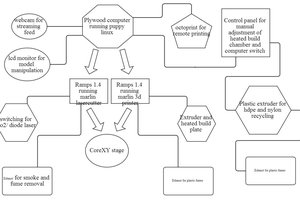

I've first seen the [StyroPyro] video about a Nd:YAG laser embded in tattoo removal machine. then I felt on this article. This gave me the idea to build this machine

1) Order the laser

2) I need to modify the moving mechanism of the FLsun cube because im not really happy with it. I will check my new design with a conventional hotend and see if it can move nicely.

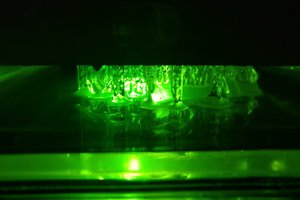

3) test the laser on metal powder, order some optics for it if needed to refocus the beam

4) Redesign the head mouting part to hold the ND:YAG laser on the 3D printer frame

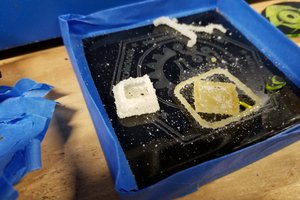

5) Design a powder dispensing and containing mechanism (powder are a pain to deal with)

6) make a slicer fitted for metal binding (a few article describe moving pattern to limit warping, thermal stress, etc)

7) Experiment with audio transducer as a way to compact the powder and increase print density

8) Maye it will work

Nathann

Nathann

Oliveira

Oliveira

Eric (Jadoo)

Eric (Jadoo)

Mark Peng

Mark Peng

You're absolutely right. Titanium printing lasers are at 1070nm. Very close to what this machine was giving off. Each material will take a different nm.

Adding black will work. I thought sla printer immediately when I saw this on styro piro. There is an arduino open source sla project.

You will need argon for allow type metals like Ti and aluminum.

Be overly carefull with this!

Metal Powder can ignight into a fire you wont be able to put out. You will need argon. Look up how not to burn your house down first! Ti and mg powder is no joke.

I suggest you look into titomic. Cold spray deposition as well!