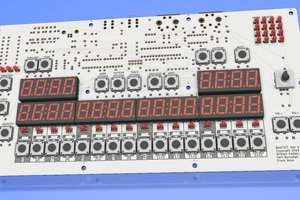

MODBUS, especially the binary serial RTU protocol through RS485 interface is still popular - sufficiently popular to create a market for ultra-cheap (hobby-grade) components, e.g. "STM8S103 Relay Control Board" with barely usable MODBUS firmware

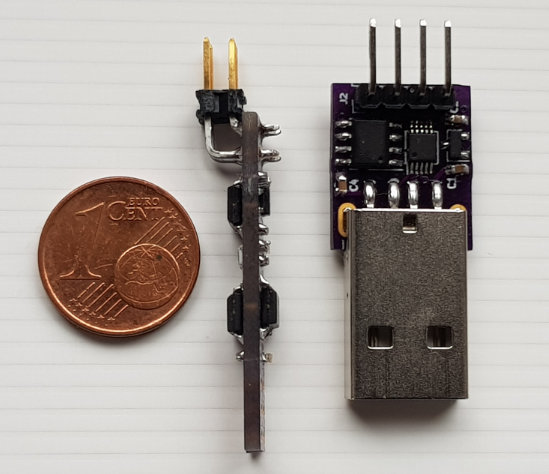

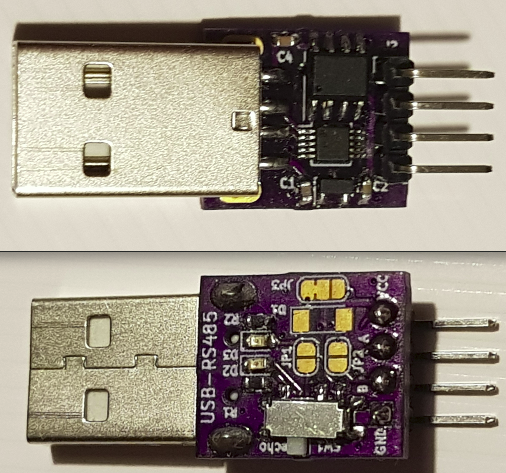

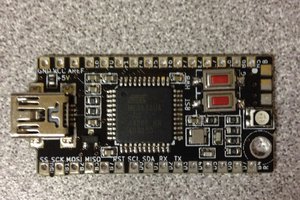

or the infamous Chinese "USB RS485 Adapter Black+Green" for less than $1 (including shipping).

For some time now I had fun with implementing MODBUS, testing it against frameworks and getting things running (or not) using Chinese gadgets. It turned out that finding the culprit sometimes takes time.

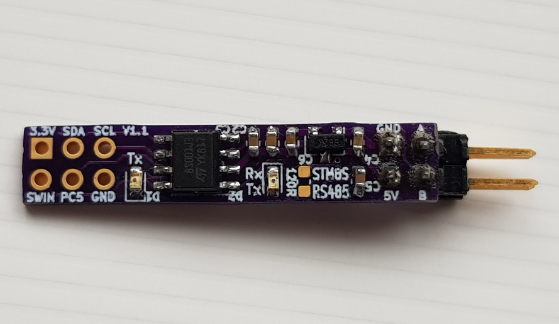

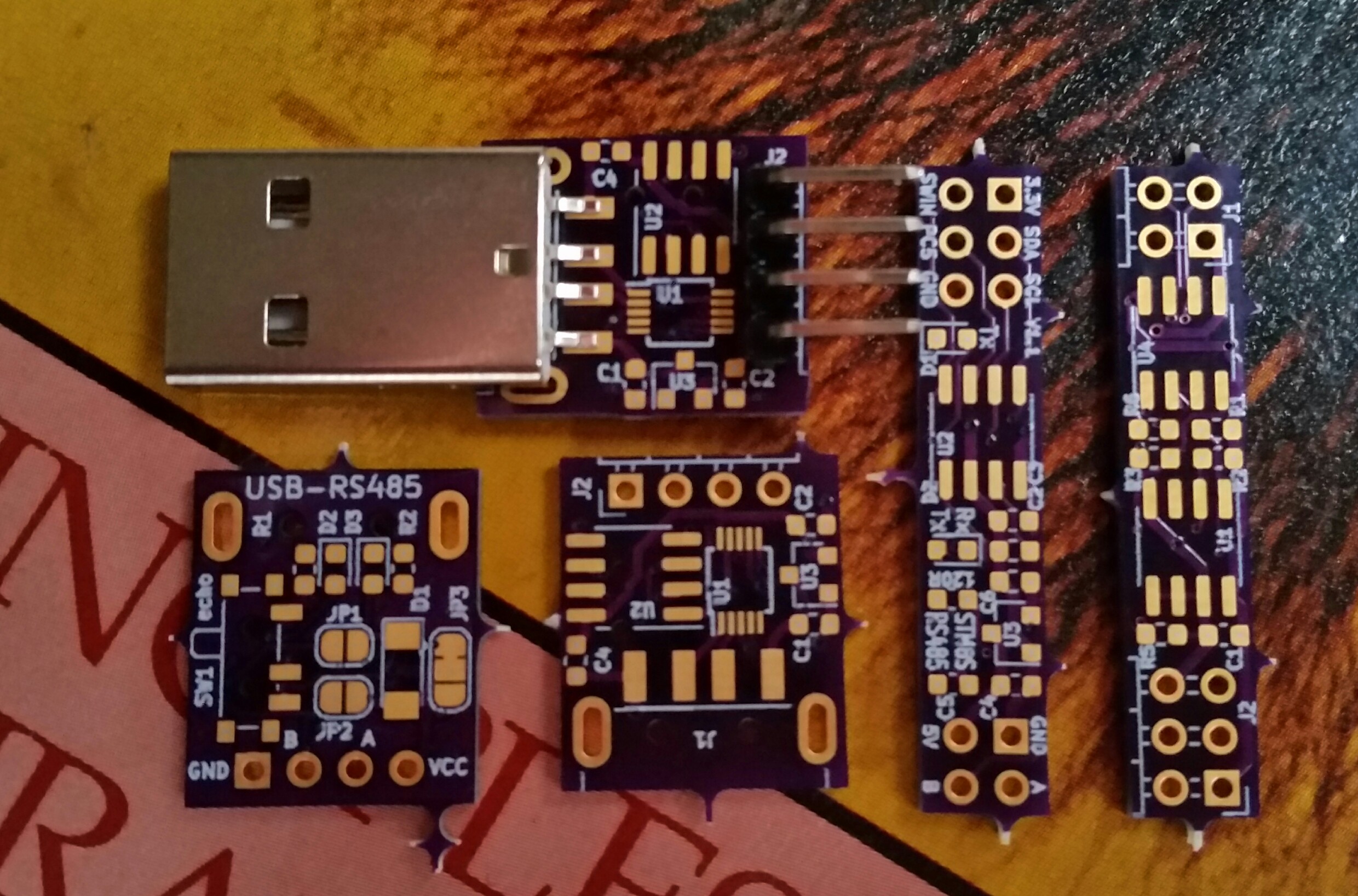

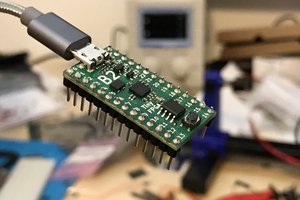

Lately, I played with KiCad, more for occupational stress relief than for creating something useful. But what the heck, why should this small STM8S001J3 MODBUS node disappear in the stream of the @oshpark shared projects list, eceiving no love?

This project shall make some attempts more visible and it I hope that it will lead to a usable platform soonish.

This project shall make some attempts more visible and it I hope that it will lead to a usable platform soonish.

Thomas

Thomas

Frank Buss

Frank Buss

hedley

hedley

Luke Valenty

Luke Valenty

The Big One

The Big One

Hello, what is the modbus rtu program for stm8s001rs485 hardware? Can you share it? Thank you