Technical specifications

1.Selective copper plating required

2.Via fill and over plate

3.10mil Rogers 4350B

4.ENIG

Methods and Processes

During the traditional PCB production process, we need use the film for image transfer. When the image transfer, we need make sure that the film affix to the copper clad, or it will cause ultraviolet rays refraction and short or open circuits because the failed conductor pattern transfer. Because the copper thickness of the selective area is thicker than the other areas, it is hard to ensure the accuracy of the image transfer. During the circuit process, we are not able to use the normal processing. In fact, this problem will also happen during soldermask and screen printing processes. we apply a special way which called the secondary plating. We can meet the customers’ requirement by plateing the pads of the selective areas, and we use the advanced LDI exposure machines. So we cancel the film directly and ensure the precision of the soldermask and circuit.

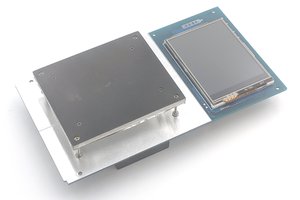

catsndogs

catsndogs

Vitaly

Vitaly

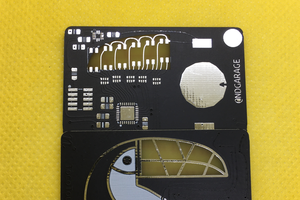

ndGarage

ndGarage

youkito1991

youkito1991