Honey bees are under extreme pressure. Recently, there have been growing concerns over the global threat to bees, with 25 species threatened and 31 of conservation concern in the UK alone. Research shows a 54% decrease in honeybee hives in the UK between 1985 and 2005, which further prompts concern over the ‘pollination crisis.The biggest contributor to this decline is viruses spread by a parasite, Varroa Destructor. But this isn’t a natural situation. The parasite is spread by beekeeping practices, including keeping the bees in conditions that are very different from their natural abode of tree hollows.

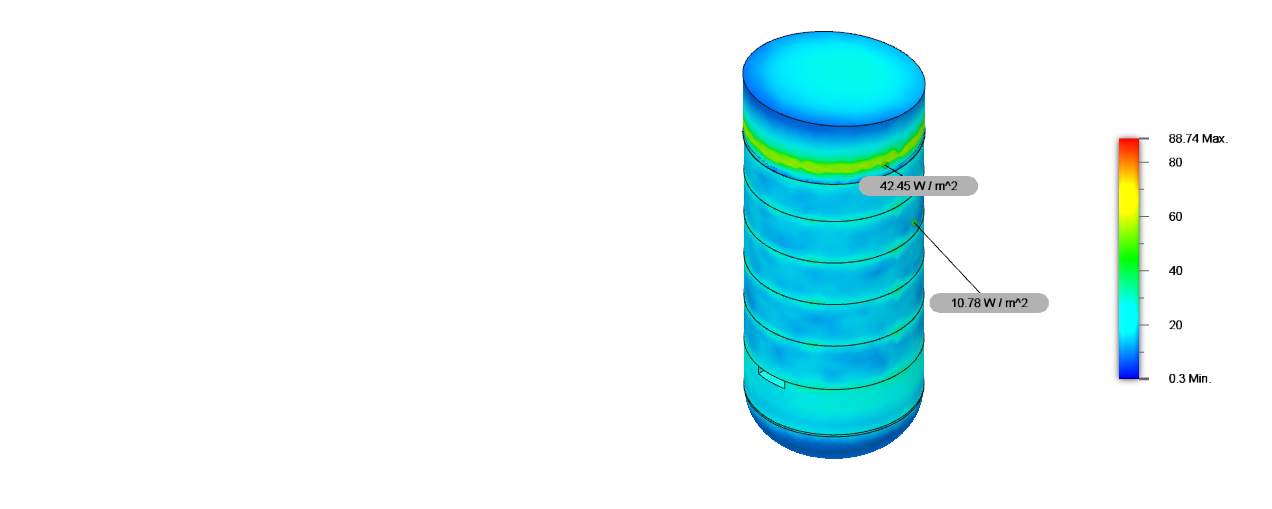

The heat losses in man-made honey bee hives are many times greater than those in natural nests. Now, using engineering techniques more commonly found probing industrial problems, it has been proven that the current design of man-made hives also creates lower humidity and temperature levels that favour the Varroa parasite. To maintain temperature homeostasis in a cool environment, energy lost through the nest enclosure must be made up by more honeybee activity and stress, either to generate more heat or to cluster. Langstroth beehives (typically made from wood) experience 7-8 times more heat loss than natural nests.

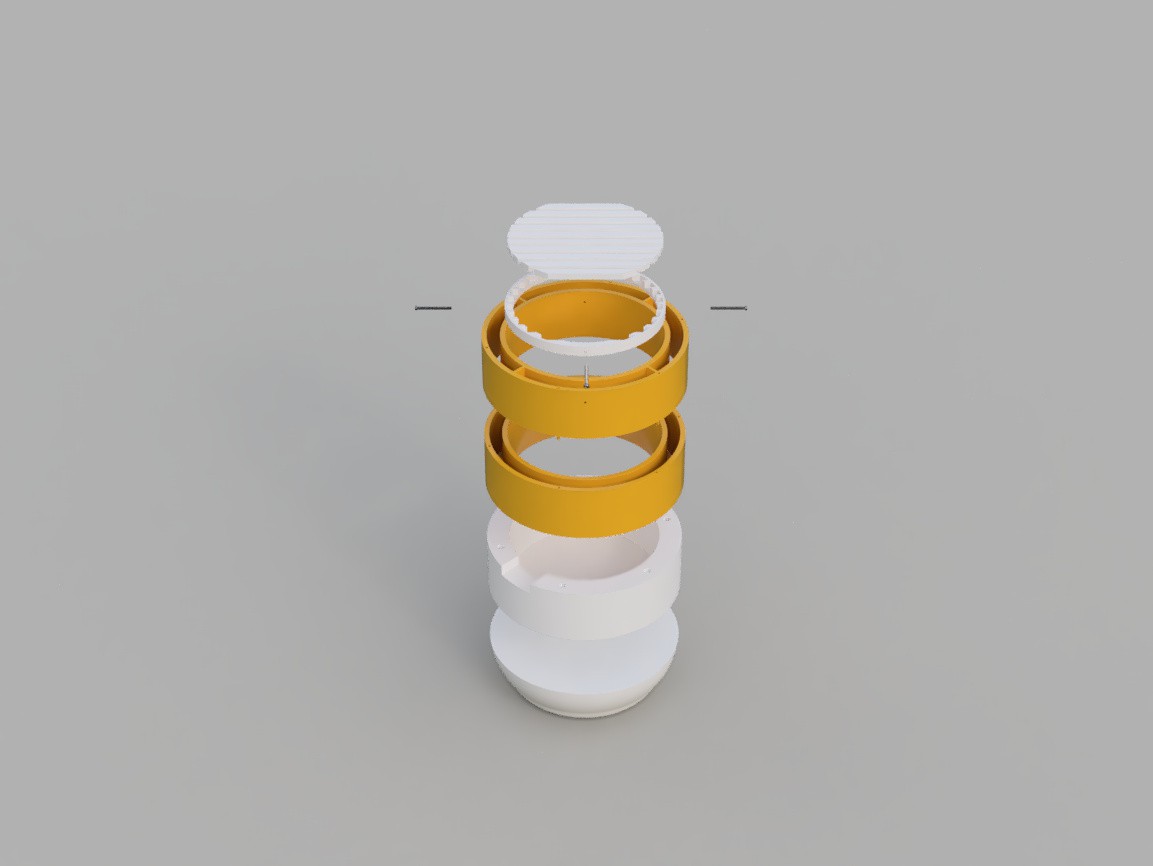

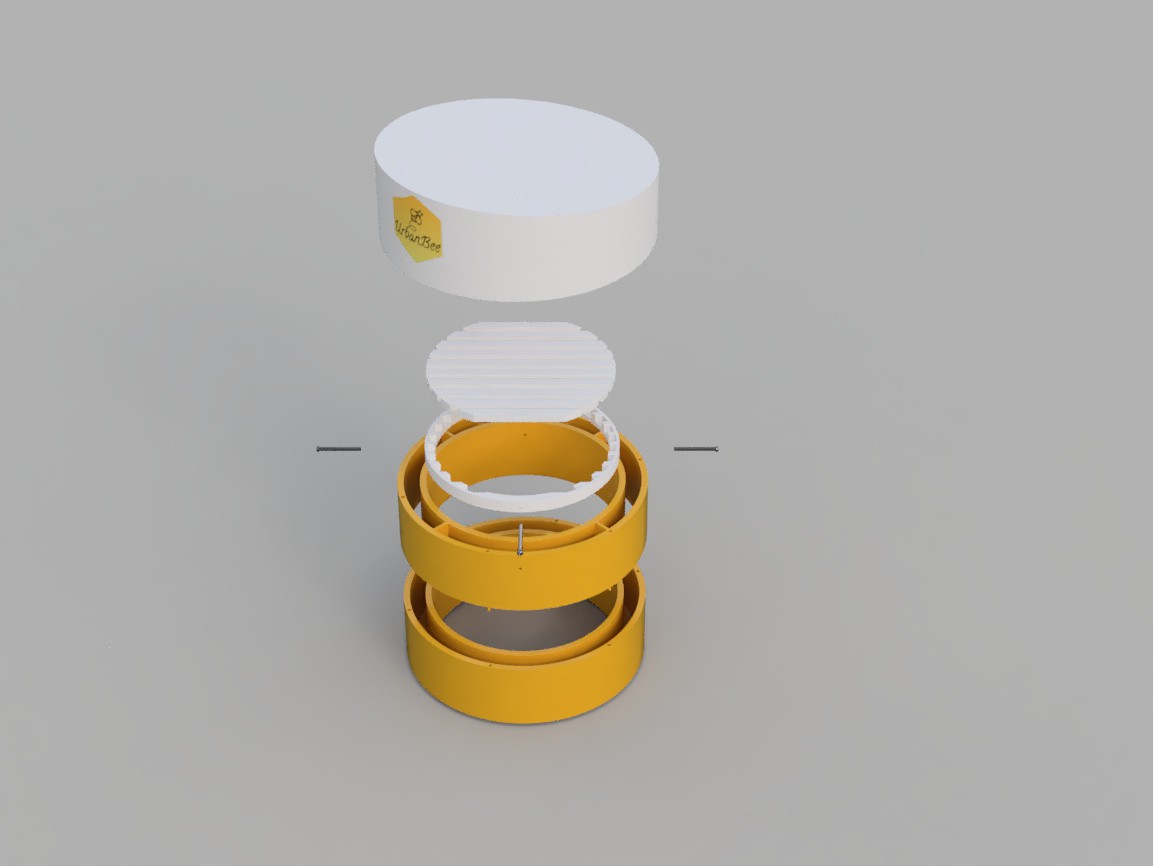

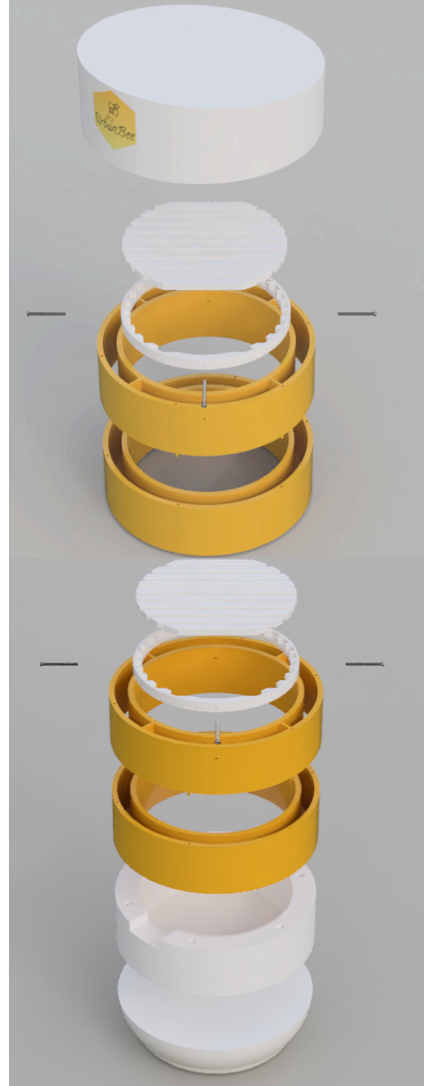

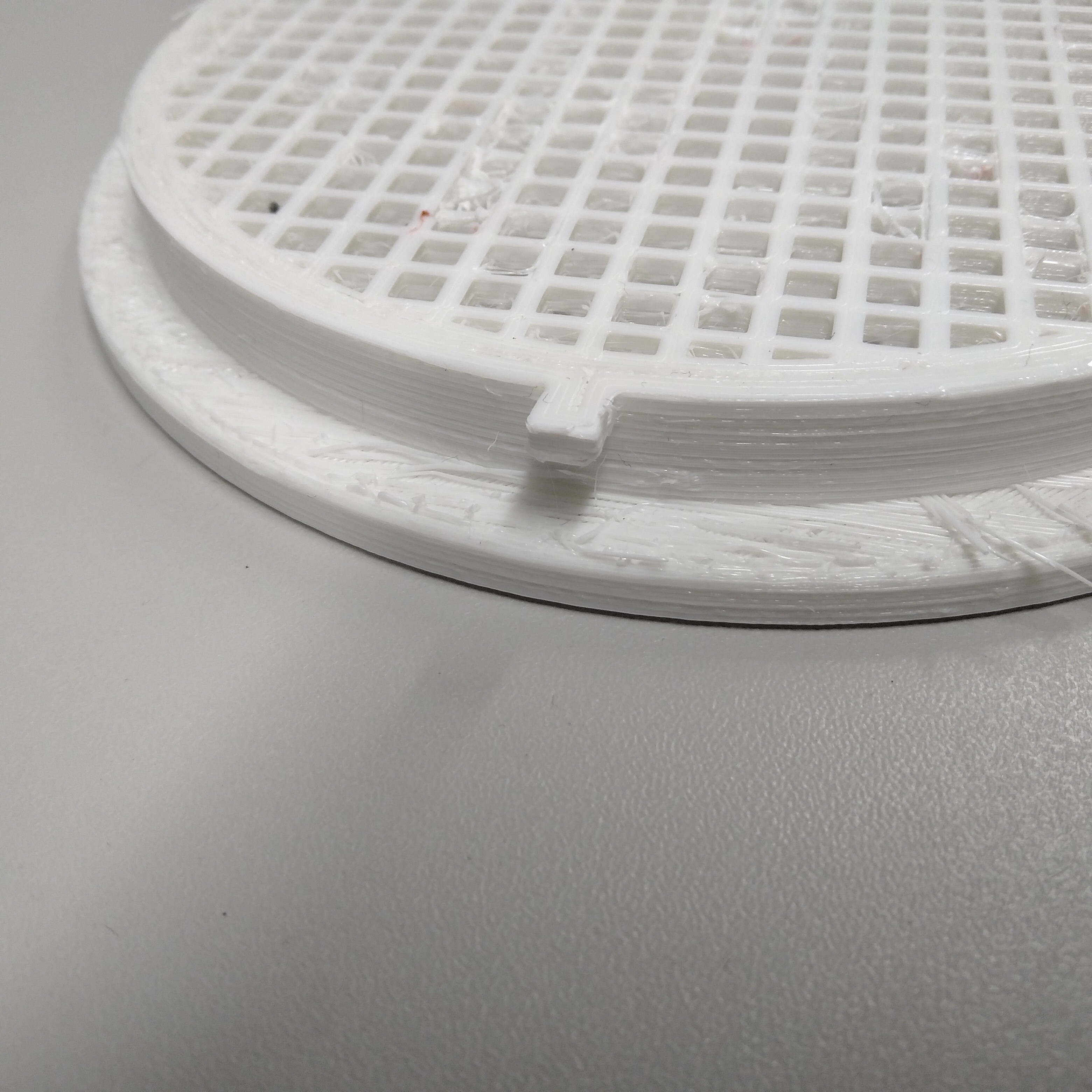

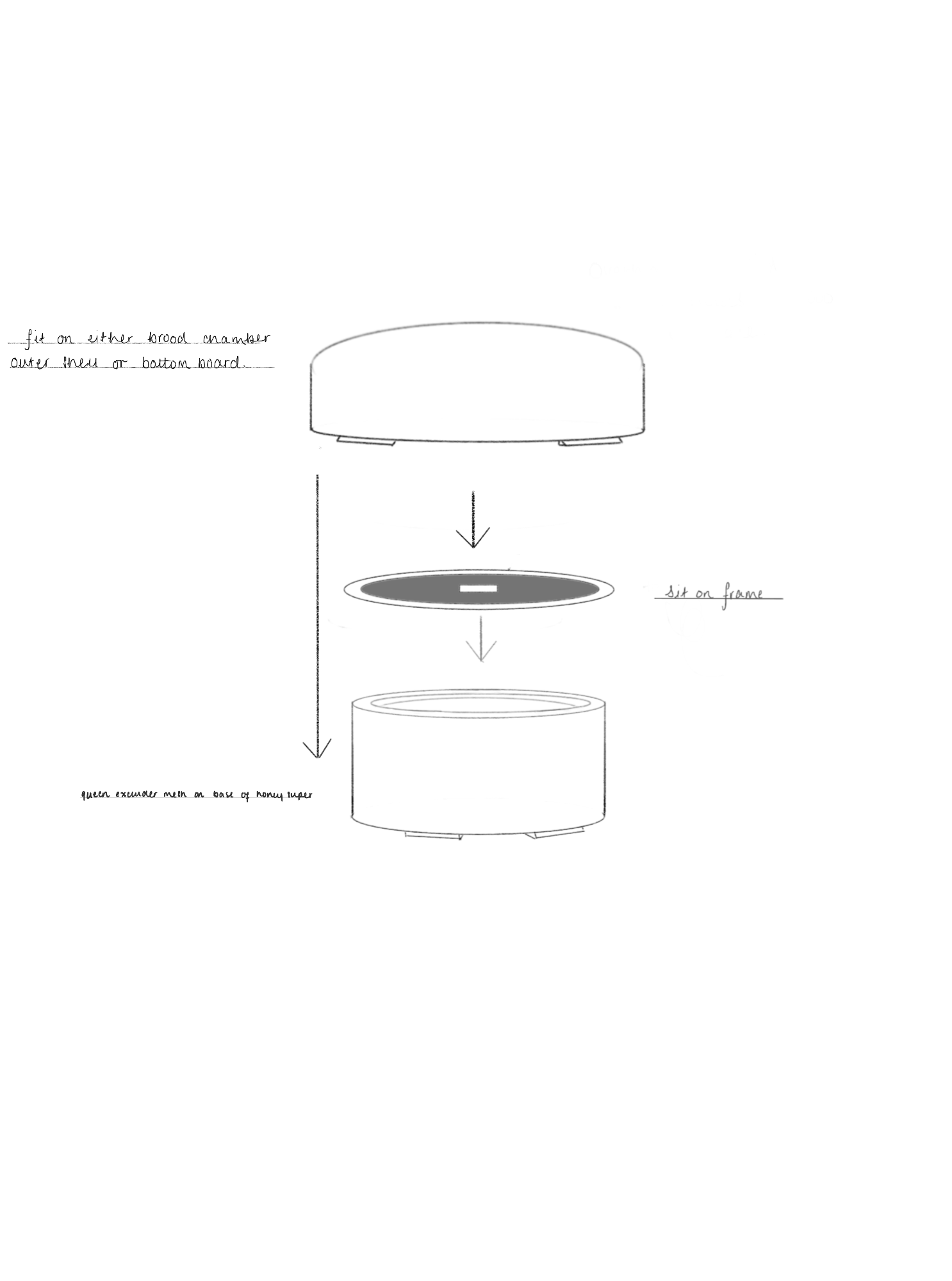

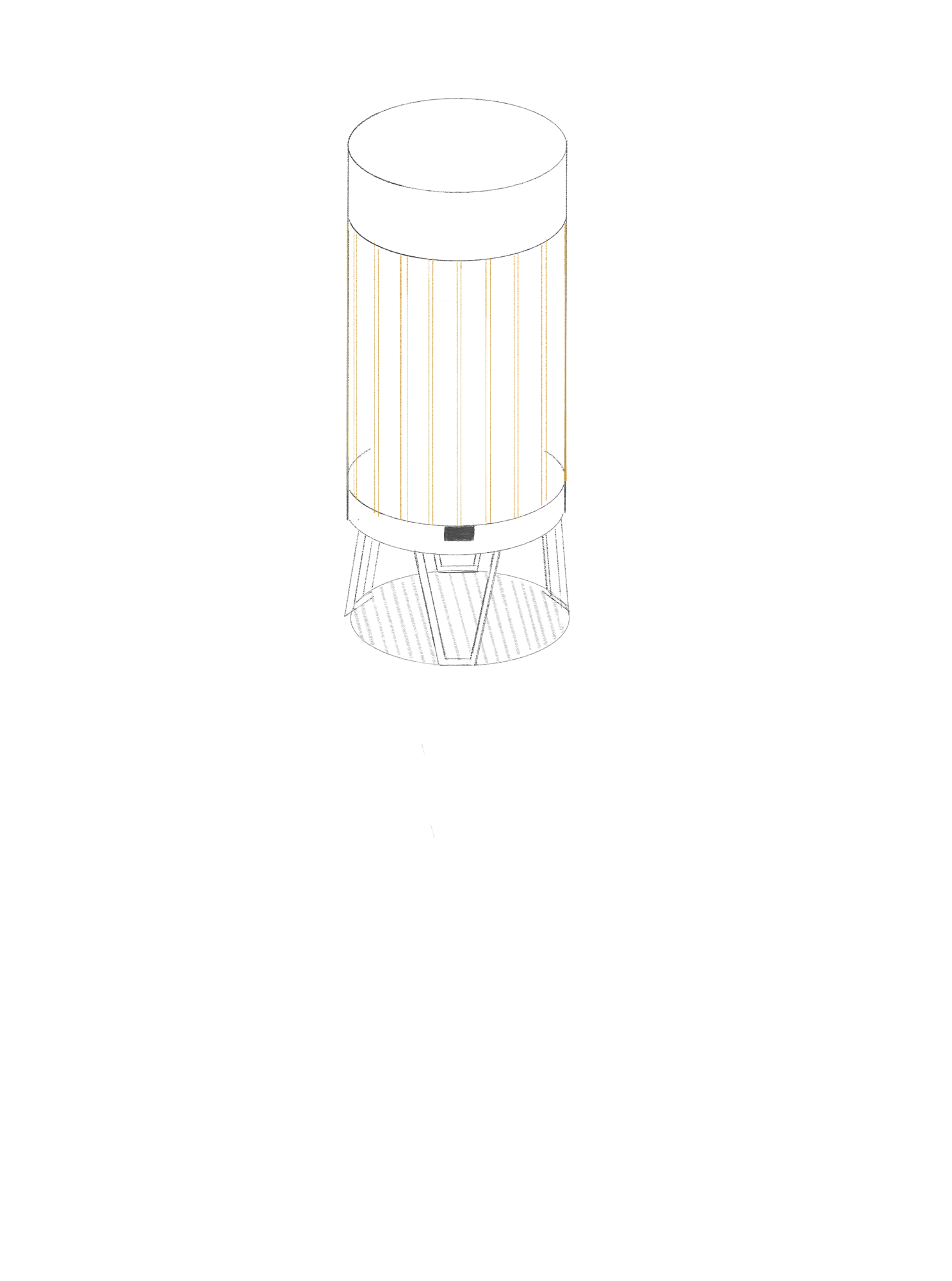

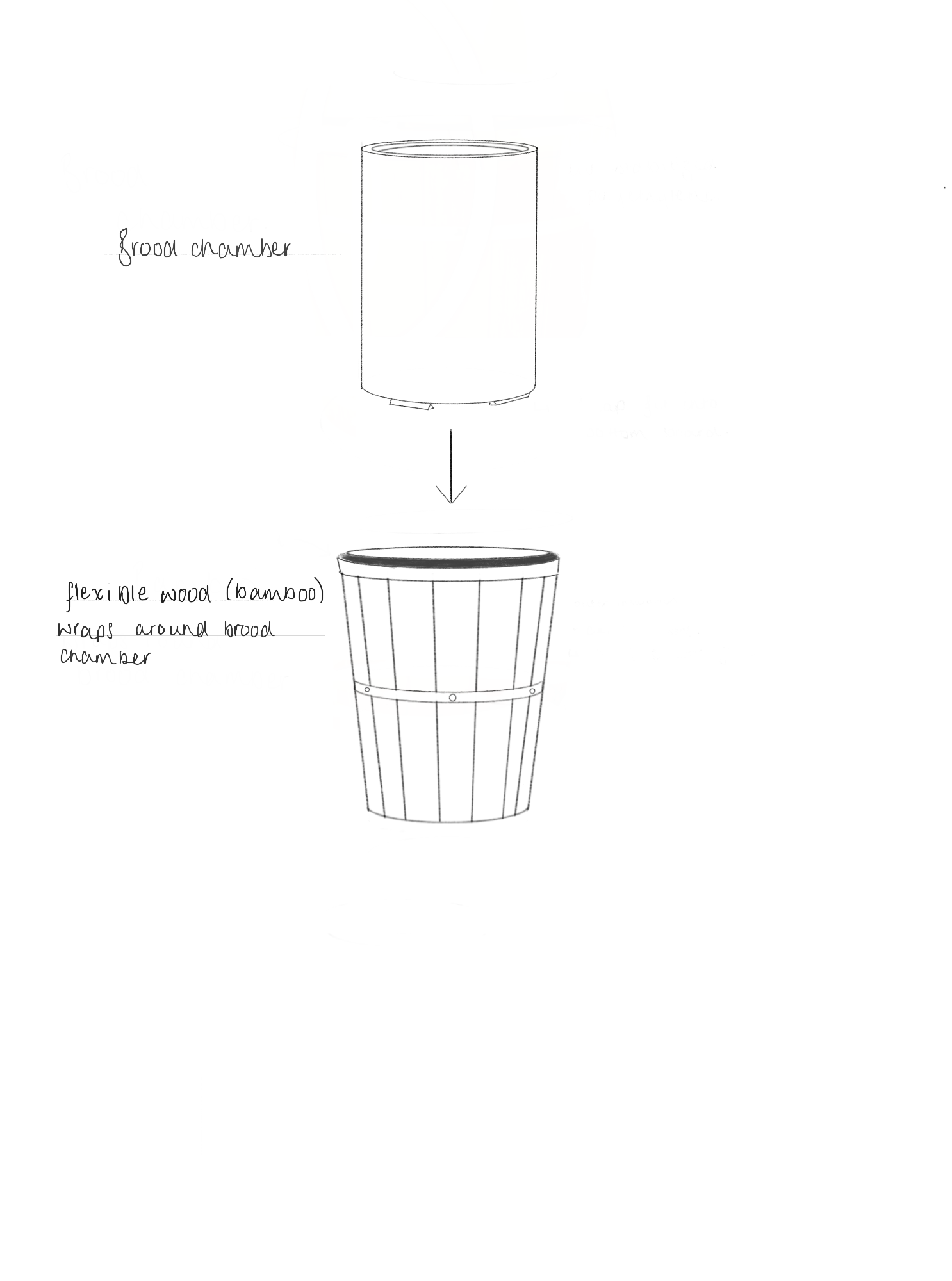

So if I can redesign beekeeper hives to recreate the conditions of a natural tree enclosure we could help stop the parasite and give honey bees a chance to recover. Therefore, after extensive research I have decided to design a beehive made from plastic (provided it is non-toxic), due to their insulating properties.

Naman Pushp

Naman Pushp

Josh

Josh

Matt Reimer

Matt Reimer

Wow neato!