To Do

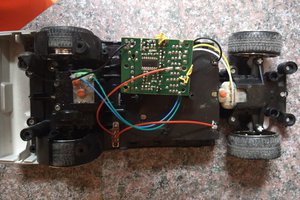

[Hardware]

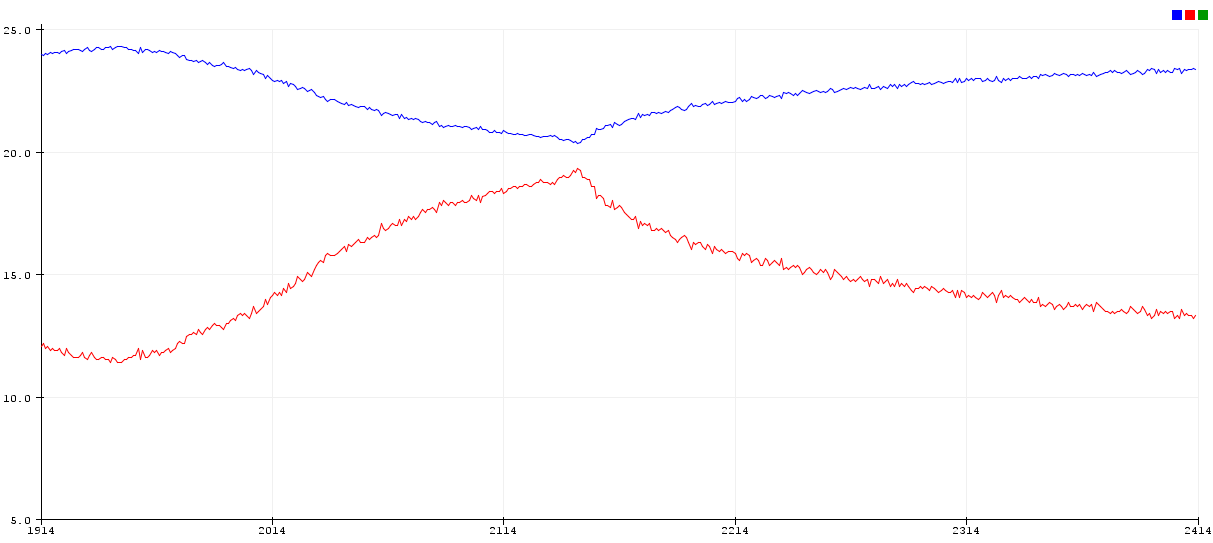

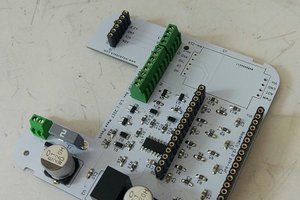

- Complete Simulations of Output Stage

- Test Power Supply

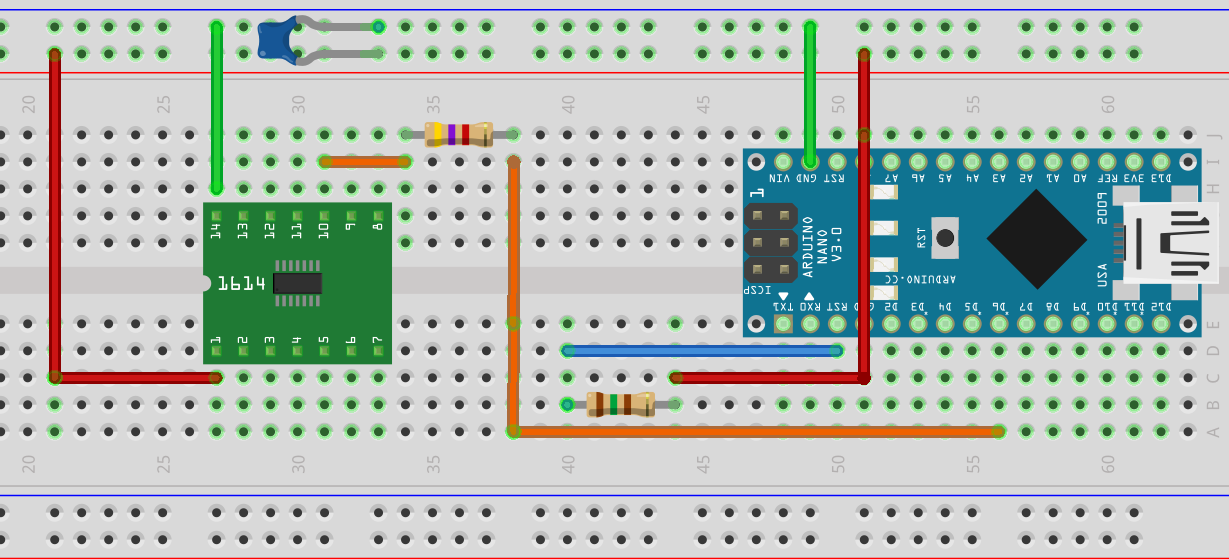

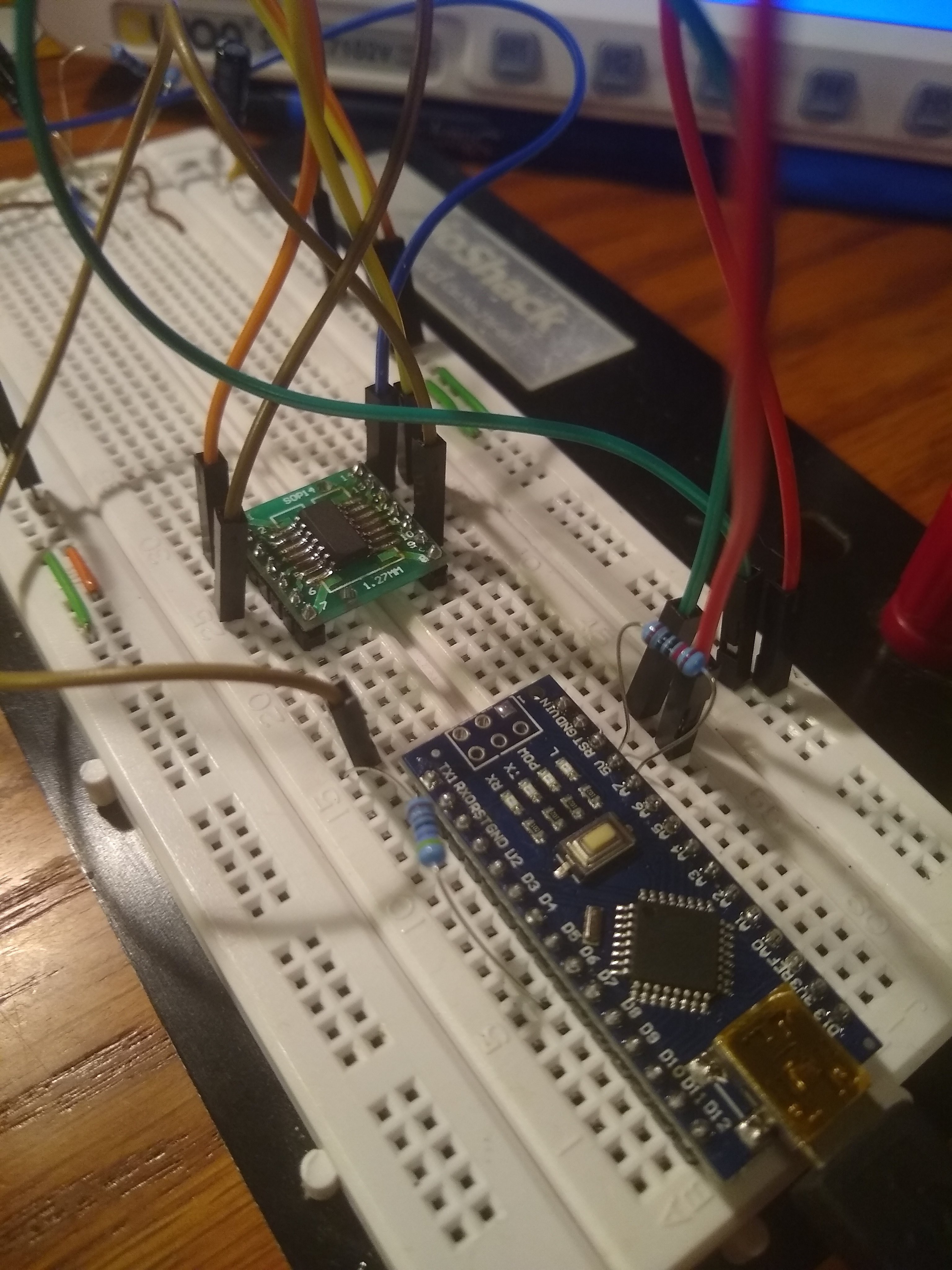

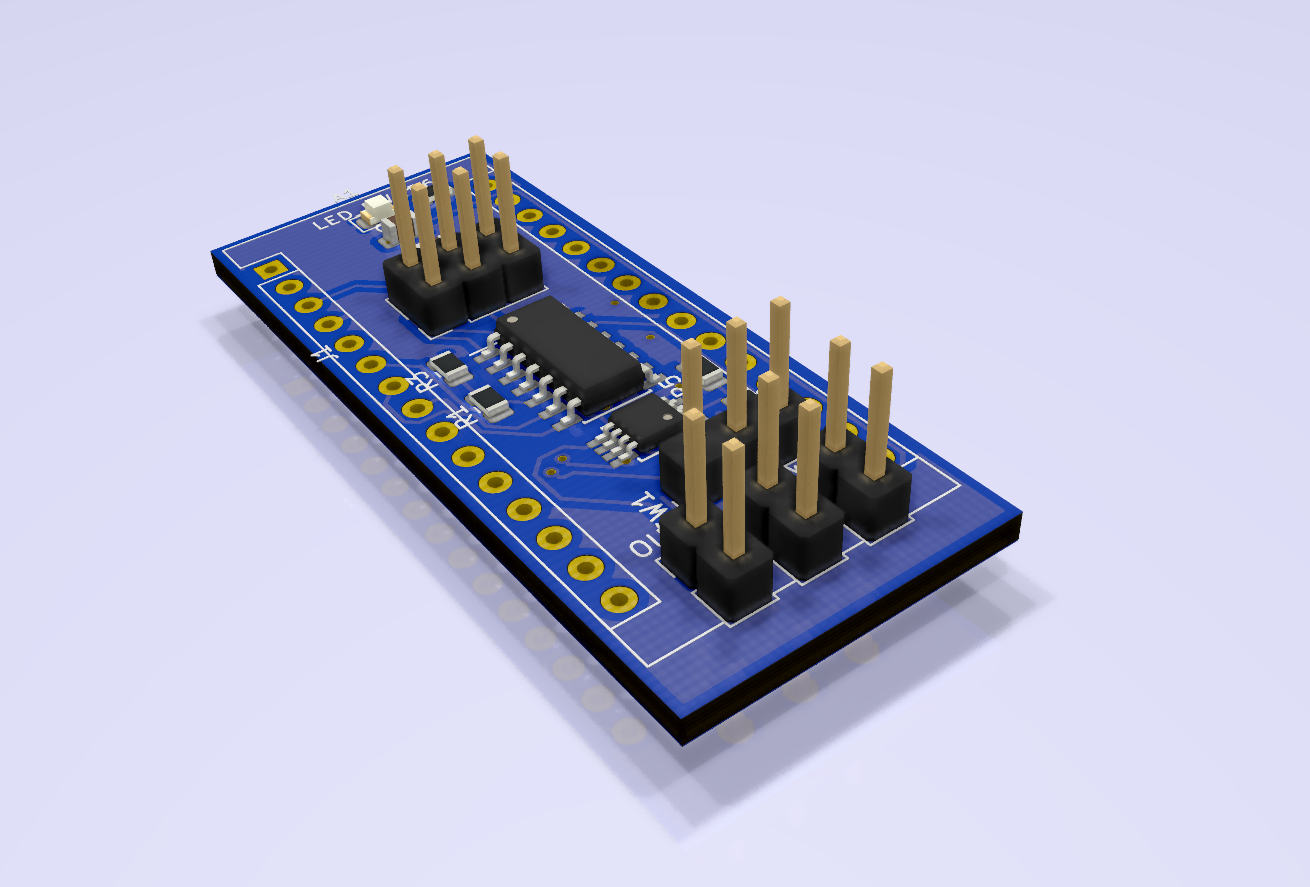

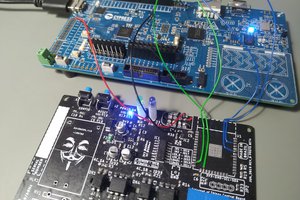

- Finish Prototype with MCU

[Software]

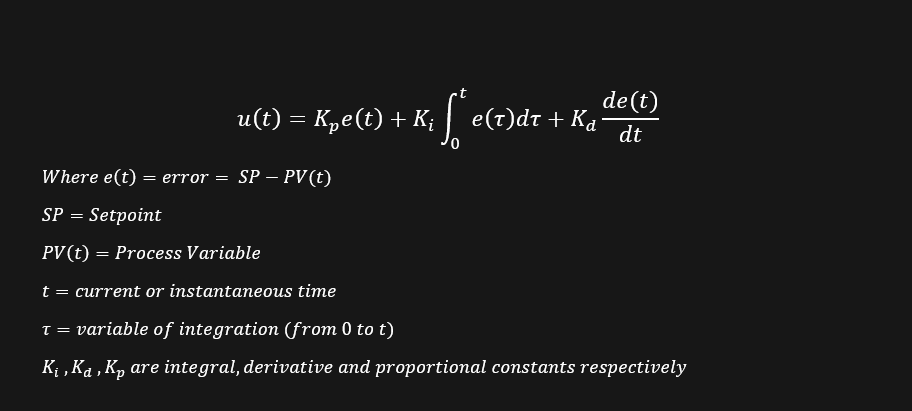

- Write PID loop software

- V0.1 of PID Library Uploaded

- Add mode selection for PID, PI, P controller types.

- Write interface library for display, buttons, encoders etc.

Changelog:

[Misc]

- Fixed broken GitHub Link

- V 0.1 of PID Library on GitHub [10/21/1019]

-----------------------------------------------------------------------------------------------------------------------------------

Useful Links

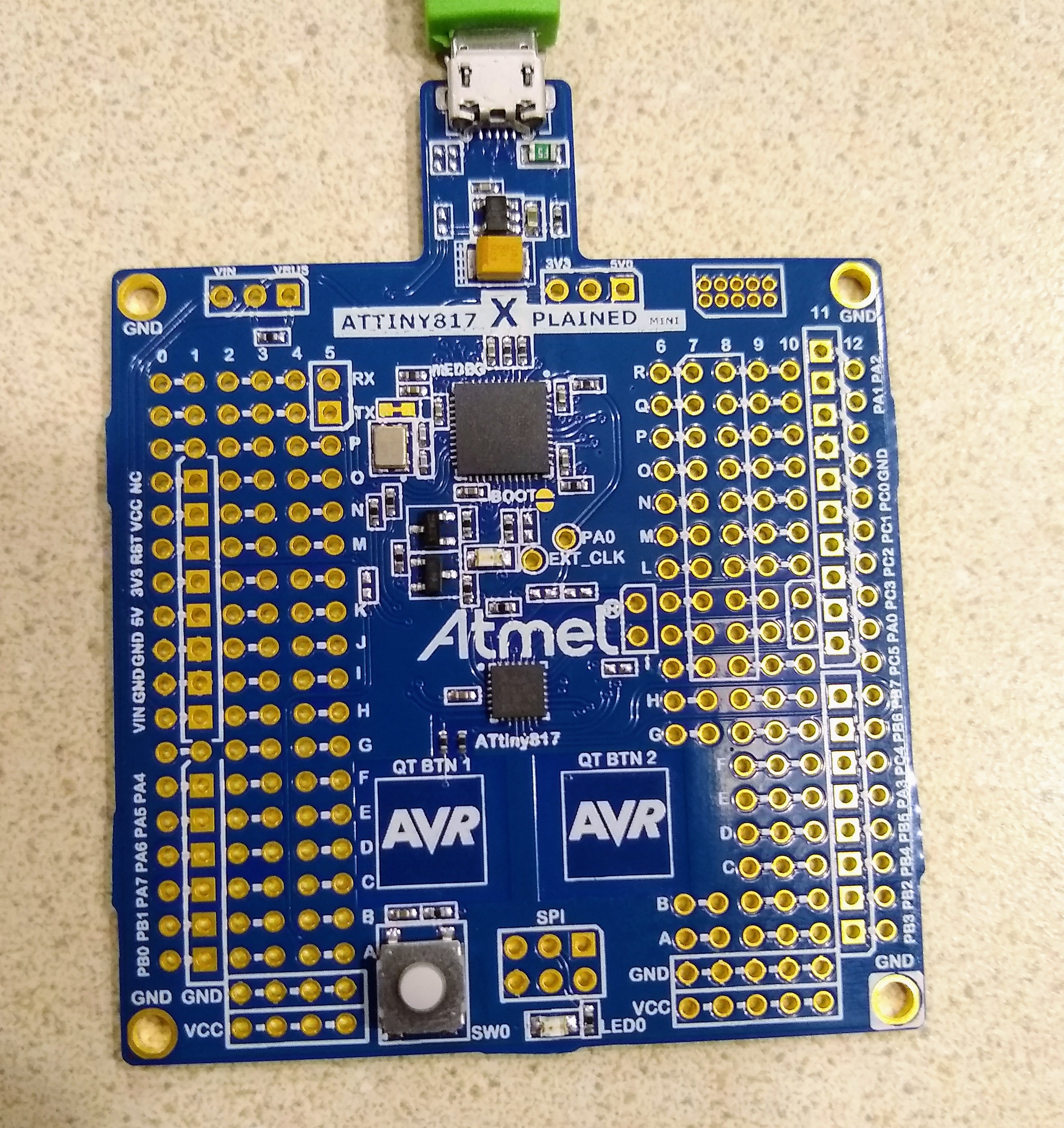

http://ww1.microchip.com/downloads/en/DeviceDoc/ATtiny1614-DataSheet-DS40001995B.pdf

http://ww1.microchip.com/downloads/en/Appnotes/TB3210-Getting-Started-with-DAC-90003210A.pdf

http://ww1.microchip.com/downloads/en/Appnotes/TB3209-Getting-Started-with-ADC-90003209A.pdf

-----------------------------------------------------------------------------------------------------------------------------------

Source Code:

[GitHub]

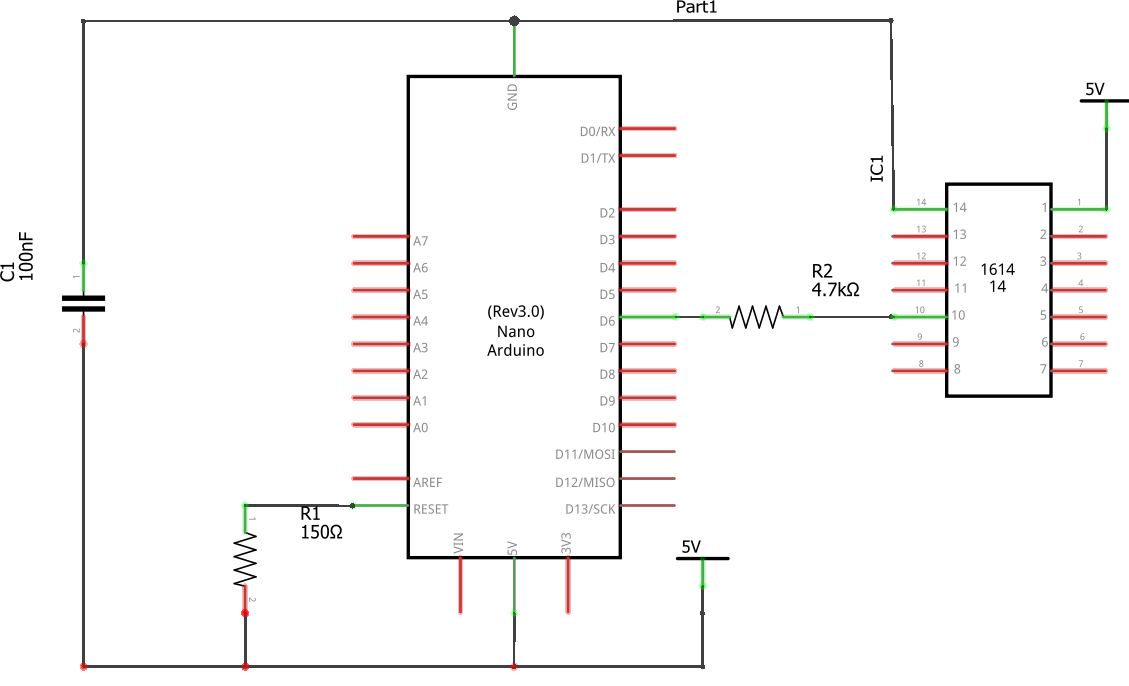

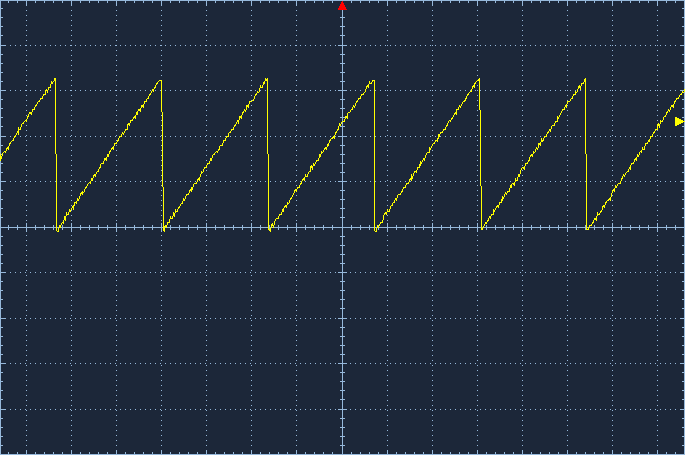

Unfortunately, the DAC can only go up to 4.3 V, so I will have to include some sort of compensation if I want true 0-5V output.

Unfortunately, the DAC can only go up to 4.3 V, so I will have to include some sort of compensation if I want true 0-5V output.

Benjamin Prescher

Benjamin Prescher

Pedro Minatel

Pedro Minatel

Maya Posch

Maya Posch

Blake W. Ford

Blake W. Ford

I like the idea of plug-and-play PID. How will you provide for loop tuning? Directly on this board, or through whatever host you wire it into?