One reason I choose the Artemis 300 was to print the shape of the rotors blades I'm building for #Goliath - A Gas Powered Quadcopter and Titan. Using the prints, I'd like to then cast a silicon mold directly from the 3D print with a minimum of post-processing. The blades will be 16" tall, making for a big 3D print. To minimize the material used and the print time, it's desirable to use infill. I decided to do some tests to see how to get the best quality.

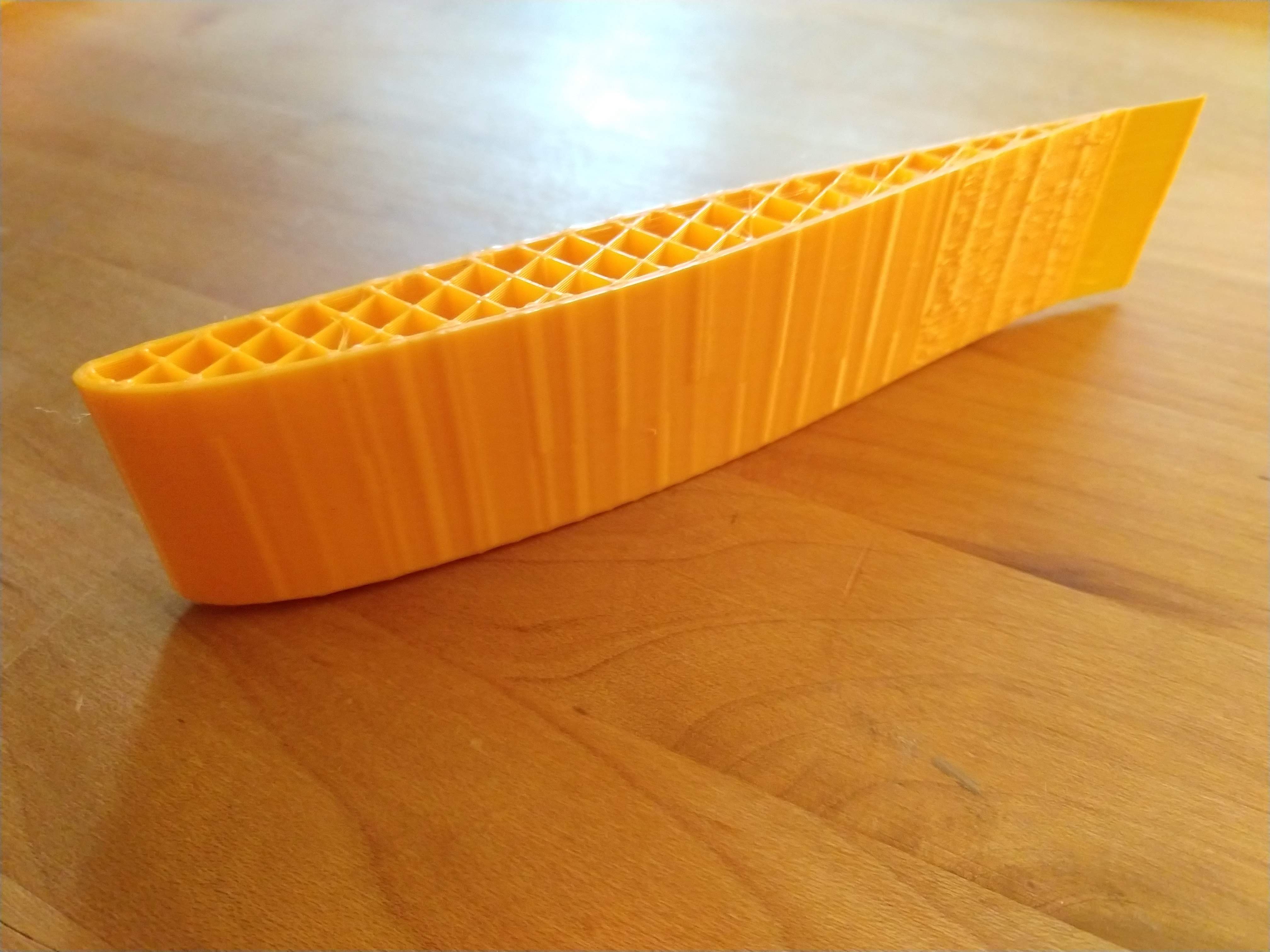

SeeMeCNC recommends the Cura slicer, and using the default settings with 20% infill I made a test print with just the first inch and a half of the rotor blade.

The results were less than desirable. The outer wall is visibly deformed wherever the infill intersects it. More wall layers could help (I used 2 here), but I'd really like to minimize the amount of material I'm using.

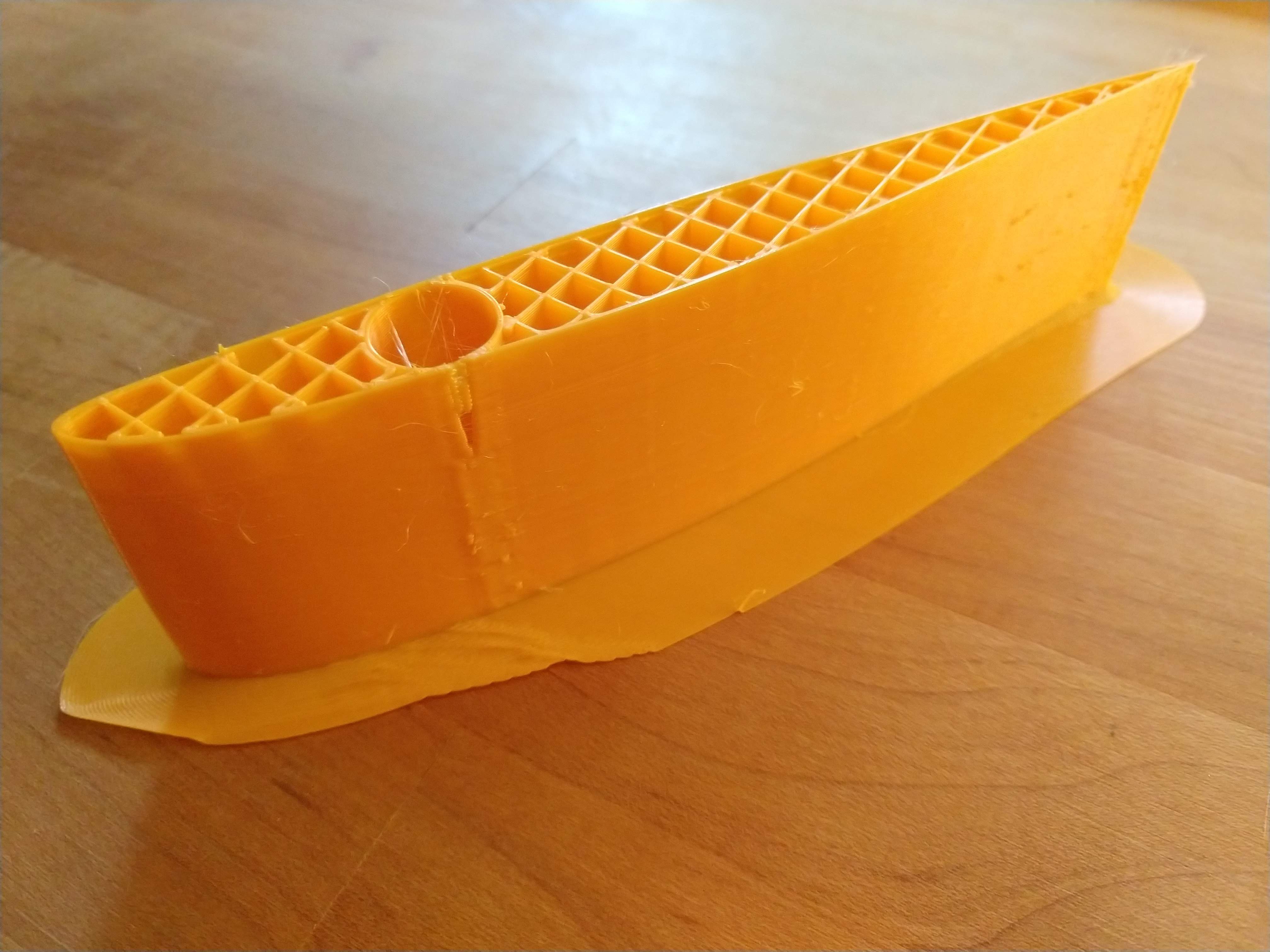

After a few iterations, playing with the infill overlap settings, the best result (thus far) was achieved enabling the "Connect Infill Lines" setting. Here is the result using one wall layer.

Besides the hole, which needs more work because it's interfering with the outer surface quality, the infill no longer affects the surface quality. The few surface blemishes that remain are easily scrapped off using a razor blade.

The full 16" blade will only need 188 grams of filament. I had intended to use this to cast the foam cores. But with the prints being so light, it may make sense to use the prints directly as the composite cores.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.