which also heats the wire with high current instead of an arc.

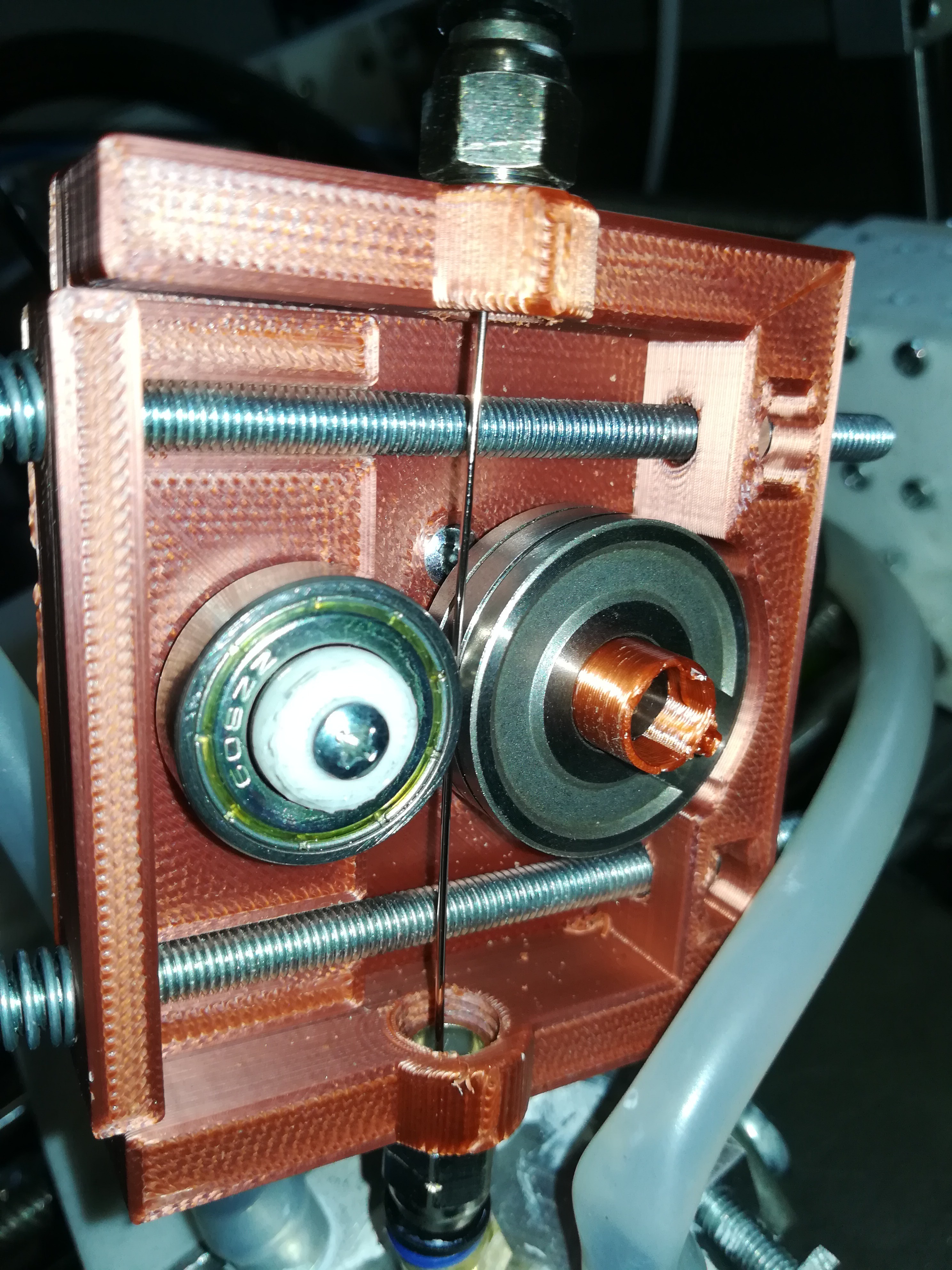

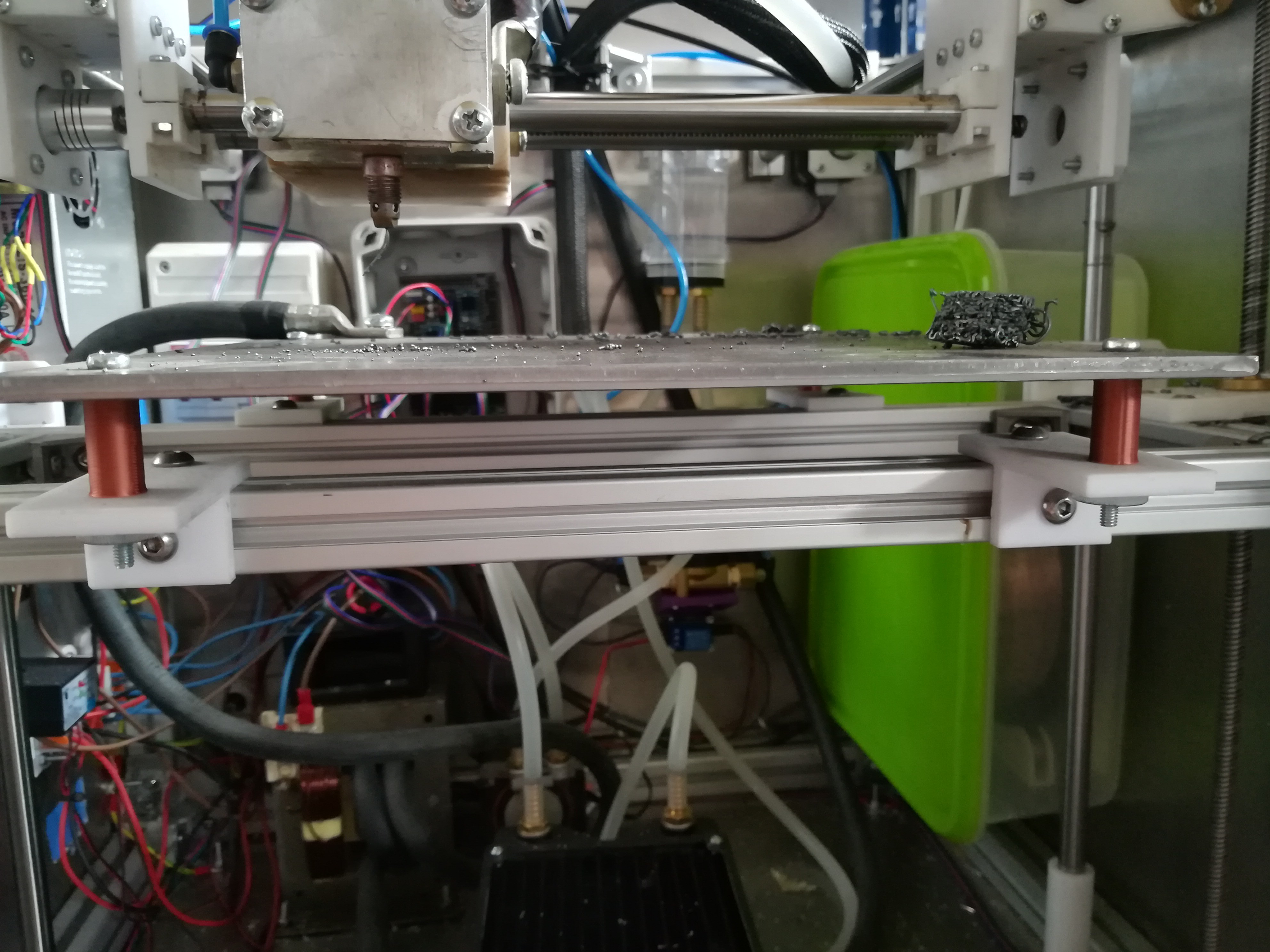

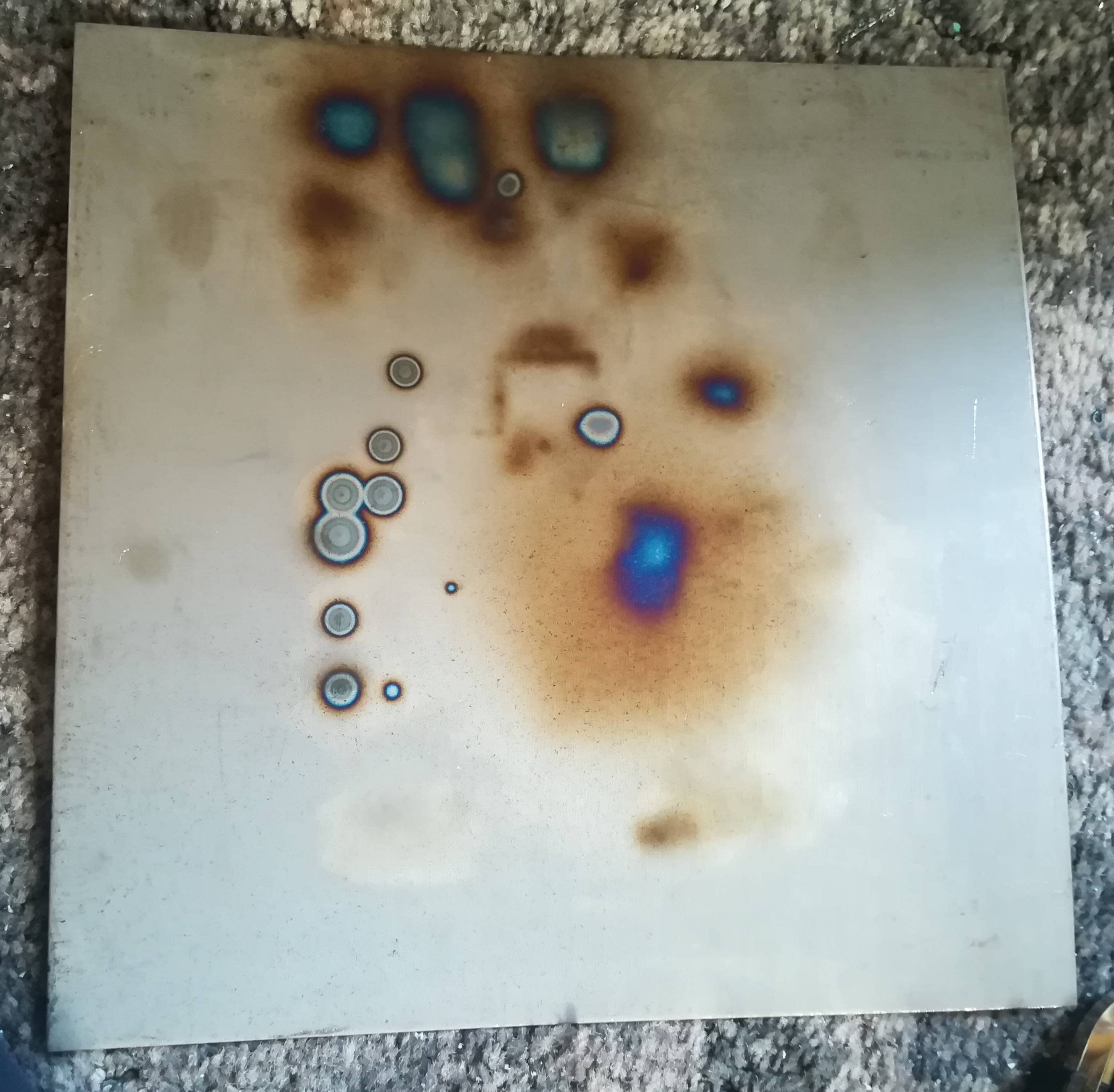

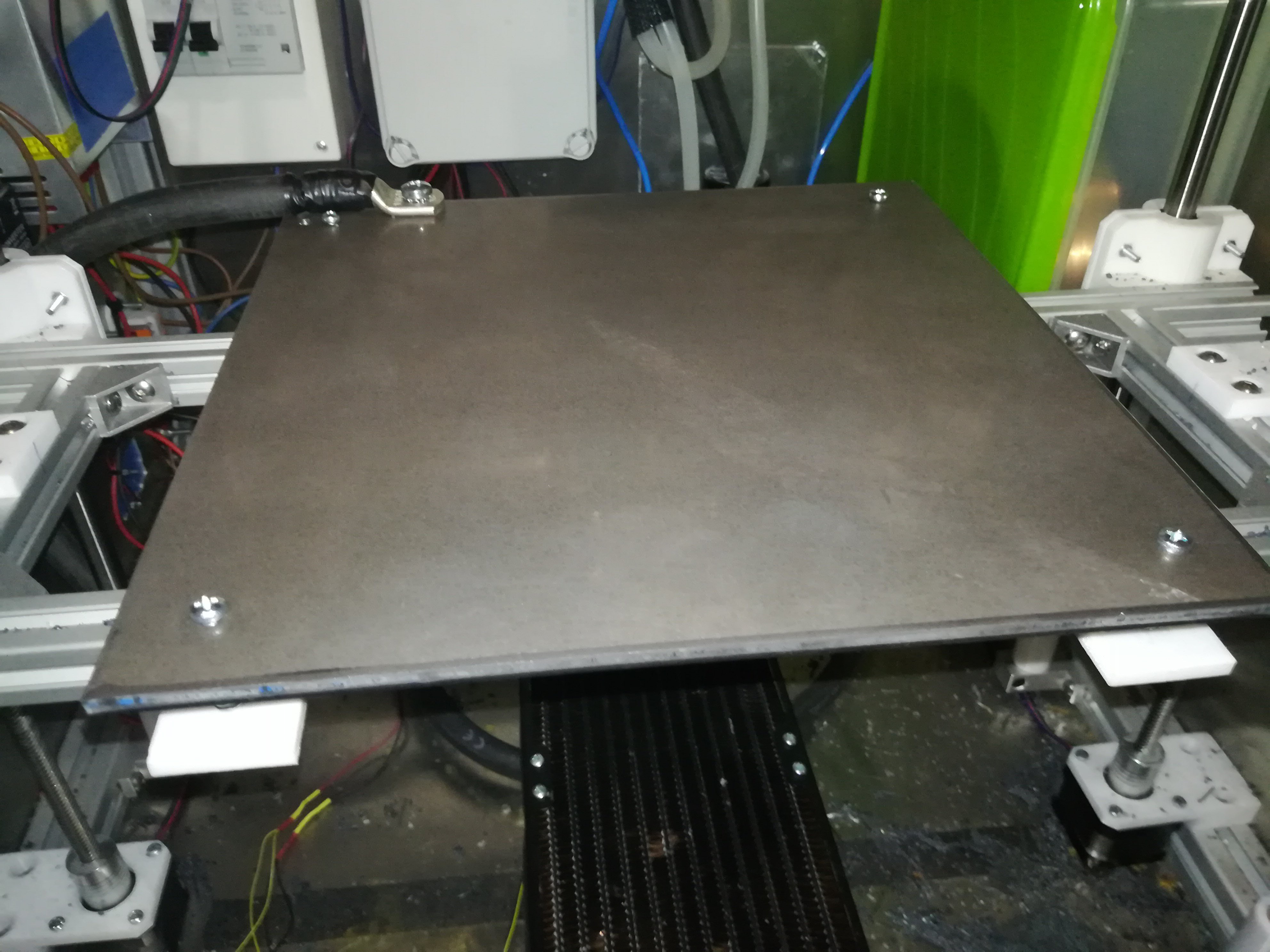

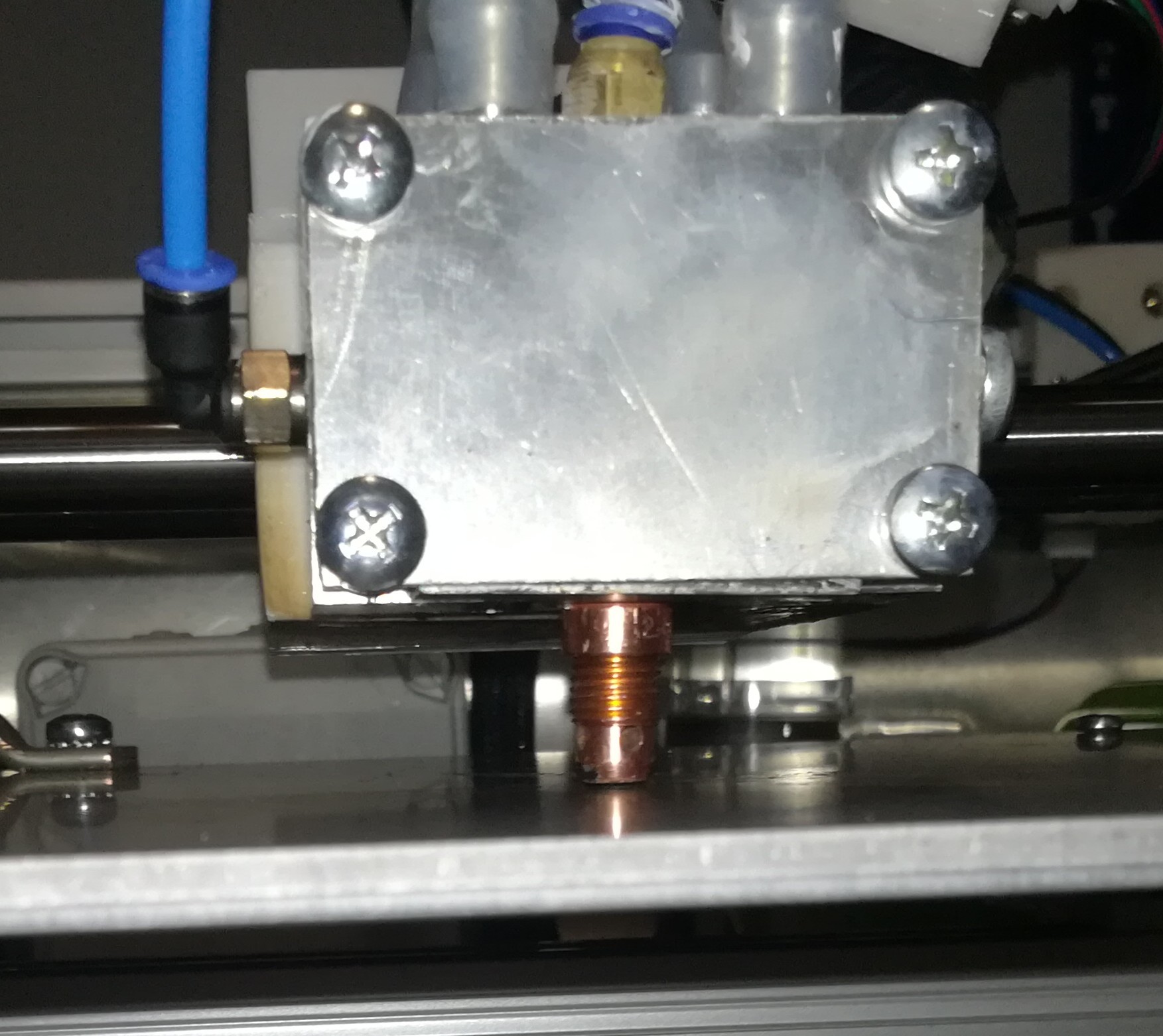

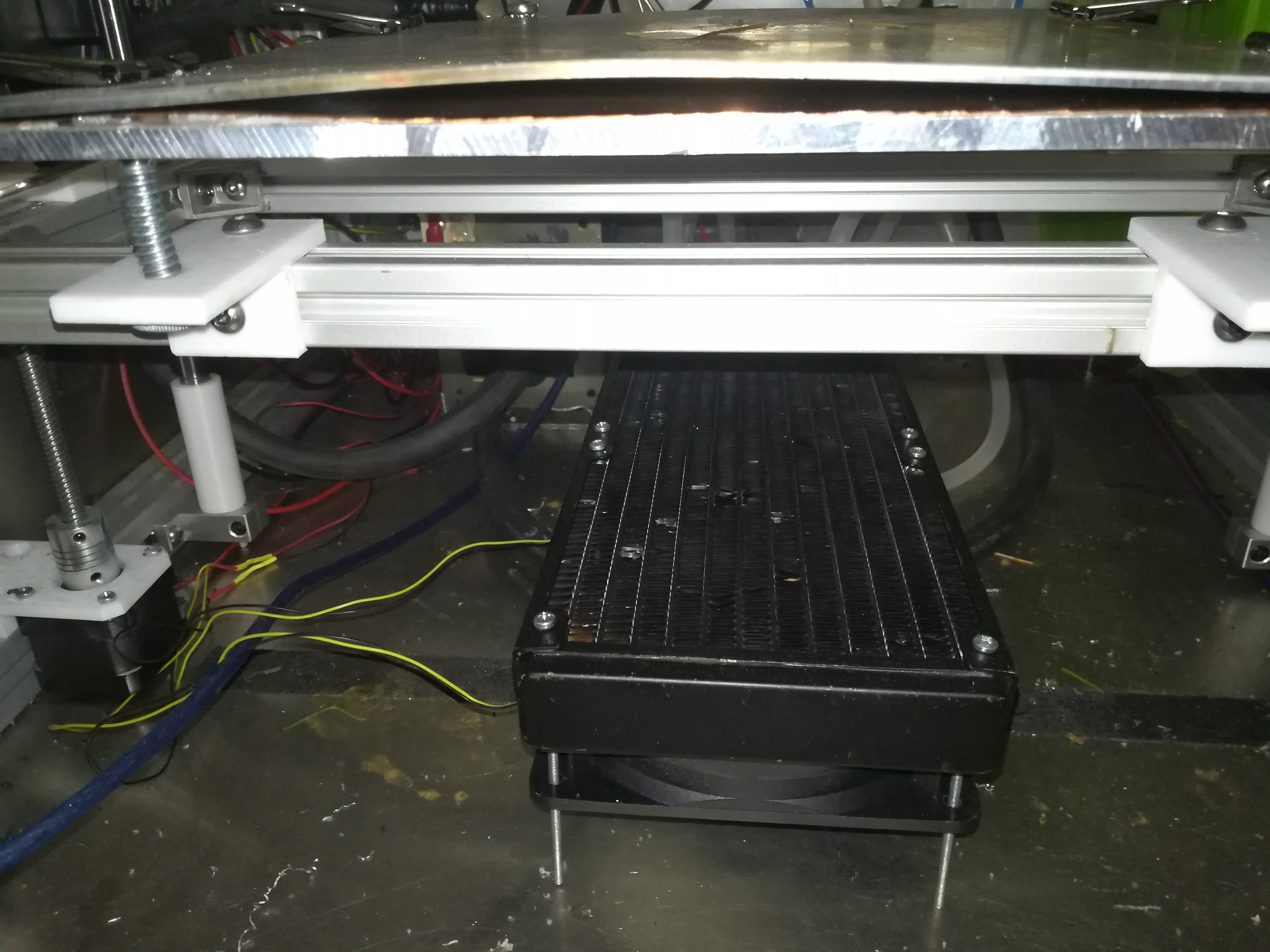

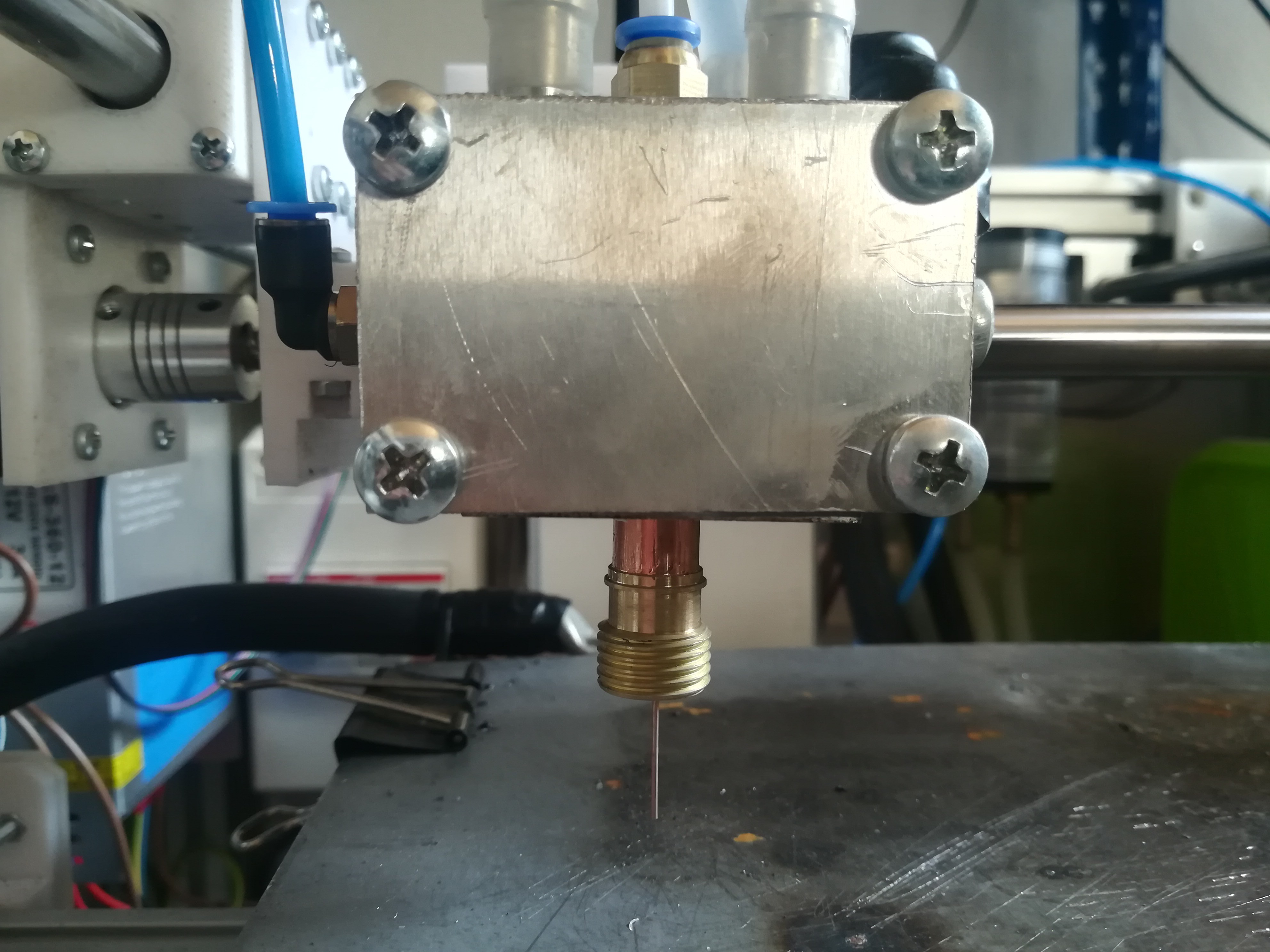

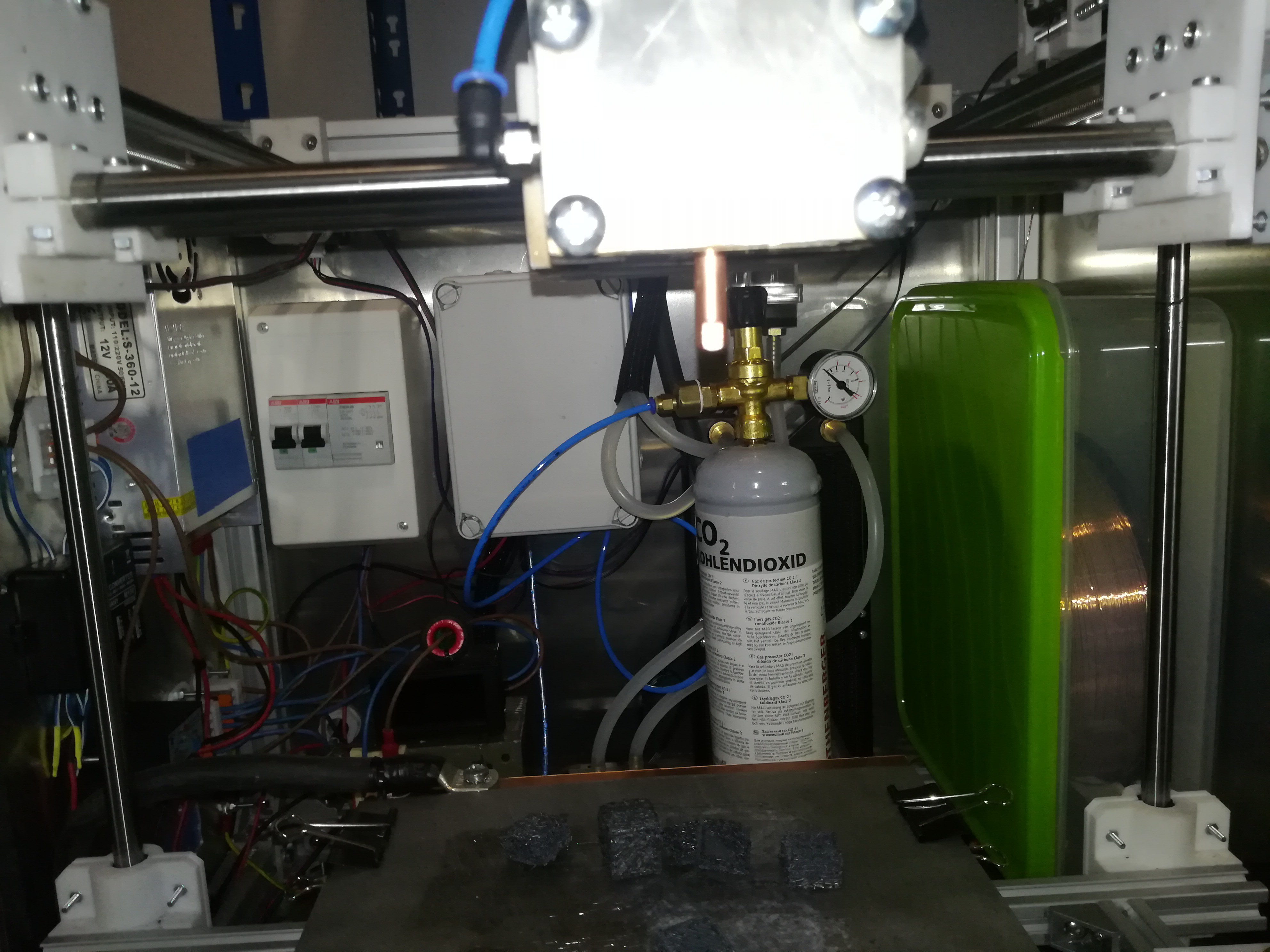

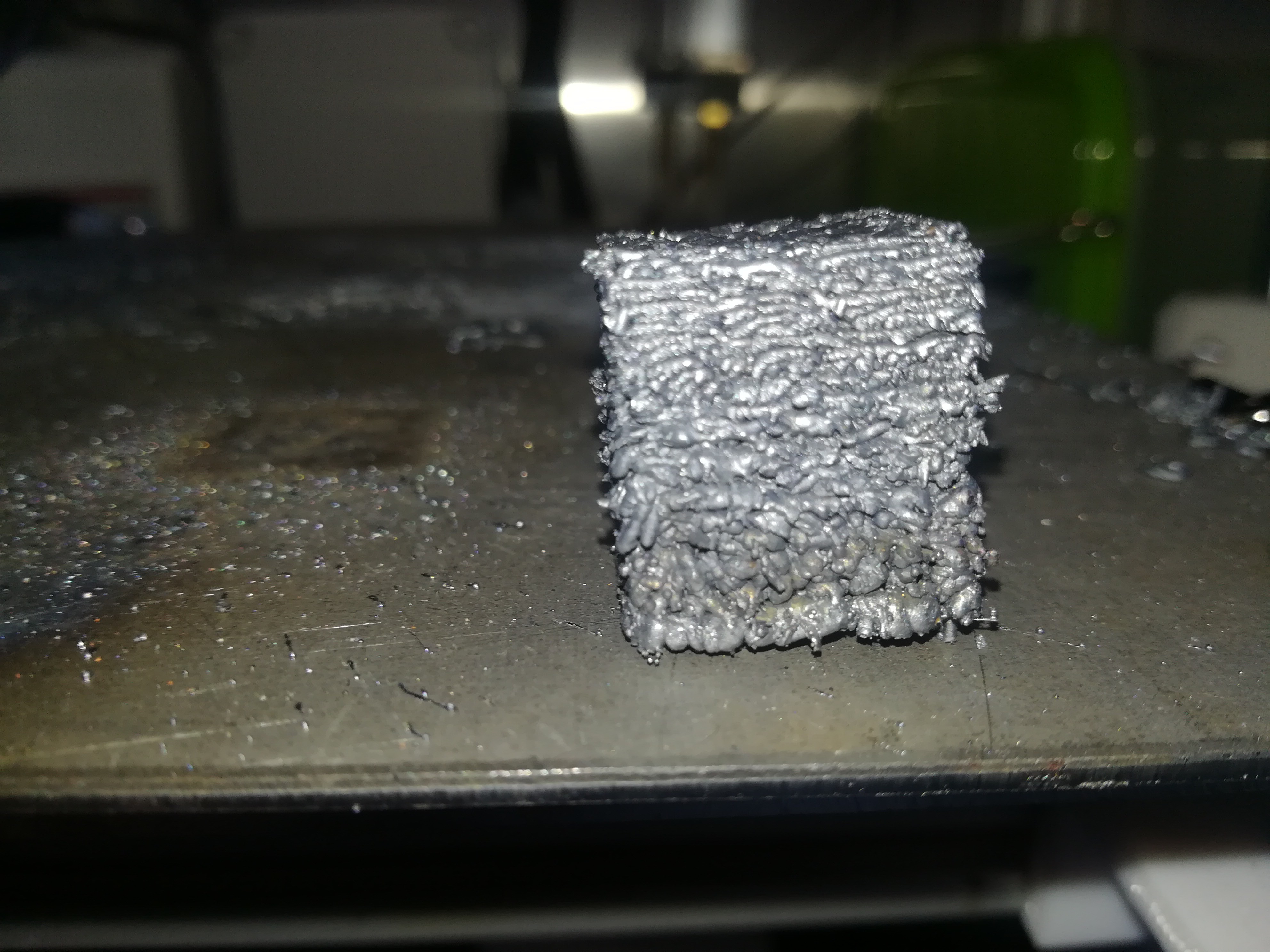

The printer is actually a FDM 3D printer built from an old microwave oven transformer and some other not special parts, which prints with welding wire instead of plastic filament. The only difference to a normal plastic FDM printer is, that the heat (around 1450°C) is created by high current flowing trough thin wire instead of plastic filament melting in a heated nozzle.

Things I could get to work:

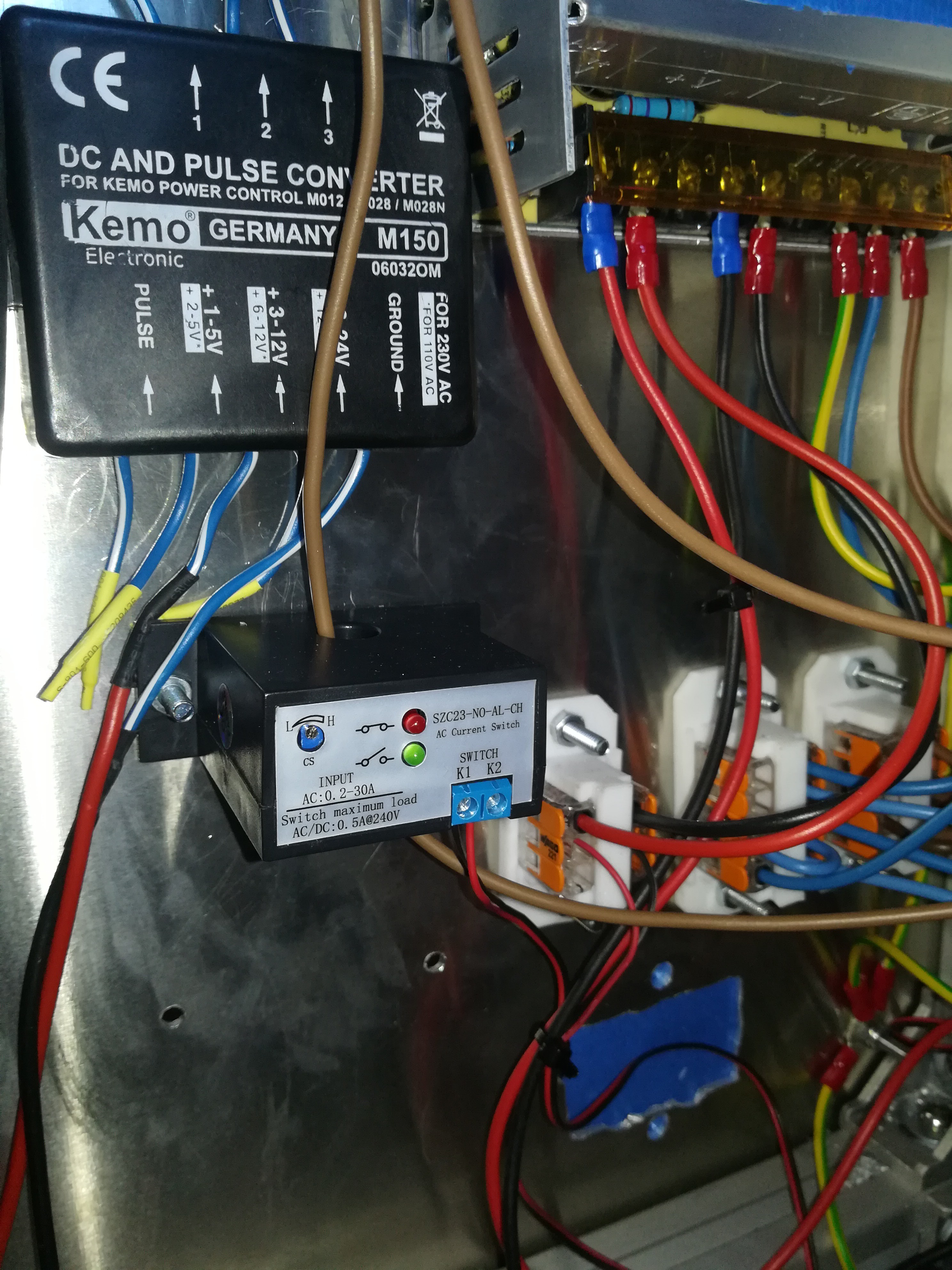

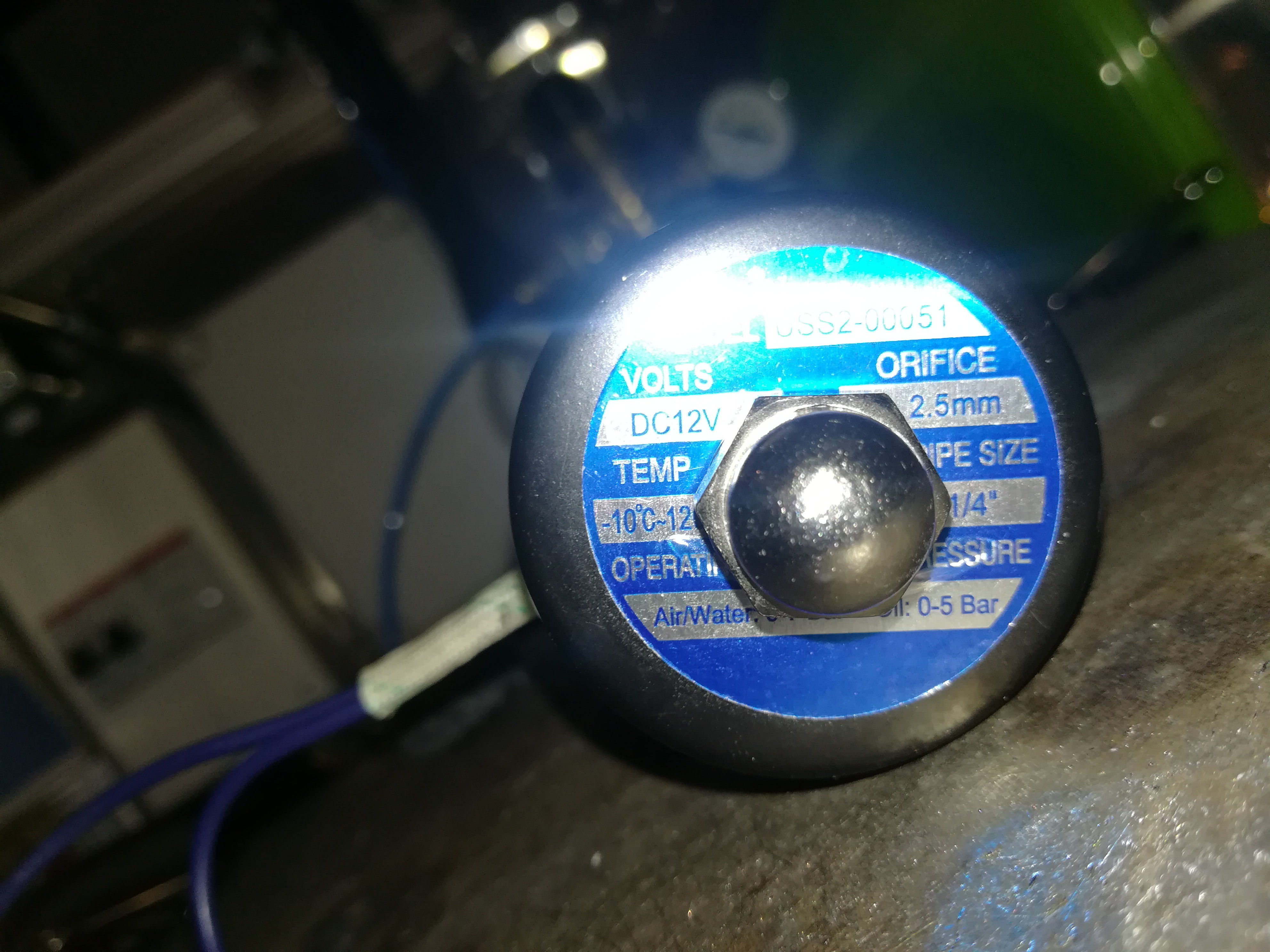

- Creating low voltage/ high current with a microwave oven transformer and controlling its power output with a Phase Fired Controller.

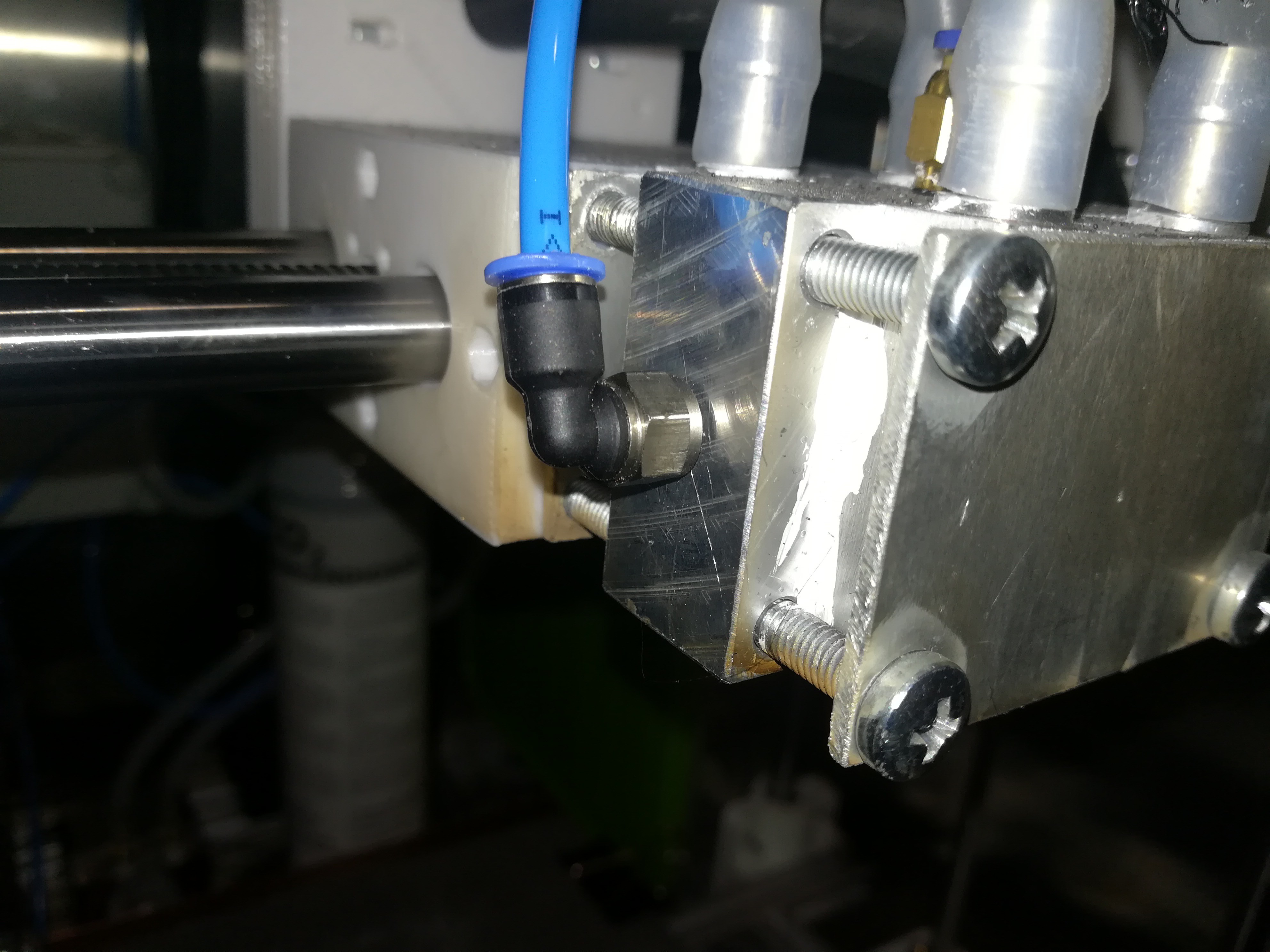

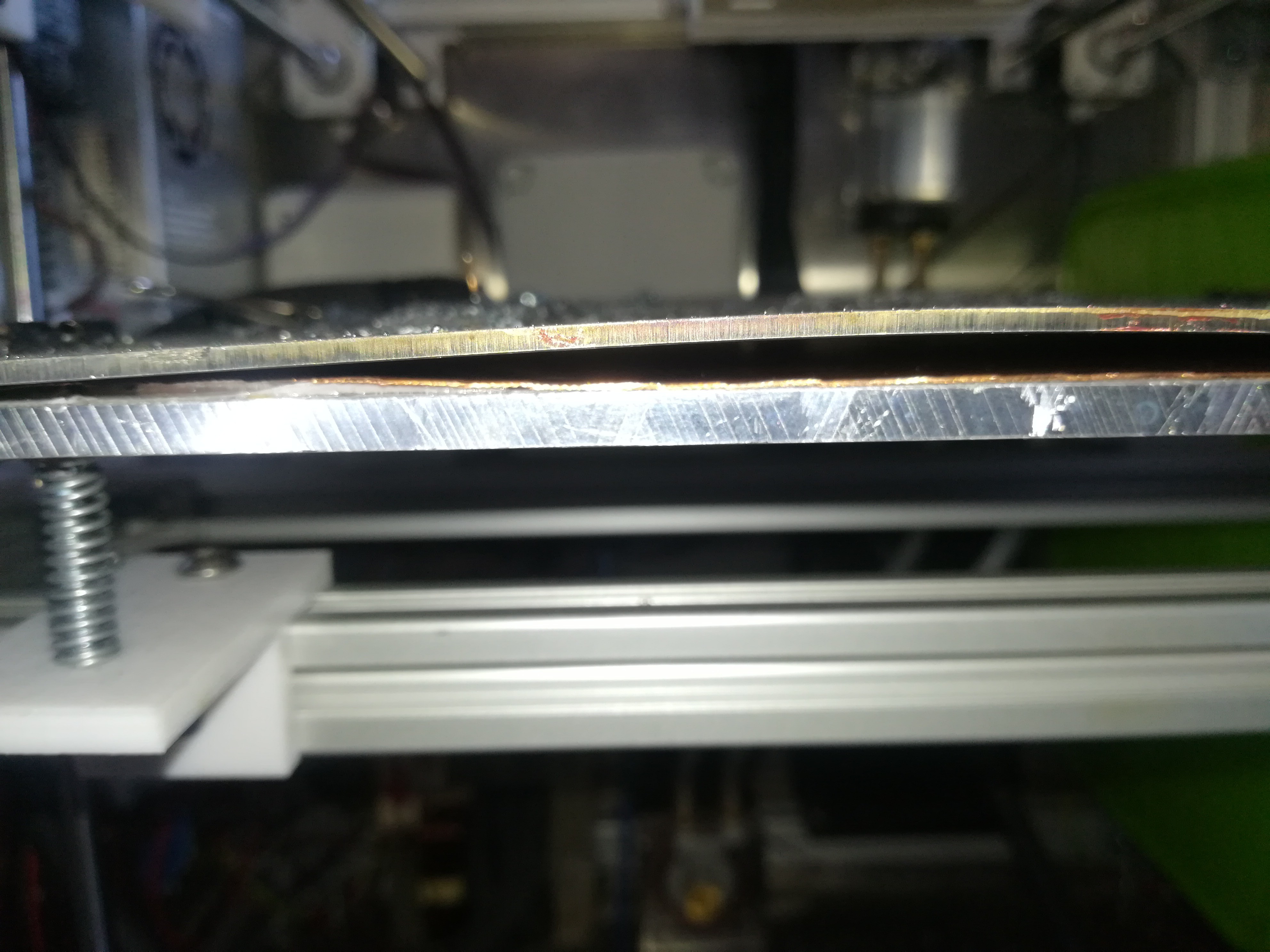

- Attaching the circuit to a 3D printer.

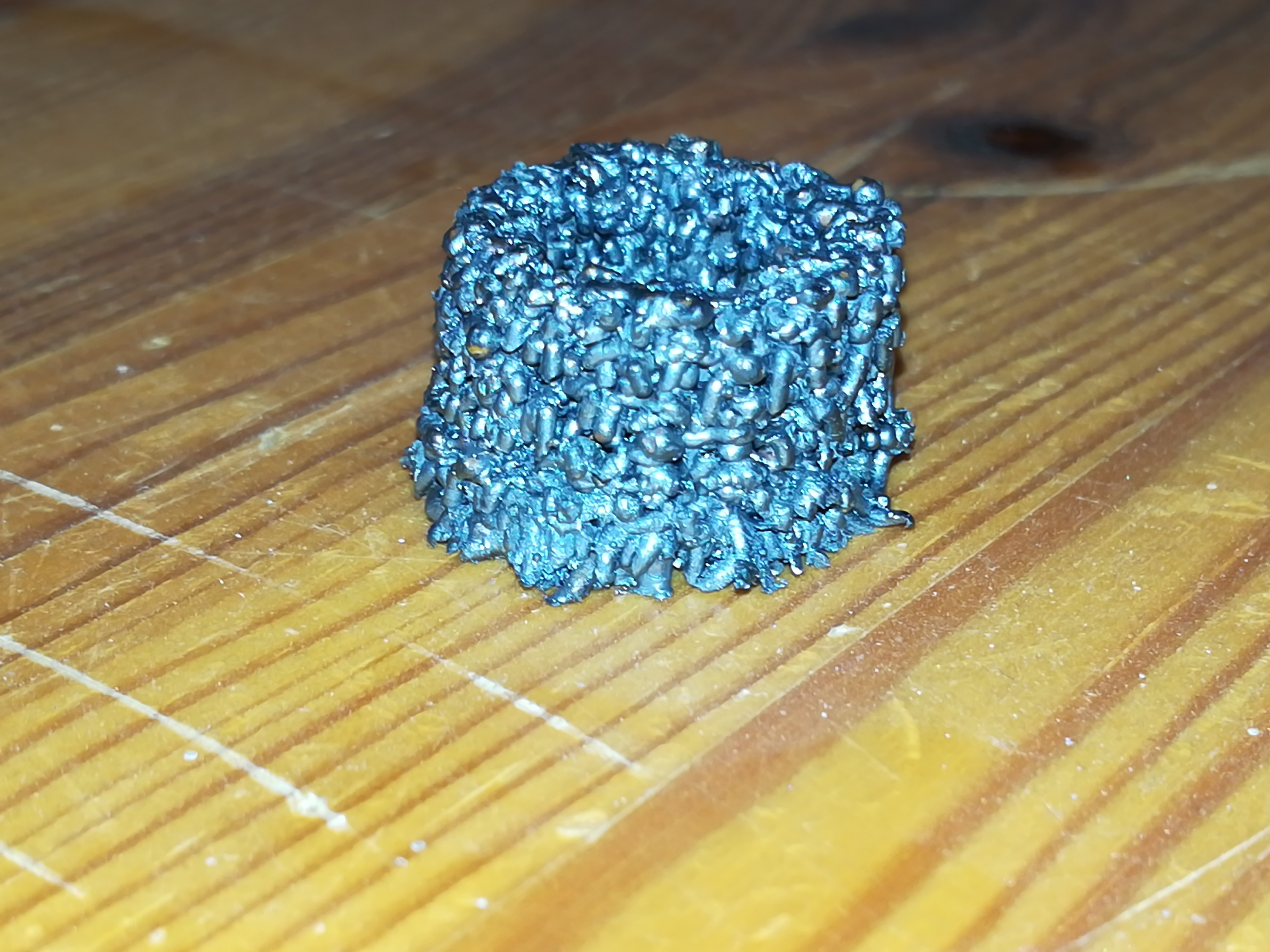

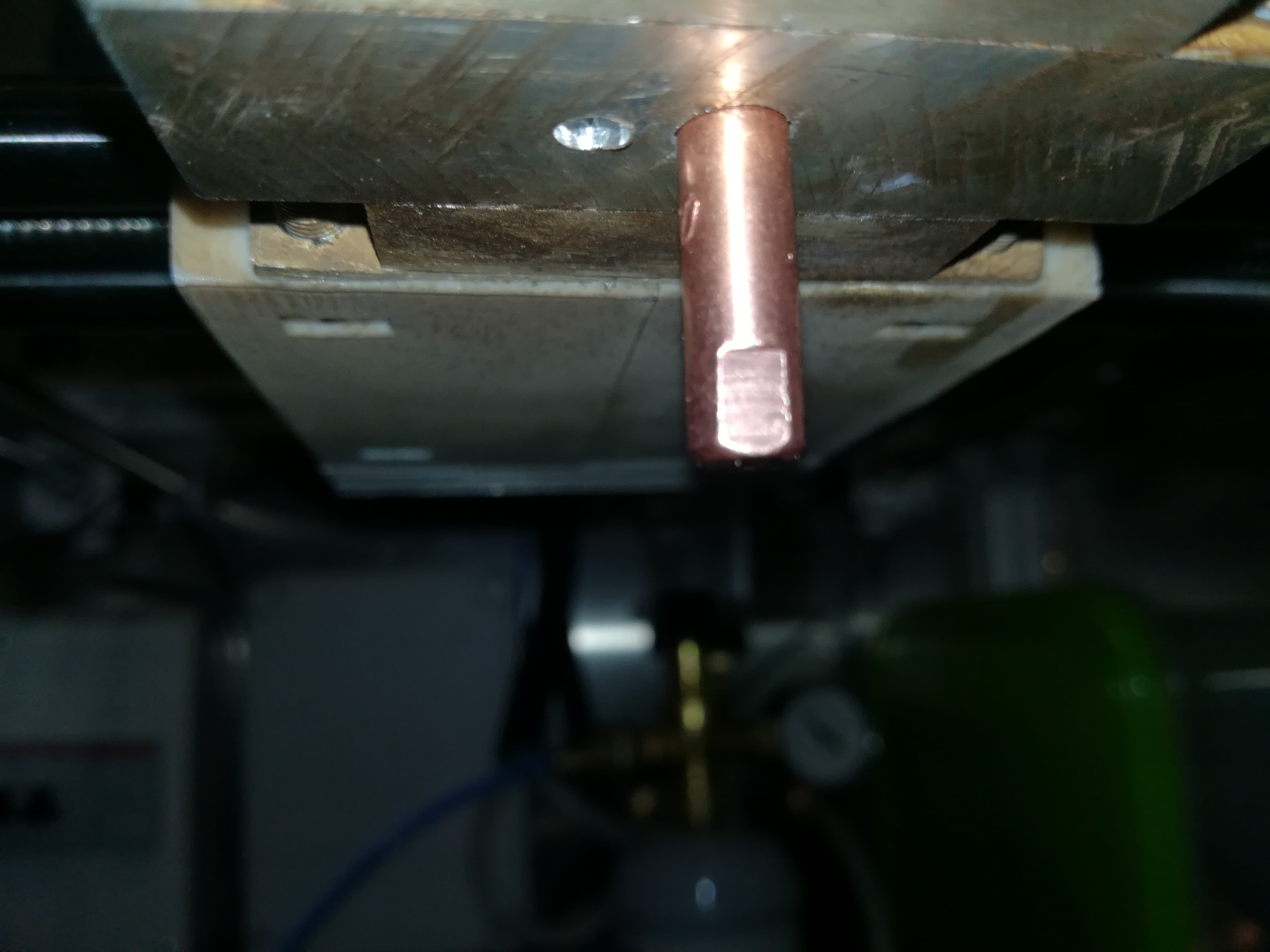

- Melting welding wire with high current.

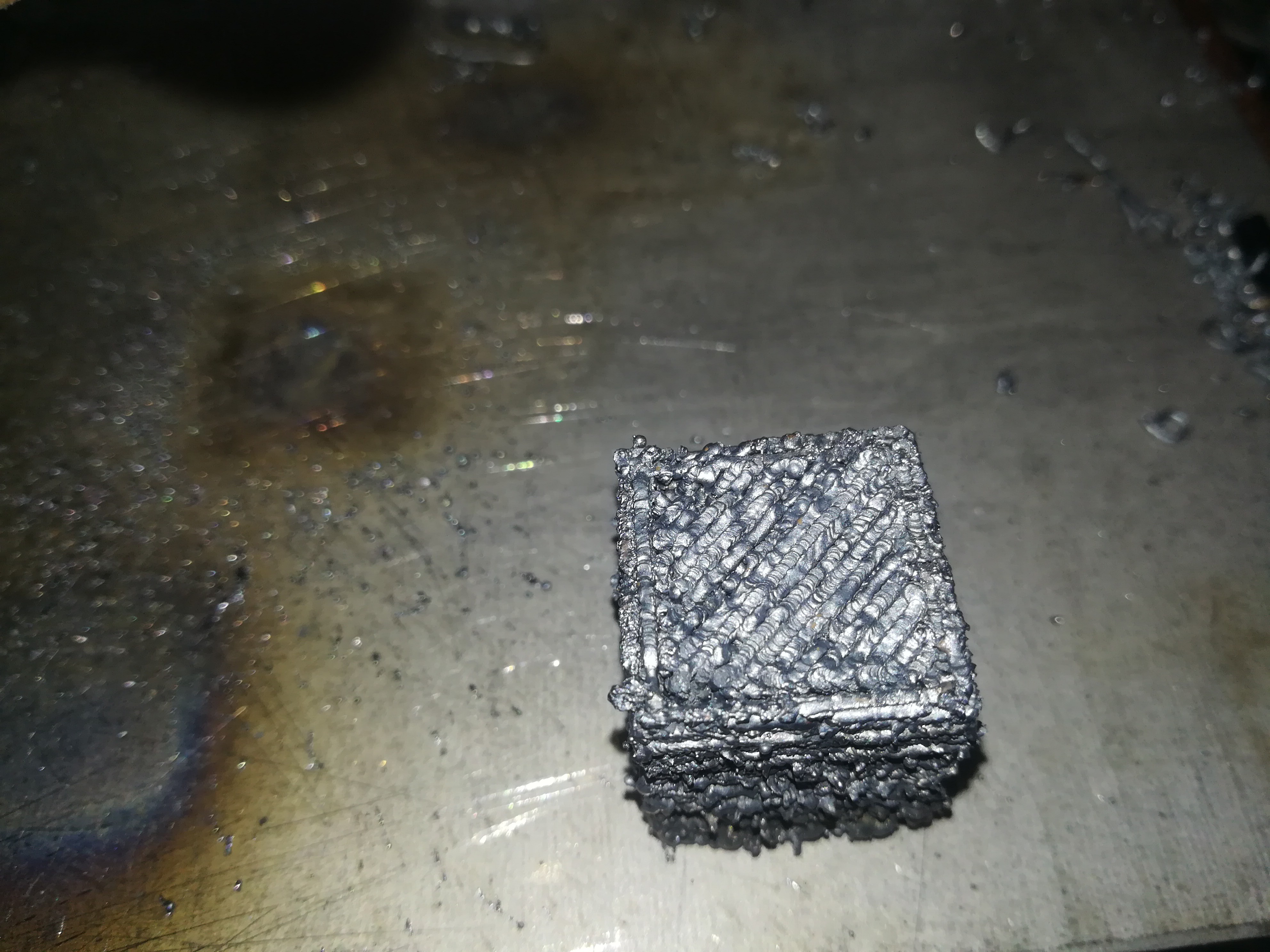

- Partially successful printing with welding wire.

Problems:

- I could not get it to work reliable, yet.

- Wire got stuck in the nozzle.

- Printed part got loose from the buildplate.

- Printed lines did not fuse together.

Maybe this project can help someone with getting started with his own metal printing project :)

The printer is also suitable for welding/heating small metal parts.

Dominik Meffert

Dominik Meffert

Daren Schwenke

Daren Schwenke

JP Gleyzes

JP Gleyzes

Big wire printer - in case you haven't seen already:

https://www.youtube.com/watch?v=kz165f1g8-E#t=137s