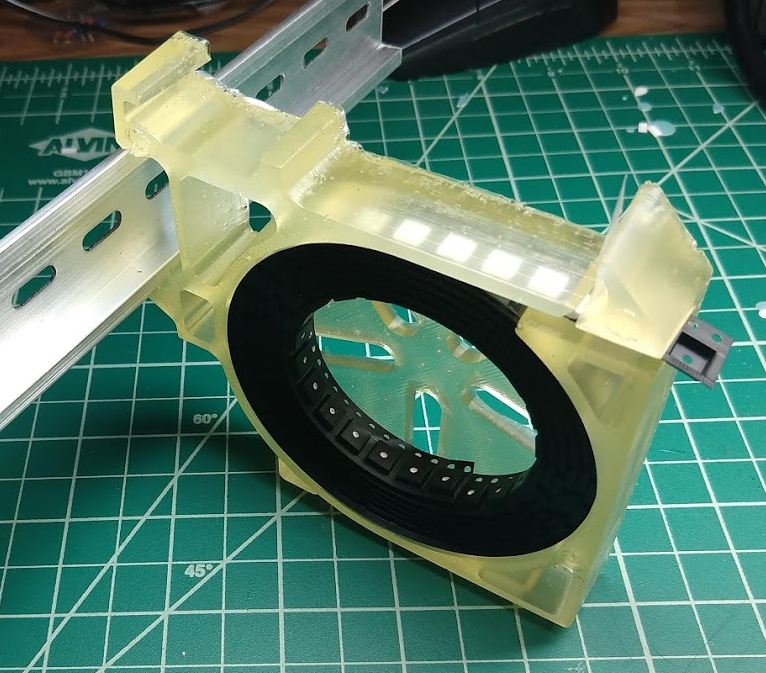

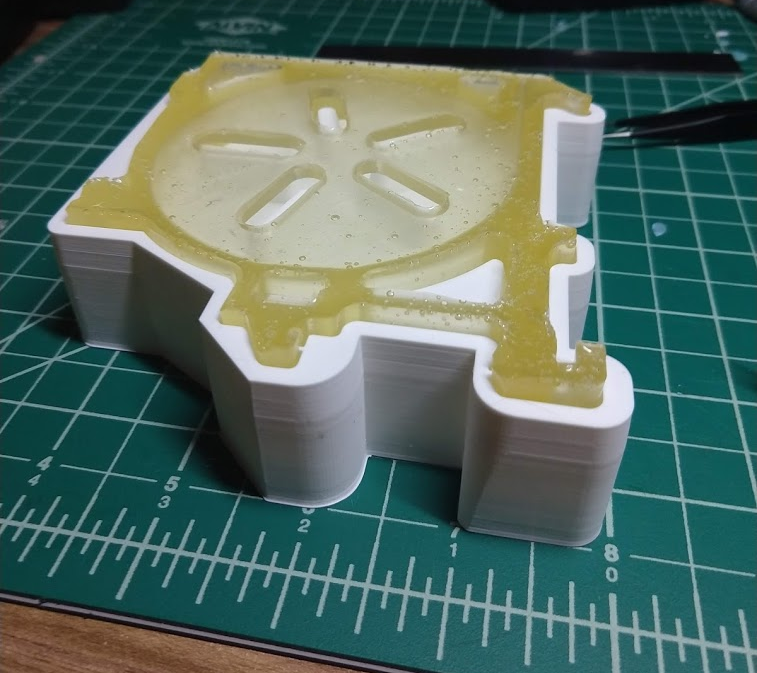

Hey, I made a part that (mostly) works!

And best of all, I used PLA as the mold. Mold release is definitely needed.

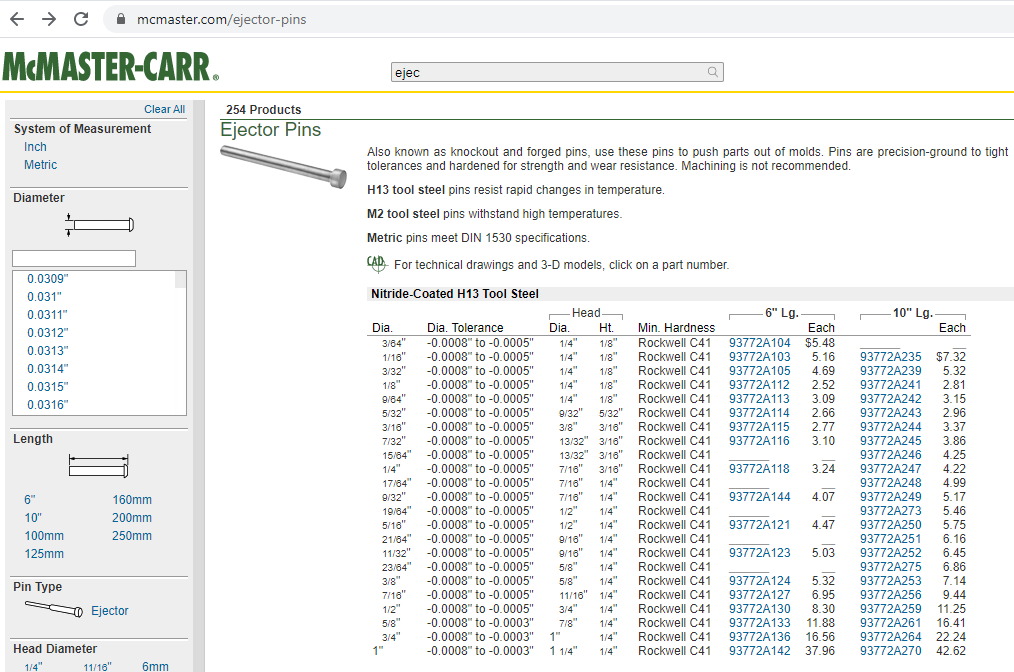

The PLA mold is much less expensive to set up than the silicone mold but it comes with some drawbacks. With a silicone mold it is possible to flex the mold in order to make your part pop out. Rigid molds can't be folded so they need a different mechanism to remove the part. Injection molding folks use ejector pins.

Presumably that's the thing you need if you're making a mold that reliably makes hundreds of thousand of parts but I'm interested in learning how to make a few hundred parts without spending too much money.

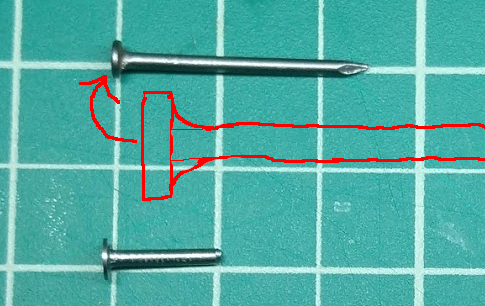

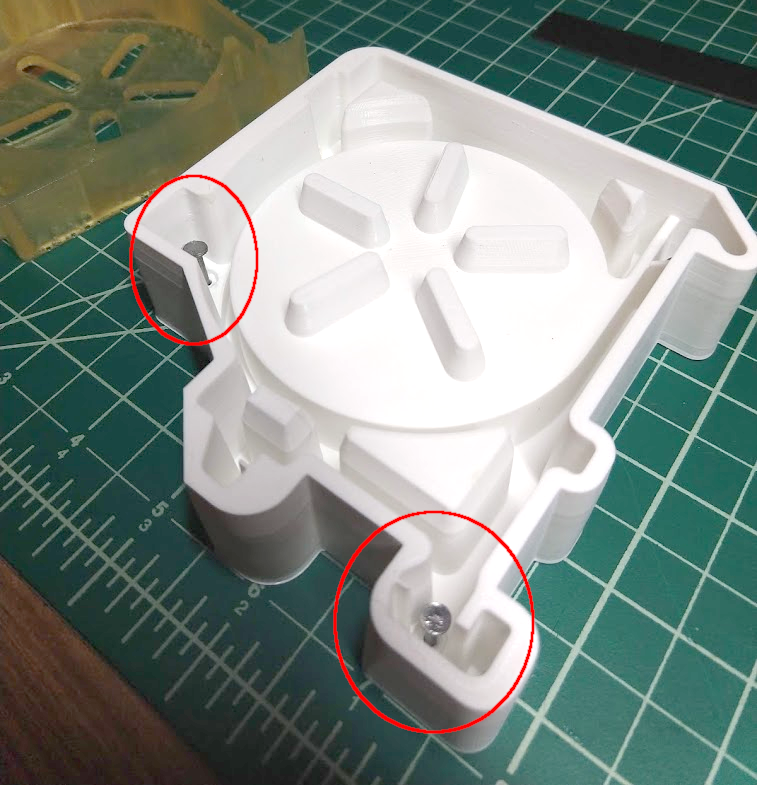

So, from the big box home store, I have a box of nails.

Now, in my head nails always looked like ejector pins. But upon close inspection I see significant diameter variance, weird surface finishes, bent nails, massively out of round heads, and weird rib structures that were produced as part of some forming process.

I have a big box of nails, so I can avoid some of the issues. Other ones (out of round heads) aren't as important. But those ribs between the head and the shaft are a problem. Fortunately, the nails can be popped into a drill chuck and worked over with a file.

The resulting part is much better than what I started with, but nothing remotely like a proper ejection pin, so I coat the bottom of the nail head with petroleum jelly.

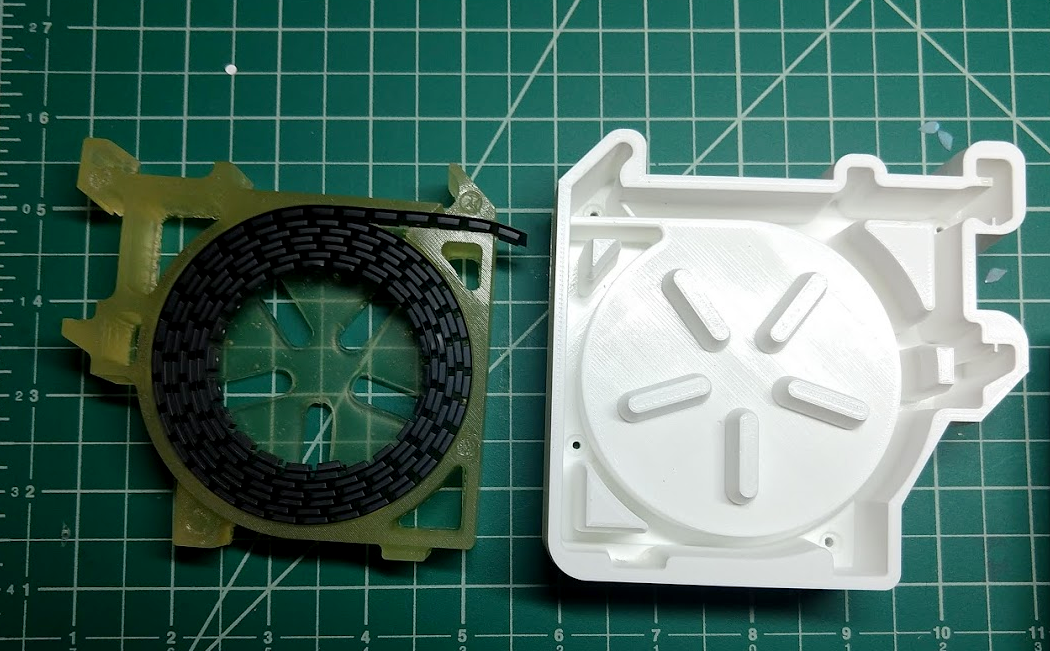

I've cut the resulting nails so that they all stick about 10mm down from the bottom of the mold.

This is good for two reasons. First, putting longer pins into the mold is much easier. Secondly, once the resin has cured I can push the mold down onto a table and that makes the pins push up and eject the part.

Note: this wasn't the actual part ejection. I put the part back in the mold to demonstrate the pins working.

I've still got a number of problems to work through:

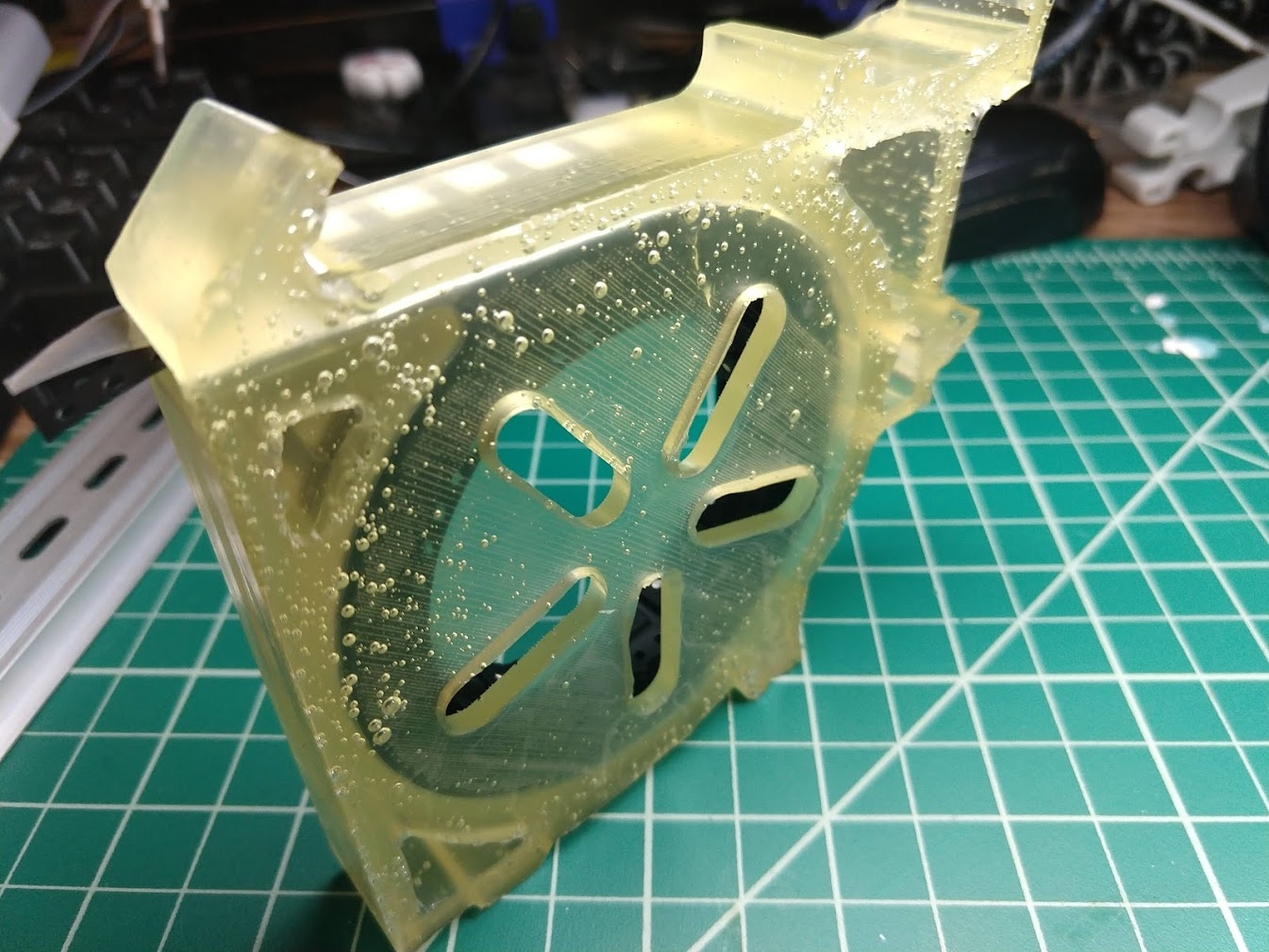

First of all I'm degassing the resin and that works but when I'm pouring the resin I'm re-introducing a ton of bubbles.

I don't think pressure casting will work with a semi-hollow PLA mold, so I'll either have to work on a better pouring technique or try something else. The documentation says this resin is good for cartridge dispensing, so I've ordered some equipment to give that a try. If that works it'll actually be ideal because it'll open the door to fast work time resins that can be removed from a mold in about an hour.

Second, I goofed and when I adjusted the front triangular piece so that it was more taller I forgot to adjust the lever point for the DIN clip and there's no longer clearance to use the lever point with a standard screwdriver.

Third, the resin is a bit slippery and it might be nice to have a lid to keep the SMD tape from tipping out.

And lastly, I'm exploring some additional mold release compounds. I have some parting wax and PVA that will get here sometime RealSoonNow.

Matthew Reeves

Matthew Reeves

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.