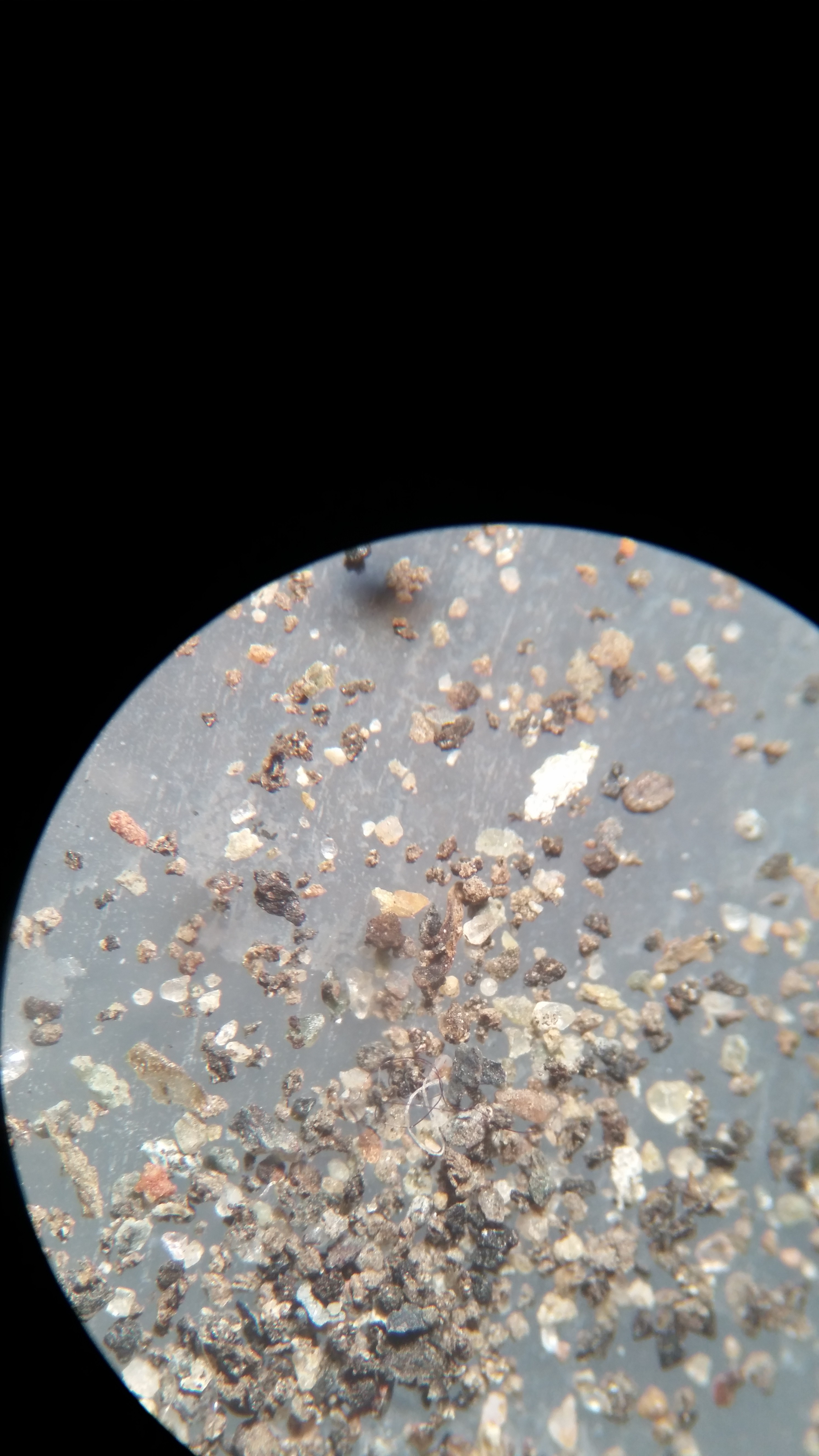

I just spent the last couple of hours on a dissecting microscope looking through grains of sand for things that were more round than usual. And I did find things. 7 or 8 candidate rough or shiny stones of size 150-500 microns, which I transferred to a tiny plastic bag using a sliver of moistened matchstick. It's not exactly the same, but right now I'm glad for my training in handling nematodes, which can be of similar size and which are also fragile and try to squirm away. Tiny rocks, in comparison, are relatively easy to pick up --- though I'm not convinced that every single one of the specks actually made it into the bag afterwards. (Edit: instead of a a plastic bag, use a sticky note or bit of conductive tape if planning on using an SEM).

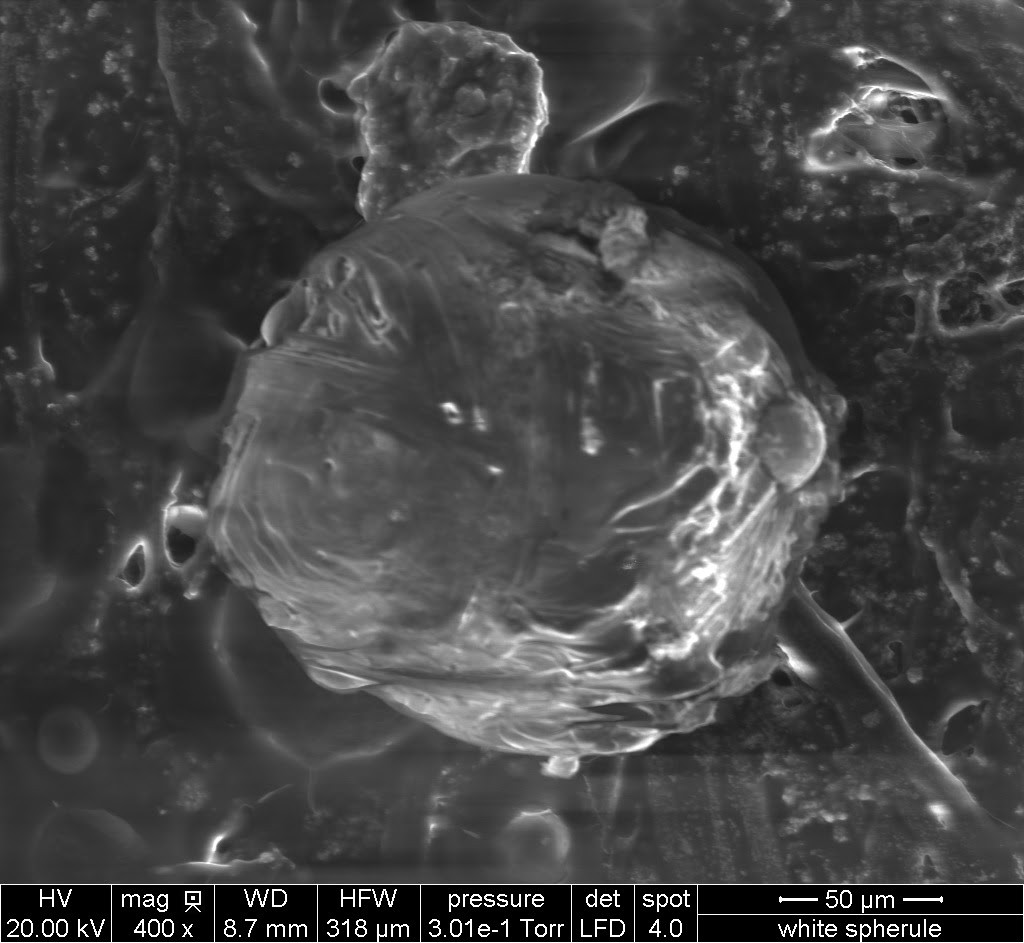

Unfortunately, while clearer when viewed directly with my eyeballs, the best pictures I could get with my phone on the eyepiece don't vastly exceed that of the USB microscope. Here's the large spherule I showed in the last post --- if it were extraterrestrial it would probably be "I type", but again, most that look like this are manmade contamination.

So when I get a chance they'll go right into the SEM to look in proper detail. In the meantime, let's play: Spot the blurry spherule!

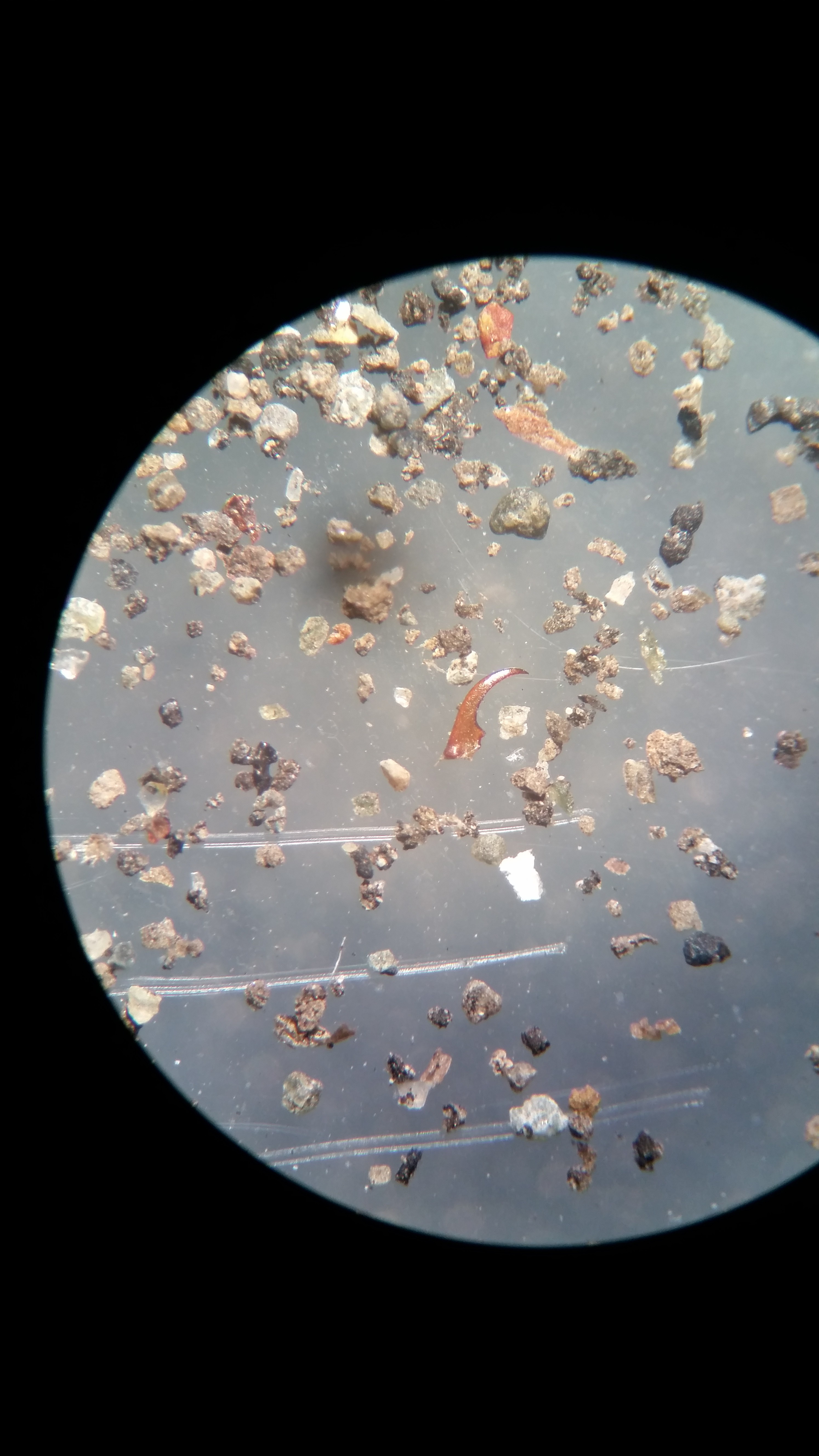

There's actually quite a bit of interesting "other" that I didn't transfer over, too:

is that an insect mandible? a thorn?

After spending this time looking through with my eyeballs, I am still convinced that some form of automation, or further enrichment of the sample, is possible. After all, we already did the latter with our washing, sieving, and magnetic sorting.

First we can be even stricter: Wash more thoroughly, in order to remove all the little tiny dirt flecks which complicate the search in the small size fraction, and allow non-magnetic particles to stick to the magnetic ones. And I would sieve to an even narrower particle size --- perhaps 50 microns in variation.

With that size fraction I would like to then try a method to physically separate out jagged samples from rounded ones. My ideas are to merely shake them dry in a container until the smaller, round objects end at the bottom, to put them on a shaker with a slight slant so that rounded particles tend to roll to the bottom, or to (most complicated) use a dense liquid like saturated sucrose solution to separate them out based on drag.

I still think the automated machine vision part is possible, too, again, trying to put the particles in single file so we can use good optics and not have to make them move. But the idea of a magnetic needle picking out individual particles is pretty much absurd. I mean yes, it's possible, but it would be a pain in the butt to build.

Something like what they use to separate out seeds would be ideal:

or, actually, it turns out they have this optimized for sand-sized particles --- for sand!

Apparently, the "Wesort Intelligent Full-Color CCD Quartz sand Color Sorter is specialized for the Quartz sand processing industry". What a world.

(Once again, I apologize as this is straying further and further from the path of "hacking 3d printers"! But I already started titling the posts "part 1", "part 2", soo....)

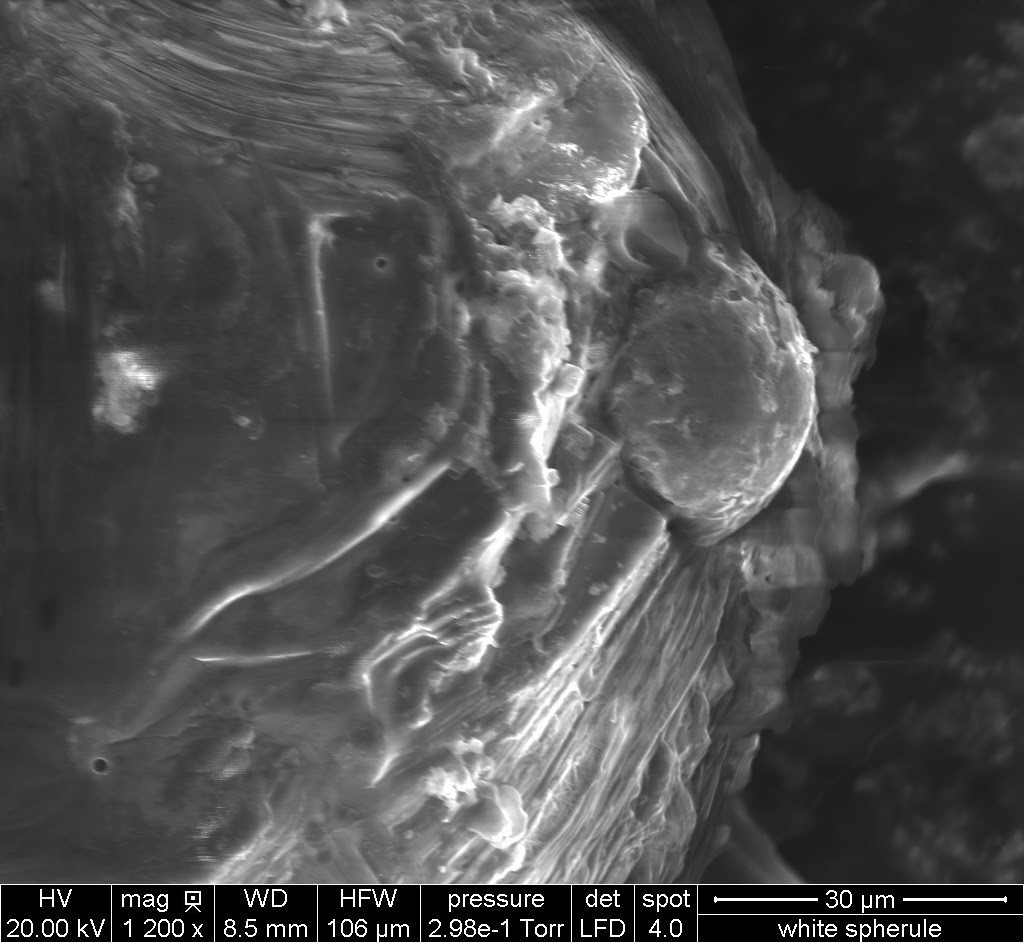

Edit: No meteorites in this batch, but here's a couple SEM pictures of what was a promising candidate.

I'm also currently expecting (march 2021) some magnetic dust from a generous stranger from the river thames. My main thoughts are still along the lines of trying to find a limitless feed material that has some verified amount of meteorites, and then focus on finding better ways to automatically purify it as much as possible before handing off to humans.

Ahron Wayne

Ahron Wayne

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

No apology needed for this superb sidebar, IMO.

Are you sure? yes | no

If I had my own "meta project" I'd spend some time talking about the choice of splitting a project up when something changes, versus just being off topic. I did that with the "automatic bug follower" even though it's using exactly the same hardware. I guess if I manage to make a separator for micrometeorites then that could go in its own project.

Are you sure? yes | no