PCB panel parameters

The primary reason for having your boards delivered in an array is to make automated assembly faster and less expensive. Running an array of boards through a pick-and-place machine is far more efficient than sending them through one at a time. Arrays are also desirable because they allow the addition of tooling rails, tooling holes, and fiducials, all of which help your assembler.panel parematers.

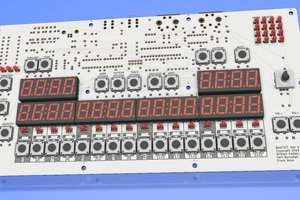

Array

An array is combining a single PCB multiple times or different pcb composed to make a larger array of connected boards.Other terms used to describe an array are: panelized, stepped out, palletized and rout and retain.

PCB Tooling Rail

Tooling Rails are the ‘frame,border’ for the array. They provide stability and make it easier to handle the arrays throughout the assembly process. Tooling holes and fiducials are usually added to the tooling rails. The rails could be on all four sides of the array or only on two sides. If you only have it on two sides, then you can usually get a few more pieces up on the panel, which will help the per board cost. Available options for panel borders: 5.00 mm – 7.00 mm – 10.00 mm – 20.00 mm To make a stable panel we propose a minimum border of 2 x 5 mm in X and Y.

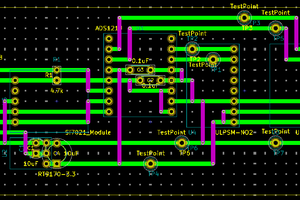

Fiducials

Fiducials are copper spots on the rails with the same finish as the rest of the board, which aid automated pick-and-place assembly equipment by providing a uniform reference point. The ideal size is .040” and will not be covered with mask to make it easier for assembly equipment to see. Typically, three fiducials are needed on an array and are placed on the rails. Some manufacturers may require fiducials on each individual board as well. However, for the most part, there are pads or other features on the individual boards that can be used to provide additional alignment targets.

Tooling Holes

Tooling Holes are non-plated holes added to the rails in the four corners to aid in alignment and orientation when assembling the board . They are typically .125″ in diameter but can be drilled to your required specification.tabs and bits.

Scoring

Scoring or V-cut is making a small V groove along the length of the board where they will be separated. The groove is typically 1/3rd on top, 1/3rd on bottom leaving 1/3rd of the material remaining in place to hold the boards together. The score will be made along the shared board outline. Scoring is performed only parallel to the x- and y-axes, not diagonally. Because scoring runs all the way across the array in a straight line, the board outline should be straight for scored arrays.

Break-rout tabs

If your design has an irregular shape, then tab routing may be required. Break-rout tab arrays will leave a small tab on all four sides of the board attached to the other boards or the rails. Small tabs of material will remain to hold the boards in place. This type of array is not as stiff as the scored array, but can be easier to break apart. Tabs are typically one on each side of every board and usually .050” wide. Our default is to add a 0.1″ (2.54mm) gap between the boards to allow the router bit to pass between them. To make separation easier, we can add small non-plated holes to the tabs called ‘mouse bites’ to perforate the tab. If you desire a smooth edge on your PCB’s, these areas will need to be sanded after the boards are removed from the array. The minimum ( and standard) clearance between PCB’s for break-routing is 2.00 mm. Any larger value is OK.

X Outs

An X out is when one of the individual boards on the array does not pass the test and is marked out with a marker. Some manufacturers will allow a certain percentage of X outs on the order, while others may require there be no X outs on any of the arrays. By having no X outs, it will make the board cost a little more since the PCB manufacturer may need to make a larger number of arrays in order to meet the order requirements depending on their yields.

Stencils

If we setup the array for you, your assembler will need to receive...

Arya

Arya

Frank Buss

Frank Buss

PCB designer

PCB designer

Mike Teachman

Mike Teachman

Yep,2x2 panel PCB cheaper than 4 separate PCBs,save tooling cost.