After a lot of designing, redesigning, scrapping and discovery of things I didn't know existed, the plan morphed into:

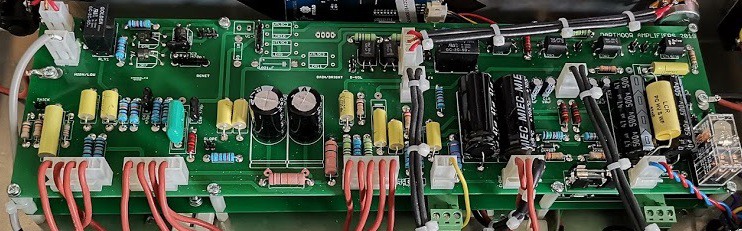

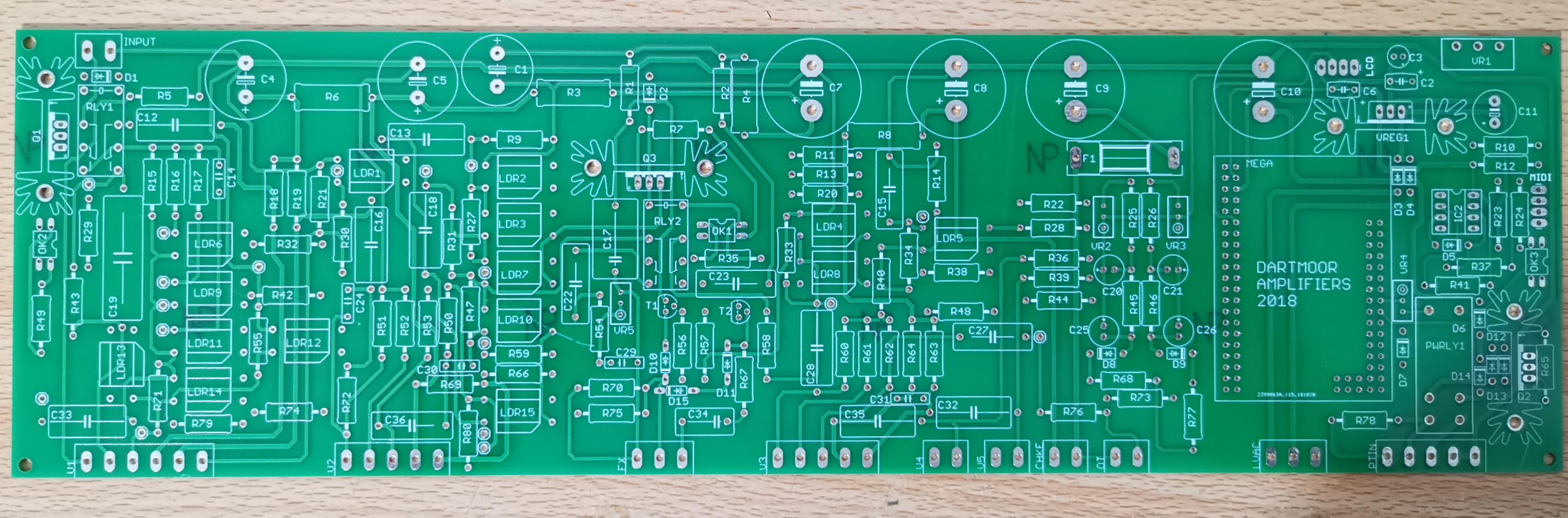

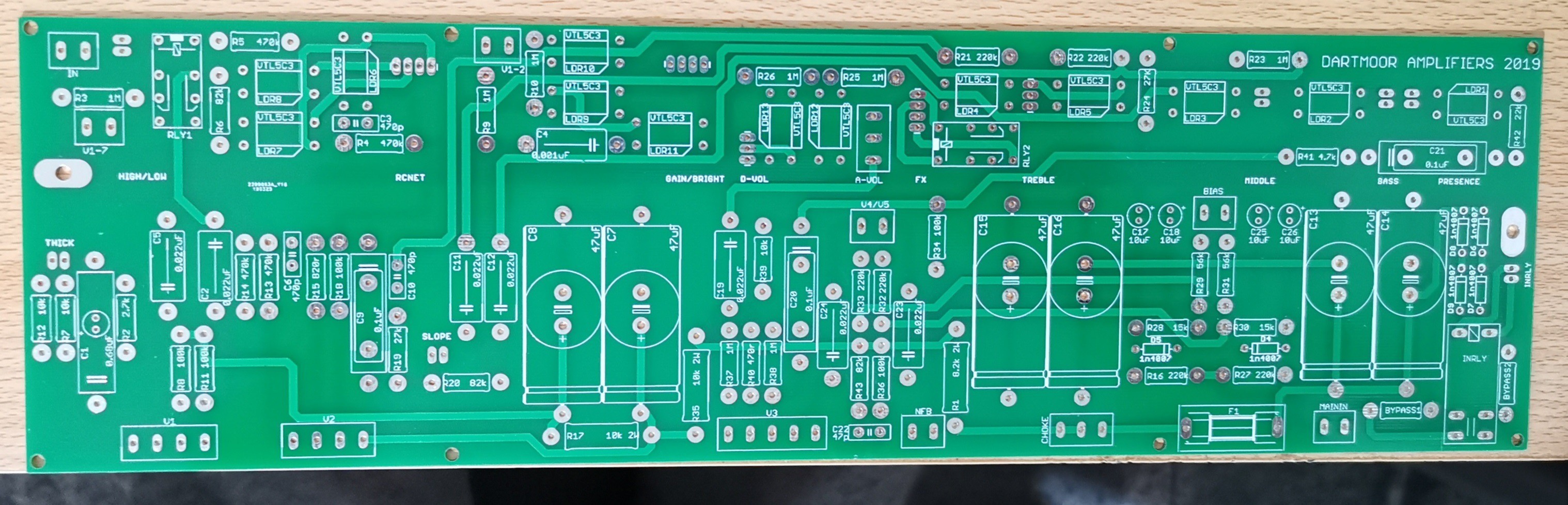

An all-in-one guitar amplifier based on the legendary Marshall 2204.

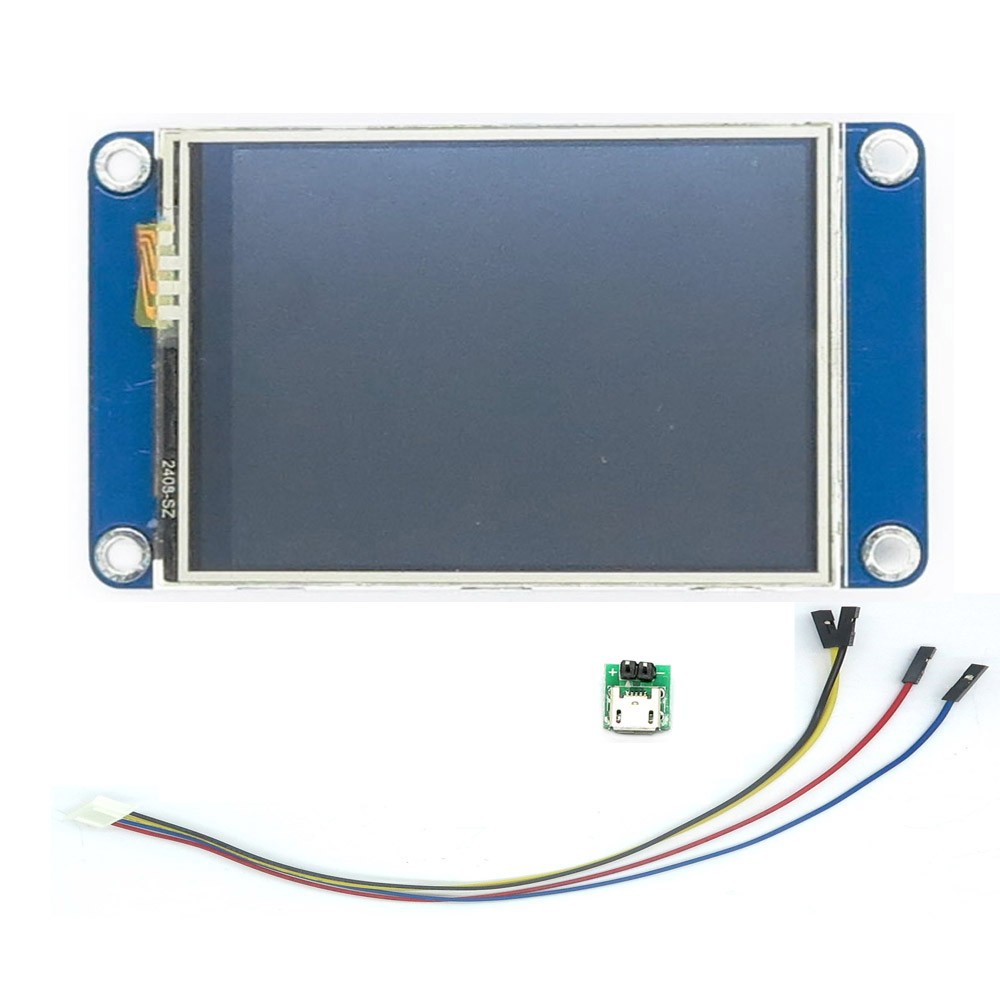

This was to be controllable by a touch screen.

It was to have space for twenty presets.

It was to have midi capability.

It was to have a zero loss effects loop.

It was to be programmable using an android app.

Paul Burford

Paul Burford

Lithium ION

Lithium ION

Sagar 001

Sagar 001

DIY GUY Chris

DIY GUY Chris

Peter G

Peter G

I'm new to Nextion touch screens and found this project, very nice idea. I don't find any info on the nextion programming or arduino here. Is this a project in development or are the files for the micros somewhere to try.