One issue with having any sort of Linux based system controlling an EVSE is that there are certain aspects of the design that must not be allowed to be software controlled.

In particular, with OpenEVSE/Hydra, responsibility for cutting off the vehicle power contactor when a ground-fault was detected was given to an interrupt service routine triggered by the GFI circuit. This was deemed acceptable, because code analysis could provide some assurance that there was no reasonable way this ISR would *not* be run. But we can't really do the same with a Linux machine controlling the show. So in this design, instead, the contactor power signal is gated by the GFI. A ground fault will cause a flip-flop to be set, and while it's set, the power relay is explicitly disabled. The software will need to first turn the relay power off, then reset the GFI state. This will insure an instant reaction to a ground-fault regardless of what Linux may be doing at the moment.

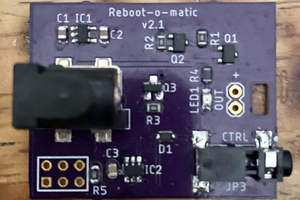

In addition, leaving the power turned on when there's no call for it is a serious safety error. To prevent that, there is a hardware watchdog that must be "fed" constantly whenever the EV power relay output is on (a GPIO pin toggled at least every 10 ms or so). If the watchdog isn't fed, it will bite, forcing the equivalent of a GFI event and turning the power off.

Linux can generate a PWM signal on GPIO18, which can be used for the pilot. We can use the same two level double MOSFET generator design to generate the ±12 volt pilot from the pin, and the boost converter and charge pump to generate the ±12 volt supply. We can also use the same voltage divider and an external ADC so the Pi can sense the voltage, and thus the impedance being imposed by the vehicle.

This project can use the same HV boards used by OpenEVSE II, which means that we have a ready made solution for relay test / GCM monitoring. The power boards also would be able to supply 5 volts to run the PI.

That's the complete list of features required for an EVSE, but we also added two more ADC channels to sense the input voltage and watch a current transformer and obtain between the two of those a power monitoring solution.

Everything else at this point becomes a software feature. Given the power and connectivity of a Raspberry Pi, there are a million different directions you could go from here.

Nick Sayer

Nick Sayer

canique

canique

Paul Crouch

Paul Crouch