I figured out, that if the nozzle is close enough to the part, so that it can heat the part up while still being able to deposit material, I can get solid parts instead of brittle loose chunks of molten wire.

The challenge is to iron the layer flat without stopping the printhead by melting to much steel away and using the right feedrate + layer height, so that if the layer is ironed flat once, it stays flat and enables printing + heating of the layer. This way it should also be able to achieve the right layer height, because the nozzle limits the height and is able to push small height differences down.

I did it before, but back then I didn't know that it is essential for the printing process.

So, with that in mind I will try to get the right settings again and try to print something.

Hope that it works this time...

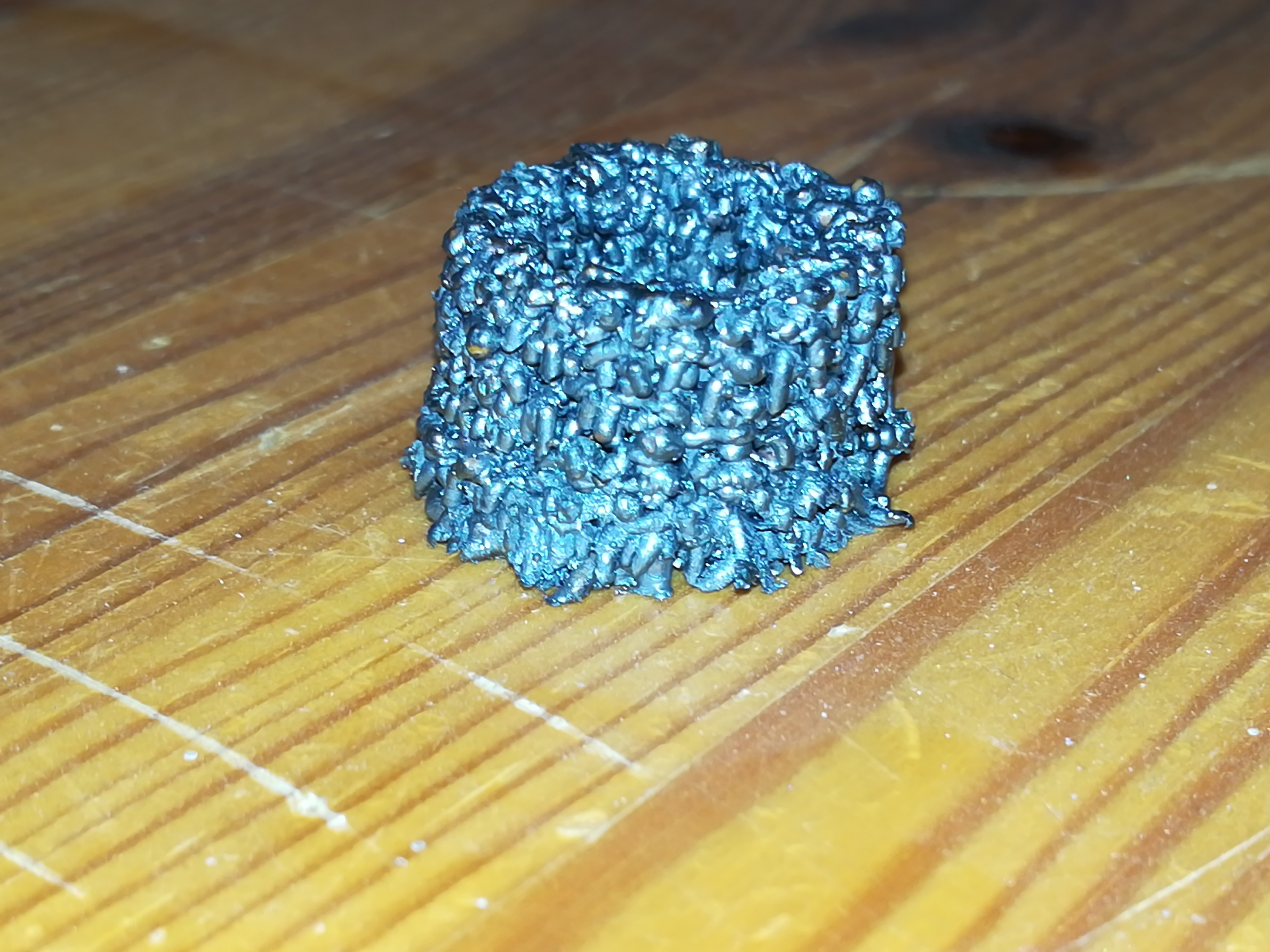

So it works in terms of:

If two printed lines get heat up at the same time they fuse together, but it's not easy to get it right and the outlines look very terrible....

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.