In the past I have compared a linear (MCP73831) with a couple switched mode (LT3652, BQ24650, CN3722) Li-Ion battery chargers, powered from solar panels, and found linear chargers actually don't perform so bad. Andreas Spiess concluded the same in this video. When the panel voltage (~5-6V) is matched to the battery (~3.7V) the losses should not be so bad. Switched mode chargers price is about 10x, so if more power is needed it is cheaper to buy a larger solar panel than a switch mode charger.

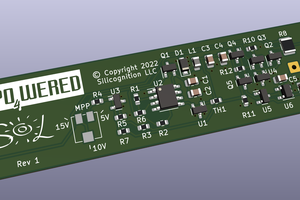

I really hoped the input under voltage lockout voltage of these chargers (~3.5V) could be matched to the maximum power point voltage of the solar panel, just like in the expensive switch mode chargers that have maximum power point approximation. I ordered below boards from aliexpress and put them to the test. All chargers are cheap and intended for USB or wall adapter.

| V in (V) | I charge-max (A) | V uvlo (V) | board price each | chip price @ qty100 | |

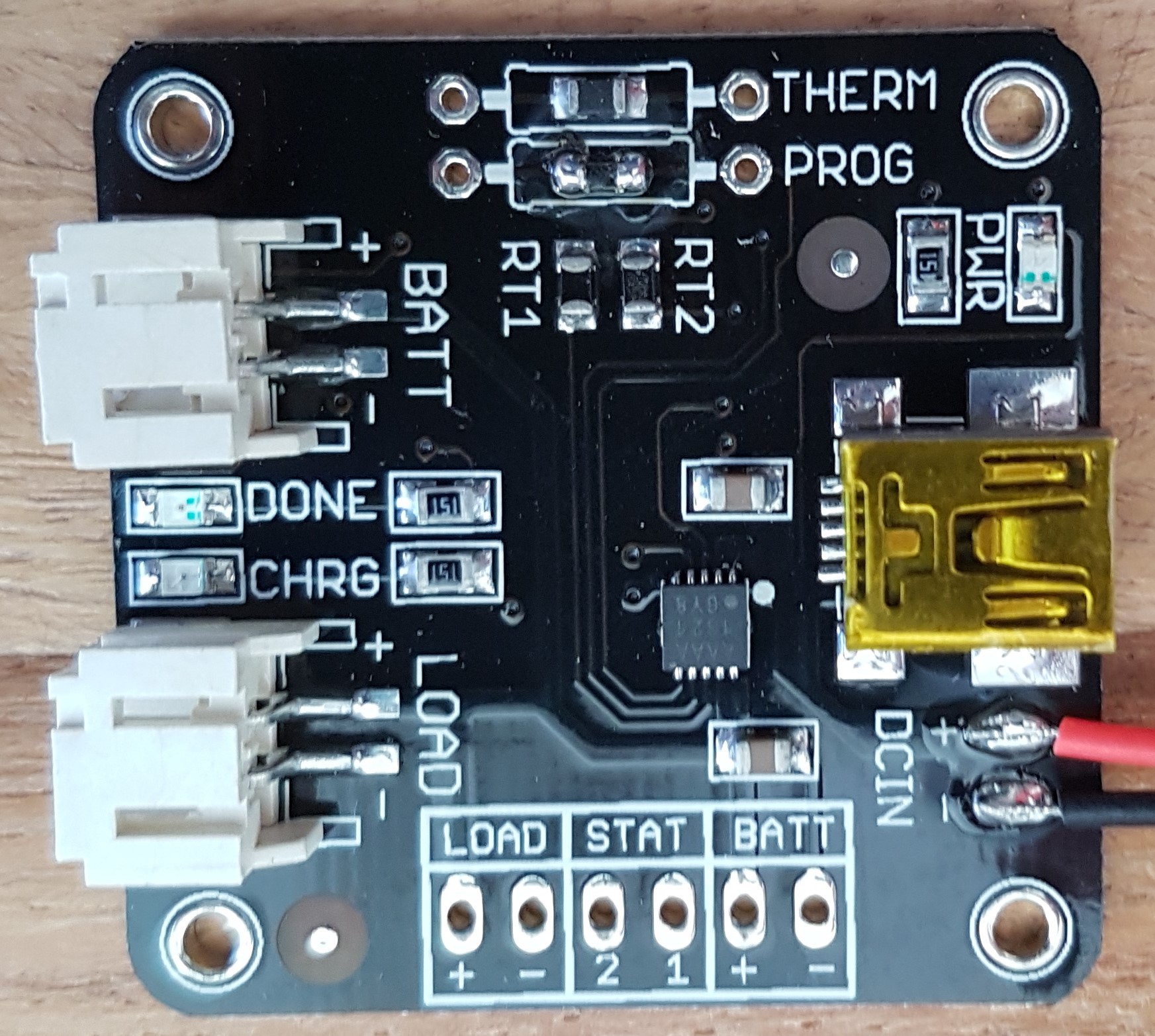

MCP73831

| 3.75 - 6 | 0.5 | 3.4 | 1.25 euro | 0.38 euro |

MCP73833 | 3.75 - 6 | 1 | 3.4 | 6.92 euro | 0.60 euro |

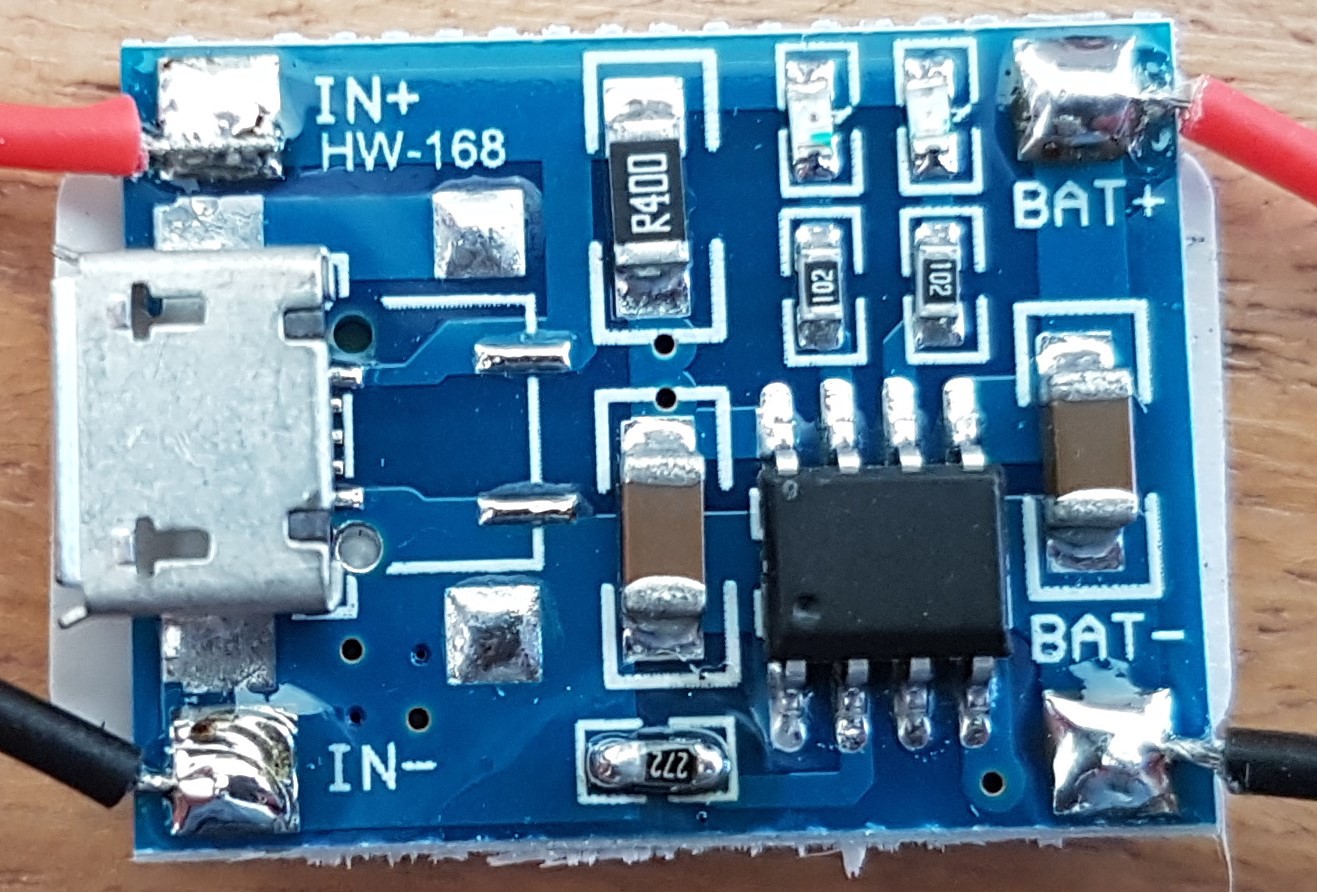

4056E / TC4056A

| 4 - 8 | 1 | ? | 0.25 euro | 0.04 euro |

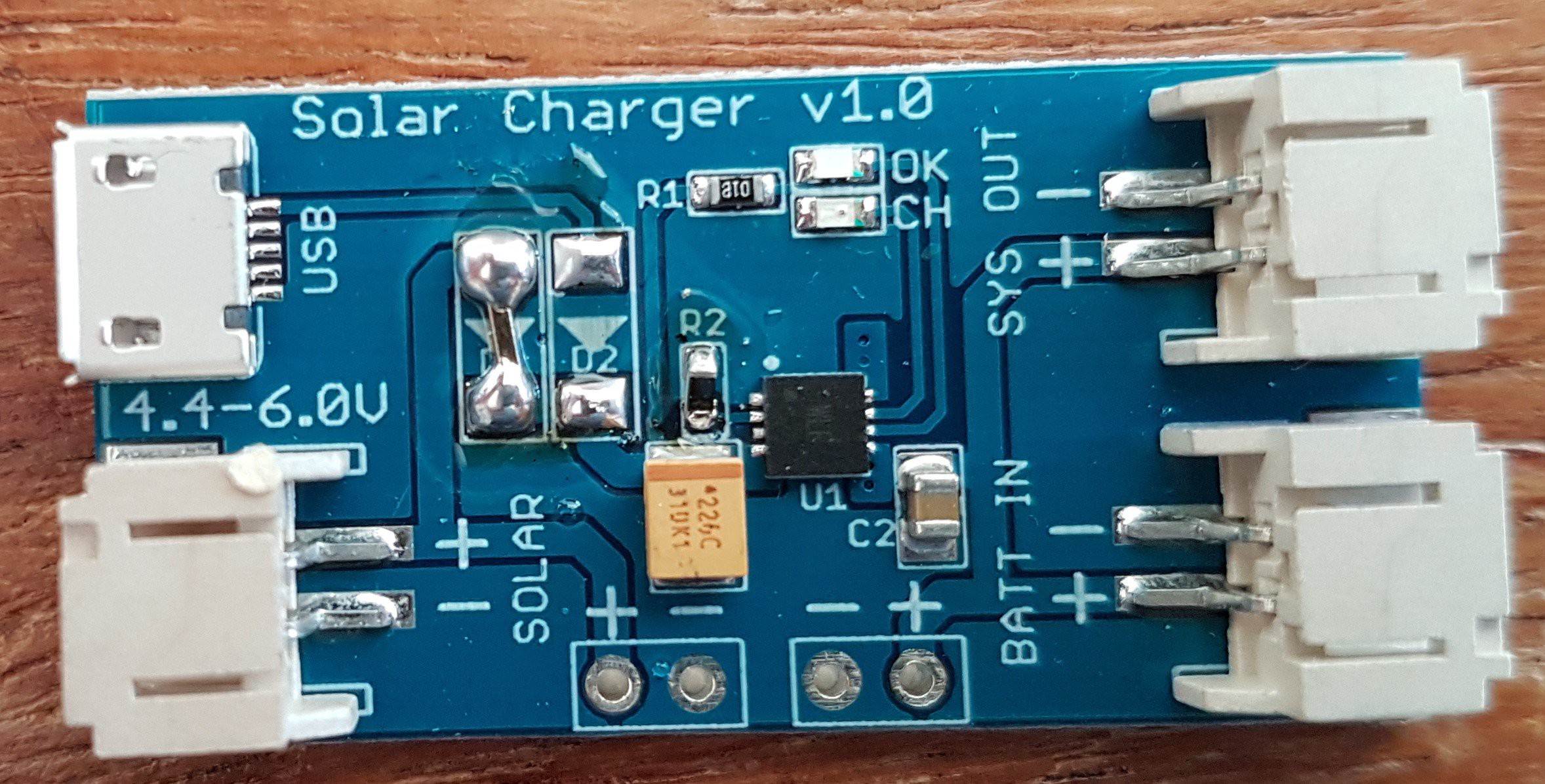

CN3065 | 4.4 - 6 | 1 | 3.7 | 0.91 euro | not available |

I had some old 4054E and some newer TC4056A, I don't know there difference. There must be several manufacturers of the same chip and TP-ASIC is the original manufacturer

The input voltage range of the MCP7383x is limited to max 6V and so I decided to buy 5V solar panels. A 5V panel would also fit nicely with the 3.5V under voltage lockout voltage level, because that is near to the maximum power voltage of the solar panel. To make a fair comparison I have limited charge current to about 500mA on all boards.

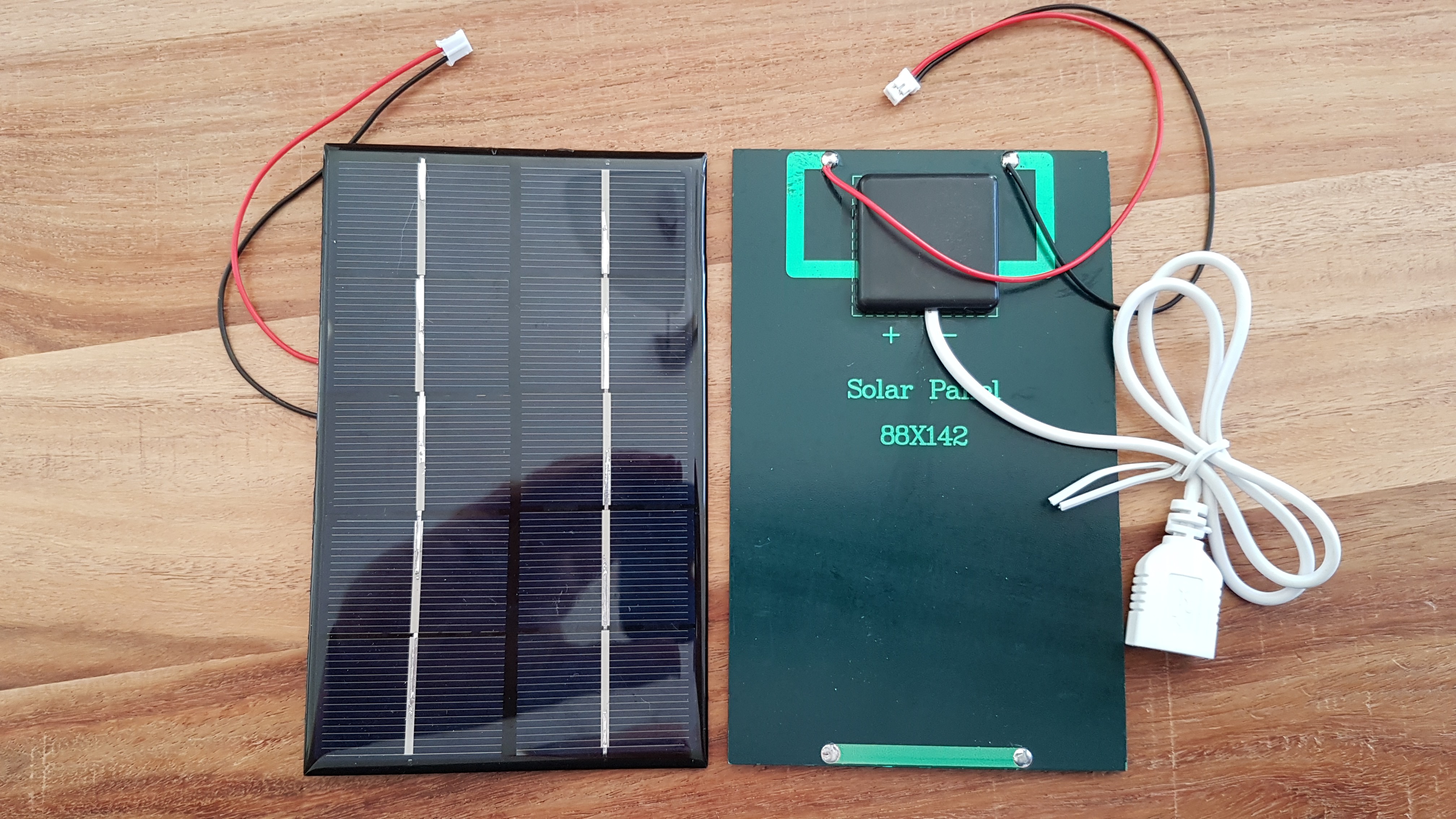

Following solar panels I have bought from aliexpress and tested at 600W/m^2 solar irradiance.

| Solar panel | Measured open voltage (Voc) | Measured short circuit current (Isc) | Estimated power | Price |

142x88mm 5V/5W | 5.75 V | 325 mA | 3W | 3.48 euro |

110x69 5V/1.25W | 5.75 V | 187 mA | 1.7W | 1.17 euro |

I measured solar panel short circuit current and nominal voltage and I have estimated maximum power at 1000W/m^2. Calculation is: Estimated power = 1.1*Isc * 5V * 1000/600 (watt). This shows that the specification is not correct at all.

Then I have measured charger input voltage and current, and output voltage and current as shown in the measurement . I have tested with above two solar panels, and two Li-ion batteries charged to different levels.

First I tested indoors. At 500 lux non of the chargers was able to charge at 1mA or more.

Then I tested outdoors in full sun, it was about 600W/m^2.

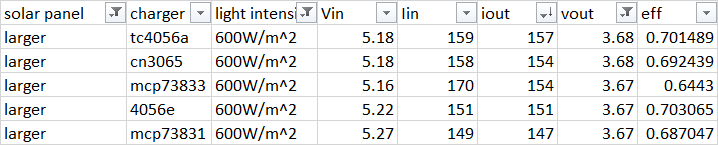

Below is the table for the larger solar panel and the lower battery voltage (~3.67V)

Charge current is a lot less than the programmed 500mA. Input voltage is still pretty high. And overall efficiency is poor (70%) due to the large voltage difference between input and output. There is no clear winner.

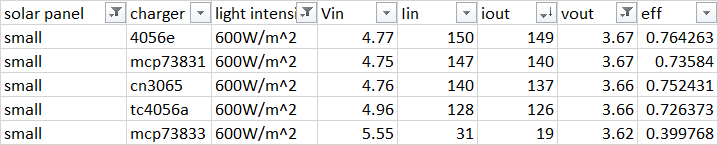

Below is the table for the smaller solar panel and the lower battery voltage (~3.67V)

Charge current is not so much worse compared to the larger panel. 4056E is the winner. MCP73833 somehow performed really bad.

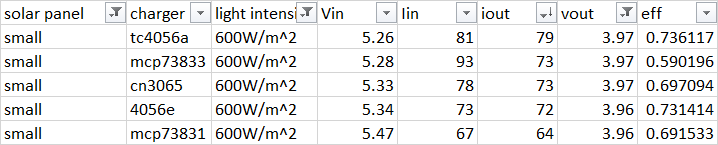

Below is the table for the larger solar panel and the higher battery voltage (~3.96

The charge current is much lower now, also input voltage is so much higher now. The MCP73831 is the loser.

Finally I tested the smaller solar panel with the higher battery voltage (~3.96V).

The results with the smaller solar panel is not different from the larger panel. Apparently it is mainly dependent on battery voltage. The MCP73831 is the loser.

Conclusions

- you can not trust solar panels specifications on aliexpress

- at indoor light levels (500lux) the chargers do not charge the battery (>1mA)

- outdoors the solar charger are capable of charging the battery from solar power, but current was lower than the solar panel max current or the programmed current

- I hoped charger input under voltage lockout voltage would work as sort of maximum power point control, but it doesn't. Efficiency...

Jasper Sikken

Jasper Sikken

mr.jb

mr.jb

Patrick Van Oosterwijck

Patrick Van Oosterwijck

Beast Devices

Beast Devices

Surprising and disappointing results. Thanks for taking the time to experiment and post.