In this robot, we need a wheel with much higher carrying capacity than the previous wheels we used.

In the Bastya 1 we used WEX omni wheel: 4" Omni-Directional ( https://www.vexrobotics.com/edr-wheels.html )

The first ide was that, we will build omniballs for the wheels: ( https://www.youtube.com/watch?v=ZOCdI2gzMqI ) It looks like simple and much higher carrying capacity.

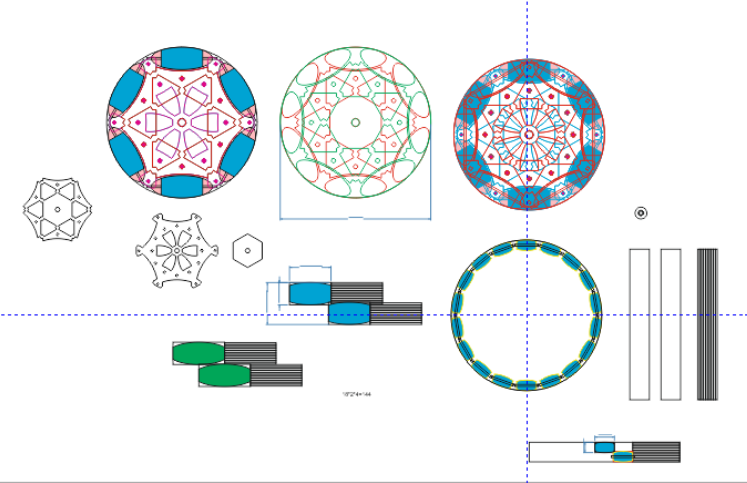

We used this for reference:

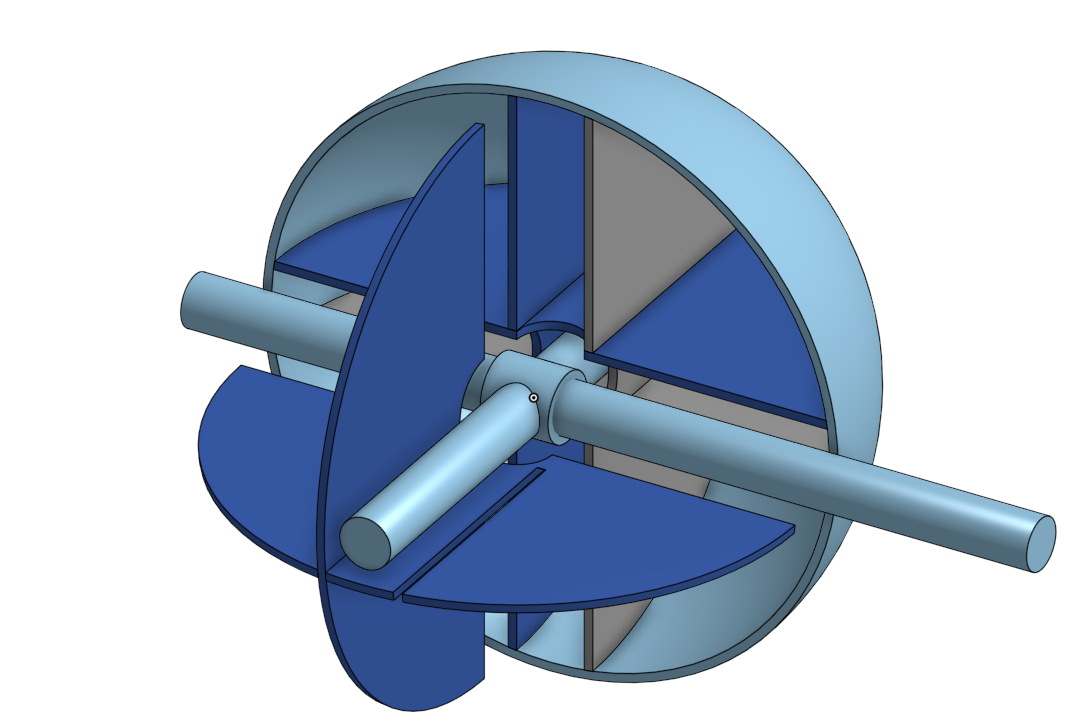

The first version:

It consist hamster ball and laser cut plastic sheets. We can't find the required sized ball. (in this picture, the wheel bearing placement isn't completed )

The next versions is fully 3D printed:

It came out it isn't have enough carrying capacity (probably it can be fixed with more thicker walls). On the other side of the hemisphere we need too put something to rotate. In the small models its a small ball. (our first plan was that if we disassemble some old PC mouse we can use the ball, and the mechanic parts to hold in place. When we examine the size of the 3D printed hemisphere, and the size of the robot, we thought it will be too weak.

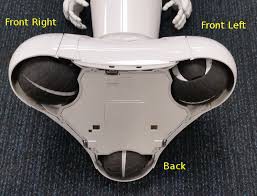

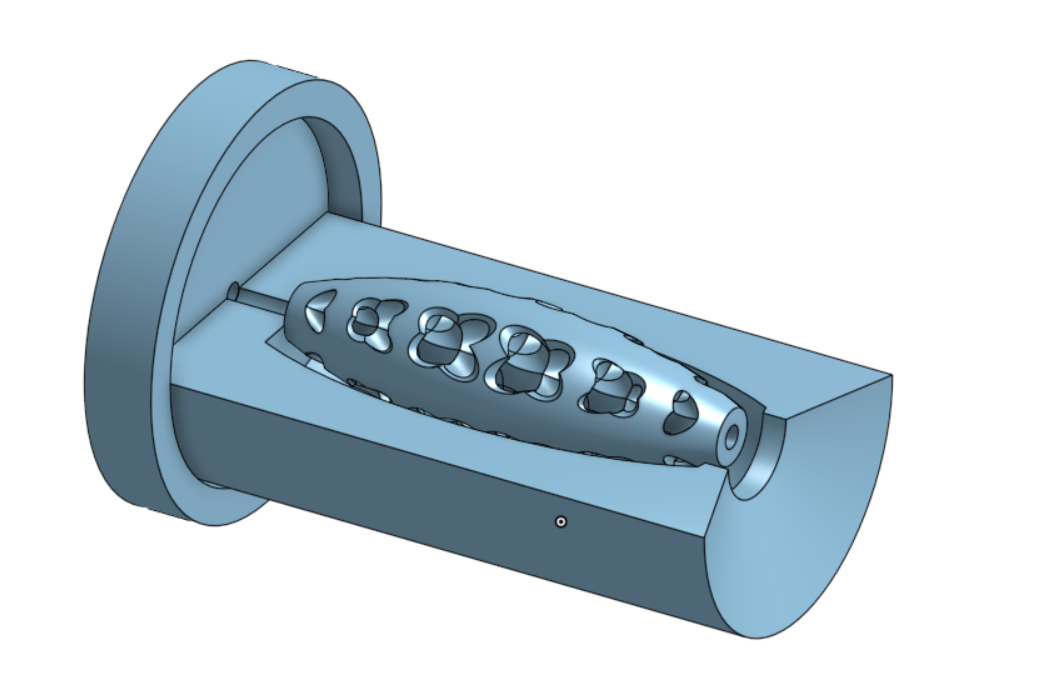

After that we found out another version of the omni ball used in the Pepper robot.

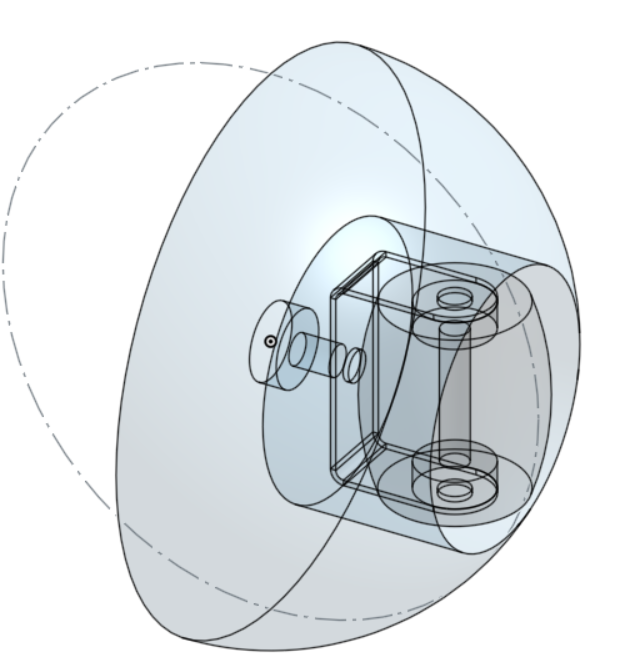

So with this reference we started to design our version of it:

When we calculated the price of this version, and the necessary machining of the parts, we thought it will be better if we stick with the omni wheel what we used previously in lots of robots:

The next idea was we will build the omni wheel:

We thought we can build an omni wheel easily, but after lots of experiments, it looks like it isn't a trivial task. In small scale we already built omni wheels with 3D printed. The bigger wheel we designed for this robot consists of aluminium and rubber wheels. The aluminium part easily can be made with CNC machine. And the rubber wheels contains a 3D printed reinforced core. We thought it is a solid plan, and thought with some experiments we can make high carrying capacity wheels cheaply with the 3D printed rubber rollers.

(spoiler alert: it came out it's much more expensive in the end, without counting the time we put in it. But we learnt a lot from it)

So in details:

First we designed the wheel, and the rollers:

We looked around about the heavy duty omni wheels and it looks like with bigger roller is the better. So we went that way with the planning.

After that we designed the core of the rollers. First idea was that, if we can mold it with 2 component rubber, we can adjust the flexibility, and hardness. The reinforced core contains the axle, and with the 3D printed core, we thought it will not cut the rubber when we put weight on it.

These is the variations for the roller core:

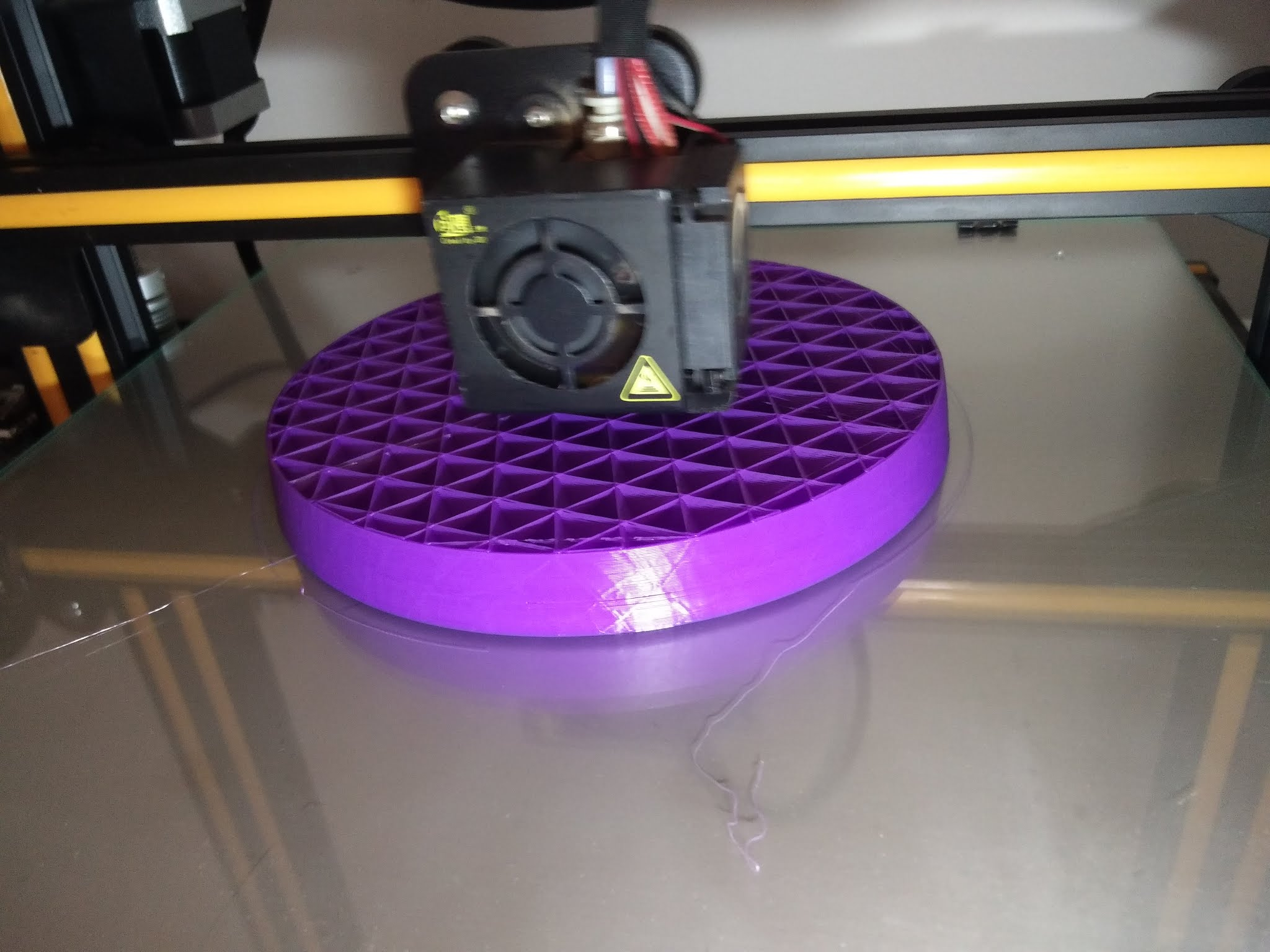

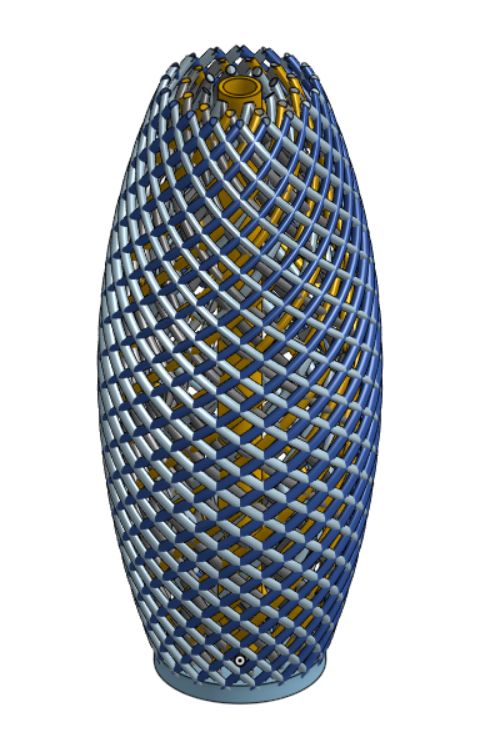

The first one, is designed with the concept of weight distribution with a grid: (it was fun to learn how to make shape like this in the CAD program :) )

It came out of the printer so dense we can't mold it.

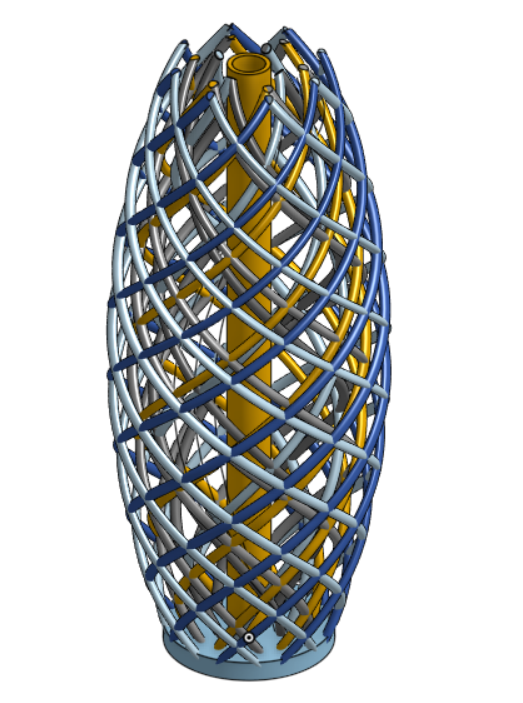

The second version contains less columns and with new grid distribution: (8, 6, 4 columns with 2 directions)

This version is possible to use in the mold, but when it came out of the printer it was too brittle.

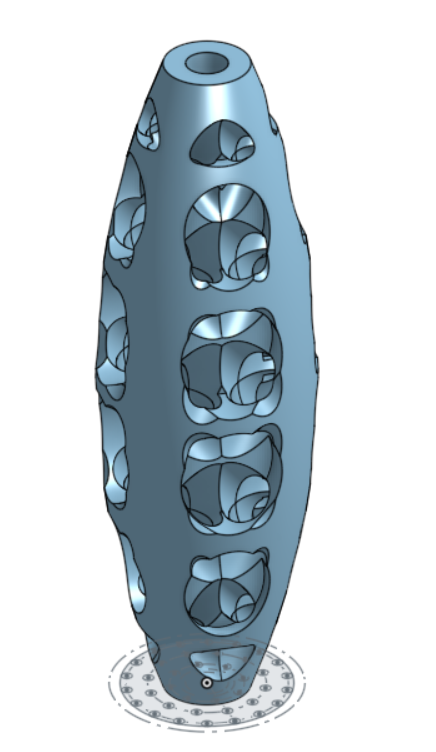

The next version contains more rigid 3D printed object.

With this version we made some test molds. We designed a reusable mold. The core is fixed in the center with an axle.

It came out looking good, but when we put weight on it. It crushed the 3D printed core.

Another problem we found out in the first tests we can't variate the flexibility easily. We thought we need a vacuum chamber for this.

The next idea was that if we can make the rolleres with lathe from some material it will be better, and cheaper. We found out that the plastic what is used in these rollers are not cheap (and didn't have lathe, so we have to order the rollers)

After this we made some calculations and looked like it is cheaper to buy the wheels :)

Finally we ordered the wheels:

It isn't cheap, but it's a matter of perspective. We can't build one cheaper with this parameters.

BTom

BTom

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.