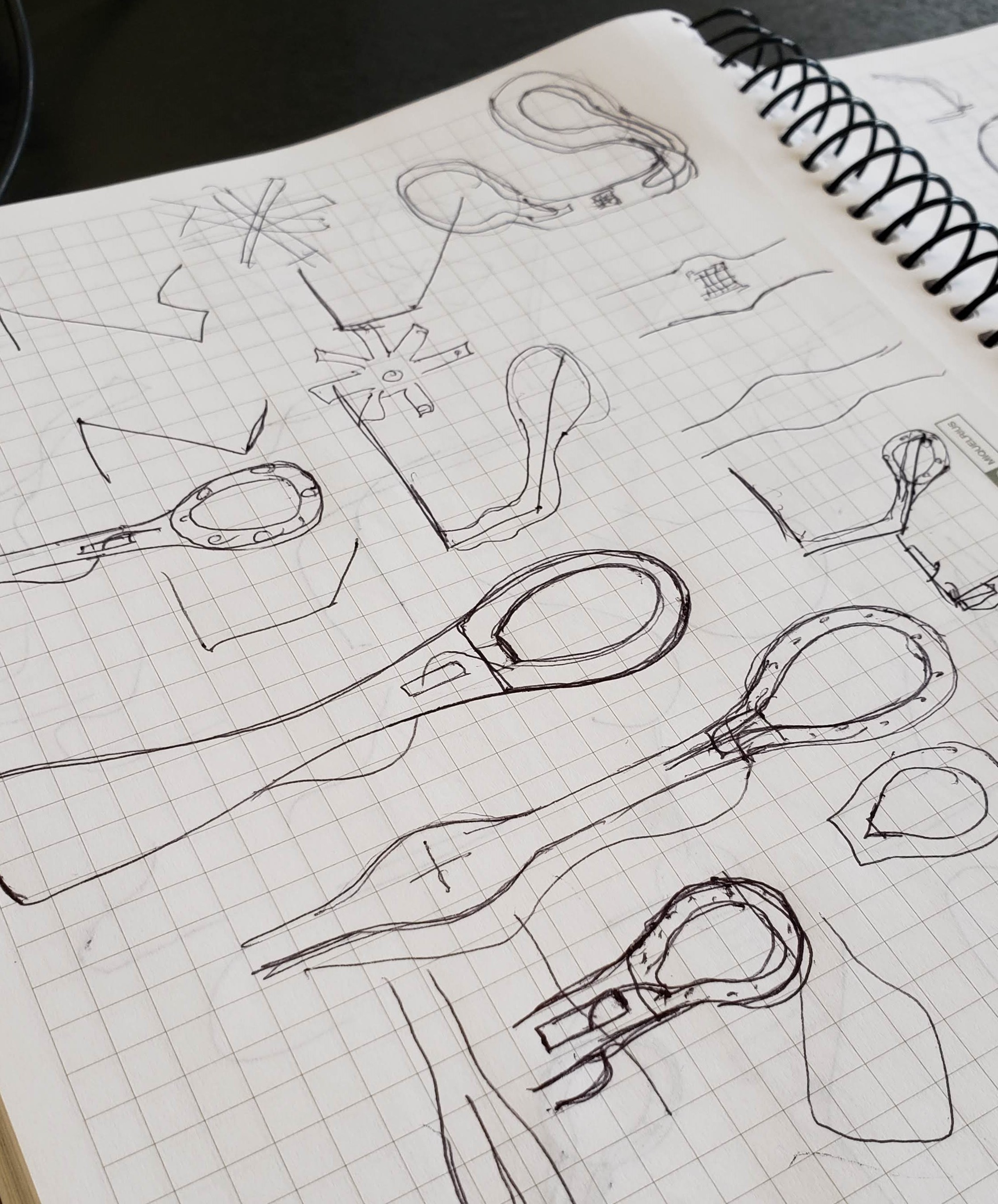

Once I had material and process defined, it was time to go back to the sketches and try to come up with a simple, yet elegant shape. Disclaimer my sketches are far from elegant. Trying to hide the wires was hard and cumbersome, so I thought of "celebrating" them. More on that later. I bounced back and forth whether I should hide the batteries under the base, or behind the body.

I decided to go for the back for the sake of an easier production.

Talking about the light pattern on top, a flat base or a strip are too conventional, and I would like to have more people work with this shape and make it a different design. So I went for a "horseshoe" design for the light and PCB pattern.

A perfect circle would be too strong in terms of visual communication and it could lead to the usual, clean, rational, minimalist design.

Giovanni

Giovanni

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.