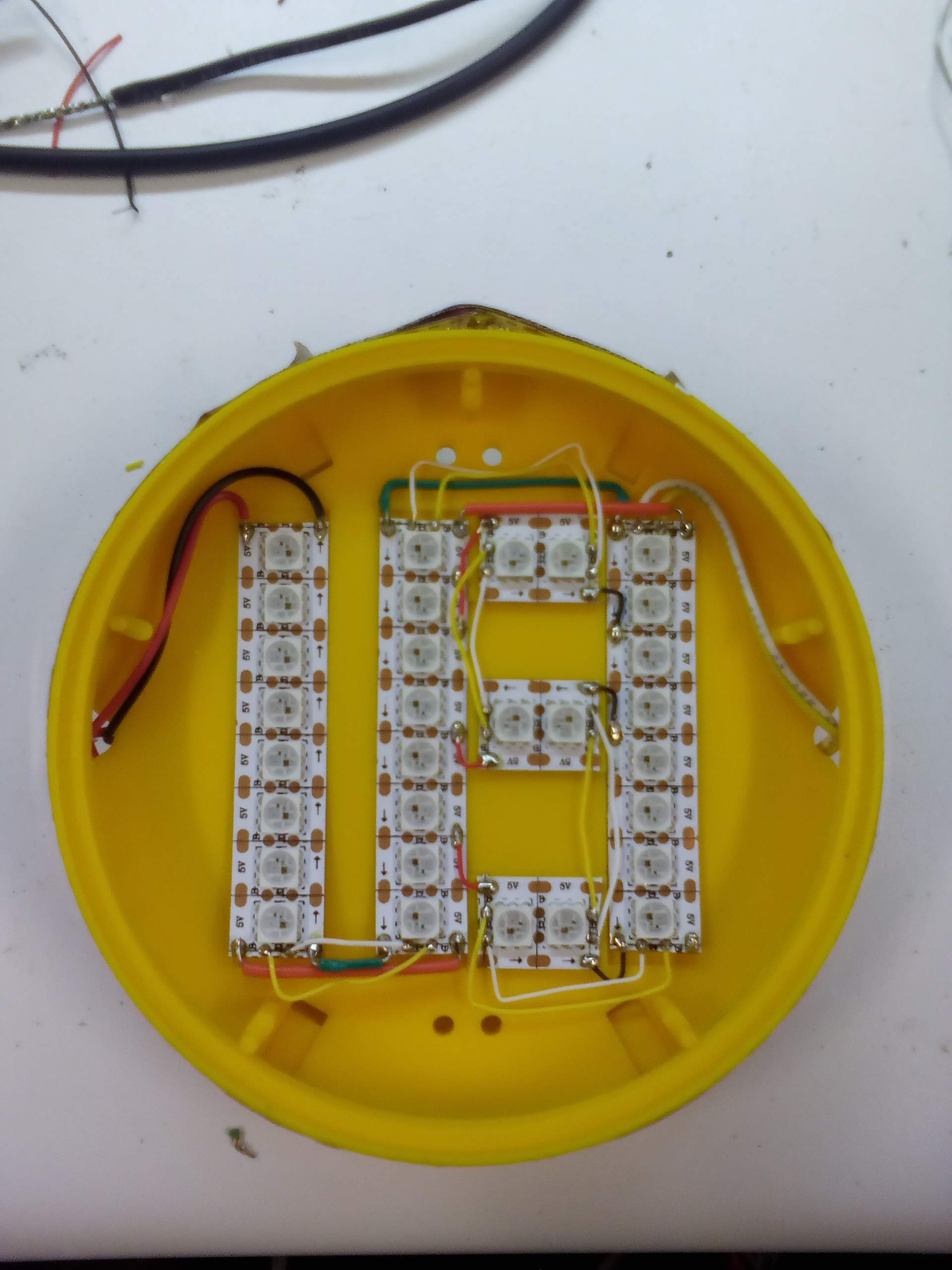

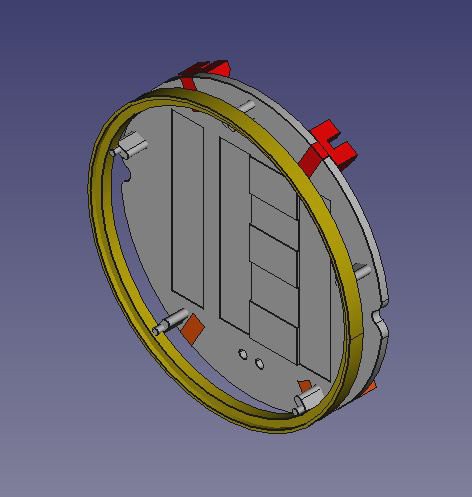

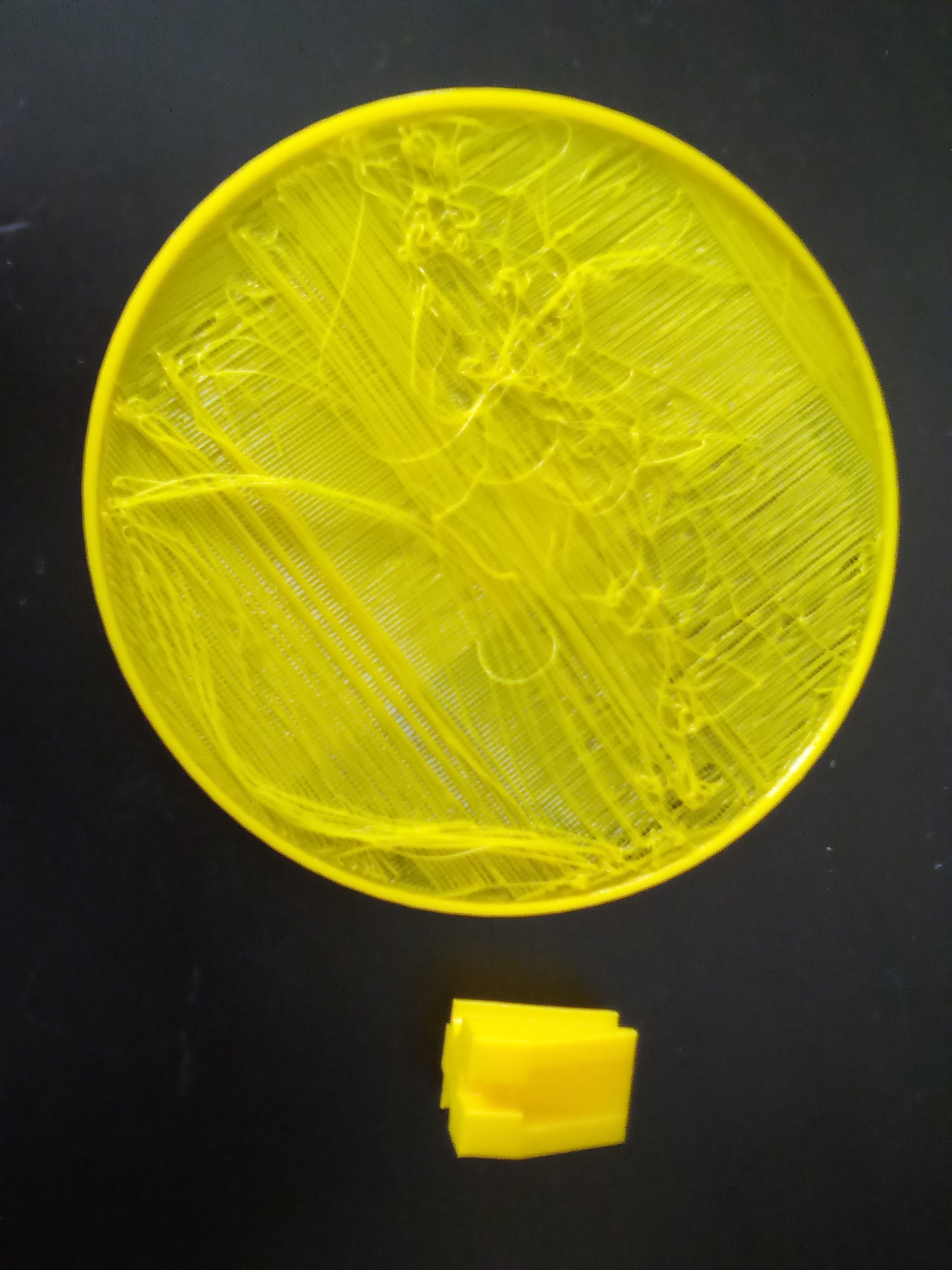

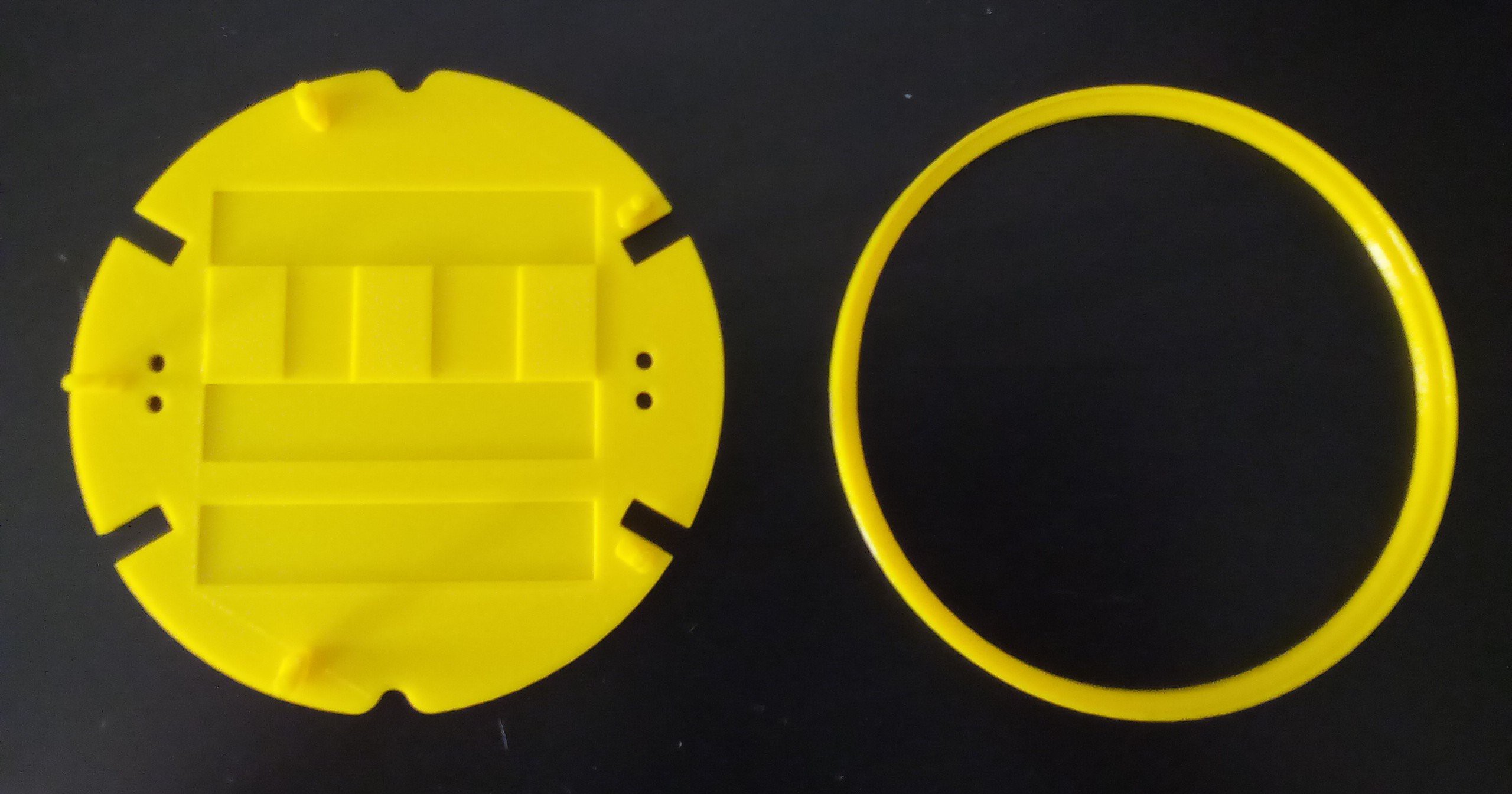

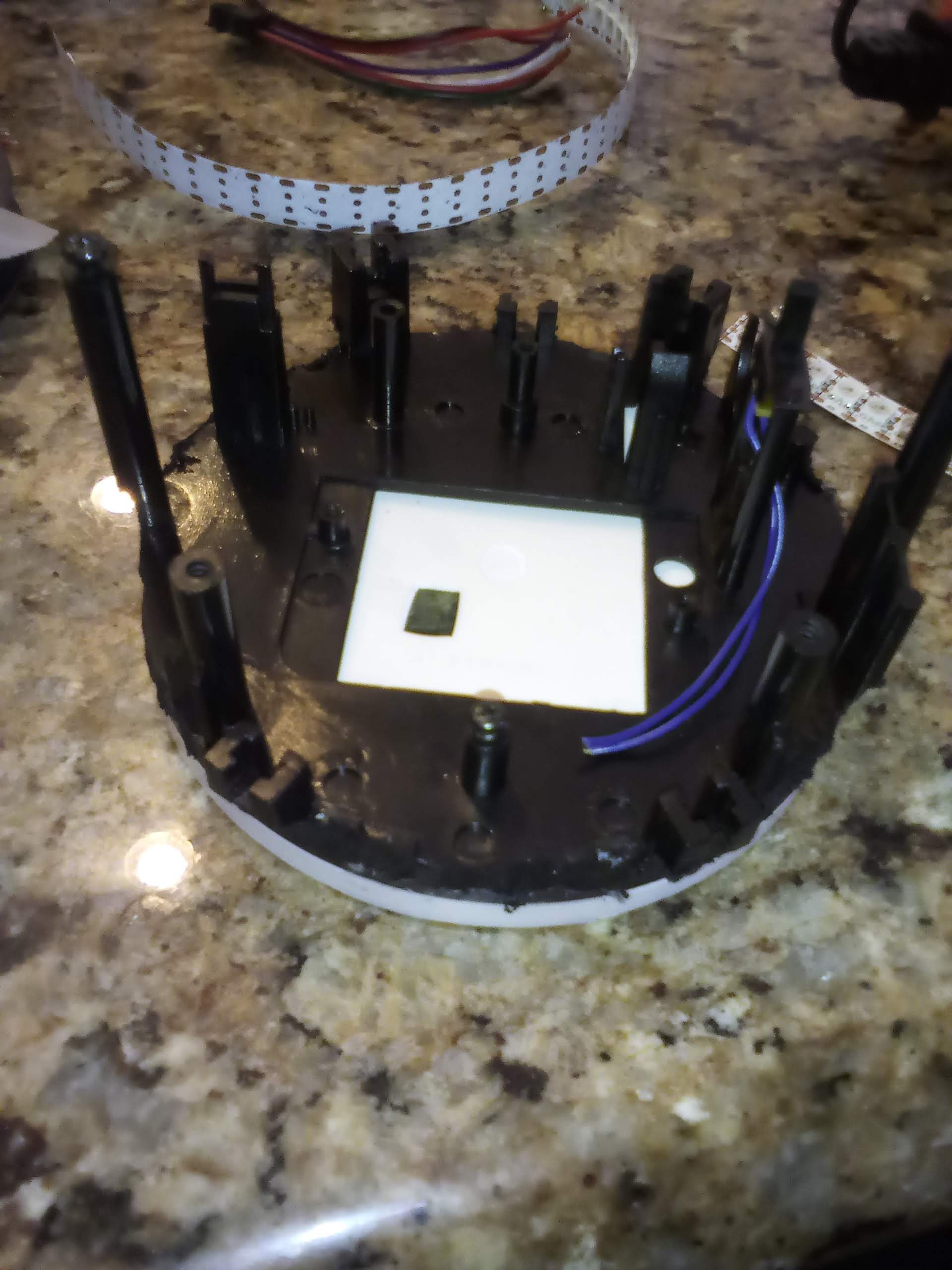

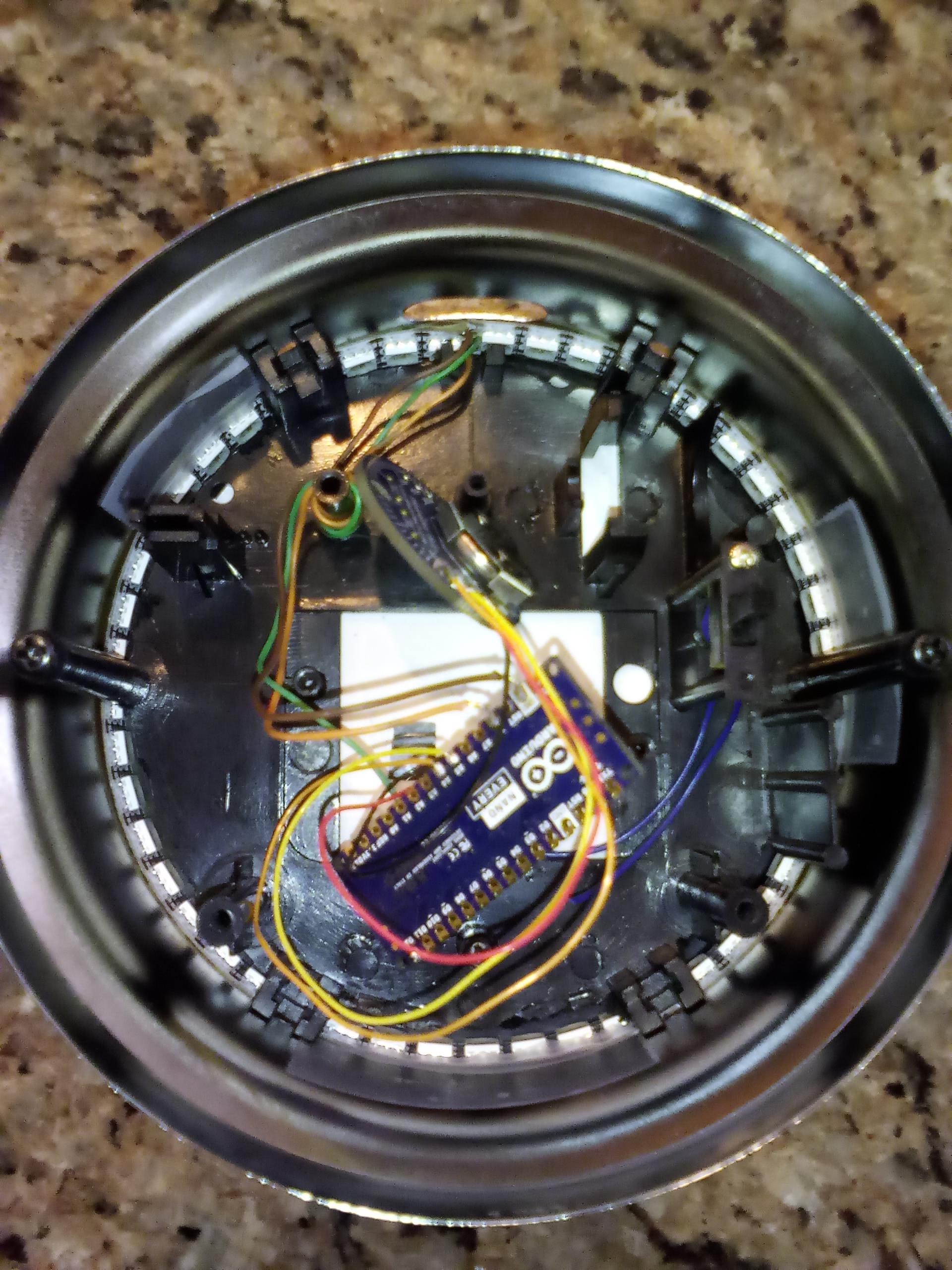

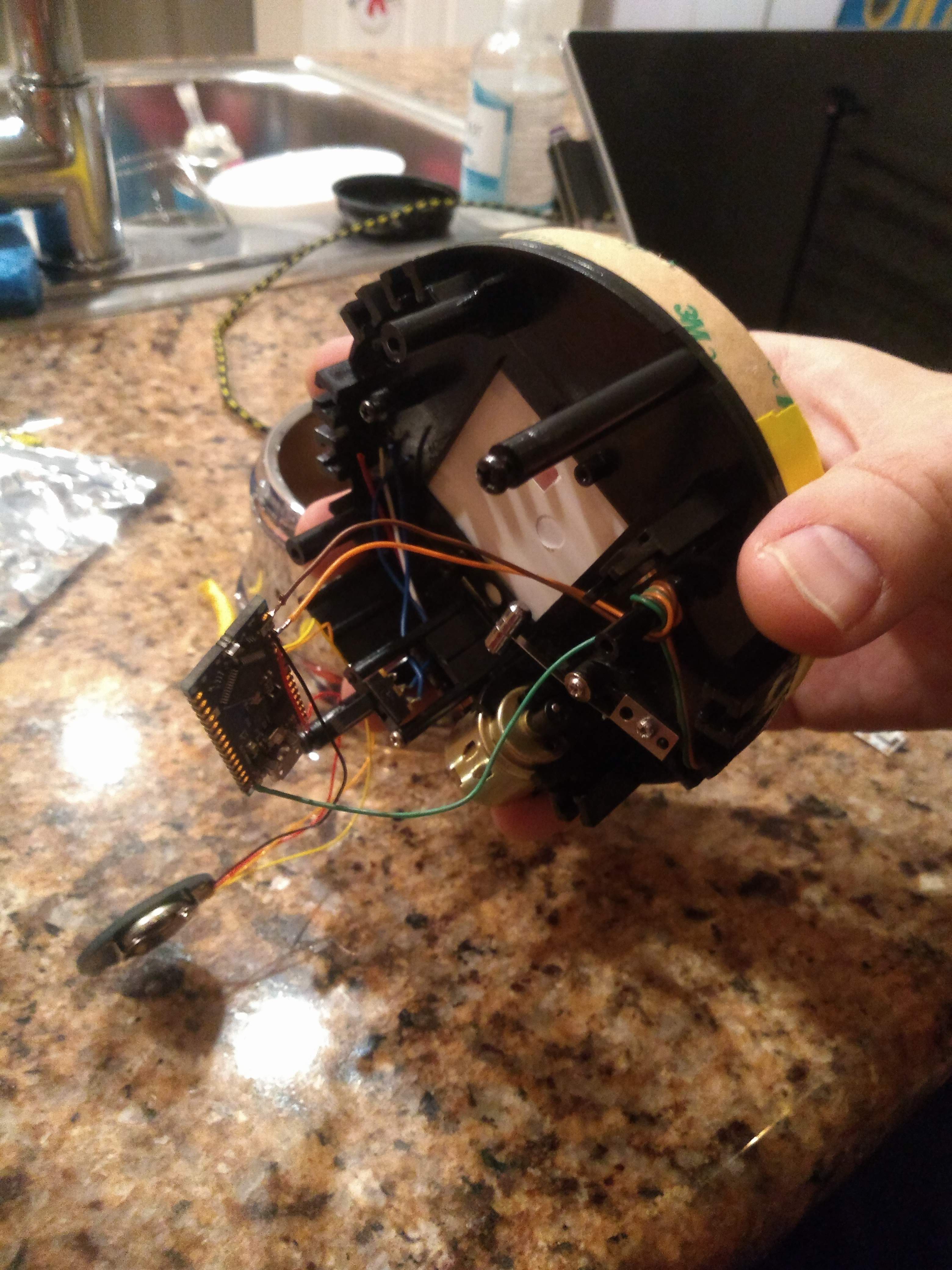

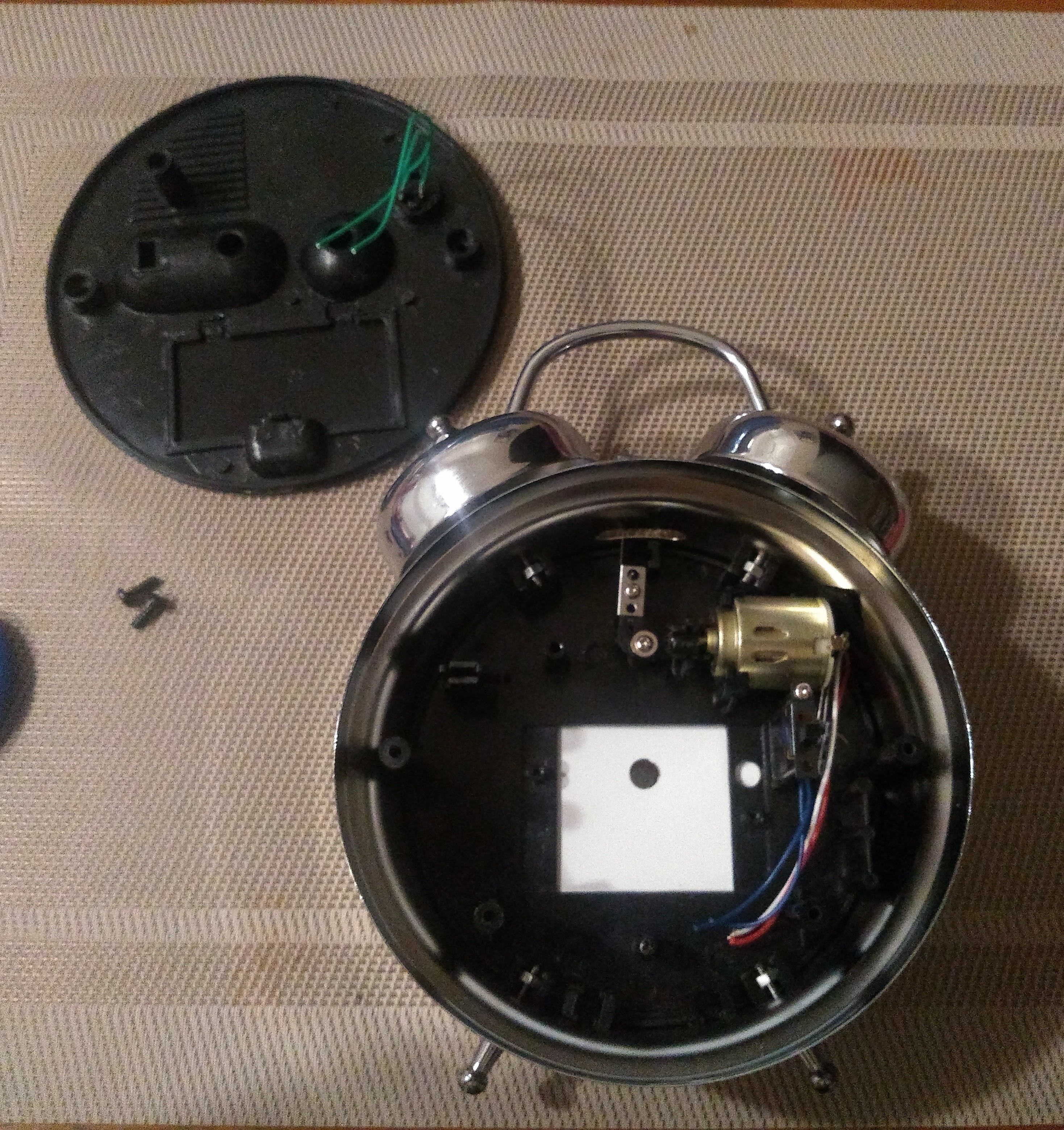

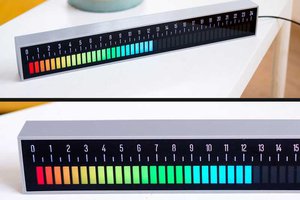

This is a re-imagined double bell clock with an illuminated LED twist.

The source documents, which currently includes Arduino source code and FreeCAD files, is located at this GitHub repository: https://github.com/akcooney/HelloDoubleBellClock

I currently have the clock working to my satisfaction, but I owe the rest of the community some better documentation. I will post that documentation to the GitHub repo and then update this page.

As of now the clock does not require a custom PCB but does require a lot of hand wiring. Since I found a second corroded double bell clock in my closet, I may take a second crack at this a build a custom board to simplify assembly.

Andrew Cooney

Andrew Cooney

See the latest code at:

See the latest code at:

Maakbaas

Maakbaas

Jan

Jan

Michael Furtak

Michael Furtak

Indeed they look innocent, simple, and quick... Next thing you know you're getting shocked by a flyback making your 200V rail.