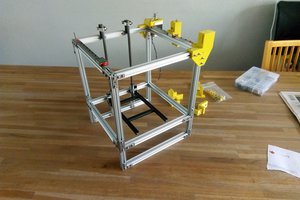

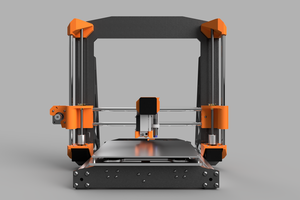

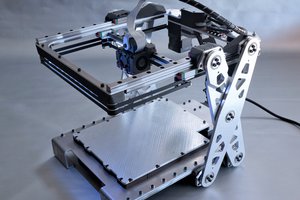

the frame of the printer is made of 1515 black aluminium sections which use a corner aluminum joint to make the frame very sturdy. The y axis is a standard slider like a cartesian printer while the xz axis is a delta mechanism .This printer is inspired from the bigger deltesian by bornity. The mix of the mechanism gives the advantage over a cartesian of having one less motor and the advantage over a delta printer of having a very easy to align frame. The print quality is as par with any cartesian printer.

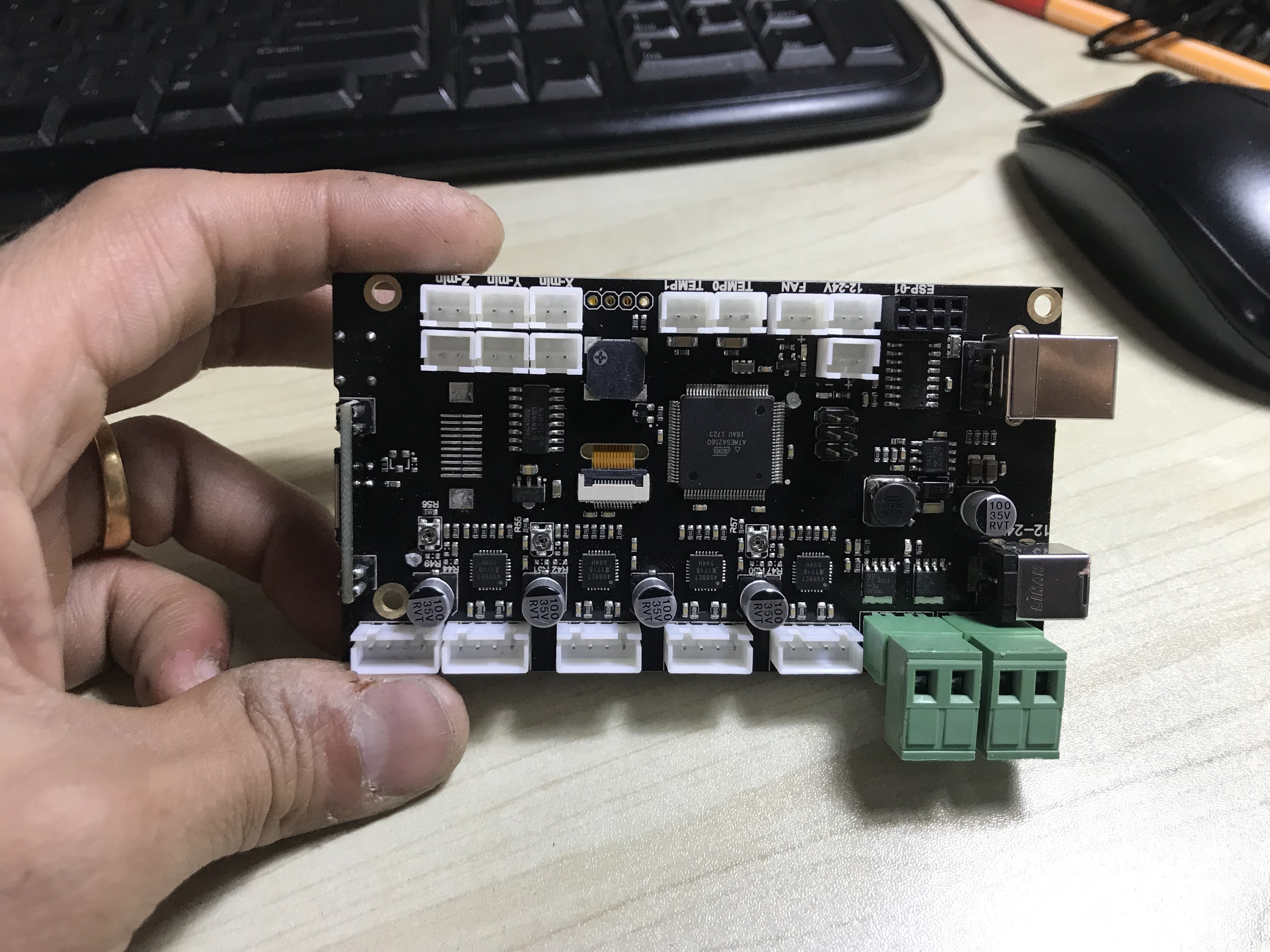

The controller board of the printer was a new product from a taobao vendor who sent it to me as a initial product run prototype. The board has everything on it including a lcd and a click knob on the back side. I eventually didn't use the click knob and lcd as i needed it to have a easy to use interface for my daughter. The final interface of the printer is a 3.5 inch touch lcd based on a stm32f106 . The touch lcd has the sd card built into it and is very fast to boot and control the printer.

The biggest challenge to make the printer easy to use was the filament loading. A small kid cant pull or push the hard spring on a standard extruder. To overcome that i uses a lever based latch type mechanism which is easy to load and unload. Also the print bed is held in place with magnets so that it can be unloaded easily.

The printer currently has no autobed level or heated bed as that adds the complexity of more wiring. The end stops are hall sensors on the corners of the axis which are triggered by magnets glued to the belts. The printer rarely looses its level as the frame is very rigid. The hall sensors on the bottom also make the wiring a lot more neat.

The overall outer frame is 190x190x240 mm and the build volume currently is 80x100x85mm which i intend on making 100x100x100 by optimizing the arms.

ekaggrat singh kalsi

ekaggrat singh kalsi

Cees Meijer

Cees Meijer

Luke Brandon

Luke Brandon

Malte Schrader

Malte Schrader

JLAM

JLAM

I love it and want to build it for my daughters as well. Will you open source the details/files/stl's ?