Machines

We started with chemistry magnetic stirrers, but we needed bigger, so we built our own gig with a drill (left). We then tried polymerizing a pre-stretched material to see if it would help (right), but the results were not particularly convincing...

Augmenting existing materials

Zipper

This is probably the simplest, but most unique to this process, we don't modify materials mechanically. This zipper used to be white, but the polymerization made it black. Here we use the constant resistance of the augmented material to measure how much the electricity has to travel depending on the closed / open state (250k => 600k). Obviously, it's a continuous measure, so this is a bit like a flexible potentiometer:

- - -

Kinesio tape

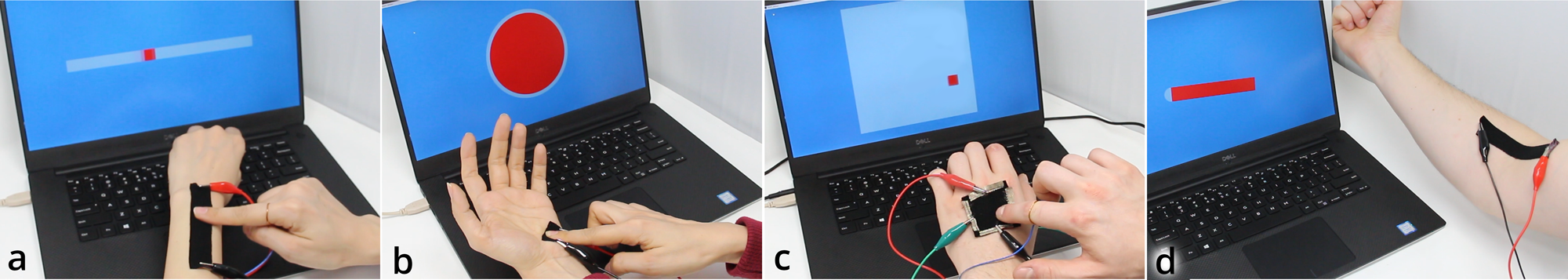

This is a sticky tape that can be purchased in most pharmacies for sprain or dislocation, it's made of cotton and glue to stick to the skin. As illustrated below, it can be used as linear slider (a), pressure sensor (b), xyz touch pad (c) and stretch/flex sensor (d).

Note: an academic paper about it was published at the Augmented Humans Conference.

Note: an academic paper about it was published at the Augmented Humans Conference.

- - -

Yarns

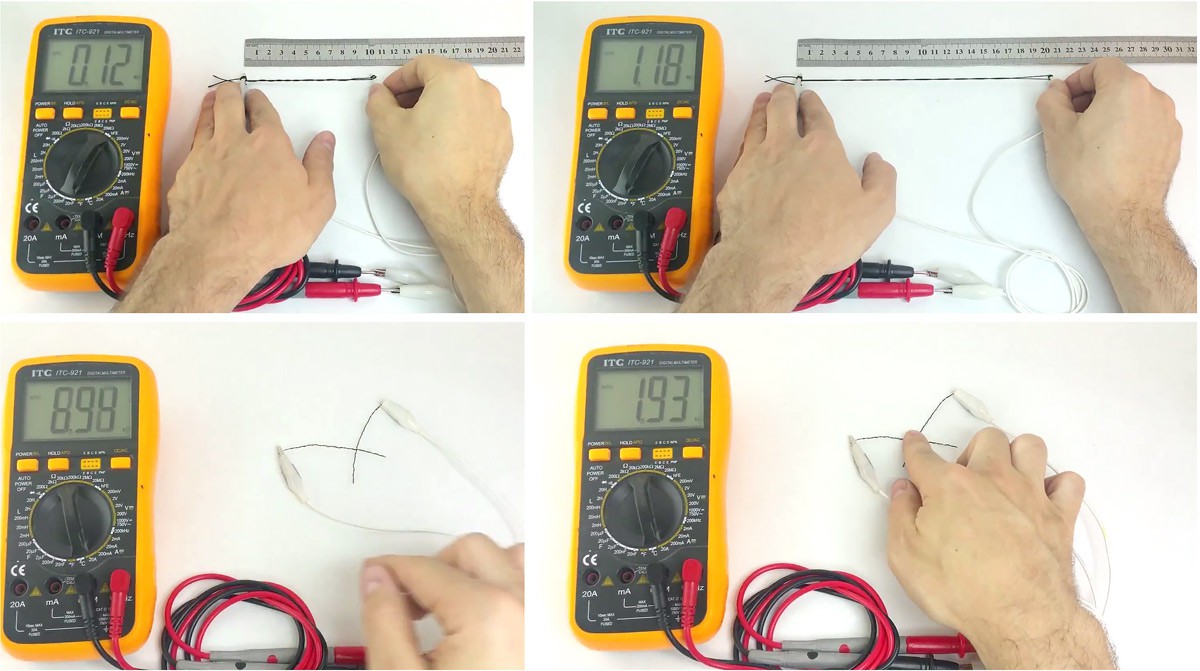

As seen in the demo video, we can functionalize stretchable materials, the top pictures show the range for a simple textile elastic: from 120 Kohms to 1.2 Mohms when stretched twice.

In the bottom picures, we can see a special thread that we polymerized: it has a copper core and a textile shield, which became piezoresistive. We can thus measure the pressure at the intersection: the resistance goes from 8 Kohms to 2 Kohms with maximum pressure.

Masking

We tried various ways to create controlled patterns.

Batik, a traditional technique from Indonesia, uses war to block dyeing process, and it works well for our polymerization too (see bottom right pictures + next section). The only trick is that wax needs a bit of fat to make it crack less.

We also used quick prototyping approaches, such as 3d printing (top pics) or hot glue (bottom) on textiles, and they both work but sometimes involve boiling to remove the mask.

Finally, we made stencils with laser cut acrylic (top pics) and the result were fairly impressive. Depending on the textile we could make 1mm traces (with 0.1mm cut in the stencil).

Hybrids:

That's where it gets exciting. If you take a "classic" conductive textile made out of silver or copper (cheaper), you can etch it with vinegar (or with the iron chloride of our process).

You can mask it with all the techniques mentioned above, then you get a flexible PCB!

The good news here is that you can also polymerize some parts of this flexible PCB, and get pressure sensors for example - see 'c' below. By folding it, you can measure the variable resistance between 'a' and 'b':

Bonus

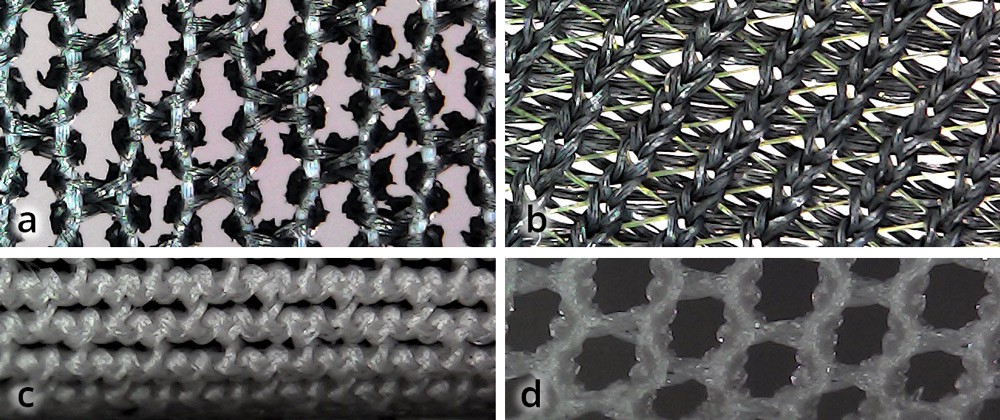

Cheap USB microscope give pretty good images now, so we looked at what polymerized, and what didn't. In picture 'a' we can see vertical thread that stayed white, probably because it's synthetic, but also possibly because it's "masked" when this textile is not stretched.

Drix

Drix

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.