Micrometeorites are tiny little rocks that fell from the sky, and they're actually pretty common: on average, about one falls on the earth's surface per square meter, per year. Finding them is quite easy, too, if you live in Antarctica --- just melt some drinking water and save the particles at the bottom of the hole. After all, the entire continent is covered in ice, so said particles must have come from up above.

Everywhere else in the world, though, finding micrometeorites is not easy. In fact, it was only until 2016 that a Norwegian Jazz guitarist (really) proved to the world that you could find these particles amidst the noise of urban contamination. He has since found thousands, and leads an active Facebook group where many do the same. The secret is first physically reducing the noise as much as possible, and then being patient enough to sift through large amounts of material. I've thought for a while that a project like LadyBug could be used to automate both processes to some level, with the eventual goal of being able to take a scoop of dirt from anywhere, chuck it into a machine, and have it spit out tiny meteorites at the other end.

The reason I'm updating the project now is because my dad and I finally got around to emptying the rain barrel, which has been sitting under the spout for about five years now. Theoretically, any tiny rocks that landed on the roof would get flushed into the barrel, sink below the point of the spigot, and concentrate there over time.

...Maybe?

I took this nice bucket of at-the-bottom rainbarrel sludge and set to work extracting the small mineral particles, as described by "on the trail of stardust". Basically, I added water, waited a little bit of time for heavy particles to settle, then poured off the liquid. Over and over, like gold panning. Once I had done this a few times in the bucket, I transferred it over to a smaller bowl and basically just directed a stream of running water into it, so that the container was constantly overflowing. This worked much better for removing all the tiny leaves and dirt, and, when dried, I was rewarded with a couple of spoonfuls of non-dirt that could be separated into different size fractions.

Finally, I took these size fractions (>0.5mm, 0.25-0.5, and 0.15-0.25, because these are the meshes I had) and separated out the magnetic particles by using a magnet covered by a plastic bag. Not all micrometeorites are magnetic, but most are, and the extra separation is necessary to have a chance at finding one, at least for an amateur like me.

From there, I immediately noticed my first spherule with the naked eye in the larger size fraction. Woohoo!

Unfortunately, the magnification/quality I can get with my USB microscopes turns not good enough to make any kind of identification other than being able to tell that it's round. I'll have to take this and any others I find in to a proper stereoscope and then possibly an SEM to be sure. Most spherules like this are of human formation, anyway.

Now, I probably have about half a gram of magnetic mid-sized particles, or a few thousand to tens of thousands. Really, not that much --- certainly not too many that I can't search by eye, and I plan to. But again, let's imagine that we are truly ambitious and want to come up with something that would scale to checking through millions and millions of particles a day.

Anyway, let's first start with the USB microscope sees in the magnetic 250-500 micron fraction:

(excuse the background --- it is sharpie'd cardboard. I am still trying to figure out the best thing for imaging rocks of varying but mostly blackish colors).

Note that we have quite a range of particle sizes and colors, and some things are shiny and some are not and some are blurry and some are not. The first thing we could easily do is separate to a very consistent size, which would make things easier. But let's brute force the issue with a stack+stitch:

(click for full size). Is that gold?

So now we've got a much larger field of view, and more rocks to see at once. We could feed this into some kind of image segmentatorator, but really, stitching doesn't actually help here, since the object of interest fits into a single image! And segmentor doesn't care whether it gets one big image or many small ones. Since we would presumably be keeping track of position information, stitching only adds an extra step where we now have to figure out where the rocks individually were.

Okay, but maybe your system does a scan at low magnification and then zooms in to a higher magnification to take a closer look at anything of interest.

Here's one rock:

And here's the whole stitched view (non-stacked --- there was a bump).

Stitching is a bit more useful at this magnification, because you don't have to worry about your particles fitting into each frame. But this is even less of an issue for the smaller rocks, which we haven't looked at yet.

And in any case, steady-state would probably make more sense than stitching over a wide field of view. Rather than having an operator spread some particles over a plate and replacing them after the scan is done and any particles have been picked it, a serious system should use a hopper and conveyor belt to spread them out thin past a stationary (or moving in 1 axis) microscope. If you see anything worth keeping, direct the rocks into a new container. Expert mode: Use a tiny electromagnetic needle to separate each grain of sand individually.

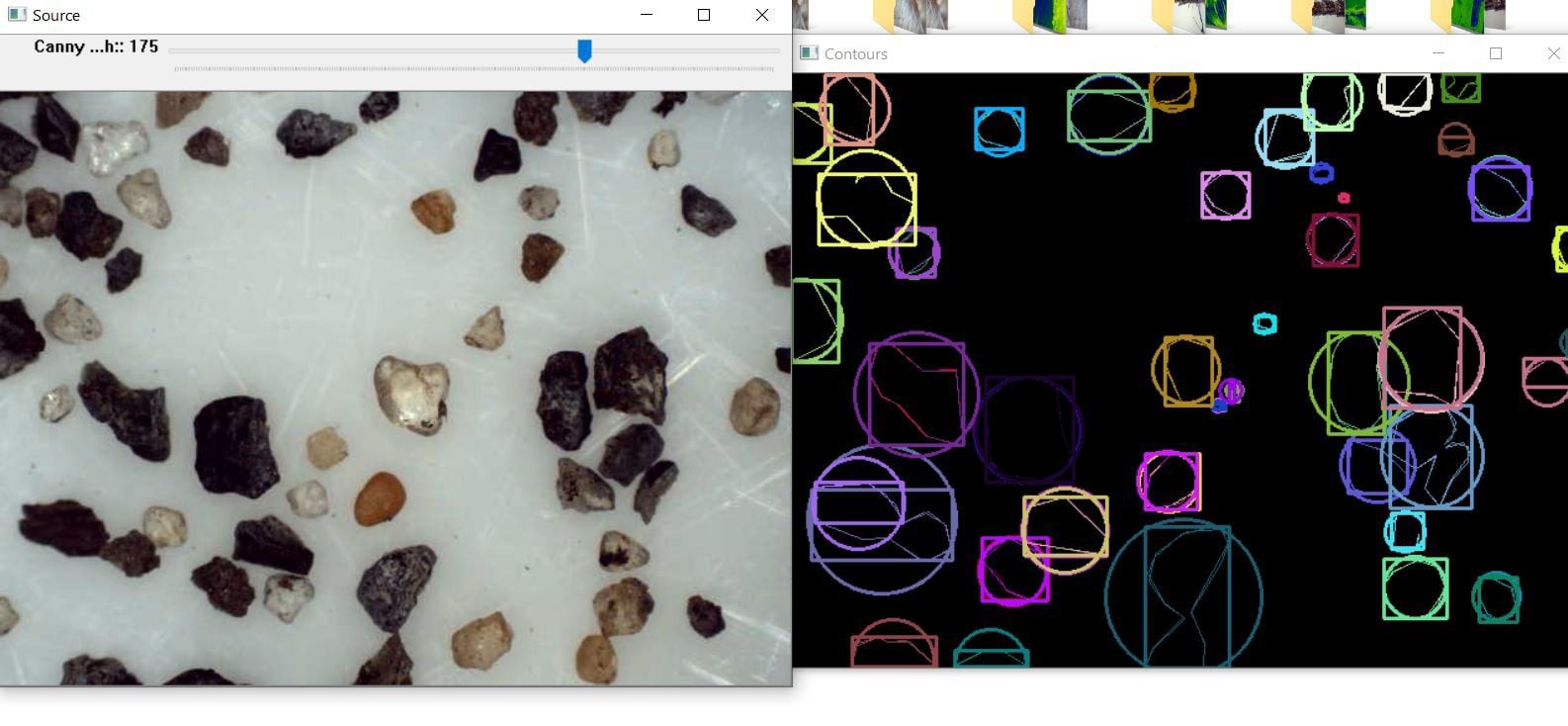

I'll leave you with an example of edge and roundness detection (on my smaller grains) using a script I found from someone who isn't me, Definitely some potential, but I think that it would also be worth trying to physically separate out by roundness rather than immediately jumping into computer vision. That is, if our goal is to solve the problem of finding micrometeorites, rather than forcing the problem to be solved using the hardware that we have.

Ahron Wayne

Ahron Wayne

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.